"How much raw material should I order from my supplier?"

"When should I place my next supply order?"

Yes, we know that these are the top two questions you always have to ask yourself as a business owner. We also know that these questions aren’t easy to answer as well.

Hence, today with this article we have come to your rescue. In this article we will tell you about inventory reorder point technique that will help cut the struggle out of answering these crucial questions.

Inventory management or inventory control isn’t an easy one when you have too much on your plate to manage. Along with that, getting the optimal level of inventory right in your warehouse is nearly impossible. Once you know when exactly to order your inventory/raw materials and the quantity of the goods, consider your job done. And for that, you will need Inventory Reorder Point.

Worry not, you will learn all about it right here.

By the end of the article you will know:

- What is Inventory Reorder Point?

- What is the difference between reorder quantity and reorder point?

- 3 Reasons why it is important to calculate Inventory Reorder Point.

- How to calculate Inventory ROP?

Let’s delve right into it.

What is Inventory Reorder Point?

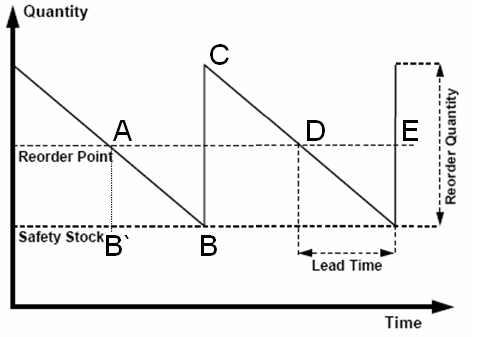

The inventory reorder point in inventory management is the minimum level of stock for a specific product. When you reach that stock level it triggers the reordering of that particular product.

While ascertaining the reorder level of the inventory for different SKUs, Inventory ROP determines the lead time it will take to restock so that you are not ordering goods in the nick of the time. Rather, setting an accurate reorder point allows you to offer the goods available while hanging tight for new stock.

However, what can be often confusing is if reorder quantity and reorder point are the same. If you get confused too, the upcoming section will free you from that confusion.

Difference Between Reorder Quantity and Reorder Point

Let us look at how reorder quantity and reorder point vary:

- Reorder level is the stock level of a specific product based on which order for new stocks is placed. On the other hand, reorder quantity is the number of units to be ordered while placing a new purchase order.

- Reorder level indicates when to submit a request for the new stock of goods and reorder quantity makes clear the number of goods to order.

- Reorder point involves factors like utilization of goods during the lead time, security level, and renewal period, and the factors involved in reorder quantity are carrying cost of stock per unit, cost of the order, and so on.

- Reorder level is the priority. You first evaluate whether the stock level of a product is above the reorder level or below the reorder level. At the same time, reorder quantity is determined to be put in on the new purchase order, solely after it has been concluded that new stock has to be bought.

- The main risk factor in reorder level is being out of stock; whereas the main risk factor in reorders quantity is the high cost per unit of the inventory ordered.

Hope the difference between reorder quantity and reorder point is now clear.

Now let us understand why it is essential to calculate the reorder point of your inventory.

3 Reasons Why it is Important to Calculate Inventory Reorder Point

Reorder point makes sure that you don't fall behind on your next stock. With a precise reorder point for each product, you'll always have sufficient stock available to fulfill your customer's demand. Here are a few more reasons why it is important to calculate inventory reorder point:

Reduction in Inventory Cost

Storing goods, raw materials more than necessary, and customer demand is not a useful utilization of capital. Reorder points provide businesses with greater financial understanding and allows you to keep the minimum inventory based on the customer’s demand.

No Stockouts

A lot of inventory is costly, however too little can result in running out of stocks, which is harmful to your growing business. The customer orders are postponed or dropped, and you start losing your loyal customers. With reorder points you will be able to maintain an optimum level of inventory. You will know exactly when to order new goods, raw materials.

Improved Forecasting

Calculation of the reorder points goes inseparably with knowledge of the running trends in a given period. The more regularly you study the ROP for any product, the more precisely you will be able to estimate the demand for a product in the future. It will also give reassurance that you have utilized the available resources efficiently.

