Managing inventory has always been one of the biggest hurdles for businesses, regardless of size or industry. When handled poorly, it doesn’t just create operational bottlenecks—it leads to massive financial setbacks. In fact, the global cost of inventory distortion, which includes shrinkage, overstocking, and stockouts, hit a staggering $1.8 trillion in 2020. This figure highlights just how costly mismanaged inventory can be when companies fail to implement effective systems and strategies.

The ripple effect of poor inventory practices is even more visible in lost revenue and customer dissatisfaction. For instance, stockouts are responsible for 40% of lost e-commerce sales, directly impacting profitability and brand loyalty. On the flip side, businesses that overstock often end up tying up too much capital in excess goods, with the average company holding $142,000 more in inventory than necessary. These imbalances not only disrupt cash flow but also limit opportunities for growth.

Visibility and accuracy remain at the core of these challenges. Research shows that only 6% of companies have full supply chain visibility, while a staggering 69% lack any real-time visibility into their operations. Add to this the fact that 58% of retail brands and D2C manufacturers operate with less than 80% inventory accuracy, and it becomes clear why businesses often struggle to forecast demand, manage stock levels, and make data-driven decisions. Even at the warehouse level, inefficiency takes a toll, with 40% of staff time spent on manual inventory tasks, diverting resources from more productive work.

