In today’s fast-paced business environment, managing inventory efficiently has become more critical than ever. Yet, many companies struggle with disconnected systems, manual updates, and inaccurate stock data, leading to operational bottlenecks and lost revenue. This is where inventory integration comes into play — the seamless connection of inventory systems with sales, accounting, procurement, and other business platforms to ensure real-time visibility and accuracy across the organization.

The benefits of inventory integration are backed by compelling data. Studies show that integrating inventory systems can reduce excess stock by 15–20% and increase overall sales efficiency by 10–15%. Companies with connected systems also experience 20% faster order fulfillment and improved accuracy in stock levels, directly enhancing customer satisfaction. On the flip side, poor or missing integration can have severe financial consequences, contributing to an estimated $1.6 trillion in costs worldwide due to inventory distortion.

Beyond operational efficiency, inventory integration empowers businesses to make smarter decisions. By automating data flow between multiple platforms, companies gain a single source of truth for their inventory, streamline processes, and respond quickly to changing market demands. This approach not only minimizes human error but also allows teams to focus on strategic tasks such as demand forecasting, supply chain optimization, and customer experience enhancement.

For businesses looking to implement seamless inventory integration, tools like Deskera ERP offer an all-in-one solution. Deskera ERP connects sales, accounting, inventory, and procurement systems on a unified platform, providing real-time insights and automated workflows. Its AI-powered assistant, David, helps monitor stock levels and suggests actionable decisions, while mobile accessibility ensures that inventory can be managed anytime, anywhere. With Deskera ERP, companies can reduce manual errors, improve operational efficiency, and scale their business with confidence.

What Is Inventory Integration?

Inventory integration is the process of connecting your inventory management system with other core business platforms, such as accounting software, warehouse management tools, and order fulfillment systems. This synchronization ensures that every department works from the same set of accurate numbers, turning inventory management from a tactical stock-tracking function into a strategic hub for decision-making and automation.

Harmonization Across Departments

- Blends data from stock levels, order statuses, and financial records.

- Minimizes or eliminates isolated data silos.

- Enables faster, smarter operational and financial decisions.

- Example: When inventory levels fall below a threshold, integrated systems can automatically trigger replenishment orders.

Two-Way Data Flow for Optimization

- Insights from sales analytics, marketing campaigns, or demand trends feed back into inventory systems.

- Allows proactive stock allocation to high-demand locations.

- Ensures accurate financial reporting and compliance.

- Provides supply chain partners with transparent, real-time inventory information.

Enhancing Customer Experience

- E-commerce and omnichannel platforms can display precise stock availability across stores.

- Reduces stockout frustration and prevents wasted customer trips.

- Increases trust and loyalty: a 2025 study found consumer satisfaction rose by 30% when real-time inventory visibility was provided.

How Inventory Integration Works

Inventory integration works by connecting inventory management systems with other critical business platforms, allowing seamless data flow and real-time updates. This connection can be achieved through APIs, middleware, or built-in platform integrations. Once set up, inventory data is synchronized across systems, enabling automated processes, accurate reporting, and strategic decision-making.

1. Data Synchronization Across Systems

- Inventory levels, order statuses, and financial records are automatically updated in all connected systems.

- Reduces manual entry errors and ensures consistency across departments.

- Example: A sale recorded in an e-commerce platform automatically updates stock levels in the warehouse system and the accounting software.

2. Automated Workflows

- Triggers automated processes such as stock replenishment, order routing, or invoice generation.

- Example: If a product falls below a defined stock threshold, integrated systems can automatically generate a purchase order to the supplier.

- Minimizes delays, errors, and operational bottlenecks.

3. Real-Time Insights for Decision-Making

- Provides managers with up-to-date information for better demand forecasting and inventory planning.

- Example: Sales or marketing trends indicate higher demand in a specific region, prompting proactive stock allocation.

- Helps reduce overstocking, understocking, and missed sales opportunities.

