Why do some supply chains consistently outperform others, even in volatile markets? The answer often lies in how well organizations connect data, processes, and decision-making across their operations. As supply chains grow more complex—spanning suppliers, manufacturers, warehouses, and customers—manual processes and disconnected systems create blind spots that slow growth and inflate costs. This is where ERP (Enterprise Resource Planning) becomes a critical enabler of modern supply chain management.

Despite the growing availability of digital tools, many organizations still operate without real-time visibility. Studies indicate that nearly 63% of companies do not use technology to actively monitor supply chain performance, yet 81% of supply chain professionals agree that analytics plays a vital role in reducing costs. The gap between awareness and adoption is significant—and costly. Businesses that fail to leverage integrated systems often struggle with inefficiencies, inaccurate forecasts, and delayed responses to market changes.

In contrast, organizations with well-optimized, ERP-driven supply chains see measurable advantages. Companies with mature supply chain capabilities report up to 15% lower operational costs, 50% reduction in inventory holding, and cash-to-cash cycles that are three times faster than their peers. These outcomes highlight how ERP systems go beyond automation—providing a unified platform for planning, execution, and continuous improvement across the supply chain.

Modern solutions like Deskera ERP are designed to support this transformation. Deskera helps businesses streamline procurement, inventory management, production planning, and financial tracking within a single, cloud-based platform. With real-time dashboards, demand forecasting, and integrated MRP capabilities, Deskera ERP enables organizations to build more agile, data-driven, and resilient supply chains—ready to scale with evolving business needs.

