Ever wondered what keeps successful online stores running seamlessly, even during peak shopping seasons? The answer lies in effective eCommerce inventory management — the backbone of every thriving online business. As digital marketplaces grow more competitive, the ability to balance supply and demand efficiently has become a key differentiator between top-performing brands and those struggling to keep up. Without a well-structured inventory system, even the most innovative eCommerce businesses can face stockouts, overstocking, and profit loss.

Recent trends highlight the growing importance of automation in this space — in fact, 78% of eCommerce companies planned to invest in inventory management automation by 2025. This shift reflects a collective realization that manual processes can no longer sustain modern retail demands. For instance, the average out-of-stock rate for eCommerce is around 8%, rising to 10% for promotional or discounted items, leading to missed sales and frustrated customers. These inefficiencies can quickly erode customer loyalty and brand reputation if left unchecked.

Another crucial performance metric is the inventory turnover ratio, which measures how often a company sells and replaces its stock within a given period. For eCommerce, the ideal turnover ratio typically falls between 4 and 6 times per year, while top performers reach 8 or higher. A higher ratio signifies efficient stock management and stronger cash flow, whereas a lower one often points to overstocking or weak demand. Monitoring this balance helps businesses stay agile and responsive to market fluctuations.

This is where technology-driven solutions like Deskera ERP come into play. Deskera ERP simplifies eCommerce inventory management by providing real-time visibility, automating stock updates across channels, and leveraging AI-driven forecasting to predict demand accurately. It integrates seamlessly with major eCommerce platforms, helping businesses prevent stock discrepancies, reduce manual errors, and maintain healthy inventory levels — all while improving profitability and operational efficiency.

What Is eCommerce Inventory Management?

eCommerce inventory management is the process of tracking, organizing, and controlling the movement of products in an online retail business — from procurement and storage to order fulfillment and delivery. It ensures that the right products are available at the right time, helping eCommerce businesses meet customer demand efficiently while minimizing excess stock and operational costs. In simple terms, it’s about maintaining the perfect balance between supply and demand across digital sales channels.

Unlike traditional retail, eCommerce inventory management deals exclusively with products sold over the internet, often across multiple marketplaces such as Amazon, Shopify, and WooCommerce. This adds layers of complexity, including real-time stock synchronization, multichannel tracking, and logistics coordination with third-party fulfillment centers (3PLs) or drop-shipping partners. When managed effectively, it helps online retailers avoid costly stockouts, overstocking, and delays that could negatively impact customer satisfaction.

A strong eCommerce inventory management system covers every stage of the supply chain — from ordering and warehousing to restocking and returns. It relies heavily on real-time stock tracking, accurate demand forecasting, and efficient order fulfillment to maintain smooth operations. Businesses can use these insights to identify best-selling products, set precise reorder points, and make data-driven decisions about inventory replenishment. This synchronization between sales forecasts and stock levels enables retailers to respond swiftly to changing market trends and customer behavior.

In a globalized and fast-moving market, proper inventory management isn’t just about keeping shelves stocked — it’s a strategic advantage. By adopting a robust system, eCommerce companies gain complete visibility over their inventory, whether it’s stored in-house, managed by a 3PL provider, or part of a drop-shipping arrangement. This visibility allows for proactive decision-making, ensuring products are always available when customers need them, while maintaining healthy cash flow and reducing waste.

How eCommerce Inventory Management Works

eCommerce inventory management works by tracking, organizing, and optimizing stock levels across all sales channels to ensure customer demand is met without overstocking. It involves a series of interconnected steps — from receiving and storing products to forecasting future demand — all designed to maintain accuracy, speed, and efficiency. Modern systems rely on automation and real-time tracking to minimize errors and keep inventory data synchronized across online marketplaces, warehouses, and fulfillment centers.