4. Customer-Facing Integration

- Integrates inventory with e-commerce or omnichannel platforms to display accurate stock availability.

- Improves the shopping experience by preventing stockouts and enhancing order fulfillment reliability.

- Builds customer trust and satisfaction through transparency.

5. Bi-Directional Data Flow

- Data flows not just from inventory to other systems but also back into inventory management.

- Example: Financial or sales performance data informs inventory decisions, ensuring optimal stock allocation and reporting.

Why Inventory Integration Matters

Modern inventory management relies on real-time visibility of stock throughout its lifecycle. Yet, many teams still spend up to 16 hours per week manually syncing inventory across disconnected systems and channels, wasting over $21,000 annually per entry-level employee. Inventory integration solves this problem by unifying data across departments, providing actionable insights, and enabling automation that drives efficiency and accuracy.

1. Empowering Sales Teams

- Accurate inventory data allows sales teams to set clear expectations with customers regarding product availability.

- Reduces stockouts and overselling, improving customer satisfaction and trust.

- Example: An integrated system can instantly confirm whether a product is available for immediate shipping or backorder.

2. Streamlining Production

- Integration helps production teams keep manufacturing lines running smoothly.

- Automates lean processes, ensuring raw materials arrive on time to prevent production delays.

- Example: Inventory thresholds trigger automatic purchase orders to suppliers when materials run low.

3. Improving Financial Accuracy

- Inventory integration allows finance teams to automate journal entries, accurately reflecting revenue, cost of goods sold (COGS), and inventory valuation.

- Reduces manual bookkeeping errors and improves reporting for management and compliance.

- Example: Real-time inventory adjustments automatically update financial records, saving hours of reconciliation work.

4. Optimizing Warehouse Operations

- Warehouse managers can make data-driven decisions about storage layout and workflow.

- Fast-moving items can be placed near packing stations, improving order fulfillment speed.

- Example: Integrated systems highlight stock movement patterns, enabling smarter space utilization.

5. Enabling Strategic Decision-Making

- A unified view of inventory across systems allows businesses to implement dynamic pricing, omnichannel fulfillment, and optimized distribution strategies.

- Siloed inventory data limits the ability to plan and act efficiently.

- Example: Real-time inventory insights can guide promotions, transfer stock to high-demand locations, or prioritize shipping routes.

6. Supporting Advanced Forecasting and AI-Driven Analytics

- Integrated systems enable AI and predictive analytics to contextualize inventory trends with sales, financial, and supply chain data.

- McKinsey & Company estimates this approach can reduce inventory levels by up to 30%, cut logistics costs by 20%, and lower procurement spend by 15%.

- Example: AI-powered forecasting predicts demand spikes and automatically adjusts inventory across locations to maximize efficiency.

Key Benefits of Inventory Integration

Inventory integration transforms how businesses manage and respond to the flow of goods, data, and customer demand. By connecting inventory systems with accounting, sales, supply chain, and analytics platforms, companies can operate with agility, accuracy, and confidence. The result is a business that’s not just efficient, but adaptable to evolving customer and market needs.

1. Automation and Efficiency

- Integration eliminates the need to manually update multiple systems, reducing repetitive administrative tasks.

- Automated workflows can restock items when inventory reaches a predefined threshold, preventing stockouts and overordering.

- Businesses can reallocate time from manual reconciliation to strategic growth initiatives.

- Example: A connected system automatically triggers purchase orders when raw materials run low, ensuring uninterrupted production.

2. Optimization and Adaptability

- Integration helps businesses quickly adapt to shifting customer needs and market trends.

- By maintaining optimal stock levels, companies avoid tying up capital in excess inventory or warehouse space.

- Enables dynamic adjustments in pricing, promotions, and procurement strategies based on real-time insights.

3. Enhanced Supply Chain Visibility

- Real-time tracking of stock movement across the supply chain improves transparency and responsiveness.