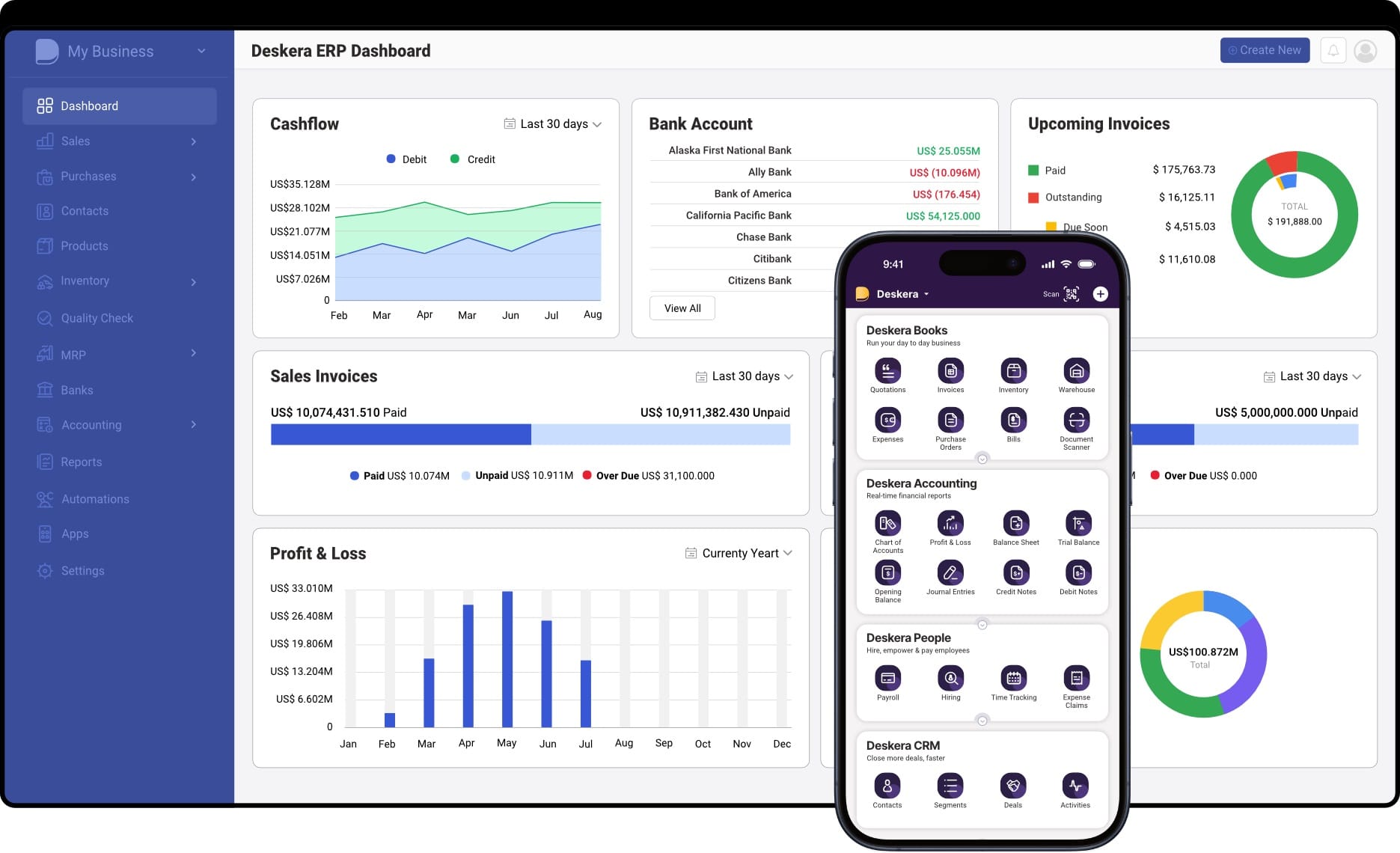

To overcome these obstacles, businesses are increasingly turning to advanced inventory management systems. Modern ERP solutions like Deskera ERP provide real-time visibility, AI-powered demand forecasting, automated warehouse operations, and integrated supply chain management—all within a single platform. By reducing manual errors and enabling data-driven decision-making, Deskera ERP helps businesses cut costs, improve efficiency, and maintain healthier inventory levels, ultimately driving growth and customer satisfaction.

Impact of Inventory Management Challenges

Poor inventory management doesn’t just create temporary hiccups—it has far-reaching consequences that affect finances, operations, and customer satisfaction. Many businesses operate in a fast-paced, data-rich environment, yet rely on disconnected tools and manual processes that aren’t built to scale. While this may seem manageable at first, the hidden costs and inefficiencies eventually surface, hurting growth and profitability.

1. Resource Drain and Staff Inefficiency

When inventory is tracked manually or across siloed systems, employees spend excessive time reconciling data, entering duplicate information, or switching between applications. This drains valuable resources that could otherwise be spent on more strategic tasks. In fact, research shows that 40% of warehouse time is lost on manual inventory processes, highlighting the inefficiency caused by outdated practices.

2. Higher Costs and Financial Losses

Inventory challenges often translate directly into higher costs. Overstocking ties up capital in unnecessary goods, while stockouts result in missed sales opportunities. Beyond this, businesses face risks of theft, spoilage, or product damage, all of which impact profitability. Mismanagement can also inflate storage expenses and increase overhead costs, making it harder for companies to maintain healthy margins.

3. Disrupted Operations and Scalability Issues

A lack of accurate, real-time inventory insights can cause production halts and supply chain delays. Managers struggle to make timely decisions, especially when systems don’t provide a clear view of stock levels or pending orders. While manual processes may work at a small scale, they quickly break down as order volumes grow, creating bottlenecks, slowdowns, and unnecessary stress for teams.

4. Customer Dissatisfaction and Churn

The customer experience is one of the most visible casualties of poor inventory management. Stockouts lead to order cancellations, delivery delays, and frustration, while excess stock can mean offering outdated or spoiled products. Over time, this erodes brand trust and increases churn, as customers move to competitors who can provide consistent availability and reliable service.

5. Strategic Risks and Leadership Blind Spots

Perhaps the most significant impact is the lack of visibility for decision-makers. Without real-time, accurate data, senior leaders operate with blind spots, unable to pivot quickly during demand surges or supply chain disruptions. This reduced agility hampers competitiveness and makes the business vulnerable to crises. Ultimately, inefficient inventory practices don’t just cost money—they threaten long-term resilience and growth.

Benefits of Overcoming Inventory Management Challenges

Businesses often see inventory management challenges as barriers, but solving them opens the door to efficiency, profitability, and sustainable growth. Addressing these challenges does not just prevent errors—it transforms operations into a competitive advantage.

Here are the key benefits companies gain when they successfully overcome inventory management hurdles:

1. Improved Cash Flow

One of the most immediate benefits of overcoming inventory inefficiencies is better cash flow. Overstocking ties up valuable capital in unsold products, while stockouts can lead to lost revenue. By maintaining the right balance, businesses free up liquidity that can be reinvested into growth initiatives such as marketing campaigns, product development, or technology upgrades. This ensures that every dollar works harder for the business instead of sitting idle in excess inventory.

