Have you come across a jaw-dropping sale of an outstanding product where the e-commerce site went berserk and the stock sold out in a few hours. What happened here is that when the e-commerce site realizes that the product is the top pick of the day, they still continue with taking orders. Doing this, they still have retained their customers and therefore, the revenue. In this case, they have enabled backordering and shall fulfill the orders when the stock is back.

The catch term is - Backordering. We shall look at the concept in detail.

In this post:

- What is backordering and why do they happen?

- How can you reduce backordering?

- We shall also learn about the difference between a backorder and a backlog

- How does the backordering work?

- Difference between Backorder and out of stock

- Causes of backorders and how can we minimize them

- Challenges faced while backordering

- What are the backorder management tools

What is Backordering?

Backordering refers to the order of a product which is out of stock currently. The product could either be unavailable in the company’s inventory or is under production.

Backordering is a signal to the company that its products’ demand exceeds its supply. In such a case, the company is said to have a backlog of products. The number of goods on backorder and the type of backorder shall determine when the customer finally receives the order.

Lack of inventory cannot hold back the company from taking new orders. Backordering allows a company to maintain its customers and retain the level of estimated revenue. It also helps in amplifying the demand for a product apart from increasing the customer base.

Moreover, in any company’s inventory management analysis and inventory control, backordering plays an important role. The number of backordered items and the time taken to fulfill those orders helps the company assess its inventory management capabilities. A shorter turnabout time is indicative of a good performance by the company.

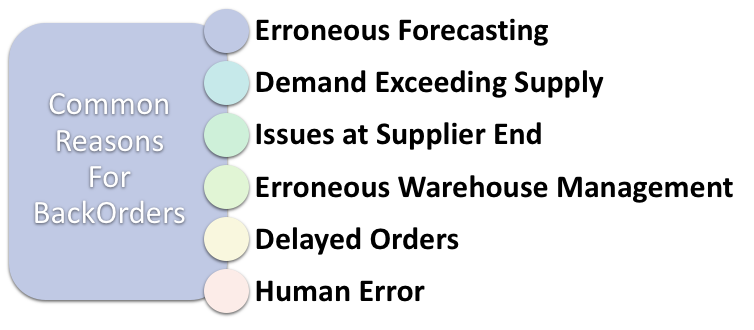

Why do Backorders Happen?

Looking into the causes of backorders helps you reduce and eliminate them in the future. Let’s take a look at the most common causes of backorders.

Erroneous Forecasting

If there are errors in the forecasting then the risk of shortage of stock increases. The company would not be prepared for an increased order due to miscalculation in forecasting.

Demand Exceeding Supply

This is a case there is an extraordinary demand which the firm is not prepared for. This kind of situation can be specifically observed during holidays when people head out shopping typically. Bad weather conditions could lead to power cuts and thereby, leading to an increased demand for power generators. Such unusual buying and demand lead to a backorder situation.

Issues at Supplier End

Any issues faced either by the supplier or the manufacturer could lead to a decreased supply of the product. This gives rise to backorders.

Erroneous Warehouse Management

Daily multiple warehouse management is a long process entailing a number of processes. Any problem or error in the warehouse management area could generate inaccurate reporting and error-ridden data entry.

Delayed Orders

If a stock does not arrive at the destination in time, the company will face the risk of backorders.

Human Error

A mistake made by a staff member of entering an order as backorder even if the product is available in stock is an example of human error.

How do You Reduce Backorder?

In this section, we get to learn about how to handle a backorder. Here are certain points you can implement to do well as an e-commerce entrepreneur.

Study the Past Patterns

This is of prime importance for any retailer. It is essential that they study past purchasing patterns and be able to forecast purchasing as close as possible. Doing so certainly helps the company in avoiding backorders.

Let’s take an example of a retailer who makes extraordinary sales during the winter and the sales see a drop during the summer. If this is the observed pattern, then the retailer can consider maintaining a larger stock before the onset of winters to avoid the backorder.

Frequent Connecting and Communicating with the Supplier

It is essential you let your supplier know at the earliest about the backorder and work with him on getting a timeline on when would the stock be available. Even if you do get into a situation of backordering, a well-updated supplier connection can help you handle the situation better. This will also help you give your customers an update about when will the next stock be available.

Working around with your Stocking Capacity

It could generally be helpful in avoiding backorder if you consider stocking up a little over the forecast purchasing. This is specifically relevant before the start of the season in which a particular product is much in demand. To keep away from being in such circumstances, you may have to work around with a logistics company. They could bail you out by making it possible to obtain additional storage capacity for your inventory. This excess stock management can safely let you handle the unexpected surges in demand for that product.

Diversifying your Suppliers

It could be beneficial if you maintain a list of multiple suppliers. This way you can have multiple suppliers to bank on, in times of unprecedented surge. If one of the suppliers is unable to provide you with the required product, the other can come to your rescue and avert backordering. Moreover, if there is an unexpected surge you can look to restock with the help of all your suppliers with the required quantities to avoid backordering.

Being Proactive in your Communication

Communicate with customers in a proactive manner. If a problem causes a successful product to go on backorder, inform your customers right away. People are less likely to be caught off guard by delays if an alert is placed on the product's page. It may also be beneficial to indicate why the item is on backorder in order to better manage client expectations. You can always let them know if there is a supply issue, manufacturing problems, and so on. You might wish to provide customers the option of being notified when a backordered item becomes available again so they can take advantage of it.