Below is a breakdown of the key processes that define how eCommerce inventory management works:

Receiving and Storing

The process begins when new products arrive at the warehouse or fulfillment center. Items are inspected for quality, sorted according to SKU (Stock Keeping Unit), and stored in designated locations for easy retrieval. A well-organized storage system ensures faster picking and restocking, helping maintain warehouse efficiency and accurate stock counts.

Tracking Stock

Real-time tracking forms the foundation of effective inventory management. Using barcodes, RFID tags, or automated scanning systems, businesses can continuously monitor stock levels across multiple locations and sales channels. This visibility prevents both stockouts and overstocking, ensuring that sales and inventory data remain accurate at all times.

Order Fulfillment

Once a customer places an order, the system instantly updates stock records and notifies the fulfillment team. The team then picks, packs, and ships the correct items with precision. By integrating order management with inventory data, businesses can reduce errors, improve shipping speed, and deliver a seamless customer experience.

Updating Stock Data

After an order is fulfilled, the system automatically updates inventory levels across all connected platforms — whether that’s an online store, marketplace, or warehouse. This synchronization ensures that product availability remains accurate everywhere, eliminating issues like overselling or duplicate listings.

Replenishment

When stock levels fall below a predefined reorder point, the system triggers alerts or automatically generates purchase orders to restock items. Automated replenishment helps maintain optimal inventory levels and reduces the risk of losing sales due to stockouts.

Demand Forecasting

Demand forecasting uses historical sales data, seasonal trends, and market insights to predict future product needs. Accurate forecasting allows businesses to make informed purchasing decisions, optimize cash flow, and avoid overstocking slow-moving items.

Analysis and Optimization

Continuous analysis is key to long-term efficiency. By reviewing inventory turnover ratios, carrying costs, and shipping data, businesses can identify bottlenecks and refine their processes. Regular optimization ensures that inventory operations remain cost-effective and aligned with business goals.

How It Works with Automation

Modern inventory management software automates these processes to minimize manual errors and enhance operational efficiency. Automated systems track inventory in real time, sync stock levels across multiple channels, and even handle automatic replenishment when items run low.

Advanced automation tools also provide cross-channel synchronization, ensuring that when a product sells on one platform, the update reflects instantly across all others — keeping every part of your eCommerce ecosystem connected and accurate.

Key Benefits of Effective eCommerce Inventory Management

Poor eCommerce inventory management can disrupt your operations, delay deliveries, and damage your brand’s reputation. When customers don’t receive their orders on time or find products frequently out of stock, their trust erodes — and so does your revenue.

Conversely, an efficient inventory management system helps you maintain product availability, optimize storage costs, and ensure faster fulfillment, all while improving customer satisfaction and overall profitability.

Below are the key benefits of effective eCommerce inventory management and why it’s vital for your business success.

1. Enhances Customer Satisfaction and Loyalty

In eCommerce, customer satisfaction is directly tied to product availability and delivery speed. Effective inventory management ensures that products displayed online are genuinely in stock and can be shipped on time.

This reduces cancellations, delays, and backorders — all of which contribute to a smoother buying experience. According to Bain & Company, even a 5% increase in customer retention can boost profits by at least 25%, showing how reliable inventory operations directly impact loyalty and profitability.

2. Provides Clearer Oversight of Your Inventory

A robust inventory system gives you complete visibility across all sales channels and storage locations — whether products are stored in-house, with a third-party logistics provider, or through drop-shipping arrangements.

This oversight helps identify fast- and slow-moving items, determine which products are underperforming, and plan your restocking more effectively. By maintaining transparency, you can prevent hidden costs, reduce waste, and make more informed purchasing and pricing decisions.

3. Boosts Operational Efficiency

Streamlining how products move through your supply chain — from procurement to delivery — enhances overall business performance. With automated tracking, barcode scanning, and integrated software, businesses can minimize manual errors and accelerate order processing.

Efficient inventory management also improves supply chain coordination, making it easier to handle demand fluctuations, manage supplier relationships, and optimize logistics for faster fulfillment and lower operational overhead.