2. Higher Inventory Accuracy

Manual record-keeping and fragmented systems often result in data discrepancies. By implementing automated inventory systems and standardizing processes, businesses achieve real-time visibility into stock levels. Higher accuracy means fewer errors during audits, reduced discrepancies between physical and system records, and faster reconciliation. This not only saves time but also builds confidence among managers, suppliers, and customers in the reliability of operations.

3. Reduced Operational Costs

Carrying costs, storage fees, and losses from spoilage, shrinkage, or obsolescence can add up quickly. Overcoming these challenges through better demand forecasting, optimized storage practices, and automation helps significantly reduce unnecessary expenses. Efficient processes also minimize labor-intensive tasks, saving time and reducing payroll costs. The end result is a leaner, more cost-effective operation that maximizes ROI.

4. Enhanced Customer Satisfaction

Customers expect fast, reliable service with accurate order fulfillment. By eliminating inventory-related challenges such as stockouts and delays, businesses ensure consistent product availability and on-time delivery. Meeting these expectations not only boosts customer satisfaction but also strengthens brand reputation and loyalty. Happy customers are more likely to return, recommend, and engage in long-term relationships, driving sustained revenue growth.

5. Better Demand Forecasting

Accurate forecasting is critical to avoid both overstocking and understocking. By overcoming challenges like poor visibility or lack of historical data analysis, businesses can use advanced analytics to predict demand with precision. This ensures smooth operations during peak seasons, reduces excess stock during slower periods, and aligns procurement with actual sales patterns. Improved forecasting ultimately leads to smarter decision-making and consistent profitability.

6. Increased Productivity

Manual inventory tracking, repetitive stock counts, and constant firefighting drain valuable employee time. Implementing systems that automate routine tasks frees up staff to focus on higher-value activities such as process optimization, customer service, or innovation. A streamlined workflow reduces bottlenecks on the shop floor and in warehouses, boosting overall productivity and employee satisfaction.

7. Scalability and Growth

Businesses aiming for expansion often struggle with scaling operations when inventory systems are inefficient. By overcoming these challenges, companies build robust processes capable of handling increased order volumes, new product lines, or additional sales channels. With scalable inventory systems in place, growth becomes smoother, enabling businesses to explore new markets and opportunities without being held back by logistical constraints.

8. Stronger Profit Margins

Profitability often erodes due to excess carrying costs, frequent markdowns, or missed sales opportunities. Overcoming inventory challenges ensures that products are sold at the right time and at optimal pricing. This reduces waste, prevents unnecessary discounts, and maximizes revenue per unit. When combined with cost savings from improved efficiency, businesses enjoy healthier margins and stronger financial performance.

9. Improved Decision-Making

Inventory touches almost every aspect of a business—from sales and procurement to finance and customer service. When challenges are resolved, businesses benefit from centralized data and real-time reporting. Leaders gain a clear, accurate view of operations, empowering them to make faster and more strategic decisions. Whether it’s expanding into new regions, renegotiating supplier contracts, or adjusting pricing, decisions are backed by reliable data.

10. Competitive Advantage

In today’s fast-paced market, businesses with agile and resilient inventory systems consistently outperform competitors. Overcoming inventory management challenges enables companies to respond quickly to changes in customer demand, supply chain disruptions, or market trends. This agility provides a competitive edge, positioning the business as reliable, efficient, and customer-centric in the eyes of both consumers and partners.

With a unified platform like Deskera ERP, businesses can achieve these benefits by automating inventory tracking, enabling accurate demand forecasting, and providing real-time insights across sales, procurement, and accounting. This ensures they not only overcome challenges but also turn inventory management into a driver of long-term success.

20 Common Inventory Management Challenges and How to Overcome Them

Inventory management challenges don’t just create temporary setbacks—they directly affect cash flow, profitability, and customer loyalty. From stockouts that cause lost sales to overstocking that locks up capital, businesses must navigate these hurdles with precision. Below are 20 of the most pressing challenges, along with proven strategies to overcome them.