What is the Difference Between Backlog and Backorder?

To differentiate between a backlog and a backorder, let us first understand the concept of backlog.

Backlog

The entire order size that your customers have sent but have not yet been shipped out is your company's backlog.

Many companies don't value their supply chains as much as they should. The fact is that a company's performance determines its success. Building a firm successfully also entails making an effective supply chain. The goal of a well-designed supply chain is to reduce all backorders to zero

Example: You receive an order on the 4th July from a customer for an order which is to be shipped by 12th July. So, for the duration between the 4th to 11th July, the order is your backlog. This means, that till the time you ship the order, it is considered as your backlog.

Difference between Backlog and Backorder

Because of their similarity, people frequently mix up the two terms. A backorder can also be referred to as a backlog.

While many people think of backlog as a bad thing, it can actually be beneficial to the supply chain. In this case, you are not turning away your customers because they have already paid for the item. Customers can obtain what they want and when they need it if your supply chains are optimized.

Backordering means that you are not able to provide clients what they want right now since they'll have to wait till the item becomes available. Also, while backordering can be beneficial, it can also be detrimental. You may be optimistic about a backorder with the thought that you will ultimately ship the order. However, no one can guarantee the customer’s patience at this point. They may choose to cancel the order and look for it at other places.

This way, you will not only lose your customers to your competitors, but these customers may not return back due to the frustration experienced.

So, to sort the backorders and the backlog, we suggest you increase your supply chain. Doing so will give you the advantage of providing your customers with the products whenever they order.

Are Backlogs and Backorders good for your business?

In theory, a backlog is beneficial for your business as it implies you're getting more business. However, it’s only when the backlog turns into a backorder does the issue crop up.

Too many backorders can indicate troubled times for the business because it suggests your customers aren't getting their orders on time.

To conclude, it is critical to check the two metrics of backlog and backorder on a frequent basis to keep an eye on the stability of your supply chain.

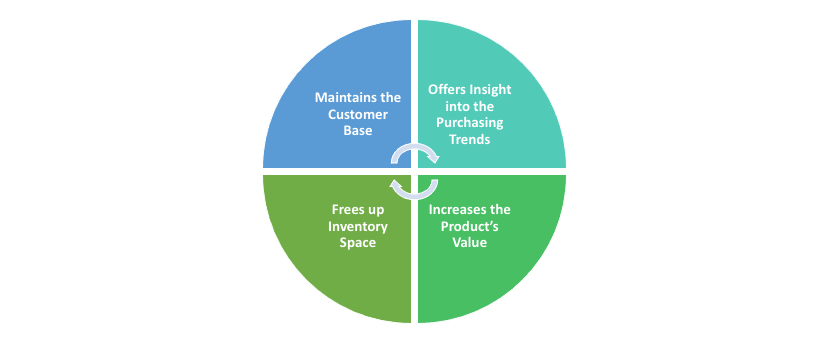

Why is Backordering Important?

Although backorders may not sound good to customers, they indicate business to companies. This also gets them an insight into the demand for the product and how loved the product is. However, in a situation of demand surge, the companies need to walk on a fine rope between having enough inventory and overstocking.

Nevertheless, here are some reasons why backordering is important to a business:

Maintains the Customer Base

This is probably the biggest benefit of backordering. Based on the definition of the backorder, we know that even if the order hasn’t been shipped, you have maintained your customer base. We can understand this by an example where we assume that a retailer makes it certain to his customers that the relevant product is out of stock and he doesn’t sell it any longer. Now, this could result in the rise of the competitor’s business.

Alternately, if the retailer allows backordering, he essentially maintains his customer base with his customers awaiting their shipments. Therefore, this could be termed as one of the biggest advantages of backordering.

Offers Insight into the Purchasing Trends

When you experience backordering, you know that there is surplus demand for a product and that the customers are being loyal to that product. They are ready to wait for the product to arrive at their doorstep. This entire process gives you a chance to study and analyze the customer’s mindset. You can now collect data and recognize the customer purchasing patterns to better your inventory management skills and decisions.

Increases the Product’s Value

Let’s assume there is this smartphone that has been newly introduced into the market and the customers have been lining up to get their hands on it. The demand has certainly led to backordering. In a way, this sudden upsurge creates a buzz around the product, making it seem like an astounding product with equally exceptional features. As a result, there are more customers placing orders for the same product.

This way, the whole process contributes to increasing the value of the product.

Frees up Inventory Space

Backordering is a result of a lack of stocks in your inventory. But to avoid it, you would need to stock or over-stock, for which you would need a surplus space. This inventory space will lead to an increased expenditure at your end. So, in a way, we could say that backordering helps you save a considerable amount on the inventory space.

Accounting for Backorders

Backorders need special accounting and are expressed as the value of sales in dollars, or by the number of items ordered or sold. This accounting for inventory is done because it requires the company to let the customers know about the delivery of their order and other details.

The backlog of a corporation is typically represented as a subcategory of sales, a cash figure, or the number of items sold or requested. The backorder will be registered as such on the company's accounts, rather than being considered a completed transaction.

That way, if the customer terminates the order or the company is unable to obtain the stock, the company won't have to go back and adjust its accounting records.

The firm makes a purchase once a backorder is noted. When the items arrive, the company puts emphasis on delivering the product in accordance with the customer's order. Following that, the sale will be logged and tagged as completed.