- Managers can monitor inventory at every stage—procurement, production, warehousing, and delivery.

- Early detection of supply disruptions allows businesses to take proactive measures and maintain service continuity.

- Example: A sudden shipment delay triggers an alert, prompting managers to reroute fulfillment from another warehouse.

4. Accurate Financial Reporting

- Inventory is a significant business asset, and integration ensures it’s reported accurately in financial records.

- Automated updates to accounting systems reflect real-time changes in inventory valuation, COGS, and revenue.

- Reduces manual bookkeeping errors and strengthens compliance with audit requirements.

5. Improved Forecasting and Decision-Making

- Integrated systems combine inventory data with broader business analytics to enhance demand forecasting.

- Enables the creation of more accurate models that account for sales trends, seasonality, and supplier lead times.

- According to McKinsey & Company, AI-driven forecasting enabled by integration can reduce inventory levels by up to 30% and lower logistics costs by 20%.

6. Increased Accuracy and Reliability

- Integration reduces human error through automated data entry and real-time synchronization.

- When connected with technologies like RFID or IoT, it ensures precise tracking and instant updates on stock movement.

- Businesses with high inventory accuracy can save up to three times the costs incurred by those with poor accuracy.

7. Scalability and Growth Readiness

- Integrated systems make it easier to manage multiple warehouses, channels, and locations from a unified dashboard.

- Businesses can scale operations without overloading staff or disrupting workflows.

- Consistent, real-time data supports quick adjustments to production schedules and promotional campaigns.

8. Cost Savings and Profitability

- Accurate data and efficient forecasting help reduce excess inventory and operational waste.

- Automation cuts labor costs linked to manual order processing and reconciliation.

- Integration also improves supplier negotiations by providing better visibility into purchasing trends and performance metrics.

Common Challenges in Inventory Integration

While the advantages of inventory integration are significant, achieving seamless synchronization across systems can be complex. The challenges extend beyond technology—they also involve data consistency, security, and cross-departmental coordination. Even businesses with advanced tools often face difficulties when trying to fully operationalize their integration efforts.

1. Coordinating Complex Systems

- Integrating multiple systems such as ERP, WMS, POS, accounting, and supply chain platforms can be challenging when each operates with different data structures and workflows.

- Organizations using legacy software or custom-built modules may face added difficulty, as these systems often lack modern API support or standardized integration protocols.

- Without proper coordination, integration can result in slow data syncing, duplicated records, or misaligned business processes.

2. Inaccurate or Inconsistent Data

- Inventory integration is only as strong as the data it connects. Manual data entry, inconsistent units of measurement, or mismatched product codes can all cause discrepancies.

- These inaccuracies can ripple through connected systems, leading to incorrect stock counts, faulty forecasts, and unreliable financial reports.

- Regular data validation, cleansing, and auditing are crucial to maintain integrity across integrated systems.

3. Data Security and Privacy Risks

- Integration increases the volume and sensitivity of shared data, including supplier, customer, and financial information.

- Without strong encryption, access control, and governance, businesses risk exposing critical data to breaches or unauthorized access.

- Each integration point can potentially widen the attack surface, making it vital to build secure connections and monitor them continuously.

4. Handling Inventory Discrepancies

- When integrated systems rely on inaccurate or delayed data, inventory mismatches can quickly escalate into operational disruptions.

- For example, a small error in stock reporting can cascade across platforms—affecting procurement, production, and order fulfillment.

- Businesses must adopt best practices such as regular cycle counting, RFID tracking, and real-time reconciliation to maintain data reliability.

5. Technical Debt and Legacy Systems

- Many companies still rely on outdated software with hard-coded data exchanges, obsolete APIs, or one-off customizations.

- These technical constraints limit flexibility, slow integration projects, and increase long-term maintenance costs.

- Overcoming this requires a strategic decision to modernize or refactor legacy systems, enabling smoother, future-ready integrations.

