Are you tired of relying on guesswork and gut feelings to make decisions in your chemical manufacturing business? Do you wish a crystal ball could tell you what will happen before it does? Well, say hello to Big Data - your new best friend in the world of chemical manufacturing!

According to a report by MarketsandMarkets, the global Big Data market in the chemical industry is expected to reach $5.6 billion by 2025, with a compound annual growth rate (CAGR) of 22.7%.

This growth is driven by the increasing adoption of Big Data solutions in the chemical industry to optimize production processes, reduce costs, and improve product quality.

By leveraging Big Data, chemical manufacturers can gain valuable insights into their processes and products. They can use advanced analytics, machine learning algorithms, and predictive modeling to identify patterns and trends, optimize production processes, reduce waste, and increase efficiency.

Additionally, they can predict equipment failures, optimize maintenance schedules, and anticipate demand to ensure they're always meeting their customers' needs.

Here's what we shall cover in this post:

- Introduction to Big Data and Its Application in Chemical Manufacturing

- Importance of Big Data Analytics for Chemical Manufacturers

- How to Collect and Store Big Data in Chemical Manufacturing

- How Big Data Can Improve Quality Control and Safety in Chemical Manufacturing

- Predictive Maintenance Using Big Data in Chemical Manufacturing

- Future Trends for Big Data in Chemical Manufacturing

- Conclusion

- Key Takeaways

Introduction to Big Data and Its Application in Chemical Manufacturing

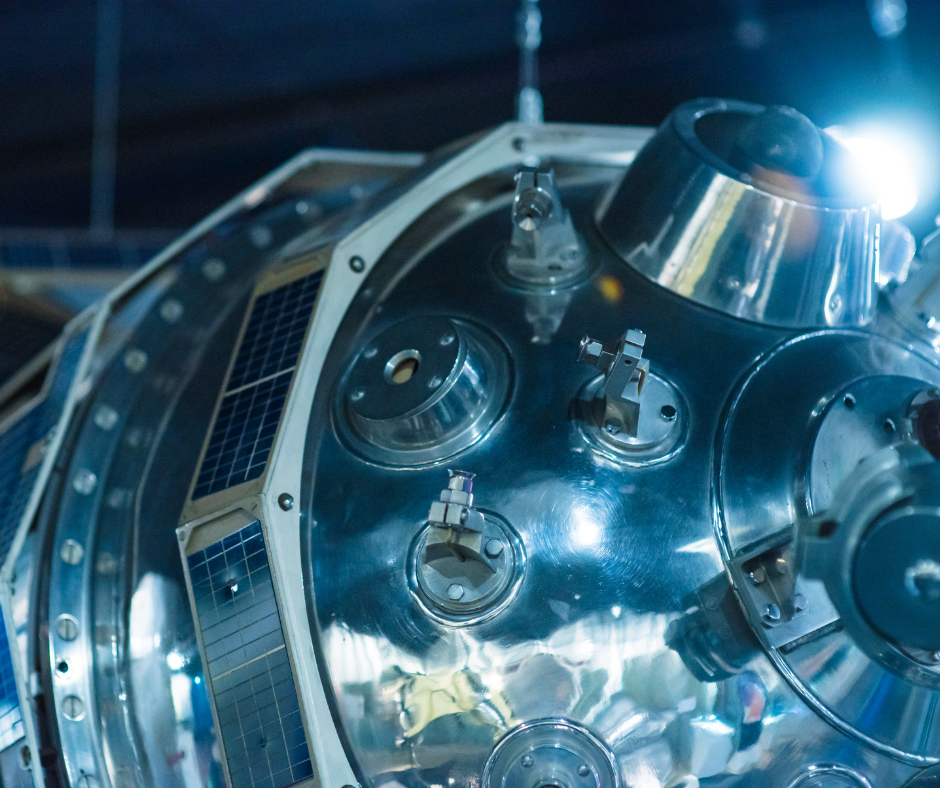

Big data has emerged as a buzzword in recent years and refers to the enormous volume of data - structured and unstructured - that inundates businesses on a daily basis. In the chemical industry, big data is generated at every stage of the production process, from research and development to manufacturing and distribution.

Here are some key points about big data and its applications in chemical manufacturing:

What is Big Data?

Big data refers to vast amounts of data that are generated in different forms, such as text, images, videos, and sensor data. These data sets are so large and complex that traditional data processing software and tools are inadequate to handle them. The concept of big data involves collecting, analyzing, and utilizing this data to derive insights and drive business value.

Applications of Big Data in Chemical Manufacturing

Big data has numerous applications in chemical manufacturing. Here are some examples:

- Predictive Maintenance: Big data analytics can help manufacturers detect potential equipment failures and proactively plan maintenance activities. This can help reduce downtime and improve overall equipment effectiveness.