Also, it is vital that the companies calculate their backordering rate which is given by the following expression:

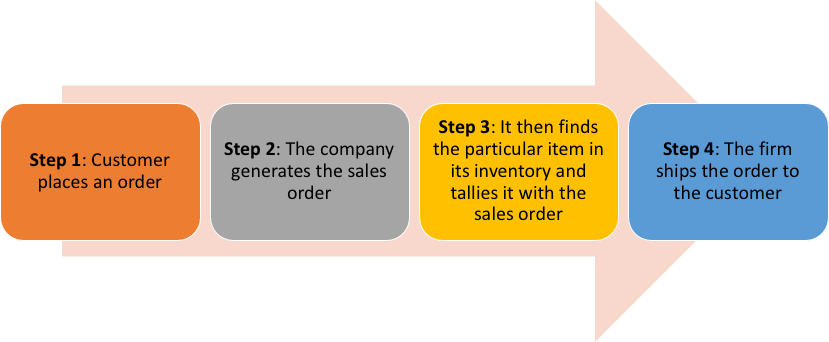

How Does Backordering Work?

To understand how the backordering works, let’s consider two scenarios. In one, the company consists of the required stock and in the other one, the goods are out of stock.

Scenario 1: When the Item is in Stock

Step 1: Customer places an order

Step 2: The company generates the sales order.

Step 3: It then finds the particular item in its inventory and tallies it with the sales order

Step 4: The firm ships the order to the customer

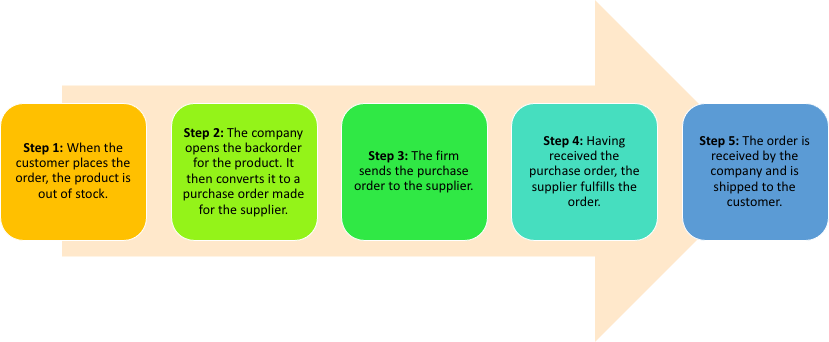

Scenario 2: Backordering Scenario

Step 1: When the customer places the order, the product is out of stock

Step 2: The company opens the backorder for the product. It then converts it to a purchase order made for the supplier.

Step 3: The firm sends the purchase order to the supplier

Step 4: Having received the purchase order, the supplier fulfills the order

Step 5: The order is received by the company and is shipped to the customer

From the scenarios, we observe that the backordering works well for one product that is out of stock. However, you cannot rely on it as the sole inventory strategy.

Before you initiate the product delivery process, you must be able to match each purchase order with the corresponding sales order. It helps to have an inventory management system that corresponds to your sales and purchase orders for you. This helps you to manage your arriving goods and outgoing sales at the same time.

Backordering allows you to keep your customers and guarantee that your sales continue to grow and that too when you don't have enough in your inventory. Moreover, the company can gain a considerable amount by lowering expenses, enhancing the value of your product, eliminating waste. It also enables you to offer custom orders.

Backordering might be an effective approach for you if you have good customer service and an efficient inventory management system.

Backorder vs. Out of Stock

When you mark a product as Out of Stock, it suggests that the customers can no longer place an order for the product, at least till the time it will be next available. Now, this is different from backorder, which allows you to accept orders even when the product or the good isn’t available.

It totally depends on the model of your business whether to mark a good as out of stock or available to customers. You need to ensure a few things before deciding upon this.

- Understand if your customers are ready to wait that long for the product to be shipped to them.

- Do you have a robust system that traces the orders?

- You will also have to assess if your inventory management will be affected by this backorder.

There are ample reasons why a backorder is most often considered worse than an out of stock. Let’s understand how:

- A backorder is more problematic than an out of stock situation. That's because, while out of stock may signify a marketing error that may be swiftly corrected, a backorder problem is considerably more serious.

- You could also face financial ramifications owing to your supplier's lack of inventory.

- There could be reputational damage.

- Furthermore, your customers despise being kept waiting for their shipment.

Tips for Minimizing Backorders

Backorders have been around since the supply chains were introduced. Monitoring stock to avoid backorders is a key component of achieving consumer expectations, especially with increased competition from eCommerce companies. Modern warehouse management systems are here to help.