4. Improves Demand Forecasting and Planning

By leveraging real-time sales data and analytics, inventory management systems enable accurate demand forecasting. Businesses can predict customer purchasing trends, plan seasonal stock requirements, and adjust procurement strategies proactively.

This helps maintain ideal stock levels, ensuring you’re never overstocked or unprepared for spikes in demand. Accurate forecasting also supports smarter financial planning and helps avoid cash flow bottlenecks.

5. Reduces Operational and Storage Costs

Holding excess stock leads to unnecessary expenses in storage, insurance, and depreciation, while understocking can result in missed sales and expedited shipping fees.

Effective inventory management helps maintain a balanced inventory, reducing carrying costs and freeing up warehouse space. The savings can be reinvested into other growth initiatives such as marketing, product development, or expanding sales channels.

6. Optimizes Cash Flow and Profitability

Inventory represents a significant portion of working capital in any eCommerce business. By avoiding overstocking and deadstock, companies can free up capital tied to unsold goods.

A leaner, more efficient inventory system means better cash flow — allowing businesses to reinvest in areas that drive growth and innovation. A higher inventory turnover ratio also indicates that products are selling efficiently, directly contributing to improved profitability and liquidity.

7. Eliminates Stockouts and Deadstock

One of the most critical outcomes of effective inventory management is the ability to avoid both stockouts and excess inventory. With automated reorder points and real-time stock updates, businesses can restock products before they run out.

Similarly, data-driven insights help identify slow-moving items early, preventing them from turning into deadstock. This balance keeps customers happy while minimizing losses from unsold inventory.

8. Enables Data-Driven Decision-Making

Modern eCommerce inventory systems generate detailed reports and analytics on sales performance, stock levels, and order fulfillment. These insights allow managers to make data-backed decisions regarding pricing, promotions, and product assortment. By analyzing trends over time, businesses can refine their strategies, improve marketing ROI, and gain a competitive edge in a crowded marketplace.

9. Strengthens Brand Reputation and Business Resilience

Ultimately, strong inventory management supports consistency — one of the key traits customers value most. When your brand consistently fulfills orders accurately and on time, it builds trust and credibility.

In addition, maintaining supply chain resilience through proper inventory control allows your business to adapt quickly to disruptions such as supplier delays or sudden spikes in demand, ensuring long-term sustainability.

Common Challenges in eCommerce Inventory Management

Managing inventory in eCommerce isn’t as simple as keeping stock on shelves. With fluctuating demand, multiple sales channels, and rising customer expectations, businesses face a range of challenges that can impact efficiency and profitability.

Here are some of the most common challenges in eCommerce inventory management and how to overcome them effectively.

1. Stockouts and Overstocking

Balancing stock levels is one of the toughest challenges in eCommerce. Stockouts can lead to missed sales and frustrated customers, while overstocking ties up capital and increases storage costs. Both situations hurt profitability and customer trust.

Solution: Using advanced forecasting tools and real-time inventory tracking can help strike the right balance. Deskera ERP, for example, offers accurate demand planning and real-time stock visibility, ensuring you always have the right products available when needed.

2. Inaccurate Demand Forecasting

Predicting customer demand accurately is crucial but difficult in a fast-paced eCommerce environment. Inaccurate forecasts can result in excess stock or shortages, affecting both cash flow and fulfillment rates.

Solution: Leverage data analytics to forecast trends based on historical sales and customer behavior. Deskera ERP’s reporting and analytics features help businesses make data-driven forecasts, improving accuracy and reducing the risks of overstocking or stockouts.

3. Multi-Channel Inventory Synchronization

Selling across platforms such as your website, marketplaces, and social media increases reach—but also complexity. Without proper synchronization, you risk overselling on one platform or underutilizing inventory on another.