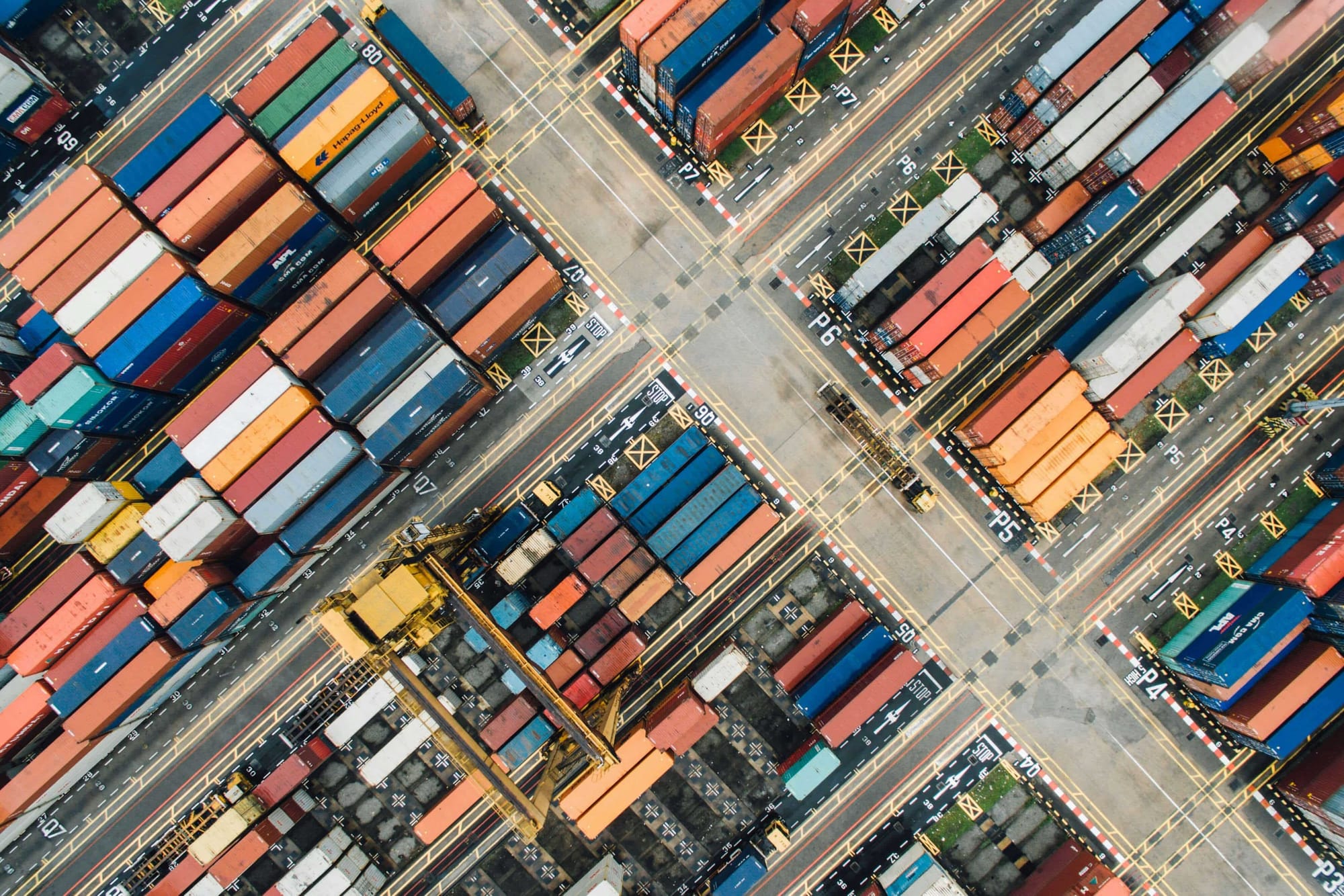

What Is Supply Chain Management?

Supply Chain Management (SCM) is the process of planning, coordinating, and controlling the flow of goods, services, information, and finances from raw material sourcing to final delivery to the customer.

It involves managing every stage of the supply chain—procurement, production, inventory management, warehousing, transportation, and distribution—to ensure products are delivered efficiently, cost-effectively, and on time.

At its core, supply chain management focuses on:

- Optimizing operations by reducing waste, delays, and unnecessary costs

- Improving visibility across suppliers, manufacturers, and distributors

- Balancing supply and demand to avoid stockouts or excess inventory

- Enhancing customer satisfaction through faster and more reliable fulfillment

In today’s digital and global business environment, effective supply chain management relies heavily on technology such as ERP systems, analytics, and automation. These tools help organizations gain real-time insights, make informed decisions, and build supply chains that are resilient, agile, and scalable.

The Role of ERP Across the Supply Chain Lifecycle

Supply chain management spans every link in the value chain—from sourcing raw materials to delivering finished products to customers. ERP systems play a central role in strengthening this lifecycle by embedding intelligence, automation, and visibility into each stage.

By harmonizing supply chain activities with finance, operations, sales, and product development, ERP enables organizations to move from fragmented execution to coordinated, goal-driven supply chain management.

Below are the key areas across the supply chain lifecycle where ERP delivers the most impact.

Supply Chain Planning and Demand Forecasting

ERP systems support proactive supply chain planning through data-driven demand forecasting. By leveraging historical trends, real-time signals, and predictive analytics, ERP helps businesses anticipate demand more accurately, allocate resources efficiently, and avoid excess inventory or stockouts. Advanced ERP platforms also enable AI-driven scenario modeling, allowing organizations to prepare for market volatility, supply disruptions, and shifting customer demand.

Procurement and Sourcing Management

ERP centralizes procurement processes into a single platform, providing end-to-end visibility into supplier selection, purchase orders, contracts, invoices, inventory levels, and delivery performance. Automation accelerates approvals and order processing, reducing cycle times and costs. With access to consolidated data, organizations can continuously assess vendor performance, enforce compliance, and negotiate more favorable supplier terms.

Manufacturing and Production Coordination

In manufacturing environments, ERP aligns production schedules with demand forecasts, inventory availability, and order priorities. This synchronization reduces lead times, minimizes material waste, and improves shop-floor efficiency.

By integrating Material Requirements Planning (MRP), ERP ensures the right materials are available at the right time, optimizing production planning and overall cost control.

Product Development and Lifecycle Alignment

Supply chain considerations are critical to successful product development. ERP systems connect product design, sourcing, and manufacturing teams, ensuring that new products are developed with material availability, cost efficiency, logistics feasibility, and regulatory compliance in mind. This alignment helps businesses launch products faster while maintaining quality and profitability.

Warehouse and Logistics Management

ERP systems enhance supply chain logistics by integrating warehouse management and transportation processes. Real-time visibility into stock levels, order status, and delivery schedules enables better coordination across warehouses and carriers. ERP-driven automation supports optimized picking, packing, routing, and replenishment—reducing delays, transportation costs, and fulfillment errors.