1. Stockouts

Stockouts occur when inventory levels fall short of demand, often due to poor forecasting, delayed reordering, or lack of visibility. This not only results in immediate lost sales but also damages customer trust, as buyers may turn to competitors. For e-commerce businesses, stockouts can account for up to 40% of lost sales, making it a critical issue to solve.

Solution: Implement automated reorder points and safety stock levels within your inventory system. Using real-time tracking tools ensures businesses can anticipate shortages and replenish on time, reducing the risk of lost revenue and unhappy customers.

2. Overstocking

Holding excess inventory ties up working capital and adds unnecessary storage costs. The average business keeps around $142,000 more inventory than needed, creating a financial burden while also risking spoilage or obsolescence. Overstocking reduces cash flow flexibility, limiting the ability to invest in growth opportunities.

Solution: Conduct regular demand analysis using historical data and sales trends. Tools like ABC analysis can help identify which products require closer monitoring, ensuring that purchasing aligns with demand. This approach balances availability with cost efficiency, helping businesses avoid waste while maintaining sufficient stock levels.

3. Inaccurate Demand Forecasting

Forecasting errors can lead to both stockouts and overstocking, affecting customer satisfaction and profitability. Many companies still rely on spreadsheets or outdated models, ignoring external factors like seasonality, promotions, or economic changes. This leads to mismatches between actual demand and supply.

Solution: Adopt predictive analytics and AI-driven forecasting tools that integrate with sales, marketing, and supply chain data. These systems provide dynamic insights to adjust inventory levels proactively. By factoring in historical data and market signals, businesses can significantly improve forecast accuracy and optimize stock planning.

4. Inefficient Multichannel Tracking

For businesses selling across multiple channels—like retail stores, e-commerce platforms, and marketplaces—inventory mismatches are a common issue. Without a unified view, one channel may show stock availability while another has already sold out, leading to overselling or customer dissatisfaction.

Solution: Use centralized inventory management software that integrates all sales channels into one system. This ensures real-time updates across platforms, preventing errors and maintaining consistent stock data. Such integration not only avoids overselling but also streamlines order fulfillment and improves the overall customer experience.

5. Obsolete Inventory

Obsolete or dead stock occurs when products remain unsold for long periods, eventually losing value or becoming unsellable. This is particularly damaging in industries with short product life cycles or perishable goods, where unsold items directly result in wasted capital.

Solution: Track inventory turnover ratios to identify slow-moving items early. Businesses can use discounting, bundling, or promotional strategies to clear aging stock. Additionally, adopting demand-driven replenishment methods ensures future purchases align closely with actual sales patterns, reducing the risk of accumulating obsolete inventory.

6. Lack of Real-Time Updates

Without real-time inventory visibility, businesses struggle to make timely decisions, leading to delays in order fulfillment, inaccurate stock counts, and lost opportunities during demand spikes. Static or outdated systems often cause managers to rely on yesterday’s data, which isn’t reliable in fast-moving industries.

Solution: Implement an automated inventory management system with real-time tracking. These solutions sync stock levels instantly across sales channels, warehouses, and suppliers. By providing immediate visibility, businesses can respond quickly to fluctuations, improve order accuracy, and maintain customer trust while avoiding costly miscommunication.

7. Human Errors in Stock Management

Manual data entry, spreadsheets, and physical counts often lead to human mistakes such as duplicate entries, incorrect counts, or misplaced items. Even minor errors accumulate into significant discrepancies, causing overstocking, stockouts, and unreliable reports. This undermines operational efficiency and decision-making.

Solution: Automate stock management processes using barcode scanning, RFID technology, or perpetual inventory systems. Automation reduces reliance on manual inputs while improving accuracy. Regular cycle counts can also complement automation, ensuring discrepancies are caught early. Together, these measures minimize human errors and create a more reliable inventory database.

8. Inefficient Warehouse Organization

Poorly designed warehouse layouts cause picking delays, misplaced inventory, and higher labor costs. Staff may waste valuable time searching for products, resulting in slow order fulfillment and dissatisfied customers. As businesses scale, inefficiency compounds and directly impacts profitability.