Solution: A centralized inventory management system like Deskera ERP helps synchronize stock across all sales channels. This ensures that every transaction automatically updates your inventory count, preventing costly errors and maintaining consistency across platforms.

4. Inefficient Warehouse Management

Manual stock counting, picking, and packing can lead to misplaced items, slower fulfillment, and reduced productivity. As order volumes grow, these inefficiencies become more pronounced.

Solution: Automating warehouse processes with barcode scanning and ERP integration improves accuracy and speed. Deskera ERP enables real-time warehouse tracking, streamlined order processing, and optimized stock placement to enhance efficiency.

5. Handling Returns and Reverse Logistics

Returns are inevitable in eCommerce but can create operational bottlenecks if not managed efficiently. Poor returns handling can lead to inaccurate stock data, increased costs, and customer dissatisfaction.

Solution: Implement clear return policies and integrate return processes within your inventory system. Deskera ERP simplifies return management by automating restocking, quality checks, and refund updates, ensuring accurate inventory records and improved customer experience.

6. Supply Chain Disruptions

Delays from suppliers or logistics issues can quickly cause stock shortages and order backlogs. Without real-time visibility, even small disruptions can cascade into larger fulfillment problems.

Solution: Building a resilient supply chain with multiple supplier options and end-to-end visibility is crucial. Deskera ERP’s supplier management module helps monitor lead times, track purchase orders, and improve coordination with vendors to minimize disruptions.

7. Lack of Real-Time Visibility

Many eCommerce businesses struggle with limited visibility into their inventory levels across warehouses or regions. This lack of transparency leads to inaccurate reporting and poor decision-making.

Solution: A cloud-based ERP like Deskera provides a single, real-time view of inventory across all locations. With live dashboards and reporting tools, you can monitor inventory movement, analyze stock trends, and make informed decisions instantly.

8. Scaling Inventory Operations

As eCommerce businesses grow, manual systems and spreadsheets often fail to keep up. Expanding product lines, customer bases, and fulfillment locations can make inventory management increasingly complex.

Solution: Implementing scalable ERP software early on ensures smooth expansion. Deskera ERP grows with your business—automating workflows, integrating with marketplaces, and managing complex inventory structures without disruption.

In summary, overcoming eCommerce inventory management challenges requires visibility, automation, and data-driven insights. Tools like Deskera ERP empower businesses to streamline operations, optimize stock levels, and deliver exceptional customer experiences, even in a competitive online marketplace.

Best Practices for Efficient eCommerce Inventory Management

Efficient inventory management is the backbone of any successful eCommerce business. With fluctuating demand, multi-channel sales, and customer expectations for fast delivery, maintaining accuracy and control over your inventory is essential. Implementing proven best practices ensures that businesses can meet customer needs while minimizing operational costs and maximizing profitability.

1. Maintain Safety Stock

Unexpected supply chain disruptions or sudden surges in customer demand can quickly lead to stockouts. Maintaining safety stock acts as a buffer to ensure consistent product availability even when supply fluctuates.

You can calculate your ideal safety stock using the formula:

Safety Stock = (Max daily usage × Max lead time in days) – (Average daily usage × Average lead time in days).

While keeping safety stock provides flexibility, it’s important to balance it with carrying costs. Using historical data and predictive analytics can help determine optimal levels that avoid both excess storage and missed sales opportunities.

2. Implement Demand Planning

Accurate demand planning helps businesses predict future stock requirements by analyzing historical sales, seasonal trends, and market dynamics. Tools that incorporate PEST analysis (Political, Economic, Sociocultural, and Technological factors) can refine these predictions further.

By leveraging real-time analytics, businesses can make data-driven purchasing decisions, minimizing both overstocking and understocking risks. Advanced demand forecasting not only stabilizes inventory flow but also enhances customer satisfaction through timely product availability.

3. Use Inventory Kitting to Manage Slow-Moving Stock

Kitting—or bundling multiple products into one package—is a smart strategy for reducing dead stock and boosting average order value. Pairing slow-moving items with popular ones through promotions or bundle deals helps clear inventory space and improve turnover.