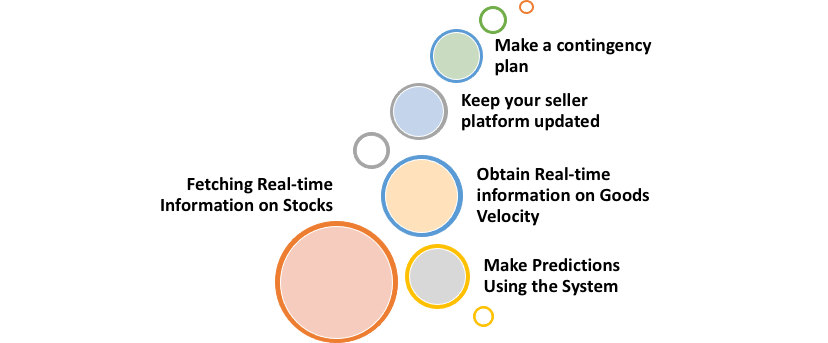

We share with you the 5 tips and tricks to minimize backorders in your business:

Fetching Real-time Information on Stocks

This is the first and the foremost step you need to take to control backorders. You need to set up a system to accurately track inventory as close to real-time as feasible. Stock and backorder concerns can be avoided by synchronizing your warehouse inventory systems with the newest scanner technology and receiving real-time notifications. Between the time you run out of stuff and the time you realize it, you shall be able to avoid a lot of delays.

Make Predictions Using the System

You must be able to estimate when things will be depleted and compare this schedule to how long it would take to replenish once you know how quickly they are moving. Assume that getting a resupply of an item from your supplier takes around two weeks. You can now estimate to set up a system alarm or trigger. This shall alert you when the inventory in your warehouse reaches about a month's worth of volume; there would be a reorder is automatically implemented. The fresh items should finally appear well within the time frame.

Obtain Real-time information on Goods Velocity

Apart from knowing the stock levels, it is also essential you know how rapidly are they moving. This is a part of your inventory forecasting, too. For instance, if you spot a very low level of stock, say 20% remaining in your inventory, and if the good is moving slowly then you may not need to restock for a few days. But, if a product has been selling out rapidly, then you may need to order in quick successions.

Keep your seller platform updated

Your order platforms and carts need to be aligned and synchronized with your inventory levels. This not only updates your customers about the availability of the product but can also create a buzz about t ‘soon-to go out of stock’ product; for example: ‘only 2 remaining in stock’ can actually coax the buyers to order.

Make a contingency plan.

Even with the meticulous planning, you may run out of goods. There are numerous reasons for this:

- A vendor may go out of business or have shipments held up in customs.

- The weather may cause delays in shipments.

- Alternatively, an item may no longer be manufactured.

Such situations prompt you to seek out a replacement. Implementing an alert such as investing in a plugin might as well be a great idea to avoid such scenarios.

The Challenge of Backorders and How to Address it

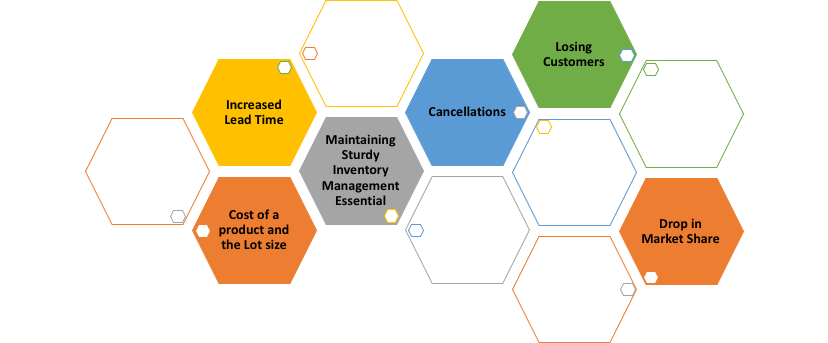

Let’s learn about some of the most common challenges of backorders and how they can be addressed.

Cost of a product and the Lot size

The quantity of things acquired or made on a specific date to fulfill a client request is referred to as the lot size. When backordering, large lot sizes now raise carrying costs. Producing smaller lot sizes in one production run may be uneconomical, depending on your setup. This creates a dilemma between piling up backorders and incurring excessive carrying costs. Handling such problems is unique to each company, and it is best left to competent executives.

Maintaining Sturdy Inventory Management Essential

Accepting orders, backordering, placing orders with the suppliers; all need a thorough integration and attention from your end. This is when you need to keep a track of your inventory to complete the orders well within time.

Increased Lead Time

Lead time refers to the duration between you placing an order with the supplier and when it actually arrives at your doorstep. If the lead time is a long period then it would certainly be tough for you to fulfill your orders in time. To avoid a situation like this, you'll have to take the risk of increasing carrying costs by storing commodities with long lead times. In such cases, you can also opt to look for local providers.

Cancellations

When a company amasses too many backorders, there are bound to be delays. The customers tend to lose their patience and end up cancelling the orders. This is probably one of the most common challenges faced due to backorders.

Losing customers

With cancellations of order comes the disappointment of losing customers. The customers who have had a not so pleasant experience tend to move on to another site. So, losing the customers is also a big challenge of backordering.

Drop in Market Share

It's a chain reaction that starts with delays, then order cancellations, then clients leaving. This ultimately leads to market share loss. Backordering done correctly has its advantages, but it also has its drawbacks.

How to Address Challenges of Backorders

Here's how to deal with backorders successfully if you're in the bind of selling out of goods that's currently on its way.

Determine whether or not to provide backorders

Determine whether a sold-out item is appropriate for backordering based on the following criteria:

- An accurate forecast of when the item will be back in stock.

- A dependable approach for keeping track of backorders.

- Backorders will be filled with enough stock on the way.

- When stock comes, a mechanism for efficiently and completing orders.