Solution: Optimize warehouse design with slotting strategies that group frequently picked items in accessible areas. Use RFID or barcode systems to locate items quickly. Implementing warehouse management software (WMS) further streamlines storage, picking, and replenishment, ensuring staff can operate efficiently while reducing handling costs and fulfillment times.

9. Ineffective Reporting

Inventory reports that are outdated or generic fail to provide actionable insights. Without detailed reporting, managers can’t identify sales patterns, inefficiencies, or risks. This lack of visibility leads to poor planning, wasted resources, and missed growth opportunities.

Solution: Use inventory systems with customizable reporting features, tailored to specific business KPIs like turnover rates, shrinkage, or carrying costs. Modern dashboards present data visually, making it easier to spot trends. With accurate, real-time reports, managers can make data-driven decisions that improve both operational efficiency and profitability.

10. High Shrinkage Rates

Inventory shrinkage, caused by theft, damage, or administrative errors, significantly cuts into profit margins. In retail, shrinkage can account for billions in losses annually. Beyond financial damage, shrinkage also disrupts accurate stock counts, leading to stockouts or overstocking.

Solution: Strengthen internal controls through better surveillance, POS security, and regular audits. Train employees to follow strict inventory handling procedures. Using technology like RFID tagging can also track products more closely, reducing theft and errors. By combining preventative measures with oversight, businesses can limit shrinkage and protect profitability.

11. Seasonal Demand Fluctuations

Retailers often face unpredictable spikes in demand during holidays or special events. If demand is underestimated, stockouts occur; if overestimated, businesses are left with unsold stock. Both scenarios impact profitability and customer trust. Seasonal trends require more precise planning than regular demand.

Solution: Use historical sales data combined with advanced analytics to predict seasonal demand. Incorporate factors like promotions, market trends, and lead times into forecasting models. With data-driven preparation, businesses can strike the right balance—keeping shelves stocked during peak periods without carrying excessive inventory once demand subsides.

12. Complex Pricing Structures

Frequent price changes caused by competition, promotions, or market conditions complicate inventory valuation. Errors in pricing can disrupt sales and lead to inaccurate financial reporting. For businesses with large assortments, manual price adjustments become impractical and error-prone.

Solution: Implement automated retail pricing optimization software that adjusts prices across channels in real time. These tools ensure consistency while considering demand, competitor pricing, and margins. Automated systems also integrate with inventory management tools, keeping valuations accurate and enabling smoother decision-making.

13. Inefficient Order Management

Poorly managed supplier communication, misplaced purchase orders, and delays in reordering create bottlenecks in inventory flow. Manual order tracking often leads to missed deliveries or late replenishments, which directly affect sales and customer satisfaction.

Solution: Adopt order management software that automates purchase orders, tracks deliveries, and sends reminders for reorders. These systems also improve supplier collaboration by providing transparency into stock needs and delivery timelines. With streamlined order management, businesses maintain steady inventory flow and minimize costly disruptions.

14. No Scalability

As businesses grow, outdated inventory systems can’t keep pace with rising SKUs, multiple warehouses, or increased sales volume. This creates inefficiencies and limits expansion opportunities. Without scalability, customer demand may outstrip a business’s ability to fulfill orders.

Solution: Invest in scalable inventory or POS systems that expand alongside business growth. Cloud-based platforms allow easy addition of new locations, products, and users. Scalable systems ensure that operations remain efficient as demand increases, protecting service quality and supporting long-term growth without constant system upgrades.

15. Poor Employee Training

Employees without proper training on inventory systems and processes often misuse tools, make frequent errors, or skip essential procedures. This results in inaccurate records, inefficiencies, and potential financial losses. A lack of training also decreases staff confidence and productivity.

Solution: Implement structured training programs focused on inventory systems, reporting, and best practices. Ongoing workshops, refresher courses, and hands-on sessions help staff stay updated as systems evolve. Investing in employee knowledge not only reduces errors but also improves accountability and overall inventory management efficiency.

16. Low Stock Visibility

Limited visibility into inventory creates uncertainty for managers and decision-makers. Without real-time data, businesses risk overordering, stockouts, and missed sales opportunities. Physical stock counts or outdated spreadsheets make the situation worse, slowing response times and creating costly inefficiencies.