Maintenance and Asset Management

Unplanned downtime can disrupt the entire supply chain. ERP systems support preventive maintenance by tracking asset performance, spare parts inventory, maintenance schedules, and work orders. This ensures equipment operates reliably, minimizes production stoppages, and protects supply chain continuity.

Sustainability and Compliance Management

As sustainability becomes a strategic priority, ERP provides the data foundation needed to track environmental impact, resource consumption, and regulatory compliance across the supply chain. By monitoring emissions, waste, and energy usage, ERP enables accurate sustainability reporting and supports data-driven decisions to meet environmental and regional compliance requirements.

Supply Chain Financial Management

ERP connects supply chain operations with financial performance by centralizing transactions, cost tracking, and reporting. Real-time access to financial data improves visibility into procurement spend, inventory carrying costs, and cash flow. Automation of invoicing, payments, and reconciliations ensures financial accuracy while supporting faster cash-to-cash cycles.

Customer Service and Experience Management

ERP bridges supply chain and customer service functions by providing shared, real-time data. This synchronization improves order accuracy, delivery reliability, and issue resolution. Customers benefit from greater transparency into order status, delivery timelines, and financial transactions—strengthening trust and long-term relationships.

Collaboration and Cross-Functional Communication

ERP systems act as a centralized collaboration layer across the supply chain, enabling seamless communication between procurement, production, sales, finance, and logistics teams. Because all stakeholders work from a shared database, updates made by one function are instantly visible to others, eliminating silos and misalignment.

ERP platforms also extend collaboration beyond the organization through supplier and customer portals, allowing real-time order tracking, faster issue resolution, and more coordinated decision-making across the supply network.

Analytics and Data-Driven Decision-Making

Advanced analytics is a core strength of modern ERP systems in supply chain management. By consolidating operational, financial, and transactional data, ERP provides real-time dashboards, performance metrics, and predictive insights across the supply chain.

These analytics help organizations monitor key indicators such as demand variability, inventory turnover, supplier performance, and delivery timelines. With AI-enabled forecasting and scenario analysis, ERP empowers supply chain leaders to identify risks early, optimize costs, and make faster, more informed decisions aligned with business objectives.

Across planning, sourcing, production, logistics, and customer fulfillment, ERP acts as the connective layer that aligns supply chain execution with broader business objectives. By improving collaboration, visibility, and decision-making at every stage, ERP transforms supply chain management from a cost center into a strategic driver of efficiency, resilience, and profitability.

Key Benefits of Using ERP in Supply Chain Management

When embedded into supply chain management, ERP systems synchronize planning, execution, and financial controls with overarching business objectives. By centralizing data and workflows across the value chain, ERP empowers teams, partners, and leaders to operate in unison—driving efficiency, visibility, and resilience at scale.

End-to-End Supply Chain Visibility and Transparency

ERP systems consolidate data from procurement, inventory, manufacturing, logistics, and distribution into a single, contextualized platform. This delivers real-time, 360° visibility across the supply chain, enabling stakeholders to track materials and products from source to delivery. Enhanced transparency helps teams identify inefficiencies early, optimize resource allocation, and respond faster to disruptions.

Improved Demand Forecasting and Supply Chain Planning

By leveraging historical data, real-time signals, and predictive analytics, ERP improves demand forecasting accuracy. This allows organizations to better synchronize supply and demand, plan production proactively, and reduce last-minute firefighting. Scenario planning and AI-driven modeling further support strategic decisions in volatile market conditions.

Optimized Inventory Management

ERP systems help organizations maintain optimal inventory levels across locations. Automated reorder points, safety stock calculations, and real-time tracking reduce the risk of stockouts during peak demand while minimizing excess inventory. This balance lowers carrying costs, frees up warehouse space, and supports uninterrupted operations.

Enhanced Collaboration and Cross-Functional Alignment

ERP acts as a centralized collaboration platform, breaking down silos between procurement, production, finance, sales, logistics, and external partners. Shared access to real-time data ensures all stakeholders work from a single source of truth. Supplier and customer portals further strengthen coordination, helping organizations manage dependencies, reduce bottlenecks, and adapt quickly to change.