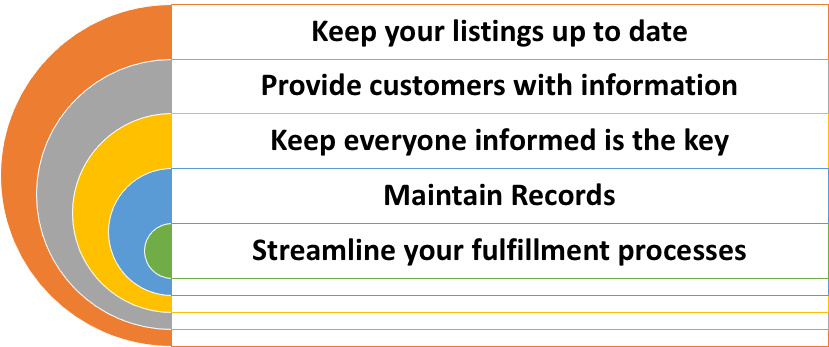

Keep your listings up to date

Add a backorder status to a product's listing and include the projected delivery date to make the backorder status evident to anybody who visits the listing. This avoids the situation of clients accidently placing a backorder having unreasonable expectations about when it will arrive. A pop-up may also be used by some retailers to notify customers who have added a backorder to their cart.

Provide customers with information

Customers should get an email confirmation confirming their backorder and reiterating the expected delivery date. Some clients may slip through the cracks and place a backorder without realizing it, or they may not comprehend what a backorder is. As a result, giving clients the choice to cancel is a good idea.

Keep everyone informed is the key

Maintain strong relations and minimize inbound enquiries by keeping everyone informed all through process. This involves notifying customers when fresh stock appears and their purchase is shipped, as well as notifying suppliers if additional stock is required to satisfy demand.

It's also critical to maintain your listings' anticipated delivery dates current, allowing for the time it will take to execute the quantity of received backorders. A higher number of backorders imply a longer projected delivery date. It is also important at this point to notify consumers right immediately if there are any delays, giving them a revised estimate and the choice to cancel.

Maintain Records

You will need to keep detailed records of consumers who place backorders, including the date and quantity they ordered.

Records are necessary for bookkeeping and for other reasons such as the order of precedence for completing orders and how much capacity for fulfillment do you require. Records also assist you to know if you adequate inbound inventory to meet demand.

Streamline your fulfillment processes

Ascertain that you have the logistical capabilities in place to fulfill backorders as soon as they are received and meet your delivery deadlines. This may necessitate the hiring of more personnel and warehouse space, as well as the employment of a third-party fulfillment service.

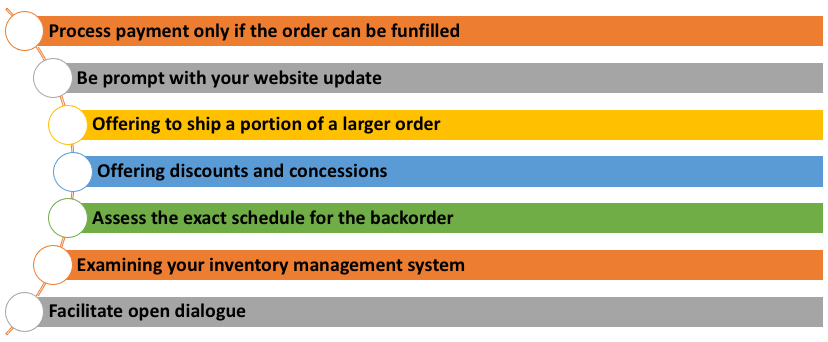

The Best Customer Service Practices When Dealing with Backorder

The easiest method to avoid backorders is to use inventory control systems and best practices to prevent the need for them. These best practices can assist you in your supply chain and plan to protect future revenues against backorders.

Process payment only if the order can be funfilled

It's easier for everyone if you don't have to refund money if your supplier can't complete the order at all or the delay is greater than intended.

Be prompt with your website update

When it comes to highly popular commodities, wouldn’t it be great if you let your customers know when to expect their purchases? Something like ‘ Available by May 1’ can give your customers insight. Giving a particular date can be more motivating for new products and client confidence than simply mentioning ‘backordered’. Customers want to know why a product isn't accessible and how you plan to fix the problem. Communicate across your social media platforms as well, especially for highly popular items or during peak purchasing seasons.

Offering to ship a portion of a larger order

At times, some clients may prefer that your in-stock items arrive sooner, while others may prefer to wait until all of your things arrive. Here, you can make a call to either choose to absorb the extra delivery costs or pass them on to the consumer.

Offering discounts and concessions

Offering a discount on the item or a future order can help you keep your customers engaged with your company. An offer of free delivery or free gift-wrapping may be enough to keep customers interested until the item comes back in stock. If you're worried about your customers discovering the product somewhere else, make the wait worthwhile.

Assess the exact schedule for the backorder

Determining how long the backorder will take to arrive is important. Your distributor or wholesaler might be able to deliver you a new supply in a matter of days. If you still expect to ship within their requested timeline, you may skip notifying your consumers.

Examining your inventory management system

If backorders are a regular occurrence, it may be time to review your ordering and inventory management procedures. Your past performance reports will assist you to determine when to replenish before supply runs out; you may also be able to arrange reorders automatically.

Facilitate open dialogue

There are numerous ways to communicate with your customers like a phone or through the mail. However, a human touch is like an honest response that provides the most warmth. If you have a dedicated customer support staff, inform them right away that customers may be contacted you for an update on the back ordered product. Make sure your contact details are conspicuously posted on your webpage. Your website can also stress how important client happiness is to your business.