Solution: Invest in inventory visibility tools like RFID systems and real-time dashboards. These technologies provide instant access to stock levels across all warehouses and sales channels. Enhanced visibility enables faster decisions, more accurate restocking, and better alignment between demand and supply, ensuring smooth operations and improved customer satisfaction.

17. Lack of Customization

Generic inventory systems often fail to address industry-specific needs. For example, businesses handling perishable goods require shelf-life tracking, while liquor stores need age-restricted compliance. Without customization, companies face inefficiencies, compliance risks, and difficulty managing specialized requirements.

Solution: Choose industry-customizable inventory software tailored to specific operational needs. These systems provide features such as batch tracking, expiration alerts, or compliance modules. Customizable solutions reduce errors, improve process efficiency, and ensure businesses remain aligned with regulatory requirements while meeting unique industry demands.

18. Limited Data Access

Restricted access to inventory data—whether due to location, time, or device limitations—slows down decision-making. Managers may struggle to coordinate across multiple sites, and remote teams often operate without visibility, leading to inefficiencies.

Solution: Adopt cloud-based inventory systems that enable real-time access to data from anywhere, at any time. These platforms support multiple users across locations, ensuring consistent and up-to-date information. Cloud systems also enhance collaboration, allowing managers and teams to make timely, informed decisions, regardless of their physical location.

19. Fragmented Operations

Using separate systems for sales, inventory, and reporting creates data silos. This fragmentation results in duplicate entries, inconsistencies, and wasted time reconciling information across platforms. It also prevents businesses from having a unified view of operations, leading to costly errors.

Solution: Implement unified retail management systems that integrate inventory, sales, and reporting functions. A single, centralized platform eliminates redundancies and improves accuracy. Integrated systems streamline workflows, increase efficiency, and provide leadership with a holistic view of operations, enabling more strategic and confident decision-making.

20. Lack of Transport Capacity

Transportation bottlenecks—caused by limited carriers, rising fuel costs, or seasonal demand—directly disrupt inventory replenishment and fulfillment. These delays often force businesses to hold excess stock, raising storage costs and reducing flexibility.

Solution: Strengthen logistics planning by diversifying carriers, negotiating contracts, and leveraging technology for route optimization. Businesses should also maintain backup transport options and use inventory forecasting tools to anticipate demand surges. Proactive transport planning minimizes delays, reduces costs, and ensures a smoother inventory flow even during peak seasons.

Best Practices for Managing Inventory Effectively

Effective inventory management is essential for businesses to operate smoothly, reduce costs, and keep customers satisfied. Poor inventory practices can lead to stockouts, overstocking, or unnecessary holding costs, impacting both revenue and reputation. Implementing best practices ensures that inventory is optimized, accurate, and aligned with customer demand. Here’s a detailed guide to the most effective strategies:

1. Use an Inventory Management System

Automating inventory tracking is critical in today’s fast-paced business environment. A robust inventory management system provides real-time updates on stock levels, preventing discrepancies and manual errors. These systems can integrate with sales, procurement, and warehouse operations, ensuring all departments have accurate visibility into current inventory. Automation also helps streamline processes, reduce administrative workload, and generate actionable insights for better decision-making.

2. Implement Demand Forecasting

Analyzing historical sales data, market trends, and seasonal patterns helps businesses predict future demand more accurately. Demand forecasting reduces the risk of overstocking or stockouts and allows for smarter procurement and production planning. Advanced analytics and AI-powered forecasting tools can account for variables such as promotions, economic shifts, and consumer behavior, enabling companies to maintain optimal inventory levels throughout the year.

3. Set Reorder Points & Safety Stock Levels

Reorder points ensure that new stock is ordered before inventory runs out, while safety stock acts as a buffer against unexpected demand spikes or supply chain delays. Calculating these levels accurately requires understanding lead times, average consumption rates, and variability in demand. By maintaining reorder points and safety stock, businesses can avoid stockouts without over-investing in excess inventory.

4. Adopt Inventory Control Techniques

Techniques like ABC analysis, FIFO/LIFO, and Just-in-Time (JIT) inventory help optimize stock levels and minimize holding costs. ABC analysis classifies inventory based on value and demand frequency, allowing managers to focus on high-impact items. FIFO ensures older stock is sold first, reducing the risk of spoilage, while JIT minimizes inventory on hand and improves cash flow. Selecting the right method depends on the type of inventory and business model.