Data-Driven Insights and Advanced Analytics

Modern ERP systems provide powerful analytics that transform raw data into actionable insights. Customizable dashboards, KPI tracking, and performance reports help organizations monitor trends, evaluate supplier performance, and measure operational efficiency. Predictive analytics and forecasting capabilities enable leaders to identify risks, uncover opportunities, and make confident, informed decisions.

Increased Operational Efficiency Through Automation

ERP streamlines supply chain processes by automating routine tasks such as inventory tracking, purchase orders, billing, documentation, and replenishment. Workflow automation reduces manual effort, minimizes errors, and accelerates cycle times—allowing teams to focus on higher-value strategic initiatives.

Reduced Operational and Overhead Costs

With better visibility into supply, demand, and logistics, ERP enables smarter purchasing, reduced waste, and optimized transportation and warehousing. Automated workflows lower administrative costs and prevent costly errors, while forecasting and supplier insights support cost-effective negotiations and sourcing strategies.

Stronger Supplier and Vendor Performance Management

ERP systems maintain centralized supplier records and performance metrics, enabling continuous vendor evaluation based on delivery reliability, quality, cost, and compliance. Real-time collaboration with suppliers improves responsiveness, strengthens partnerships, and ensures consistent performance across the supply network.

Greater Supply Chain Resilience and Risk Management

ERP supports regulatory compliance and risk mitigation by maintaining detailed audit trails and standardized records. Predictive analytics and scenario planning help organizations anticipate disruptions—such as supplier delays or demand spikes—and respond proactively rather than reactively.

Scalability and Flexibility for Growing Businesses

ERP systems are designed to scale with organizational growth and evolving market demands. Whether expanding operations, entering new markets, or managing multi-location supply chains, ERP provides the flexibility needed to maintain performance, consistency, and competitiveness.

Improved Customer Satisfaction and Retention

By integrating supply chain data and processes, ERP improves order accuracy, delivery reliability, and communication. Customers benefit from realistic delivery timelines, transparent order tracking, and faster issue resolution—building trust, customer loyalty, and long-term retention.

Simplified IT Landscape and Cloud Accessibility

Using ERP for supply chain management reduces IT complexity by eliminating the need for multiple disconnected systems. Cloud-based ERP solutions further enhance accessibility, security, and mobility—allowing teams to access real-time data anytime, anywhere, and act quickly in fast-moving supply chain environments.

Common Challenges When Implementing ERP in Supply Chain Management

While ERP systems deliver significant value across supply chain operations, implementation is often complex and requires careful planning. Organizations frequently encounter the following challenges when deploying ERP for supply chain management.

Resistance to Change and User Adoption

One of the most common hurdles is resistance from employees accustomed to legacy systems or manual processes. Without proper change management, training, and leadership support, users may struggle to adopt new workflows, limiting the system’s effectiveness.

Data Migration and Data Quality Issues

ERP implementations rely heavily on accurate, standardized data. Migrating data from multiple legacy systems can expose inconsistencies, duplicates, or gaps. Poor data quality can undermine forecasting accuracy, inventory planning, and decision-making across the supply chain.

Integration with Legacy Systems and External Partners

Many organizations operate with a mix of legacy applications and third-party tools. Integrating ERP with existing systems, suppliers, logistics partners, and customer platforms can be technically challenging and time-consuming, especially in complex or global supply chains.

Implementation Cost and Timeline Overruns

ERP projects often require significant upfront investment and resource commitment. Without clear scope definition and governance, implementations can exceed planned budgets and timelines, delaying value realization and increasing operational risk.

Process Misalignment and Over-Customization

Adopting ERP without aligning it to standardized supply chain processes can create inefficiencies. Excessive customization to mirror old workflows may increase complexity, hinder upgrades, and reduce system scalability over time.

Limited Cross-Functional Coordination

ERP success depends on collaboration across procurement, manufacturing, logistics, finance, IT, and sales. Siloed decision-making or lack of stakeholder alignment can result in fragmented implementation and suboptimal supply chain outcomes.

Inadequate Training and Change Management

Insufficient training often leads to underutilization of ERP capabilities. Users may rely on workarounds or parallel systems if they do not fully understand how to use the ERP effectively within supply chain operations.