This method also enhances the shopping experience for customers, providing them with perceived value while helping you recover costs from stagnant stock.

4. Optimize Storage and Routing

Warehouse efficiency plays a major role in eCommerce operations. Optimizing your warehouse layout for easy picking and packing, using inventory segmentation, and implementing warehouse management systems (WMS) significantly enhance speed and accuracy.

Techniques such as cross-docking—transferring goods directly from inbound to outbound shipments—can minimize storage time and reduce handling costs. Regular evaluation of warehouse space utilization can further streamline fulfillment processes and improve delivery timelines.

5. Set Reorder Points for Timely Restocking

A reorder point (ROP) ensures that new stock arrives before existing inventory runs out. You can calculate it using the formula:

Reorder Point = (Average daily usage × Average lead time in days) + Safety stock.

This proactive approach prevents costly stockouts and helps maintain consistent availability across all sales channels. Automated systems can alert managers when inventory levels hit the reorder threshold, saving time and reducing manual tracking errors.

6. Apply ABC Inventory Analysis

ABC analysis classifies inventory into three categories based on value and demand:

- A-items: High-value, low-quantity products that require tight control.

- B-items: Moderate value and frequency.

- C-items: Low-value, high-quantity goods.

Focusing more attention on A-items helps allocate resources efficiently and ensures top-performing products are always available. Regularly updating your ABC categories ensures alignment with changing market trends and product lifecycles.

7. Conduct Regular Stock-takes and Audits

Even with automation, discrepancies can occur due to errors, theft, or returns. Conducting regular stock-takes—whether full audits or cycle counts—helps verify data accuracy and identify process inefficiencies.

Frequent auditing not only improves reporting accuracy but also enhances compliance and forecasting accuracy. For growing eCommerce businesses, scheduling monthly or quarterly audits is recommended to maintain control as product lines expand.

8. Leverage Automation and Real-Time Tracking

Automation is key to eliminating manual errors and increasing efficiency. Implementing real-time inventory tracking systems integrated with your eCommerce platform ensures that all stock updates, order fulfillments, and returns are automatically synchronized.

Businesses that adopt automation report up to a 20% reduction in operational costs and a 35% improvement in stock accuracy. Real-time visibility enables smarter decision-making, faster order fulfillment, and higher customer satisfaction.

9. Monitor Carrying Costs and Use Just-in-Time (JIT) Practices

Inventory carrying costs—including storage, insurance, and depreciation—can consume a large portion of revenue if stock levels are not optimized. Regularly reviewing these costs and adopting a Just-in-Time (JIT) approach helps free up capital tied up in unsold goods.

However, JIT requires reliable suppliers and accurate demand forecasting to ensure smooth replenishment without delays.

10. Train Staff and Update Policies Regularly

Your inventory management system is only as effective as the team using it. Provide ongoing training on software use, inventory policies, and audit procedures. Establishing clear policies around reorder points, safety stock, and handling returns helps maintain consistency and accountability across your organization.

Future Trends in eCommerce Inventory Management

As technology continues to evolve and customer expectations rise, the future of eCommerce inventory management is set to undergo a major transformation.

From artificial intelligence to automation, the focus is shifting toward smarter, faster, and more predictive systems that improve efficiency and elevate the customer experience.

Here are the key trends shaping the future of eCommerce inventory management.

1. Artificial Intelligence (AI) and Machine Learning (ML) Integration

AI and ML are revolutionizing inventory management by enabling data-driven forecasting and automated decision-making. These technologies can analyze massive datasets to identify purchasing patterns, predict demand fluctuations, and recommend optimal reorder quantities.

AI-driven demand forecasting minimizes the risk of overstocking or stockouts, while ML continuously refines predictions based on new data. This leads to improved accuracy, reduced carrying costs, and smarter inventory replenishment strategies.