Now that you have understood the importance of calculating the ROP of your inventory, let us understand how to calculate it.

How to Improve Reorder Point Calculations with the Following 6 Reorder Point Strategies?

Here are few strategies that can help you manage inventory reorder levels efficiently.

Keep Tabs Inventory Reorder Level

An important strategy for successfully implementing a reorder point is to consistently execute on it. The benefit of a reorder point is that it tells you when you need to reorder, but it only works if you actually reorder at that point.

Stay Cautious

You won't necessarily be able to reorder at exactly your reorder point every time, unless you're using automated software to place orders. That being the case, would you rather reorder when you're approaching your ROP, or after you've already passed it?

The answer will depend on what's more costly to you: having too little inventory or too much. If your inventory is perishable, you may be more inclined to wait, while if your on-site storage costs are low and demand is highly variable, you're probably better off ordering before you hit the reorder point.

Bring Sales Forecast for your Use

Multiplying daily sales times lead time works well if lead times and daily sales are constant through the weeks and months and years. But suppose lead time is three days, and you know that sales are higher on weekends.

You'd be better off using your expected sales over the next three days in the formula, rather than your average daily sales, because what looks like perfectly fine inventory on a Monday may be insufficient on a Friday morning going into a busy weekend. In some cases, you may even want to look a few days further than your lead time to see what's coming.

Keep Eyes on your Calendar

There are often times when the lead time isn't three days but three business days? Hence it can be difficult to place an order on Thursday and have it delivered by Sunday, so the actual lead time would be longer.

Anything you need for the weekend would have to be in by Friday or you can't sell it on Saturday or Sunday. This means you need to order your weekend supplies by Tuesday, which, in turn, means you need to be looking almost a week ahead and not just three days when deciding when and how much to order.

Focus on Order Quantities

If you find yourself constantly hitting your reorder point, you may not be ordering a high enough quantity with each reorder. Conversely, if managing your on-site inventory is becoming difficult or costly due to how much you have, and you're not reordering very often at all, you may have set the quantity too high.

Reorder points are about timing, not quantity, but that doesn't mean quantity isn't important. If you're struggling with order quantity, economic order quantity (EOQ) calculations, which are designed to find a given business's optimal order quantity, may be useful.

Avoid Over Optimizing

When applying a new concept, it's easy and understandable to try to get as much value out of it as possible. But the goal of any implementation is improving your business, not optimizing an individual metric or process at any expense. Say you own a store selling art supplies.

You have reorder points for paint brushes, paints, canvases and a hundred other items. If most of them come from the same few suppliers, it might be cheaper, and much better for your supplier relationships, to group orders together in fewer, larger orders.

However, if you have a separate reorder point alert set up for every item, you may wind up placing a new order every few hours. You'll be optimizing for not having too much or too little inventory, but at a much higher cost than storing a few extra paint brushes so you can place fewer large orders.

In this specific example, you might just place orders for anything getting close to its reorder point — maybe anything under 150% or even 200% of the calculated reorder point gets a reorder in your larger, more infrequent purchases. Reorder points should be integrated into your business processes to ensure sufficient inventory levels, but they shouldn't supersede other priorities.

How to Calculate Inventory Reorder Point?

You can calculate the ROP of your inventory with the help of a simple formula.