5. Optimize Order Management

Integrating inventory with automated order processing ensures that orders are fulfilled accurately and efficiently. Modern systems track orders in real-time, reducing delays, errors, and double handling. Automation in procurement and fulfillment improves supplier coordination, decreases lead times, and ensures customers receive their products promptly, enhancing overall satisfaction and loyalty.

6. Improve Supplier Relationship Management

Strong relationships with reliable suppliers are essential for maintaining consistent inventory levels. Regular communication, performance reviews, and collaborative planning help mitigate supply chain disruptions. Trusted suppliers can offer better pricing, faster deliveries, and flexible terms, ensuring the business has the stock it needs when it’s needed.

7. Conduct Regular Audits & Cycle Counting

Periodic audits and cycle counts help verify inventory accuracy and identify discrepancies early. Regular checks prevent long-term errors, reduce shrinkage, and maintain data integrity. Cycle counting—counting a subset of inventory on a rotating schedule—is less disruptive than full inventory counts and ensures continuous accuracy.

8. Optimize Warehouse Layout

An organized warehouse reduces retrieval time, prevents stock misplacement, and improves overall efficiency. Items should be categorized, labeled, and positioned based on demand frequency. Efficient layouts free up storage space, reduce labor costs, and enable smoother inventory flow throughout the warehouse.

9. Train Staff on Inventory Best Practices

Employee training is vital for consistent and accurate inventory management. Staff should be educated on proper handling, recording procedures, inventory control techniques, and the use of management systems. Well-trained employees reduce errors, improve operational efficiency, and contribute to overall inventory optimization.

10. Monitor and Improve Continuously

Inventory management is not a one-time task. Regularly reviewing performance metrics, analyzing discrepancies, and adjusting processes ensures continuous improvement. Businesses that adopt a culture of continuous monitoring can respond to changes in demand, supplier performance, or market conditions more effectively.

Role of Technology in Tackling Inventory Management Challenges

Technology has transformed how businesses handle inventory by eliminating inefficiencies, reducing errors, and providing real-time visibility into operations. In today’s competitive landscape, relying on manual methods or disconnected systems is no longer sustainable. Modern inventory management technologies empower businesses to forecast demand accurately, optimize stock levels, and enhance customer satisfaction.

1. Real-Time Inventory Tracking

Tools like RFID tags, IoT sensors, and barcode scanning systems provide instant updates on stock movement. This reduces human error, minimizes stock discrepancies, and ensures managers always have accurate data at their fingertips.

2. Automated Replenishment Systems

Automation streamlines reordering by setting minimum and maximum stock levels. When inventory reaches a threshold, the system triggers purchase orders automatically, helping businesses avoid both stockouts and overstocking.

3. Cloud-Based Solutions

Cloud inventory platforms offer centralized data access across multiple locations and devices. This ensures seamless collaboration between teams, suppliers, and warehouses while supporting scalability as the business grows.

4. Predictive Analytics and AI

By analyzing sales history, seasonality, and market trends, AI-driven demand forecasting tools help businesses predict customer needs with greater accuracy. This reduces obsolete stock and prepares companies for seasonal fluctuations or demand spikes.

5. Integrated ERP Systems

Enterprise Resource Planning (ERP) software connects inventory with sales, finance, and supply chain functions. This integration eliminates silos, improves efficiency, and gives leadership a holistic view of operations to support strategic decisions.

6. Mobile Accessibility

Mobile-enabled inventory apps allow staff to update stock levels, track shipments, and check orders from anywhere. This boosts efficiency on the warehouse floor and ensures decision-makers have access to real-time insights on the go.

7. Enhanced Security and Loss Prevention

Advanced POS systems and surveillance technology reduce shrinkage by tracking product movement and flagging irregularities. This protects profitability and improves accountability across the organization.

With solutions like Deskera ERP, businesses can combine automation, AI-driven insights, and integrated modules for sales, accounting, and inventory into one unified platform. This not only simplifies operations but also helps teams reduce inefficiencies, cut costs, and scale seamlessly.