6. Inventory Visibility Gaps

- Ironically, integrating systems can sometimes reduce visibility if not implemented properly.

- Businesses with multiple warehouses or suppliers may find it difficult to achieve real-time tracking if systems aren’t fully aligned.

- Customizing integration workflows to match operational realities is essential to ensure visibility across all locations and partners.

7. Implementation and Training Costs

- Integrating inventory systems often involves upfront expenses for software, development, and staff training.

- The cost of data migration, vendor consultation, and ongoing maintenance can be significant for smaller businesses.

- However, these investments often pay off over time by reducing inefficiencies and improving operational performance.

Use Cases of Inventory Integration

Synchronizing inventory software with other enterprise systems transforms how businesses plan, manage, and fulfill orders. When data flows seamlessly across platforms, teams gain real-time visibility, eliminate manual bottlenecks, and make more informed decisions.

The most impactful applications of inventory integration are found in key areas such as ERP, ecommerce, accounting, WMS, third-party logistics (3PL), CRM, POS, and shipping software.

1. Enterprise Resource Planning (ERP) Integration

Integrating your inventory system with an ERP platform creates a unified data environment where every department—from procurement to finance—operates on the same information.

- ERP-driven inventory management ensures accurate stock control and demand forecasting, enabling better supplier negotiations and fulfillment planning.

- Businesses can automate reporting and analytics, using real-time inventory data to guide decisions on production scheduling, new product launches, and market expansion.

- Some ERP systems include built-in inventory modules, eliminating the need for separate platforms and reducing data silos.

2. Ecommerce Integration

For omnichannel retailers, connecting ecommerce platforms (like Shopify or WooCommerce) with inventory software ensures that inventory levels are synchronized across all sales channels.

- When a product sells online, stock updates instantly across physical stores and warehouses, preventing overselling and stockouts.

- Automated replenishment alerts and unified stock data simplify back-end operations and enhance customer satisfaction through accurate product availability and faster fulfillment.

- Real-time visibility also helps marketing and sales teams align promotions with actual stock levels.

3. Accounting System Integration

Integrating inventory with accounting software ensures financial accuracy and compliance.

- Real-time updates help automatically calculate COGS, profit margins, and inventory valuation.

- Automation reduces manual entry errors and improves the reliability of financial reports.

- With synchronized data, finance teams can better manage cash flow and align purchasing decisions with real-time inventory value.

4. Warehouse Management System (WMS) Integration

A WMS focuses on warehouse operations—storage, picking, and packing—while inventory systems manage stock levels and forecasting. Together, they create a real-time view of inventory movement.

- Each picking or packing action immediately updates stock counts, eliminating discrepancies between physical and digital records.

- Integration improves order accuracy, warehouse layout optimization, and fulfillment speed, especially for businesses managing multiple warehouses.

- It also enhances traceability by linking batch, lot, and serial number tracking directly with inventory updates.

5. Third-Party Logistics (3PL) Integration

For companies outsourcing warehousing or fulfillment, integrating inventory systems with 3PL providers ensures transparency and accuracy across the supply chain.

- Shared visibility into stock levels and order status allows seamless coordination between the business and its logistics partner.

- It minimizes manual data exchanges, reducing the risk of fulfillment delays or data mismatches.

- This integration helps businesses respond quickly to market demand without losing control over their inventory operations.

6. Customer Relationship Management (CRM) Integration

Integrating CRM software with inventory systems gives sales and support teams access to real-time stock insights during customer interactions.

- Sales teams can confirm product availability, quote accurate delivery times, and process orders directly.

- Marketing professionals can use inventory data to tailor campaigns based on buying patterns and product performance.

- Customer service teams benefit from unified visibility, helping them handle inquiries and returns more efficiently.

7. Point-of-Sale (POS) Integration

For businesses with physical outlets, integrating POS systems (like Square or Lightspeed) with inventory software ensures every transaction is instantly reflected in the central inventory database.