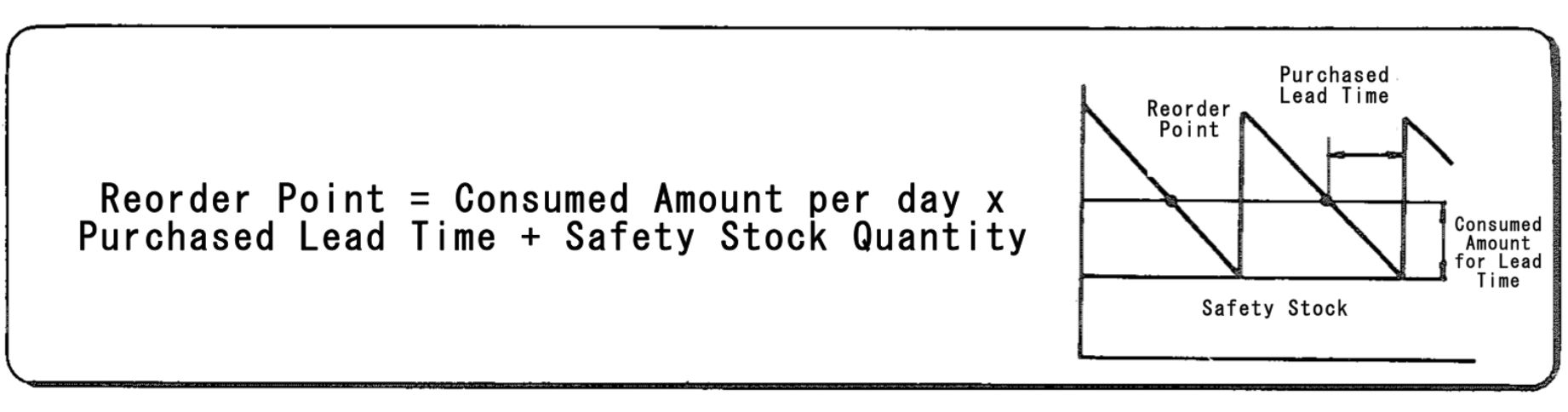

The formula for Inventory Reorder Point:

Reorder Point (ROP) = Demand during lead time + safety stock

For example, if the demand during lead time for ear pods is 104 and safety stock is 120 then the reorder point for the ear pods would be?

Reorder Point= Demand during lead time + Safety stock

Reorder Point= 104 + 120

Reorder Point= 224 units

We already know what ROP is but have no clue what demand during lead time or safety stock is. So, let us quickly learn about it before we start doing any calculations.

Demand during the Lead time

The lead time in ROP is the number of days between when you put in a purchase order to your supplier for a product and when you receive that product. Your lead time will be longer if your supplier does not come from the same country as you.

You can calculate the demand during the lead time with the following formula:

The formula for Calculating Demand During the Lead Time:

Safety Stock

Is it enough for you to know the demand for your product? The demand for your product is rarely static. It is either going up or down and this happens more frequently than you can imagine. This in return prevents you from restocking goods. Another roadblock could be unforeseen problems with the supplier to be able to deliver the goods on time, not as quickly as you expected.

With Safety Stock you can always have the “just in case” inventory ready. Whenever you are facing a failure of delivery of goods, you can use your safety stock to deliver to customer demands.

To calculate the safety stock you must have with you, you can use the following formula.

Formula for calculating your safety stock:

Once you have calculated the safety stock and demand during the lead time, you simply have to put these values in the ROP formula and your ROP is ready.

For example, If your demand during lead time is 112 and safety stock is 122 then your ROP would be

ROP = Demand during lead time + Safety stock

ROP= 112 + 122

ROP= 234

Therefore, whenever you are left with 234 units of a product you will place an order for more units of the product.

How Can Deskera Assist You?