Backorder Management Tools and Tips

Let’s learn about the ways and get some tips on backorder management and inventory management

- From the moment the product is presented, keep an eye on sales trends. This allows you to anticipate increased demand and backorders.

- Provide clients with the alternative to terminate their order if they are unable to wait.

- When clients place an order, the estimated time of arrival is displayed. Giving them an ETA lets them know when they may expect the product.

- You may also consider setting a deadline. You may also offer to refund the payment if the backordered item is not delivered within a month.

- To gain your customer's trust, you must be truthful. Follow up with emails or messages to keep them updated on what's going on.

Besides the tips, you may also want to implement certain strategic tools that help assess the situation.

Benefits of Order Management Software

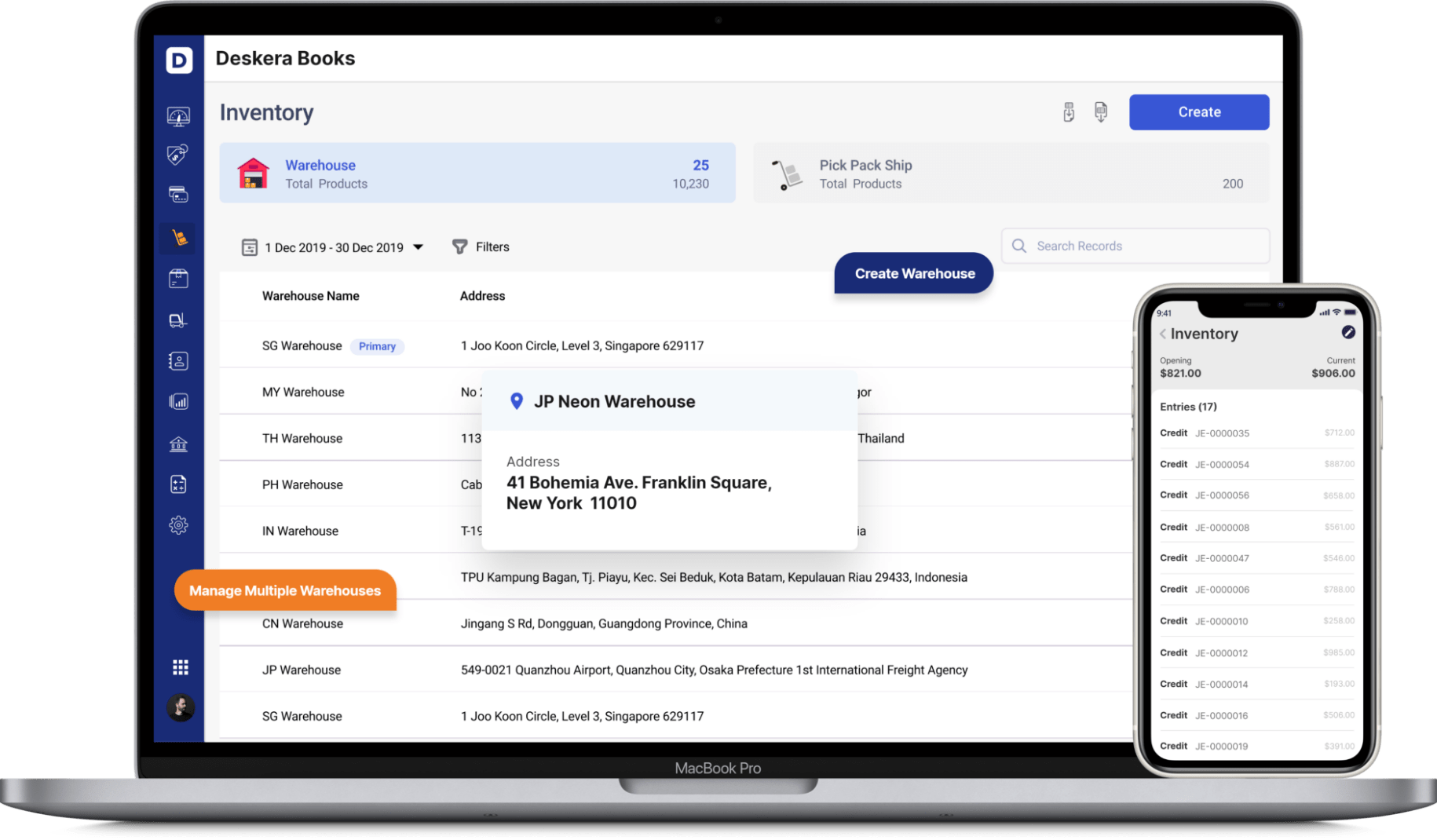

A good order management system can sail you through the rough tides. Backorder management becomes extremely difficult when your company sells different products across multiple locations. Spreadsheets are ineffective in certain situations, necessitating the usage of an Inventory Management System like Deskera. This also helps to alleviate logistical issues.

You may also take assistance from cloud-based order management software systems. They aid the process of complete sales forecasting and analyzing demand patterns. Calculating the flexibility of your supply chain also helps you predict how you'll respond to demand changes. Backorders can be effectively managed by planning for unexpected surges and establishing cooperation processes with logistical partners.