Difficulty Measuring ROI and Performance Impact

Many organizations struggle to define clear KPIs and benchmarks before implementation. Without measurable goals, it becomes difficult to assess ERP’s impact on inventory turnover, lead times, costs, or service levels.

Scalability and Future-Readiness Concerns

Selecting an ERP that cannot scale with business growth, new markets, or evolving supply chain models can limit long-term value. Organizations must balance current requirements with future needs during system selection and implementation.

ERP Best Practices for Effective Supply Chain Management

To maximize the value of ERP in supply chain management, organizations must go beyond implementation and focus on how the system is used, governed, and continuously optimized.

The following best practices help ensure ERP delivers long-term efficiency, visibility, and strategic impact across the supply chain.

Align ERP Strategy with Supply Chain and Business Goals

Begin by clearly defining what the organization aims to achieve—whether it is cost reduction, improved service levels, faster fulfillment, or greater resilience. Align ERP configurations and workflows with these objectives to ensure supply chain decisions support broader business priorities.

Standardize and Cleanse Supply Chain Data

Accurate data is the foundation of effective ERP-driven supply chain management. Establish data governance practices to ensure consistency in item masters, supplier records, bills of materials, and inventory data. Clean, standardized data improves forecasting accuracy, reporting reliability, and decision-making.

Choose the Right ERP Modules and Integrations

Not all ERP features are equally critical for every business. Select supply chain modules—such as inventory management, procurement, MRP, warehouse management, and analytics—based on operational needs. Ensure seamless integration with external systems, suppliers, and logistics partners where required.

Enable Cross-Functional Collaboration

ERP works best when departments operate from a shared source of truth. Encourage collaboration between procurement, production, finance, sales, and logistics teams by standardizing workflows and shared KPIs. This alignment reduces silos and improves coordination across the supply chain lifecycle.

Leverage Analytics for Proactive Decision-Making

Use ERP dashboards, reports, and predictive analytics to monitor key supply chain metrics such as demand variability, inventory turnover, lead times, and supplier performance. Scenario planning and forecasting tools help organizations anticipate risks and respond proactively rather than reactively.

Automate Where It Delivers the Most Value

Identify repetitive, high-volume processes—such as purchase order creation, replenishment, invoicing, and inventory updates—and automate them within ERP. Automation reduces errors, accelerates cycle times, and allows teams to focus on strategic activities.

Focus on Change Management and User Training

User adoption is critical to ERP success. Invest in role-based training, clear documentation, and ongoing support to ensure teams understand how ERP improves their daily work. Strong change management helps build trust in the system and encourages consistent usage.

Plan for Scalability and Continuous Improvement

Design ERP configurations with future growth in mind. As supply chains evolve due to market expansion, new products, or regulatory changes, regularly review and refine ERP processes to ensure the system continues to support business needs.

Monitor Performance and Measure ROI

Define clear KPIs before and after implementation to track ERP’s impact on supply chain performance. Metrics such as order fulfillment rates, inventory carrying costs, cash-to-cash cycle time, and supplier reliability help measure ROI and guide ongoing optimization.

Key Factors to Evaluate When Selecting an ERP for Supply Chain Management

Choosing the right ERP system is critical to building an efficient, resilient, and scalable supply chain. The ideal ERP should not only support current operations but also adapt as business needs evolve.

Below are the key factors organizations should evaluate when selecting an ERP for supply chain management.

Ease of Use Across Teams

An ERP system must be intuitive and user-friendly for all stakeholders—from shipping and receiving teams to production planners and finance professionals. Easy-to-use interfaces reduce training time, improve adoption, and ensure that employees across the supply chain can work efficiently without relying on manual workarounds.

Total Cost of Ownership and ROI

Cost evaluation should go beyond licensing fees to include implementation, maintenance, upgrades, and support. Modern, subscription-based cloud ERP solutions offer predictable pricing and faster time to value by bundling infrastructure, updates, and storage into a single cost model—making ROI easier to measure and achieve.

Ease of Integration with Supply Chain Systems

Seamless integration is essential for maintaining data flow across supply chain operations. ERP systems that natively integrate with SCM tools—such as logistics platforms, supplier systems, and warehouse management solutions—reduce the need for costly, custom integrations and simplify long-term system maintenance.