In the coming years, expect more eCommerce platforms to integrate AI-powered analytics dashboards that offer real-time insights and automated actions—allowing businesses to respond instantly to changing customer behavior.

2. Internet of Things (IoT) and RFID Technology

The rise of IoT-enabled inventory tracking and RFID tagging is transforming visibility across the supply chain. IoT sensors can track product movement, monitor environmental conditions (like temperature or humidity), and trigger automatic restock alerts when items reach threshold levels.

RFID technology enhances accuracy in warehouse management by automating stock counts and reducing human error.

Together, these tools create an ecosystem of real-time inventory visibility, helping eCommerce businesses synchronize data across warehouses, retail outlets, and fulfillment centers.

3. Robotics and Automation in Warehousing

Automation and robotics are quickly becoming standard in modern eCommerce operations. Autonomous robots and Automated Guided Vehicles (AGVs) are now used for tasks like picking, packing, and transporting goods, significantly reducing manual labor.

Advanced warehouse automation systems leverage AI and computer vision to improve speed and accuracy, allowing businesses to process large order volumes with minimal errors.

As robotics technology becomes more affordable, even small and mid-sized eCommerce companies will adopt automated warehouse solutions to enhance productivity and streamline fulfillment.

4. Omni-Channel Inventory Management

Today’s customers expect a seamless shopping experience across all channels—online, mobile, and in-store. Future-ready businesses are adopting centralized inventory management systems that unify stock data across all sales platforms.

This real-time synchronization ensures that if a product is purchased online, it instantly reflects in-store stock levels, preventing double-selling or backorders.

By embracing omni-channel strategies, retailers can fulfill orders from the nearest location, reduce delivery times, and enhance customer satisfaction. This level of transparency will soon become a baseline expectation in eCommerce.

5. Predictive Analytics for Supply Chain Optimization

Predictive analytics enables businesses to look beyond historical trends and forecast future demand, supply chain risks, and replenishment needs. By analyzing variables like consumer behavior, market dynamics, and external factors such as weather or economic trends, companies can proactively adjust their inventory strategies.

Predictive analytics will also support scenario planning—helping businesses simulate supply chain disruptions and develop contingency strategies to maintain resilience. The future of inventory management lies in using data not just for reporting, but for anticipating and adapting to change.

6. Sustainability and Circular Inventory Practices

Sustainability is no longer optional—it’s a competitive advantage. Future eCommerce operations will increasingly prioritize eco-friendly inventory management, using technology to reduce waste, minimize overproduction, and optimize packaging.

Companies will also adopt circular inventory models, where returned or unsold products are refurbished, recycled, or resold. This approach not only supports environmental goals but also helps businesses recover costs and enhance their brand reputation among eco-conscious consumers.

7. Cloud-Based and Integrated Inventory Systems

Cloud-based platforms will continue to dominate the eCommerce landscape, offering scalability, flexibility, and real-time collaboration. By integrating ERP, CRM, and warehouse management systems (WMS), businesses can achieve complete visibility and control over their operations.

These unified systems simplify global operations, support remote management, and enable instant updates across multiple channels—ensuring data consistency and faster decision-making.