Agreements Between Vendors and Suppliers To Avoid The Bullwhip Effect

Vendor/supplier agreements are a great way to maintain a comfortable space within the business framework. The terms and conditions spell out everything you need to know so you can avoid an overcommitment. These agreements also help your suppliers because you both know your liabilities and benefits ahead of time. If at all possible, integrate your shipping providers in the process to streamline it.

Sharing sales estimates should be done with prudence in order to avoid the bullwhip impact in your supply chain. Informing your sources of a rising demand for an item might result in overproduction, whilst dropping demand can result in underproduction. This is owing to the fact that suppliers either raise or decrease their production at each stage. This process magnifies far beyond the amount stated, resulting in a bullwhip effect. As a result, interacting with suppliers is just as important as talking with clients for a company.

Dropshipping

If a certain item is marketed in large quantities and a scarcity emerges, you should look to implement remedial actions. The regular buying cycle is circumvented in such instances. As a result, relying on worksheets rather than competent software might lead to complications. Thus, dropshipping also improves fulfillment speed, which is important for improving customer experience

- You may also consider a competent ERP order management system. Besides, Inventory management software also assists with automating orders and supplies while also allowing sales forecasting.

- Harmonize your management system in real-time at any time to get an insight into various stock.

All of these recommended practices will offer you a notion of how to commit your stock and handle customer correspondence. You can also coordinate the long-awaited stock replenishment with the help of a specific software solution. Another advantage of cloud-based solutions is the ability to synchronize planned sales and queued merchandise. For perfectly calibrated supply chains, statistical modeling also helps reduce backordering overhead cost for unanticipated events.

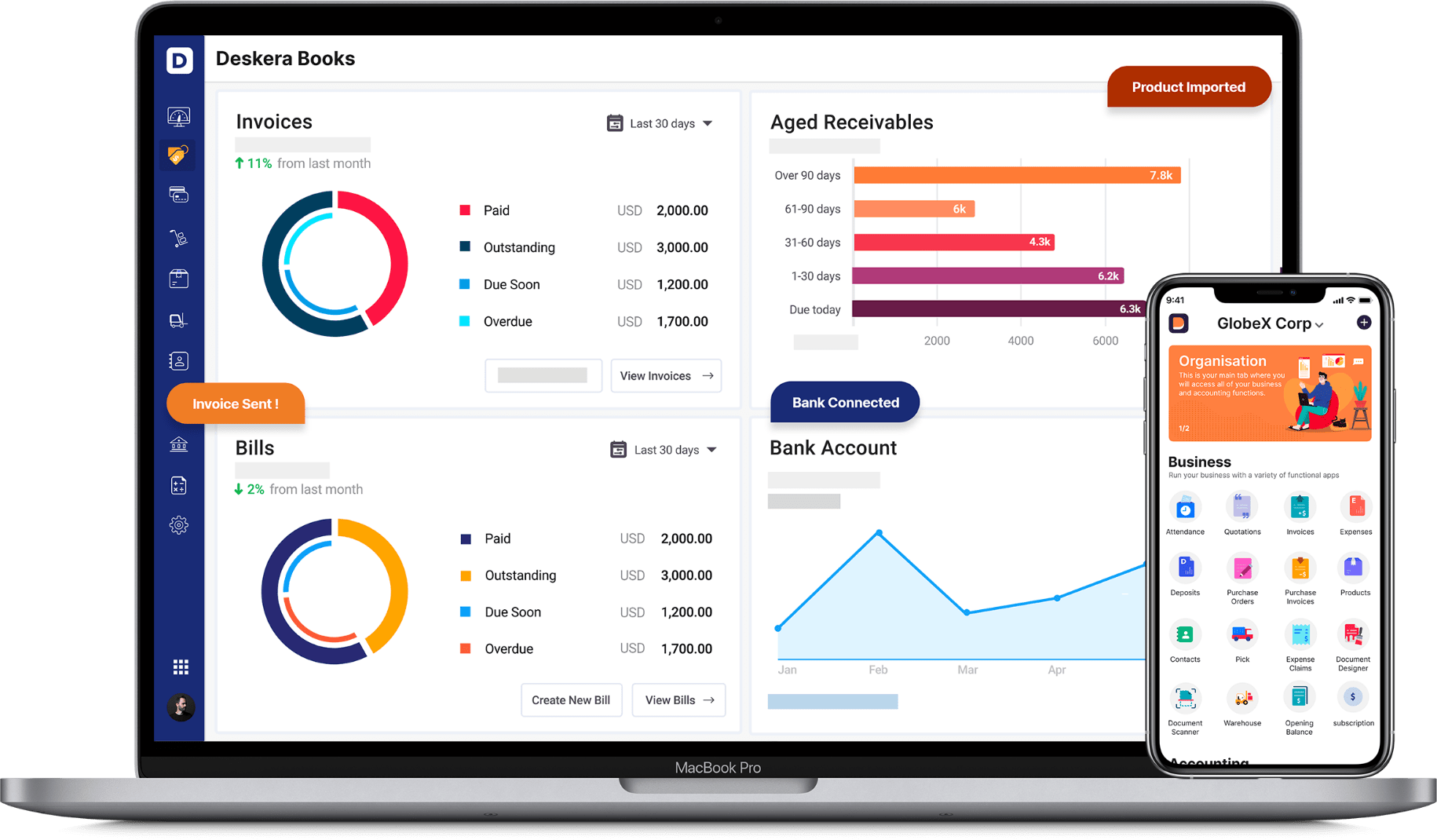

Deskera Books is online accounting software that assists you with automating the process of creating journal entries. The double-entry record will be auto-populated for each sale and purchase business transaction in debit and credit terms. Deskera consolidates transaction data into each ledger account. Their values will be quickly transferred to the financial reports that correspond to them.