Unified and Common Data Model

ERP systems that share a common data model across supply chain and business functions operate from a single source of truth. This ensures data consistency, reduces duplication, and improves accuracy across planning, procurement, inventory, production, and financial reporting—saving teams significant time and effort.

Cloud-Based Architecture and Accessibility

Cloud-based ERP systems provide real-time access to supply chain data anytime, anywhere, and from any connected device. This level of accessibility improves visibility across global operations, enables faster decision-making, and supports remote collaboration—critical for managing modern, distributed supply chains.

Scalability and Future-Readiness

As businesses grow or expand into new markets, their supply chain complexity increases. An ERP system should scale effortlessly to support additional users, locations, products, and transaction volumes without requiring major system overhauls.

Security, Compliance, and Reliability

Supply chain ERP systems must safeguard sensitive operational and financial data. Evaluating built-in security controls, compliance capabilities, data backups, and system uptime ensures long-term reliability and regulatory adherence.

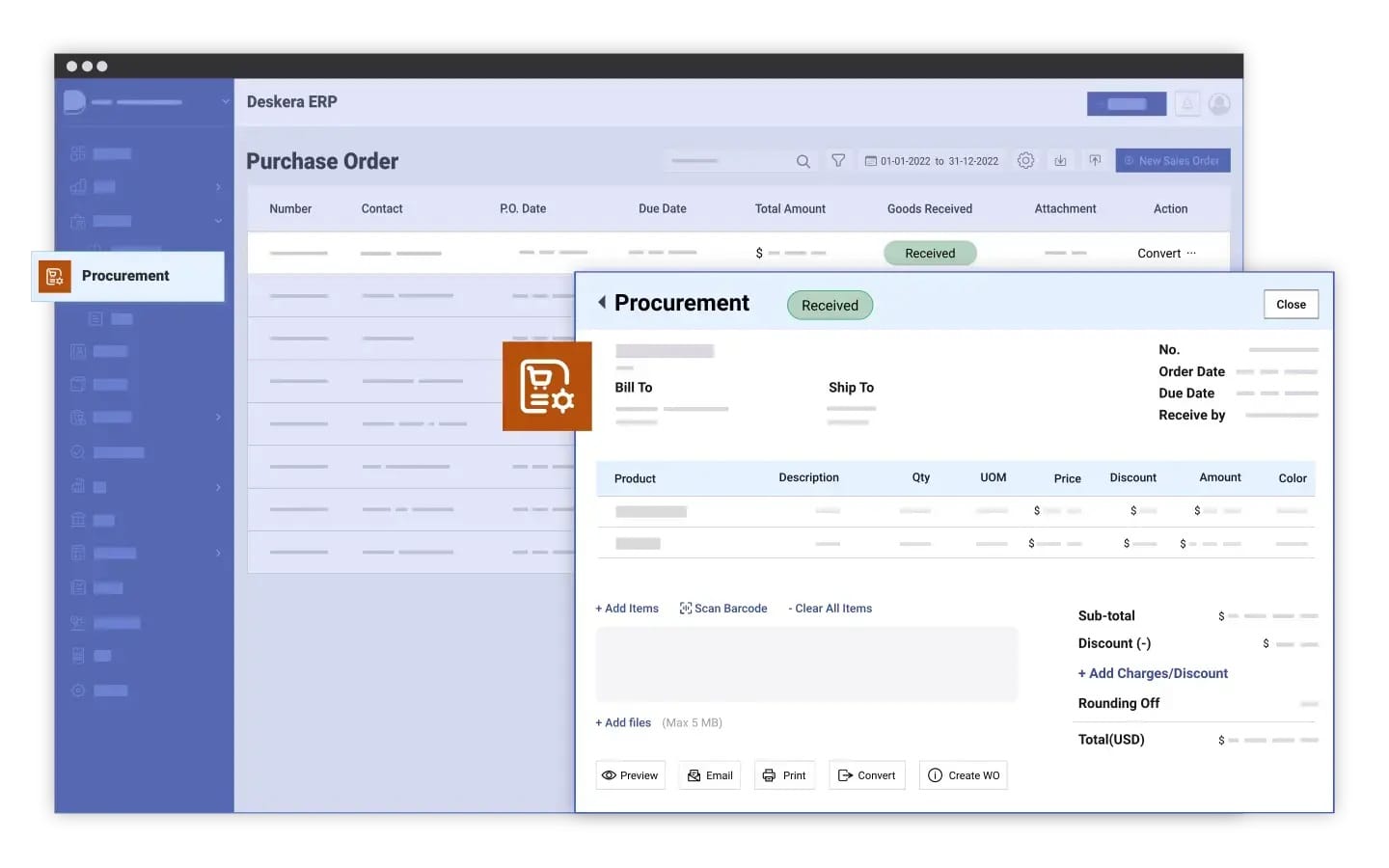

How Can Deskera ERP Help You with Supply Chain Management?