- Real-time tracking helps prevent overstocking or stockouts across locations.

- Automatic reorder triggers can be set when inventory drops below a defined threshold.

- Businesses selling both online and offline gain a consistent view of total inventory, regardless of sales channel.

8. Shipping Software Integration

Integrating shipping tools (such as ShipStation or EasyPost) with inventory management systems streamlines fulfillment workflows.

- Orders are automatically updated with shipping status, and inventory adjusts once items are dispatched.

- Businesses can automate label generation, tracking notifications, and returns, reducing manual effort and improving accuracy.

- Customers benefit from real-time order updates and faster delivery times, boosting satisfaction and loyalty.

Best Practices for Successfully Integrating Inventory Software

Reaping the full benefits of inventory integration requires more than just connecting systems — it takes careful planning, collaboration, and continuous optimization.

The goal is to establish a smooth flow of accurate, real-time inventory data across platforms to enhance visibility, automation, and decision-making. Below are key best practices to ensure a successful inventory integration strategy.

1. Define Clear Integration Goals

Every successful integration begins with well-defined goals.

- Identify what you want to achieve — improved visibility, faster reordering, reduced manual effort, or enhanced reporting accuracy.

- Prioritize objectives based on business needs. For example, a retailer may focus on reducing overselling, while a manufacturer might prioritize lean production and reordering automation.

- Clear goals provide direction for your integration roadmap and help teams measure success against KPIs.

2. Identify Key Systems, Processes, and Workflows

Understanding how inventory data moves through your organization is critical.

- Map out all systems that interact with inventory — ERP, WMS, accounting, POS, ecommerce, and CRM.

- Engage cross-functional stakeholders to uncover where data is created, updated, or consumed.

- Identify manual handoffs or redundant processes that slow down operations or introduce errors. This mapping exercise ensures no data source or dependency is overlooked before integration begins.

3. Explore Software Compatibility and Integration Capabilities

Before proceeding, evaluate your current software ecosystem.

- Check if your existing systems support modern APIs or middleware for integration.

- Identify legacy tools that may require upgrades or replacements to ensure compatibility.

- Consider migrating to cloud-based platforms, which offer greater flexibility, scalability, and built-in integration support. Investing time in compatibility analysis early helps avoid costly rework later.

4. Choose the Right Integration Method

Different integration methods suit different business needs. Common approaches include:

- Point-to-point integrations: Directly connect two systems. Suitable for simple use cases but difficult to scale.

- Middleware or integration platforms: Act as intermediaries that coordinate data flow between multiple systems. They handle complexity but can be expensive.

- APIs (Application Programming Interfaces): The most scalable and cost-effective method. RESTful APIs, in particular, offer faster, standardized communication and are ideal for modern cloud-based systems.

Selecting the right method depends on system architecture, data volume, and scalability goals.

5. Establish Rules for Data Flow and Synchronization

Consistent data management is the backbone of successful integration.

- Define what data will be shared, how often it will sync, and how conflicts will be resolved.

- For example, inventory updates for ecommerce may require real-time syncing, while financial data might sync daily or weekly.

- Establish governance policies to ensure data integrity, accuracy, and version control. Well-defined synchronization rules prevent data mismatches and promote consistency across systems.

6. Conduct Comprehensive Testing Before Launch

Testing ensures your integration works as intended and delivers business value.

- Start with technical testing — verifying API connections, data accuracy, and synchronization timing.

- Then conduct functional testing to validate real-world workflows like order processing, inventory updates, and reporting.

- Test under different load conditions to ensure stability and scalability. Document issues, track resolutions, and refine workflows before the system goes live.

7. Train Your Users for Seamless Adoption

Even the best integration fails without proper user adoption.

- Tailor training to different roles — warehouse staff, sales teams, finance, and management.

- Provide practical training on new tools, dashboards, and automated workflows.