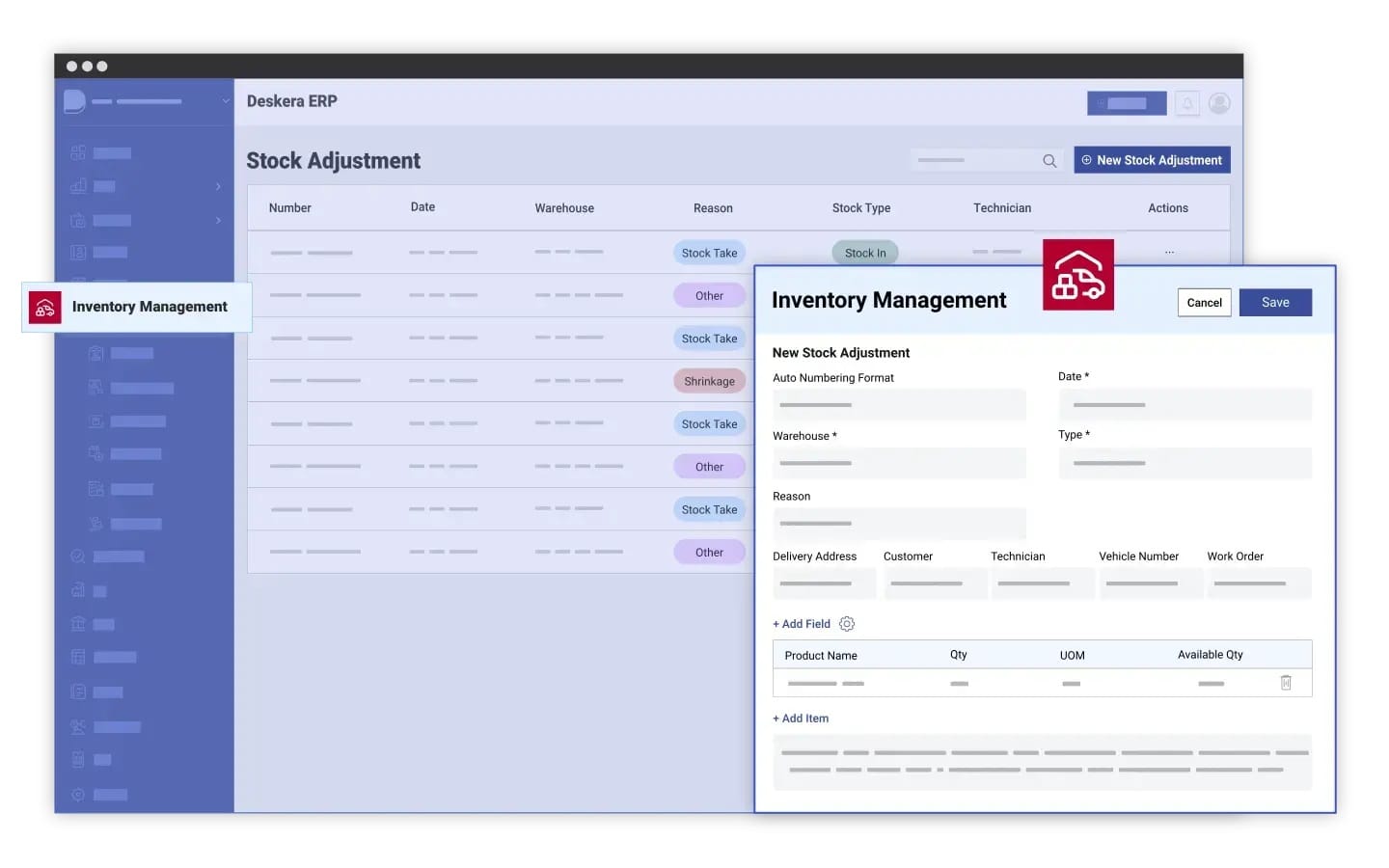

How Deskera ERP Simplifies eCommerce Inventory Management

In the fast-moving world of eCommerce, businesses need more than just manual stock tracking—they need smart, automated solutions that deliver speed, accuracy, and visibility.

Deskera ERP empowers online retailers to manage their entire inventory lifecycle seamlessly, from procurement and warehousing to order fulfillment and delivery.

By integrating real-time data, automation, and analytics, Deskera helps eCommerce companies maintain ideal stock levels, improve customer satisfaction, and streamline operations across multiple channels.