Deskera can also guide you on a variety of subjects such as depreciation schedules, straight-line depreciation, inventory valuation techniques, and understanding concepts like residual value and Salvage Value. With Desker’s all-inclusive software, managing your customers and generating more revenue just got easier.

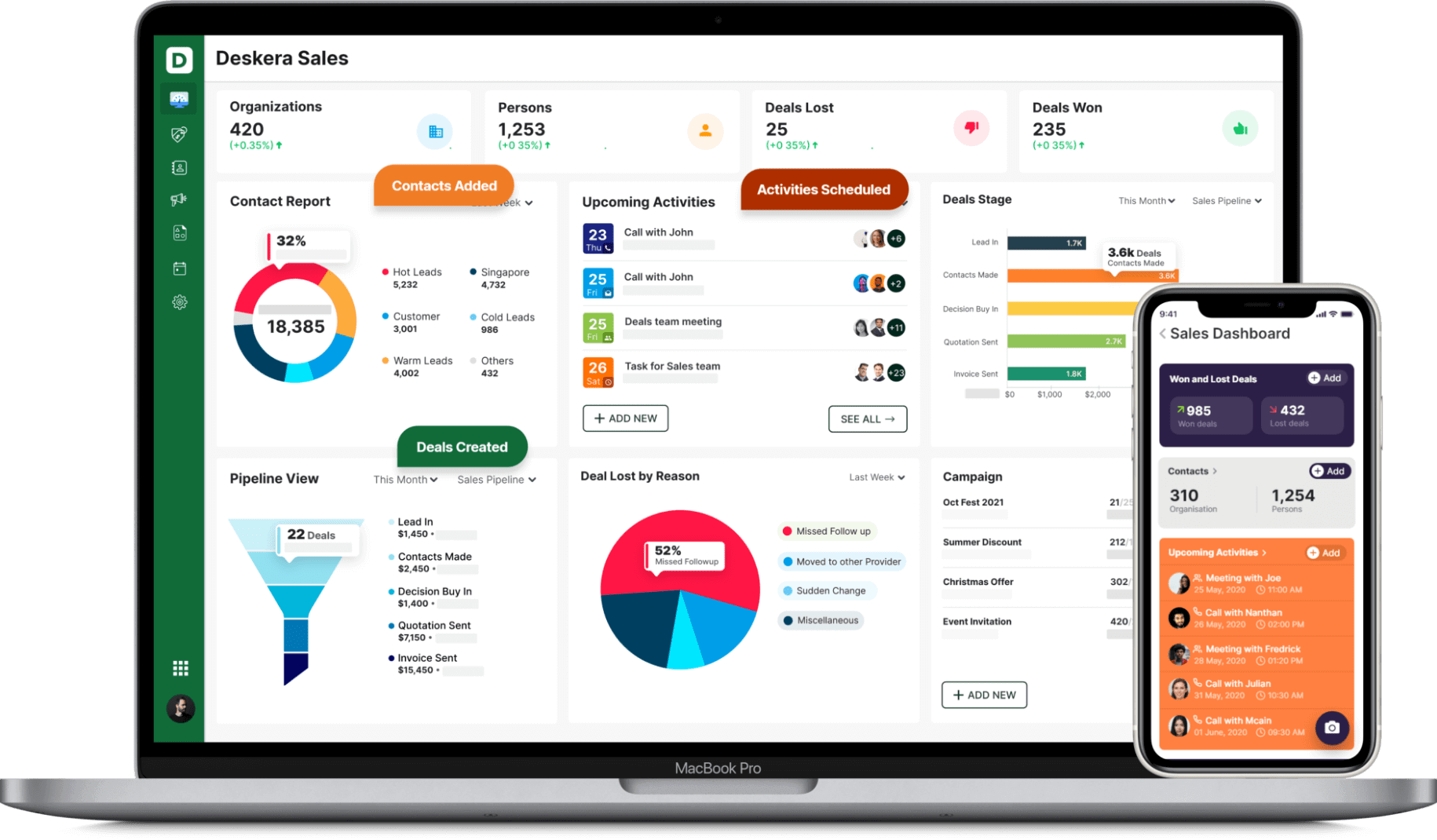

Deskera CRM is a simple yet well-eqipped platform that assists with sales pipeline management, email marketing campaigns, and many other important aspects. Through the platform, you shall be equipped to generate leads for your business and manage email campaigns.

Key Takeaways

While we wrap this post with a detailed description of backordering, let’s catch up with some of the key points discussed here:

- Backordering refers to the order of a product which is out of stock currently.

- Erroneous forecasting, excess demand supply, and supplier issues could be some of the reasons why backorders happen.

- To reduce backorders, you may adopt methods like studying the past patterns and working on stock capacity.

- Backorders help maintain customer base and help increase a product’s value.

- Fetching Real-time Information on Stocks, obtaining real-time information on goods velocity, keeping seller platform updates are some of the measures you could take to minimize backorders.

- Maintaining Sturdy Inventory Management Essential, increased lead time, drop in market share, and cancellations are some of the major challenges of backorders.

Related Links