- Offer multiple learning formats such as video guides, FAQs, or in-person workshops. Well-trained users are more confident, reduce error rates, and help unlock the full value of integration.

8. Maintain Continuous Monitoring and Improvement

Integration is not a one-time project—it’s an ongoing process.

- Regularly monitor system performance, data accuracy, and sync speed.

- Keep all systems updated with the latest patches, API versions, and data security measures.

- Periodically review integration KPIs, workflows, and user feedback to identify areas for optimization.

- Cloud-based systems can automate many maintenance tasks, offering real-time updates and backup support.

Continuous improvement ensures your integration stays aligned with evolving business goals and technology trends.

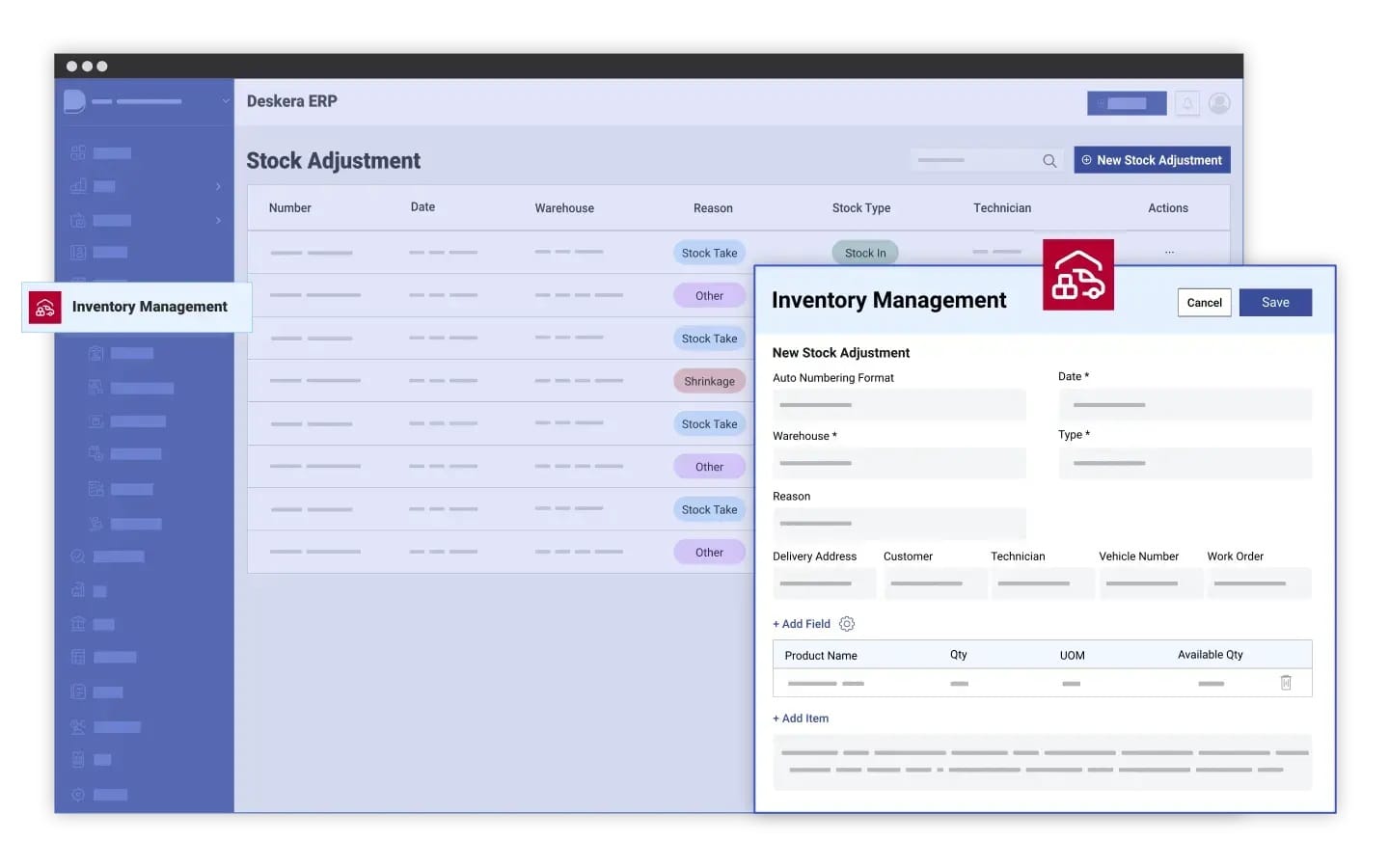

How Deskera ERP Simplifies Inventory Integration

Modern businesses need more than just standalone software — they need a unified system that connects every part of their operations. Deskera ERP makes inventory integration simple, powerful, and scalable by seamlessly linking your inventory, accounting, sales, and manufacturing processes into one intelligent platform.

With Deskera, all your key business data flows automatically across systems, eliminating silos and manual reconciliation. This ensures that every department — from production to finance — has access to accurate, real-time information. Whether it’s syncing stock movements with financial entries or aligning sales orders with available inventory, Deskera ERP helps businesses achieve total visibility and control.

Key Ways Deskera Enhances Inventory Integration:

- Real-Time Synchronization: Deskera’s centralized database keeps all modules — inventory, CRM, accounting, and MRP — perfectly aligned. This means every sale, purchase, or adjustment updates automatically across systems.

- Automated Workflows: Automate reordering, stock transfers, and fulfillment based on predefined thresholds or demand forecasts. This reduces delays and prevents both stockouts and overstocking.

- Seamless Financial Integration: Each inventory transaction instantly reflects in your general ledger, ensuring accurate valuation, COGS calculation, and financial reporting — without manual data entry.