Here’s how Deskera ERP simplifies eCommerce inventory management:

1. Real-Time Inventory Tracking Across Channels

Deskera ERP provides real-time inventory visibility across all your online and offline sales channels. Whether you’re selling through your website, marketplaces like Amazon, or retail outlets, Deskera synchronizes stock levels instantly to prevent overselling or stockouts. This centralized visibility ensures you always know what’s available, what’s running low, and what needs restocking.

2. Automated Stock Replenishment

With Deskera, you can automate reorder points and replenishment workflows based on actual sales data and forecasted demand. The system automatically generates purchase orders when stock levels hit a predefined threshold—eliminating manual intervention, reducing human error, and ensuring that popular products are always in stock.

3. AI-Powered Demand Forecasting

Deskera ERP leverages AI-driven analytics to predict demand trends, seasonal fluctuations, and product performance. By analyzing historical sales and market data, the system helps you plan inventory purchases more accurately. This enables eCommerce businesses to strike the right balance between supply and demand—improving cash flow and reducing storage costs.

4. Seamless Order Fulfillment and Warehouse Management

From order creation to dispatch, Deskera ERP streamlines the order fulfillment process with precision. Integration with warehouse management features ensures that the right items are picked, packed, and shipped on time. With barcode scanning and batch tracking, businesses can reduce fulfillment errors and accelerate delivery timelines—leading to improved customer satisfaction.

5. Multi-Channel Integration

Modern eCommerce operations often span multiple platforms. Deskera ERP’s multi-channel integration capabilities allow you to connect your online store, marketplaces, and CRM systems into one unified dashboard. This ensures accurate data synchronization across all channels—so every sale, return, or restock is reflected instantly across your business ecosystem.

6. Comprehensive Reporting and Insights

Deskera’s robust reporting tools provide detailed insights into inventory turnover, product performance, and sales trends. These analytics empower managers to make data-driven decisions, identify best-selling products, and detect slow-moving items that tie up capital. With visual dashboards and automated reporting, business leaders can monitor performance in real time.

7. Scalability for Growing Businesses

As your eCommerce business expands, Deskera ERP scales effortlessly with you. Its cloud-based infrastructure ensures you can manage large inventories, multiple warehouses, and diverse product lines without worrying about system limitations. This flexibility makes it an ideal choice for small and medium-sized eCommerce brands looking to grow sustainably.

8. Enhanced Collaboration and Workflow Efficiency

Deskera ERP connects teams across purchasing, sales, and logistics, ensuring smooth communication and workflow automation. Integrated accounting and invoicing tools allow for accurate financial tracking tied directly to inventory transactions—giving you a complete 360° view of your business operations.

In essence, Deskera ERP transforms eCommerce inventory management into a streamlined, data-driven process. By combining automation, predictive analytics, and real-time visibility, it empowers online retailers to reduce manual effort, cut operational costs, and deliver an exceptional customer experience—while maintaining full control over their inventory ecosystem.

Key Takeaways

- eCommerce inventory management involves tracking, organizing, and controlling stock levels across multiple sales channels to ensure timely order fulfillment and customer satisfaction while minimizing costs and stock imbalances.

- Effective inventory management is crucial for maintaining product availability, preventing stockouts or overstocking, reducing storage costs, and enhancing overall business profitability and customer experience.

- The process includes receiving, tracking, replenishing, and fulfilling orders—supported by automation, real-time updates, and demand forecasting to keep stock levels accurate and aligned with customer demand.

- Implementing strategies like maintaining safety stock, using ABC analysis, optimizing warehouse layouts, conducting regular audits, and leveraging technology ensures efficiency, accuracy, and cost control in inventory operations.

- Emerging technologies such as AI, IoT, robotics, and predictive analytics are transforming inventory management—enabling smarter forecasting, real-time visibility, and faster, more efficient fulfillment processes.

- Deskera ERP integrates automation, real-time tracking, demand forecasting, and multi-channel synchronization to simplify complex inventory processes—helping eCommerce businesses reduce errors, boost efficiency, and scale effortlessly.

Related Articles