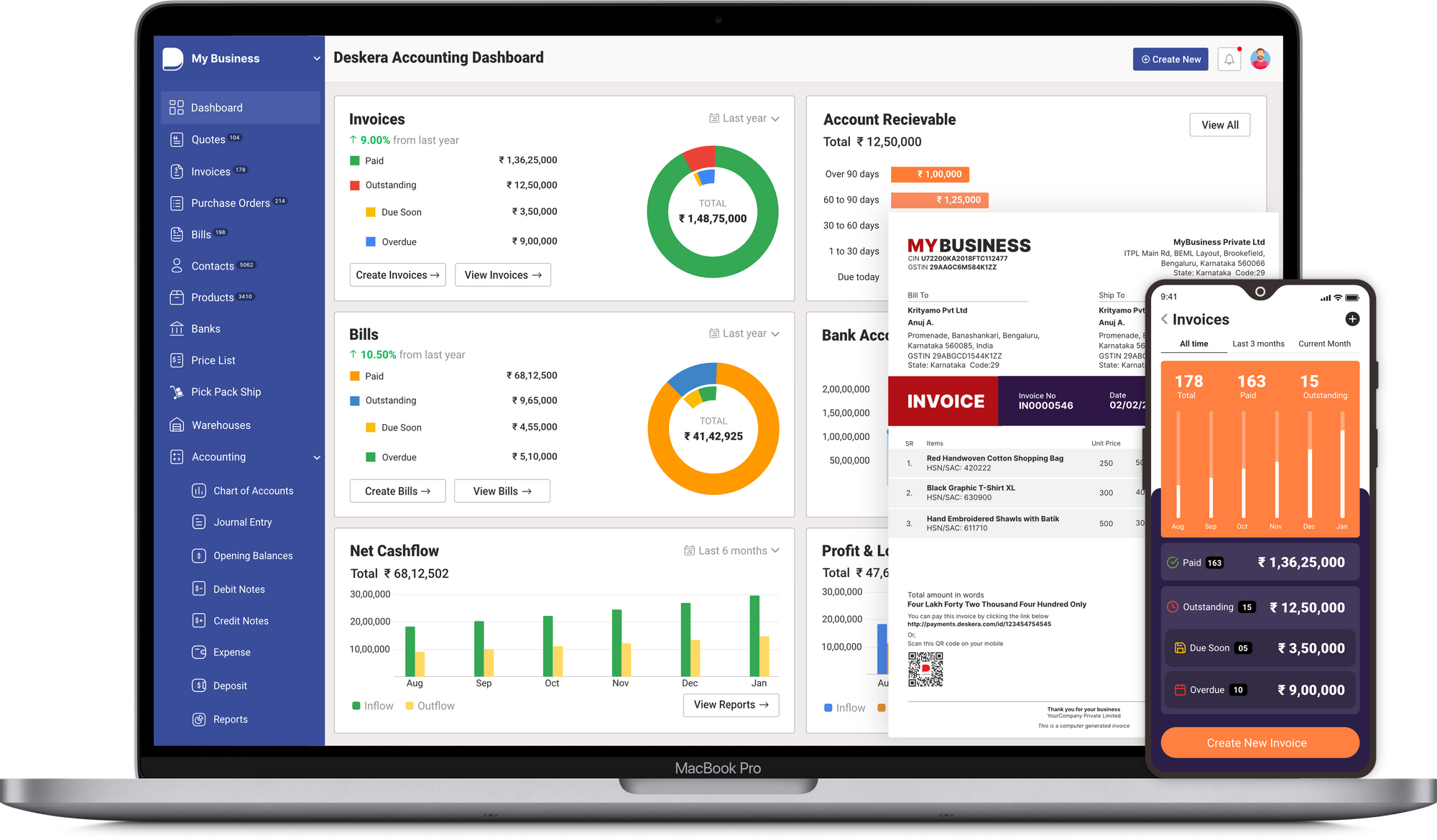

Calculating reorder points frees up your capital and guarantees your business is working at its maximum capacity. To calculate the ROP of your inventory, all you require is accurate information you can rely on for planning and managing your supply chain.

Since ROP also helps you determine your customer's demand, you cannot afford to have faulty information. If you end up with faulty information and base your ROP on that, there is an off chance that you will either overstock or have nothing to at all.

It is easy to manage inventory using softwares such as Deskera. With Deskera Books you can update all the information related to your products in real-time and make sure you are not missing out on anything. Not just that, but Deskera also allows you to maintain your balance sheets in the system and manage your inventory efficiently.

If you don’t believe it, try it yourself for 15 days, we guarantee that it will make your life easy.

Key Takeaways:

- Inventory Reorder Point in inventory management is the minimum level of stock for a specific product.

- Reorder level is the stock level of a specific product and reorder quantity is the number of units to be ordered while placing a new purchase order

- Calculating inventory reorder points helps with the reduction in inventory Cost, reduces stockouts, and improves forecasting.

- How to calculate reorder point by calculating demand lead time and safety stock.

Related Articles: