Are you seeking to understand how metal fabrication ERP can make production planning easy? If your answer is yes, then you are on the right page.

Navigating the complexities of the metal fabrication industry demands more than just skilled craftsmanship—it requires a finely tuned orchestration of resources, schedules, and customer demands.

In this dynamic environment, metal fabrication ERP systems emerge as indispensable tools, offering tailored solutions that streamline and optimize every aspect of production planning.

Metal fabrication ERP isn't just about managing resources or scheduling tasks; it's a comprehensive framework designed to empower manufacturers with the agility and insight needed to thrive in today's competitive landscape.

From raw material procurement to final product delivery, metal fabrication ERP provides a cohesive platform that integrates every facet of the production process, ensuring efficiency, accuracy, and customer satisfaction.

With its arsenal of advanced features and specialized functionalities, metal fabrication ERP enables manufacturers to achieve unparalleled levels of precision and productivity.

By leveraging real-time data insights, optimizing resource utilization, and automating repetitive tasks, metal fabrication ERP transforms production planning from a daunting challenge into a streamlined and efficient endeavor.

In this exploration, we'll delve into the transformative power of metal fabrication ERP, uncovering how it simplifies production planning, enhances operational efficiency, and empowers metal fabrication companies to not only meet but exceed the expectations of an ever-evolving market.

The topics covered in this article are:

- What is the Metal Fabrication Industry?

- What is Production Planning?

- Importance of Production Planning in the Metal Fabrication Industry

- What is Metal Fabrication ERP?

- Production Planning Made Easy with Metal Fabrication ERP

- How can Deskera as a Metal Fabrication ERP Help with Production Planning?

- Key Takeaways

- Related Articles

What is the Metal Fabrication Industry?

The metal fabrication industry involves the manufacturing and shaping of metal components and structures through various processes such as cutting, bending, welding, and assembling. This industry serves a wide range of sectors, including construction, automotive, aerospace, electronics, and machinery manufacturing.

Metal fabrication encompasses a diverse range of activities, including:

- Cutting: Using techniques such as sawing, shearing, or laser cutting to shape metal sheets or bars into desired sizes and shapes.

- Forming: Bending, rolling, or stamping metal to achieve specific shapes and contours.

- Welding: Joining metal parts together using various welding processes like arc welding, MIG welding, or TIG welding.

- Machining: Utilizing machine tools such as lathes, mills, and CNC machines to remove material from metal workpieces to achieve precise dimensions and finishes.

- Assembly: Putting together fabricated metal components to create larger structures or products.

- Finishing: Applying surface treatments such as painting, powder coating, or plating to improve aesthetics and provide corrosion protection.

The metal fabrication industry plays a vital role in manufacturing various products, ranging from structural steel for buildings and bridges to intricate components for machinery and electronics. It requires skilled labor, advanced technology, and strict adherence to quality standards to produce high-quality metal products efficiently and cost-effectively.

What is Production Planning?

Production planning is the process of determining what products to produce, how much to produce, and when to produce them to meet customer demand while optimizing resources and minimizing costs. It involves developing a detailed roadmap for the manufacturing process, from raw materials procurement to finished product delivery.

Key aspects of production planning include:

- Demand Forecasting: Analyzing historical data, market trends, and customer orders to forecast future demand for products.

- Capacity Planning: Assessing the production capacity of facilities, equipment, and labor to ensure that production can meet demand within constraints.

- Inventory Management: Balancing inventory levels to prevent stockouts while minimizing excess inventory carrying costs.

- Scheduling: Creating a detailed schedule for production activities, including machine setups, labor assignments, and production runs, to optimize efficiency and minimize downtime.

- Resource Allocation: Allocating resources such as materials, machinery, and manpower efficiently to maximize productivity and minimize waste.

- Quality Control: Implementing measures to maintain product quality throughout the production process, including inspections, testing, and corrective actions.

- Supplier Management: Managing relationships with suppliers to ensure timely delivery of raw materials and components to support production schedules.

- Risk Management: Identifying and mitigating potential risks that could impact production, such as equipment failures, supply chain disruptions, or changes in customer demand.

Effective production planning requires coordination across various departments, including sales, operations, procurement, and finance, to align production activities with business objectives and customer needs.

It also involves the use of technology, such as ERP (Enterprise Resource Planning) systems, MRP (Material Requirements Planning) software, and production scheduling tools, to automate and optimize planning processes.

By implementing robust production planning strategies, businesses can improve efficiency, reduce costs, and enhance customer satisfaction.

Importance of Production Planning in the Metal Fabrication Industry

Production planning plays a crucial role in the metal fabrication industry due to its impact on operational efficiency, cost-effectiveness, and customer satisfaction.

Here are some key reasons why production planning is important in the metal fabrication industry:

- Optimizing Resource Utilization: Production planning ensures that resources such as materials, machinery, and labor are allocated efficiently to maximize productivity and minimize waste in metal fabrication processes.

- Meeting Customer Demand: By forecasting demand and creating production schedules, production planning ensures that metal fabrication companies can meet customer orders in a timely manner, enhancing customer satisfaction and customer loyalty.

- Minimizing Lead Times: Effective production planning helps reduce lead times by streamlining workflows, minimizing setup times, and synchronizing production activities to meet delivery deadlines.

- Reducing Costs: Production planning helps identify opportunities to reduce costs throughout the fabrication process, such as optimizing inventory levels, minimizing overtime, and improving production efficiency, ultimately leading to improved profitability.

- Ensuring Quality Standards: Production planning includes measures for quality control and assurance to maintain consistent product quality throughout the fabrication process, ensuring that customers receive high-quality products that meet their specifications.

- Managing Capacity: Production planning helps metal fabrication companies manage their production capacity effectively by balancing demand with available resources, avoiding overcapacity or underutilization of equipment and labor.

- Adapting to Changes: Production planning allows metal fabrication companies to anticipate and respond to changes in market demand, supply chain disruptions, or production constraints, enabling them to adapt quickly and efficiently to changing business conditions.

- Enhancing Collaboration: Production planning facilitates collaboration among different departments within the organization, such as production, sales, procurement, and finance, ensuring alignment of goals and effective coordination of activities to achieve overall business objectives.

Overall, production planning plays a critical role in optimizing operations, reducing costs, and delivering high-quality products on time, making it essential for the success and competitiveness of metal fabrication companies.

What is Metal Fabrication ERP?

Metal fabrication ERP is a specialized software solution designed specifically for the needs of the metal fabrication industry. It integrates various business functions and processes involved in metal fabrication, such as inventory management, production scheduling, job costing, quality control, and customer relationship management, into a single cohesive system.

Key features of metal fabrication ERP typically include:

- Inventory Management: Tracking and managing raw materials, components, and finished goods inventory levels to ensure availability for production while minimizing excess stock.

- Production Scheduling: Creating and managing production schedules to optimize resource utilization, meet customer demand, and minimize lead times.

- Job Costing: Tracking costs associated with individual jobs or projects, including materials, labor, and overhead, to calculate profitability and accurately price products.

- Quality Control: Implementing quality management processes to maintain product quality standards throughout the fabrication process, including inspections, testing, and compliance tracking.

- Supply Chain Management: Managing relationships with suppliers, tracking procurement activities, and ensuring timely delivery of materials and components to support production schedules.

- Shop Floor Control: Monitoring and managing production activities on the shop floor, including machine utilization, work orders, and job progress tracking.

- Customer Relationship Management (CRM): Managing customer interactions, tracking orders, and providing customer support to enhance satisfaction and loyalty.

- Reporting and Analytics: Generating reports and analytics to monitor key performance indicators (KPIs), analyze trends, and make data-driven decisions to improve efficiency and profitability.

Metal fabrication ERP systems are designed to streamline and automate business processes, improve collaboration across departments, and provide real-time visibility into operations.

By centralizing data and providing tools for efficient resource management and decision-making, metal fabrication ERP helps manufacturers optimize production, reduce costs, and drive business growth.

Production Planning Made Easy with Metal Fabrication ERP

In the realm of metal fabrication, efficiency, and precision are paramount. To streamline operations and maximize productivity, metal fabrication ERP systems emerge as indispensable tools.

These comprehensive platforms integrate various facets of production planning, from inventory management to scheduling, ensuring seamless workflows and optimal resource allocation.

Let's delve into the intricacies of how metal fabrication ERP simplifies production planning and revolutionizes the industry landscape.

Real-Time Inventory Management

In the dynamic realm of metal fabrication, efficient production planning is the cornerstone of success. Metal fabrication ERP systems offer comprehensive solutions tailored to the specific needs of the metal industry.

Among its myriad benefits, real-time inventory management stands out as a critical feature, enabling manufacturers to optimize resources, minimize costs, and enhance productivity.

Let's explore how metal fabrication ERP revolutionizes production planning through real-time inventory management.

- Enhanced Visibility with Metal Fabrication ERP: Metal fabrication ERP provides unparalleled visibility into inventory levels, locations, and movements. Through seamless integration with manufacturing processes, manufacturing ERP systems offer real-time insights into raw materials, work-in-progress, and finished goods inventory, empowering planners with accurate data for informed decision-making.

- Optimized Inventory Control: With ERP for metal industry, manufacturers can exercise precise control over inventory levels. By setting reorder points, safety stock thresholds, and lead times, MRP software systems automate replenishment processes, ensuring that materials are available when needed without excess stockpiling, thereby reducing carrying costs and minimizing waste.

- Just-in-Time (JIT) Inventory Management: Metal Fabrication ERP facilitates Just-in-Time (JIT) inventory management practices, aligning production schedules with customer demand. By synchronizing material procurement with production requirements, manufacturers can minimize inventory holding costs, reduce stockouts, and enhance responsiveness to market fluctuations.

- Accurate Demand Forecasting: Metal Fabrication ERP leverages advanced algorithms and historical data to forecast demand accurately. By analyzing sales patterns, order trends, and market dynamics, manufacturing software systems enable manufacturers to anticipate future inventory requirements, optimize procurement decisions, and avoid overstocking or understocking scenarios.

- Efficient Supplier Collaboration: Metal Fabrication ERP fosters seamless collaboration with suppliers through integrated supply chain management modules. By sharing real-time inventory data and production schedules, manufacturers and suppliers can synchronize their activities, negotiate favorable terms, and ensure timely deliveries, thereby enhancing operational efficiency and reducing lead times.

In the competitive landscape of the metal industry, effective production planning hinges on streamlined inventory management. Metal fabrication ERP solutions offer a comprehensive suite of tools and functionalities designed to optimize inventory control, minimize costs, and maximize operational efficiency.

By harnessing the power of real-time inventory management, manufacturers can gain a competitive edge, drive growth, and propel their businesses toward success in the ever-evolving metal fabrication landscape.

Integrated Supply Chain Visibility

In the intricate ecosystem of metal fabrication, seamless coordination across the supply chain is paramount for efficient production planning. Metal fabrication ERP systems, tailored specifically for the metal industry, offer a comprehensive solution to this challenge.

Among its array of features, integrated supply chain visibility emerges as a crucial aspect, empowering manufacturers with real-time insights into every facet of their operations.

Let's delve into how ERP for metal industry facilitates production planning through integrated supply chain visibility.

- Comprehensive Supply Chain Integration: Metal fabrication ERP seamlessly integrates various supply chain functions, including procurement, production, logistics, and distribution. By consolidating data from disparate sources into a unified platform, manufacturing ERP systems provide stakeholders with a holistic view of the entire supply chain, enabling informed decision-making and proactive problem-solving.

- End-to-end Transparency: With manufacturing ERP, stakeholders gain end-to-end visibility into the supply chain, from raw material sourcing to product delivery. By tracking materials, components, and products at every stage of the production process, manufacturers can identify bottlenecks, anticipate potential disruptions, and optimize workflows for maximum efficiency.

- Real-time Data Analytics: Metal fabrication ERP harnesses the power of real-time data analytics to provide actionable insights into supply chain performance. By analyzing key metrics such as lead times, cycle times, and inventory turnover, manufacturing software systems enable manufacturers to identify trends, identify areas for improvement, and make data-driven decisions to enhance operational agility and responsiveness.

- Demand-Supply Alignment: MRP software facilitates seamless alignment between demand and supply by synchronizing production schedules with customer orders and inventory levels. By dynamically adjusting production plans based on fluctuating demand signals, manufacturers can minimize stockouts, reduce excess inventory costs, and improve customer satisfaction levels.

- Collaborative Supplier Management: Metal fabrication ERP fosters collaborative supplier management by providing tools for communication, collaboration, and performance monitoring. By sharing production forecasts, inventory requirements, and quality standards with suppliers, manufacturers can build stronger partnerships, negotiate favorable terms, and ensure timely delivery of materials, thereby mitigating supply chain risks.

In the fast-paced world of metal fabrication, efficient production planning hinges on integrated supply chain visibility. Metal fabrication ERP solutions, equipped with advanced features and functionalities, empower manufacturers to gain comprehensive insights into their supply chain operations, optimize processes, and drive business growth.

By leveraging the power of integrated supply chain visibility, metal fabrication companies can navigate complexities with ease, stay ahead of the competition, and achieve new heights of success in the dynamic marketplace.

Advanced Production Scheduling

In the intricate world of metal fabrication, precision and efficiency in production scheduling are vital for meeting customer demands and optimizing resources. Metal fabrication ERP systems, tailored specifically for the metal industry, offer a comprehensive solution to streamline this process.

Among its arsenal of features, advanced production scheduling stands out as a key component, enabling manufacturers to orchestrate their production processes with unparalleled efficiency and flexibility.

Let's delve into how metal fabrication ERP simplifies production planning through advanced production scheduling.

- Dynamic Capacity Planning: Metal fabrication ERP empowers manufacturers with dynamic capacity planning capabilities. By analyzing machine capacities, labor availability, and production constraints, manufacturing ERP systems enable planners to optimize production schedules to maximize throughput and minimize idle time, thereby enhancing overall operational efficiency.

- Real-time Production Monitoring: With metal fabrication ERP, manufacturers can monitor production activities in real time. By integrating with shop floor control systems and IoT devices, MRP software systems capture data on machine utilization, job progress, and production status, providing planners with up-to-the-minute insights to make informed scheduling decisions and adapt to changing priorities.

- Optimization Algorithms: ERP for metal industry leverages sophisticated optimization algorithms to generate efficient production schedules. By considering factors such as order priorities, lead times, and material availability, MRP software systems automate the scheduling process, minimizing setup times, reducing changeover costs, and ensuring timely delivery of orders to customers.

- Scenario Analysis and What-if Simulations: Metal Fabrication ERP enables planners to conduct scenario analysis and what-if simulations to evaluate the impact of different production scenarios on key performance metrics. By simulating changes in demand, capacity, or resource availability, manufacturers can assess the feasibility of alternative production schedules and make proactive adjustments to optimize outcomes.

- Seamless Order Prioritization: Metal Fabrication ERP provides tools for seamless order prioritization based on customer requirements, deadlines, and production constraints. By assigning priority levels to orders and tasks, manufacturing ERP systems ensure that critical orders are processed first, minimizing lead times, and meeting customer expectations while maintaining production efficiency.

In the fast-paced environment of metal fabrication, advanced production scheduling is crucial for optimizing resources, meeting customer demands, and staying competitive.

Metal fabrication ERP solutions, equipped with advanced scheduling capabilities and optimization tools, empower manufacturers to streamline their production processes, minimize costs, and maximize profitability.

By harnessing the power of advanced production scheduling, metal fabrication companies can achieve operational excellence, drive business growth, and thrive in the ever-evolving marketplace.

Resource Optimization

Efficient resource allocation is the cornerstone of successful production planning in the metal fabrication industry. Metal fabrication ERP systems offer tailored solutions to optimize resources and enhance operational efficiency.

Among its suite of features, resource optimization emerges as a pivotal component, enabling manufacturers to maximize the utilization of machinery, manpower, and materials.

Let's explore how metal fabrication ERP simplifies production planning through resource optimization.

- Machine Capacity Utilization: Metal fabrication ERP provides insights into machine capacities and utilization rates, allowing manufacturers to optimize production schedules. By balancing workloads and minimizing downtime, manufacturing ERP systems ensure maximum efficiency in machine utilization, thereby enhancing overall productivity and reducing manufacturing costs.

- Labor Allocation and Skill Matching: With ERP for metal industry, manufacturers can efficiently allocate labor resources based on skill sets and task requirements. By matching workers with appropriate job roles and providing training where needed, manufacturing software systems optimize workforce productivity, minimize idle time, and improve employee morale.

- Inventory Management and Material Tracking: Metal fabrication ERP facilitates real-time tracking of materials and components throughout the production process. By maintaining optimal inventory levels and preventing stockouts or overstock situations, MRP software systems ensure smooth operations, reduce storage costs, and minimize waste.

- Predictive Maintenance and Asset Management: Metal fabrication ERP integrates predictive maintenance functionalities to optimize equipment uptime and longevity. By monitoring equipment health and scheduling maintenance tasks proactively, manufacturing software systems minimize unplanned downtime, reduce repair costs, and prolong the lifespan of assets.

- Energy and Resource Efficiency: Metal fabrication ERP includes modules for monitoring energy consumption and resource usage. By identifying opportunities for efficiency improvements and implementing sustainable practices, manufacturing ERP systems help manufacturers reduce operational costs, minimize environmental impact, and comply with regulatory requirements.

In the competitive landscape of metal fabrication, effective resource optimization is essential for achieving operational excellence and maintaining profitability. Metal fabrication ERP solutions, equipped with advanced features and functionalities, empower manufacturers to streamline their production processes, maximize resource utilization, and drive business growth.

By leveraging the power of resource optimization, metal fabrication companies can stay ahead of the competition, meet customer demands, and navigate challenges with ease in today's dynamic marketplace.

Quality Control Management

In the intricate landscape of metal fabrication, maintaining stringent quality standards is paramount to upholding customer satisfaction and brand reputation. Metal fabrication ERP systems offer specialized solutions tailored to the unique needs of the metal industry.

Among its array of functionalities, quality control management emerges as a critical component, enabling manufacturers to enforce standards, track defects, and ensure consistency across production processes.

Let's delve into how metal fabrication ERP simplifies production planning through robust quality control management.

- Standardized Quality Parameters: Metal fabrication ERP allows manufacturers to define and enforce standardized quality parameters across all production stages. By establishing criteria for product specifications, tolerances, and inspection procedures, manufacturing ERP systems ensure consistency and compliance with industry standards.

- Real-time Defect Tracking: With ERP for metal industry, manufacturers can track defects and non-conformances in real-time throughout the production process. By capturing data on defect types, frequencies, and root causes, MRP software systems facilitate continuous improvement initiatives to address underlying issues and enhance product quality.

- Quality Assurance Workflows: Metal fabrication ERP streamlines quality assurance workflows by automating inspection tasks and documentation processes. By integrating quality checkpoints into production schedules and triggering alerts for out-of-specification conditions, manufacturing software systems enable timely interventions to prevent defective products from reaching customers.

- Supplier Quality Management: Metal Fabrication ERP includes modules for supplier quality management, allowing manufacturers to assess and monitor the performance of suppliers and vendors. By tracking supplier compliance, conducting audits, and managing corrective actions, MRP software systems ensure that materials and components meet quality standards before entering the production process.

- Traceability and Compliance: Metal fabrication ERP facilitates traceability and compliance by maintaining comprehensive records of materials, processes, and inspections. By generating traceability reports and certificates of conformance, manufacturing software systems enable manufacturers to demonstrate compliance with regulatory requirements and customer specifications.

In the competitive realm of metal fabrication, ensuring product quality is essential for maintaining customer trust and loyalty. Metal fabrication ERP solutions, equipped with robust quality control management features, empower manufacturers to enforce standards, track defects, and continuously improve processes.

By integrating quality control into production planning, metal fabrication companies can enhance operational efficiency, mitigate risks, and deliver high-quality products that meet or exceed customer expectations.

Cost Analysis and Reporting

Efficient cost analysis and reporting are essential for metal fabrication businesses to maintain profitability and make informed decisions. Metal fabrication ERP systems are tailored to meet the specific needs of the metal industry, offering robust solutions to streamline cost analysis and reporting processes.

Among its suite of features, cost analysis and reporting stand out as critical components, enabling manufacturers to gain insights into production costs, identify areas for cost reduction, and optimize financial performance.

Let's explore how ERP for metal industry simplifies production planning through comprehensive cost analysis and reporting capabilities.

- Granular Cost Tracking: Metal fabrication ERP allows manufacturers to track costs at a granular level, capturing expenses associated with materials, labor, overhead, and other production activities. By categorizing costs by job, project, or product line, manufacturing ERP systems provide visibility into cost drivers and facilitate accurate cost allocation for pricing and profitability analysis.

- Variance Analysis: With metal fabrication ERP, manufacturers can conduct variance analysis to compare actual costs against budgeted or standard costs. By identifying discrepancies and analyzing the root causes of variances, MRP software systems enable managers to take corrective actions to control costs, improve efficiency, and optimize resource utilization.

- Profitability Analysis: Metal fabrication ERP offers tools for profitability analysis, allowing manufacturers to assess the profitability of products, customers, and projects. By analyzing revenue, costs, and margins, manufacturing software systems help identify high-profit opportunities, optimize pricing strategies, and allocate resources to maximize overall profitability.

- Budgeting and Forecasting: Metal fabrication ERP includes budgeting and forecasting functionalities to support financial planning and decision-making. By creating budgets, setting targets, and forecasting future financial performance, manufacturing ERP systems enable manufacturers to plan effectively, allocate resources strategically, and mitigate financial risks.

- Customized Reporting: Metal fabrication ERP provides customizable reporting capabilities, allowing manufacturers to generate detailed reports tailored to their specific requirements. By selecting key performance indicators (KPIs), designing custom dashboards, and scheduling automated report generation, MRP software systems ensure that stakeholders have access to timely and relevant financial information for decision-making purposes.

In the competitive landscape of metal fabrication, effective cost analysis and reporting are essential for achieving financial success and maintaining a competitive edge.

Metal fabrication ERP solutions, equipped with robust cost analysis and reporting features, empower manufacturers to gain insights into production costs, optimize resource utilization, and maximize profitability.

By leveraging the power of comprehensive cost analysis and reporting, metal fabrication companies can make informed decisions, drive business growth, and thrive in today's dynamic marketplace.

Streamlined Compliance

In the regulated environment of metal fabrication, compliance with industry standards and regulations is crucial to avoid penalties and maintain operational integrity. Metal fabrication ERP systems offer specialized solutions tailored to the specific needs of the metal industry, including streamlined compliance management.

Among its suite of features, streamlined compliance stands out as a critical component, enabling manufacturers to automate documentation, maintain audit trails, and ensure adherence to regulatory requirements.

Let's explore how ERP for metal industry simplifies production planning by facilitating streamlined compliance management.

- Regulatory Framework Integration: Metal fabrication ERP integrates regulatory requirements into its workflows, ensuring that manufacturers remain compliant with industry standards and regulations. By incorporating relevant standards such as ISO, OSHA, and NIST into its processes, manufacturing ERP systems help manufacturers stay updated on regulatory changes and maintain compliance without manual intervention.

- Automated Documentation: With metal fabrication ERP, manufacturers can automate documentation processes, reducing the burden of manual paperwork and ensuring accuracy and consistency. By generating required documents such as certificates of conformance, inspection reports, and compliance certificates automatically, MRP software systems streamline compliance efforts and minimize the risk of errors.

- Audit Trail Maintenance: Metal fabrication ERP maintains comprehensive audit trails of all production activities, ensuring traceability and accountability. By recording every transaction, change, and approval within the system, manufacturing software systems provide auditors with a transparent view of operations, facilitating audits and compliance assessments with ease.

- Compliance Monitoring and Alerts: Metal fabrication ERP includes compliance monitoring features that track deviations from regulatory requirements and trigger alerts for corrective action. By monitoring key compliance metrics and notifying stakeholders of non-compliance issues in real-time, manufacturing ERP systems enable proactive risk management and ensure the timely resolution of compliance issues.

- Training and Certification Management: Metal fabrication ERP offers modules for training and certification management, ensuring that employees are adequately trained and certified to perform their roles in compliance with regulatory requirements. By tracking employee certifications, scheduling training sessions, and sending reminders for renewal, manufacturing software systems help manufacturers maintain a skilled workforce and uphold regulatory compliance standards.

In the highly regulated landscape of metal fabrication, streamlined compliance management is essential for maintaining operational efficiency and regulatory adherence.

Metal fabrication ERP solutions, equipped with robust compliance management features, empower manufacturers to automate documentation, maintain audit trails, and ensure adherence to regulatory requirements.

By leveraging the power of streamlined compliance management, metal fabrication companies can mitigate risks, avoid penalties, and build a reputation for reliability and integrity in the marketplace.

Customer Relationship Management (CRM)

In the competitive landscape of metal fabrication, nurturing strong customer relationships is essential for sustaining business growth and success. Metal fabrication ERP systems, designed specifically for the metal industry, offer comprehensive solutions to enhance customer relationship management (CRM).

Among its array of features, CRM stands out as a pivotal component, enabling manufacturers to manage customer interactions, track orders, and ensure timely delivery of products.

Let's explore how ERP for metal industry simplifies production planning by facilitating effective CRM.

- Centralized Customer Database: Metal fabrication ERP provides a centralized customer database, consolidating information on customer contacts, preferences, and order history. By maintaining a comprehensive view of customer interactions, manufacturing ERP systems enable manufacturers to personalize communication, anticipate needs, and foster stronger relationships with customers.

- Order Management and Tracking: With ERP for metal industry, manufacturers can manage orders efficiently from creation to fulfillment. By tracking order statuses, processing changes, and providing real-time updates to customers, MRP software systems ensure transparency and reliability in order management, enhancing customer satisfaction and loyalty.

- Quotation and Estimation Tools: Metal fabrication ERP offers quotation and estimation tools to streamline the quoting process and respond to customer inquiries promptly. By generating accurate quotes based on material costs, labor rates, and overhead expenses, manufacturing software systems enable manufacturers to provide competitive pricing and win new business opportunities.

- Communication and Collaboration: Metal fabrication ERP facilitates communication and collaboration with customers through integrated communication channels. By enabling email integration, customer portals, and self-service options, manufacturing ERP systems enhance responsiveness and accessibility, allowing manufacturers to address customer inquiries and concerns effectively.

- Service and Support Management: Metal fabrication ERP includes service and support management functionalities to handle customer service requests and resolve issues efficiently. By logging service requests, assigning tasks to appropriate personnel, and tracking resolution times, manufacturing software systems ensure timely resolution of customer issues, maintaining high levels of satisfaction and loyalty.

Effective customer relationship management is paramount for success in the metal fabrication industry. Metal fabrication ERP solutions, equipped with robust CRM features, empower manufacturers to streamline order management, personalize communication, and enhance customer satisfaction.

By leveraging the power of CRM, metal fabrication companies can build stronger relationships with customers, differentiate themselves in the marketplace, and achieve long-term success and growth.

Mobility and Remote Access

In today's fast-paced business environment, flexibility and accessibility are key to efficient production planning in the metal fabrication industry. Metal fabrication ERP systems offer advanced solutions tailored to the specific needs of metal manufacturers.

Among its suite of features, mobility and remote access capabilities stand out as essential components, enabling stakeholders to access critical production data from anywhere, at any time.

Let's explore how metal fabrication ERP simplifies production planning through mobility and remote access.

- On-the-Go Accessibility: Metal fabrication ERP provides on-the-go accessibility through mobile applications or web-based platforms, allowing stakeholders to access production data from smartphones, tablets, or laptops. By enabling remote access to real-time information, manufacturing ERP systems empower managers to make informed decisions and oversee operations even when they're away from the factory floor.

- Shop Floor Mobility: With Metal Fabrication ERP, shop floor personnel can use mobile devices to access work instructions, update job statuses, and record production data in real time. By eliminating the need for manual data entry and paperwork, MRP software systems streamline workflows, reduce errors, and improve productivity on the shop floor.

- Remote Monitoring and Control: Metal fabrication ERP enables remote monitoring and control of production equipment and processes through IoT (Internet of Things) devices and sensors. By providing alerts for equipment malfunctions or deviations from production targets, manufacturing software systems enable timely interventions, minimizing downtime and maximizing efficiency.

- Collaboration Across Locations: Metal fabrication ERP facilitates collaboration among geographically dispersed teams by providing tools for real-time communication and document sharing. By enabling virtual meetings, instant messaging, and shared document repositories, MRP software systems foster collaboration, knowledge sharing, and decision-making across different locations.

- Data Security and Compliance: Metal fabrication ERP ensures data security and compliance with regulatory requirements for remote access. By implementing robust security measures such as encryption, multi-factor authentication, and role-based access control, manufacturing ERP systems protect sensitive production data and ensure compliance with industry standards and regulations.

Mobility and remote access are indispensable for modern production planning in the metal fabrication industry. Metal fabrication ERP solutions, equipped with advanced mobility features, enable stakeholders to access critical production data from anywhere, at any time, fostering agility, collaboration, and efficiency.

By leveraging the power of mobility and remote access, metal fabrication companies can adapt to changing market conditions, optimize production processes, and maintain a competitive edge in today's dynamic business landscape.

Scalability and Customization

Scalability and customization are paramount for metal fabrication businesses aiming for growth and adaptability in a dynamic market. Metal fabrication ERP systems offer tailored solutions to address the unique challenges of the metal industry.

Among its array of features, scalability, and customization capabilities emerge as critical components, empowering manufacturers to expand operations, integrate new technologies, and tailor the system to their specific needs.

Let's explore how metal fabrication ERP simplifies production planning through scalability and customization.

- Flexible System Architecture: Metal fabrication ERP provides a flexible system architecture that can scale with the evolving needs of the business. By accommodating increases in transaction volumes, user counts, and data storage requirements, manufacturing ERP systems ensure seamless growth without compromising performance.

- Modular Design: With metal fabrication ERP, manufacturers can customize their system through modular design, selecting and integrating functionalities based on their specific requirements. By adding or removing modules as needed, MRP software systems enable manufacturers to tailor the system to their unique production processes and workflows.

- Integration with Third-Party Systems: Metal fabrication ERP facilitates integration with third-party systems and technologies, allowing manufacturers to leverage existing investments and incorporate specialized tools into their manufacturing ERP ecosystem. By integrating with CAD/CAM software, CNC machines, and IoT devices, manufacturing software systems enhance interoperability and extend functionality to support advanced manufacturing processes.

- Scalable Infrastructure: Metal fabrication ERP supports scalable infrastructure options, including on-premises, cloud-based, and hybrid deployments. By offering flexibility in deployment models, MRP software systems enable manufacturers to adapt to changing business needs, optimize IT resource utilization, and ensure high availability and performance.

- Customization Tools: Metal fabrication ERP provides robust customization tools that empower manufacturers to tailor the system to their specific requirements. By configuring workflows, data fields, and user interfaces, manufacturing software systems accommodate unique business processes, terminology, and reporting needs, ensuring a seamless fit with existing operations.

Scalability and customization are essential for metal fabrication businesses seeking to stay competitive and agile in today's fast-paced environment. Metal fabrication ERP solutions, equipped with scalable architecture and customization capabilities, enable manufacturers to adapt to changing market conditions, expand operations, and optimize production planning processes.

By leveraging the power of scalability and customization, metal fabrication companies can future-proof their operations, drive business growth, and maintain a competitive edge in the dynamic metal industry landscape.

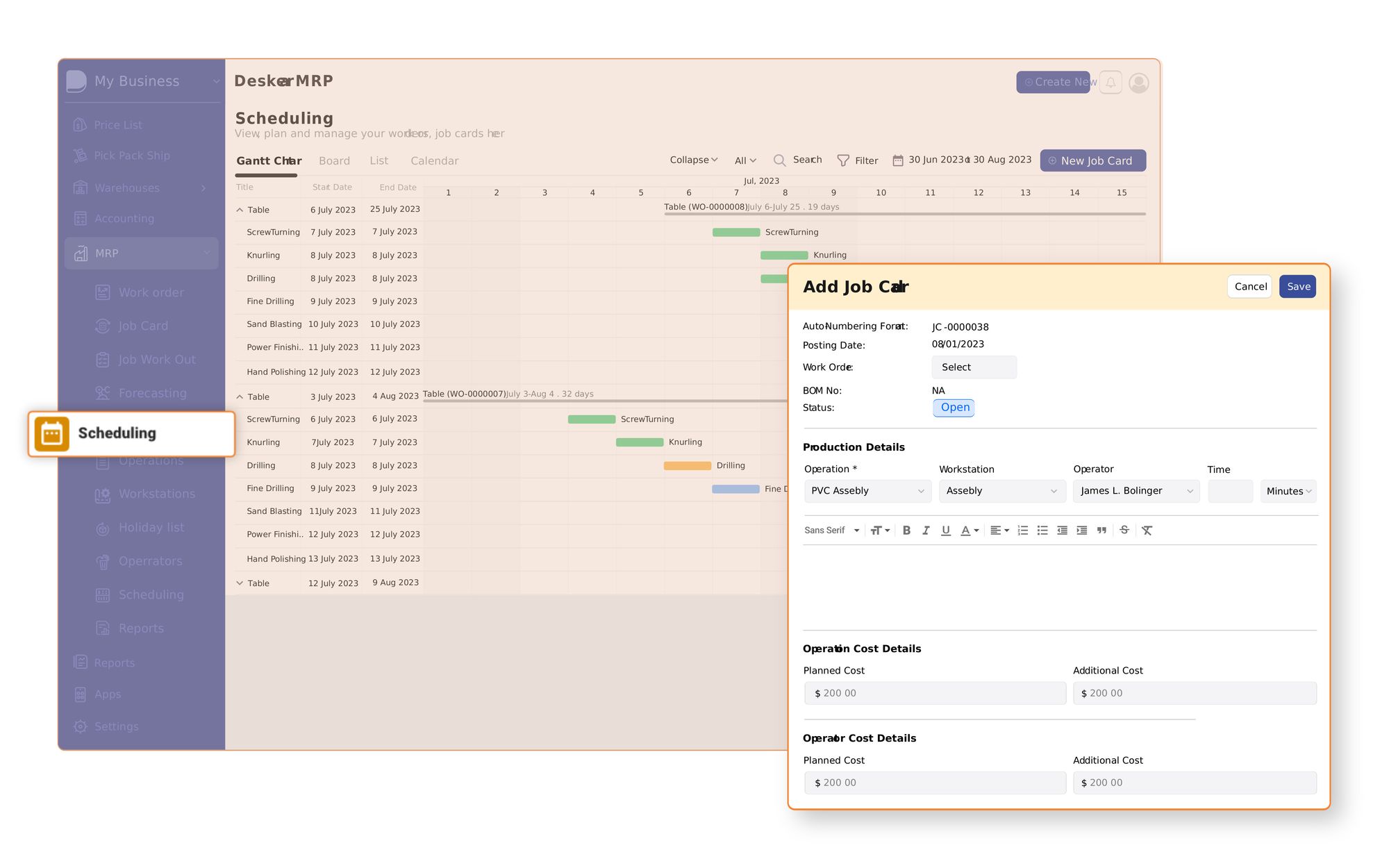

How can Deskera as a Metal Fabrication ERP Help with Production Planning?