How Deskera ERP Helps Overcome Inventory Management Challenges

Managing inventory effectively is a major challenge for businesses, especially as operations scale or expand across multiple channels. Deskera ERP offers an integrated solution designed to tackle these challenges and streamline inventory management.

1. Real-Time Inventory Visibility

Deskera ERP provides a centralized dashboard that displays live stock levels across warehouses, stores, and sales channels. This real-time visibility prevents stockouts, overstocking, and mismanagement, enabling managers to make informed decisions quickly.

2. Automated Reorder Alerts & Stock Management

The system automatically monitors stock levels and generates reorder alerts when inventory falls below defined thresholds. Businesses can maintain safety stock, avoid shortages, and ensure consistent product availability without manual tracking.

3. Advanced Demand Forecasting

Deskera ERP leverages historical sales data, seasonality, and trends to forecast demand accurately. This helps businesses align purchasing and production with actual market needs, reducing excess inventory, spoilage, or missed sales opportunities.

4. Multichannel Inventory Management

For businesses selling through multiple channels—eCommerce platforms, retail outlets, and marketplaces—Deskera ERP synchronizes inventory across all platforms. This ensures accurate stock levels, prevents overselling, and improves the customer experience.

5. Streamlined Order Management

Deskera integrates purchase orders, sales orders, and inventory tracking in a single system. Automation reduces errors, delays, and duplication, making order fulfillment faster and more efficient while maintaining optimal inventory flow.

6. Inventory Control Techniques Built-In

Deskera ERP supports ABC analysis, batch tracking, FIFO/LIFO, and serial number tracking. These features help prioritize high-value items, reduce obsolete inventory, and manage perishable or time-sensitive products efficiently.

7. Analytics and Reporting

The ERP generates customizable reports and dashboards for inventory turnover, stock aging, and performance metrics. These insights allow managers to identify slow-moving items, adjust procurement strategies, and optimize inventory costs.

8. Integration with Suppliers

Deskera ERP allows seamless collaboration with suppliers, tracking deliveries and lead times. Businesses can plan procurement effectively, reduce delays, and maintain strong supplier relationships.

9. Cloud-Based Access & Mobility

Deskera’s cloud platform enables access to inventory data anytime, anywhere. Managers and staff can track stock, process orders, and monitor performance remotely, improving efficiency for distributed operations.

10. Minimizing Human Errors

Automation reduces manual data entry and errors, ensuring accurate inventory counts and preventing discrepancies. Staff can focus on strategic tasks rather than repetitive administrative work.

Deskera ERP helps businesses maintain optimal stock levels, improve order accuracy, streamline operations, and make data-driven decisions. By integrating all inventory functions into a single platform, it reduces costs, prevents losses, and enhances customer satisfaction.

Key Takeaways

- Inventory management challenges arise when businesses struggle with stock accuracy, demand forecasting, warehouse efficiency, or order fulfillment. These challenges can disrupt operations, inflate costs, and reduce customer satisfaction.

- Poorly managed inventory leads to stockouts, overstocking, high carrying costs, lost sales, and wasted resources. In fact, global inventory distortion costs businesses trillions annually, showing how critical it is to address these issues proactively.

- Addressing inventory problems leads to stronger profitability, streamlined operations, better supplier and customer relationships, and improved decision-making. Businesses also gain resilience against demand fluctuations and supply chain disruptions.

- Challenges like stockouts, overstocking, inaccurate demand forecasts, warehouse inefficiency, and fragmented operations can be overcome with solutions such as automated alerts, ABC analysis, demand forecasting, RFID tracking, and unified ERP systems.

- Best practices include adopting inventory management systems, setting reorder points, using inventory control techniques like FIFO/ABC/JIT, optimizing warehouses, conducting regular audits, improving supplier relationships, and training staff. These steps ensure accurate, efficient, and cost-effective operations.

- Automation, AI-driven forecasting, IoT sensors, real-time dashboards, and cloud ERP systems empower businesses with visibility, accuracy, and scalability—transforming inventory management from reactive to proactive.

- Deskera ERP helps businesses overcome inventory challenges by providing real-time dashboards, AI-powered demand forecasting, multichannel integration, automated stock updates, customizable reports, and scalable solutions. This ensures efficiency, accuracy, and long-term growth.

Related Articles