- Advanced Reporting & Analytics: Deskera provides ready-to-use dashboards and AI-powered insights, enabling smarter decisions on procurement, sales performance, and inventory turnover.

- Scalability & Cloud Accessibility: Deskera’s cloud-based design makes integration flexible and secure, allowing you to scale effortlessly as your business grows.

By harmonizing every aspect of your business through integrated workflows, Deskera ERP transforms inventory management from a back-office task into a strategic powerhouse. You not only gain operational efficiency but also the agility to forecast accurately, optimize costs, and serve customers faster.

Key Takeaways

- Inventory integration is essential for modern businesses, improving accuracy, efficiency, and profitability, with potential benefits including 15–20% reduction in excess stock, 10–15% increase in sales efficiency, and 20% faster order fulfillment.

- Inventory integration synchronizes stock data across multiple systems, transforming inventory management from a tactical task into a strategic hub for automation, forecasting, and decision-making.

- By linking inventory systems with ERP, accounting, WMS, ecommerce, and CRM platforms, businesses can maintain real-time visibility, automate replenishment, and optimize allocation across locations.

- Integration prevents manual reconciliation, reduces operational inefficiencies, and provides stakeholders with accurate data for sales, production, finance, and supply chain decisions.

- Businesses gain automation, improved supply chain visibility, enhanced forecasting, cost savings, and scalability, enabling smarter, faster, and more profitable operations.

- Challenges such as data discrepancies, legacy system limitations, security risks, and integration costs can be overcome with careful planning, standardized data flows, and secure implementation.

- Integration across ERP, ecommerce, accounting, WMS, 3PL, CRM, POS, and shipping systems helps streamline operations, improve customer experience, and enhance financial and operational insights.

- Successful integration requires clear goals, mapping of workflows, choosing the right method, defining data rules, testing, user training, and ongoing maintenance.

- Deskera ERP connects inventory with accounting, sales, and manufacturing modules in real time, automates workflows, ensures accurate reporting, and supports scalable, cloud-based operations.

Related Articles