Deskera, as a metal fabrication ERP, can offer several features and functionalities to support production planning in the metal fabrication industry:

- Advanced Production Scheduling: Deskera provides tools for creating detailed production schedules, including job sequencing, resource allocation, and capacity planning, to optimize production efficiency and meet customer demand.

- Real-time Visibility: Deskera offers real-time visibility into production activities, allowing managers to monitor job progress, track inventory levels, and identify bottlenecks or delays in the production process.

- Material Requirements Planning (MRP): Deskera's MRP functionality helps forecast material requirements based on production schedules, current inventory levels, and lead times, ensuring timely procurement of materials to support production activities.

- Shop Floor Control: Deskera enables shop floor control by providing tools for tracking work orders, recording job status updates, and capturing production data in real time, facilitating better decision-making and resource management.

- Integrated Quality Management: Deskera includes quality management features to ensure that products meet quality standards throughout the fabrication process, with tools for inspections, testing, and non-conformance management.

- Supplier Management: Deskera helps manage relationships with suppliers by tracking supplier performance, managing procurement processes, and ensuring timely delivery of materials to support production schedules.

- Cost Analysis and Reporting: Deskera provides tools for analyzing production costs, including material costs, labor costs, and overhead expenses, and generates reports to help managers understand cost drivers and optimize profitability.

- Customization and Scalability: Deskera offers customization options to tailor the system to the specific needs of metal fabrication companies, with scalability to accommodate business growth and changes in production requirements over time.

Key Takeaways

Metal fabrication ERP empowers manufacturers to achieve operational excellence, drive business growth, and maintain a competitive edge in the market. With its focus on efficiency, quality, and adaptability, metal fabrication ERP proves to be indispensable for metal fabrication companies seeking to thrive in today's challenging environment.

The 10 ways in which metal fabrication ERP makes production planning easy are:

- Real-time Inventory Management: Metal Fabrication ERP facilitates real-time tracking of raw materials, components, and finished products. By providing up-to-the-minute inventory data, manufacturers can avoid stockouts, reduce excess inventory costs, and maintain optimal levels for uninterrupted production.

- Integrated Supply Chain Visibility: With Metal Fabrication ERP, stakeholders gain comprehensive visibility across the supply chain. From procurement to delivery, every stage is synchronized, enabling informed decision-making, timely reordering, and efficient supplier collaboration.

- Advanced Production Scheduling: Leveraging advanced algorithms and historical data, Metal Fabrication ERP empowers planners to create precise production schedules. By considering factors like machine capacity, labor availability, and order priorities, schedules are optimized for maximum throughput and minimal downtime.

- Resource Optimization: Metal Fabrication ERP intelligently allocates resources such as machinery, manpower, and materials. Through predictive analytics and capacity planning modules, manufacturers can optimize resource utilization, minimize idle time, and enhance overall operational efficiency.

- Quality Control Management: Ensuring product quality is paramount in metal fabrication. ERP systems incorporate robust quality control modules that enforce standards, track defects, and facilitate corrective actions. By maintaining stringent quality parameters, manufacturers uphold customer satisfaction and brand reputation.

- Cost Analysis and Reporting: Metal Fabrication ERP provides comprehensive cost analysis tools for better financial management. From tracking production costs to analyzing overhead expenses, manufacturers gain insights into profitability margins, enabling informed pricing strategies and cost-saving initiatives.

- Streamlined Compliance: Compliance with industry regulations and standards is imperative in metal fabrication. ERP systems streamline compliance management by automating documentation, maintaining audit trails, and generating regulatory reports, ensuring adherence to legal requirements, and mitigating risks.

- Customer Relationship Management (CRM): Metal Fabrication ERP integrates CRM functionalities to manage customer interactions and orders effectively. From quotation to delivery, manufacturers can track customer preferences, communicate order statuses, and address inquiries promptly, fostering long-term client relationships.

- Mobility and Remote Access: Modern Metal Fabrication ERP solutions offer mobility and remote access features, enabling stakeholders to access critical production data from anywhere, anytime. Whether on the shop floor or in the field, managers can make informed decisions and oversee operations with ease.

- Scalability and Customization: As metal fabrication businesses grow, scalability becomes imperative. Metal Fabrication ERP systems offer scalability and customization options to adapt to evolving needs and business expansion. Whether adding new production lines or integrating with third-party systems, ERP solutions ensure seamless scalability without compromising performance.

In the dynamic landscape of metal fabrication, where precision, efficiency, and agility reign supreme, metal fabrication ERP emerges as a transformative solution.

By streamlining production planning, optimizing resources, and enhancing visibility across the supply chain, manufacturing ERP systems empower manufacturers to stay ahead of the curve and thrive in an increasingly competitive market. Embracing metal fabrication ERP isn't just about managing operations; it's about revolutionizing the way metal fabrication businesses operate and innovate.

Overall, Deskera as a metal fabrication ERP can streamline production planning processes, improve operational efficiency, and support business growth in the metal fabrication industry by providing comprehensive tools and functionalities tailored to the specific needs of metal fabrication companies.

Related Articles