Deskera ERP supports end-to-end supply chain management by bringing planning, execution, and financial control onto a single, cloud-based platform. It is designed to help businesses gain visibility, improve coordination, and make data-driven decisions across their supply chain—without adding operational complexity.

Centralized Supply Chain Visibility

Deskera ERP provides a unified view of inventory, procurement, production, and order fulfillment across locations. Real-time dashboards and reports help teams track stock levels, material movement, and order status, enabling faster responses to demand changes and supply disruptions.

Smarter Demand Forecasting and Planning

With built-in analytics and historical data tracking, Deskera ERP helps businesses forecast demand more accurately. This allows organizations to plan procurement and production proactively, reduce excess inventory, and avoid costly stockouts.

Streamlined Procurement and Vendor Management

Deskera centralizes supplier information, purchase orders, and procurement workflows in one system. Teams can manage vendor performance, track lead times, and ensure timely replenishment—improving supplier coordination and cost control.

Efficient Inventory and Warehouse Management

Deskera ERP enables real-time inventory tracking across warehouses and locations. Automated reorder levels, stock movement tracking, and inventory valuation help maintain optimal stock levels while reducing carrying costs and manual errors.

Integrated MRP and Production Planning

For manufacturing-driven supply chains, Deskera’s MRP capabilities align material availability with production schedules. This ensures the right materials are available at the right time, reducing delays, minimizing waste, and improving production efficiency.

Improved Collaboration Across Teams

By connecting supply chain operations with finance, sales, and operations, Deskera ERP eliminates data silos. Teams work from a single source of truth, improving coordination, transparency, and decision-making across the supply chain lifecycle.

Real-Time Analytics and Reporting

Deskera ERP offers actionable insights through customizable reports and dashboards. Supply chain leaders can monitor KPIs such as inventory turnover, procurement spend, and order fulfillment performance—supporting continuous optimization.

Cloud-Based Accessibility and Scalability

As a cloud ERP, Deskera allows teams to access supply chain data anytime, from anywhere. This supports remote collaboration, faster approvals, and scalability as businesses grow, expand locations, or manage more complex supply chains.

Financial Alignment and Cost Control

Deskera tightly integrates supply chain activities with accounting and finance. This provides real-time visibility into costs, margins, and cash flow—helping organizations improve cash-to-cash cycles and overall supply chain profitability.

In summary, Deskera ERP helps businesses move from fragmented, reactive supply chain operations to a connected, data-driven model—improving efficiency, resilience, and long-term scalability.

Key Takeaways

- ERP systems provide the structure and tools to manage supply chain processes efficiently, enabling organizations to track materials, optimize operations, and reduce costs from procurement to delivery.

- ERP integrates supply chain planning, procurement, manufacturing, logistics, and customer service into a single system, improving visibility, coordination, and operational efficiency across the entire supply chain.

- ERP enhances decision-making, operational efficiency, collaboration, and customer satisfaction, while optimizing inventory, reducing costs, and enabling supply chain resilience and scalability.

- Successful ERP adoption requires overcoming challenges like data migration issues, user resistance, integration complexities, and cost management through proper planning, training, and governance.

- Aligning ERP with business goals, standardizing data, enabling analytics, automating workflows, and fostering cross-functional collaboration ensures maximum value from ERP implementation.

- When choosing an ERP, consider usability, integration capabilities, a unified data model, cloud accessibility, scalability, cost, and security to ensure the system meets both current and future supply chain needs.

- Deskera ERP provides centralized visibility, real-time analytics, automated workflows, integrated MRP, and cloud accessibility, empowering businesses to manage demand, procurement, production, and delivery efficiently while improving cost control and decision-making.

Related Articles