- Quality Control: Big data analytics can help manufacturers monitor and improve the quality of their products by detecting and predicting defects in real time.

- Supply Chain Optimization: Big data analytics can help manufacturers optimize their supply chain operations by predicting demand, tracking inventory levels, and identifying potential bottlenecks.

- Energy Efficiency: Big data analytics can help manufacturers reduce their energy consumption and costs by analyzing energy usage patterns and identifying areas where energy usage can be optimized.

Importance of Big Data Analytics for Chemical Manufacturers

Big Data Analytics has become a critical tool for chemical manufacturers to improve their decision-making processes, increase efficiency, and drive innovation.

Here are some points explaining the importance of Big Data Analytics for chemical manufacturers:

Improved Process Efficiency

Big Data Analytics can help chemical manufacturers optimize their processes to improve efficiency and reduce costs. By analyzing large sets of data, manufacturers can identify areas where process improvements can be made, such as reducing waste, increasing yields, and decreasing downtime.

New Product Development

Big Data Analytics can help chemical manufacturers identify new product opportunities by analyzing customer data and market trends. By identifying gaps in the market, manufacturers can develop new products that meet the needs of their customers.

Regulatory Compliance

Chemical manufacturers are subject to a range of regulations, and Big Data Analytics can help ensure compliance by analyzing data on raw materials, production processes, and product quality. Manufacturers can avoid fines and other penalties by identifying potential compliance issues early.

Competitive Advantage

By leveraging Big Data Analytics, chemical manufacturers can gain a competitive advantage by making data-driven decisions that improve efficiency, reduce costs, and drive innovation. With the right tools and expertise, manufacturers can unlock insights that their competitors may not have access to.

How to Collect and Store Big Data in Chemical Manufacturing

The chemical manufacturing industry produces massive amounts of data, which can be used to optimize production processes, reduce costs, and improve product quality.

Big data refers to large and complex data sets that require advanced techniques to process and analyze. This section will discuss how to collect and store big data in chemical manufacturing.

- Identify relevant data sources: The first step in collecting big data is to identify the relevant data sources. In chemical manufacturing, these can include production data, process parameters, quality control data, supply chain data, and customer feedback. It is important to identify all potential data sources to ensure nothing is overlooked.

- Implement data collection systems: Once the relevant data sources have been identified, the next step is to implement data collection systems. This can include sensors, automated data capture systems, and other software applications that collect and store data in real time. It is important to ensure that data is captured accurately and consistently to ensure the accuracy of the data analysis.

- Choose an appropriate data storage solution: Choosing the right data storage solution is critical to ensuring that the data is easily accessible and secure. Chemical manufacturers can choose from a variety of options, including cloud-based solutions, data warehouses, and data lakes. Each option has its own strengths and weaknesses, and manufacturers must consider their specific needs and requirements when choosing a data storage solution.

- Ensure data quality: One of the most important aspects of collecting and storing big data is ensuring data quality. This means ensuring that the data is accurate, complete, and consistent. Data quality can be ensured by implementing data validation processes, training employees on data entry protocols, and performing regular data audits.

- Implement data security measures: Data security is another critical aspect of collecting and storing big data. Chemical manufacturers must implement appropriate security measures to protect their data from cyber threats and unauthorized access. This can include encryption, firewalls, and other security protocols.

- Use data analytics tools to analyze the data: Chemical manufacturers can use data analytics tools to analyze the data and derive insights once the data has been collected and stored. These tools can include machine learning algorithms, data visualization tools, and statistical analysis software. Data analytics can be used to identify trends, patterns, and anomalies and to optimize production processes.

How Big Data Can Improve Quality Control and Safety in Chemical Manufacturing

In the chemical manufacturing industry, big data analytics can be used to improve quality control and safety and optimize production processes.

Here are some ways that big data can improve quality control and safety in chemical manufacturing:

- Predictive maintenance: By collecting and analyzing data from sensors and other sources, chemical manufacturers can predict when equipment is likely to fail and perform maintenance before it causes safety issues or production downtime.

- Process monitoring: Big data can monitor the chemical manufacturing process in real time, enabling operators to detect deviations from expected parameters and take corrective action before safety or quality issues arise.

- Risk assessment: By analyzing data from safety incidents, chemical manufacturers can identify patterns and trends that can help to prevent future accidents and ensure compliance with safety regulations.

- Supplier management: Big data can be used to monitor and analyze supplier performance, ensuring that raw materials are of the required quality and that suppliers are meeting safety and compliance standards.

- Quality control: By analyzing data from various stages of the manufacturing process, chemical manufacturers can identify any quality issues and take corrective action before the final product is released. This can reduce waste and ensure that the final product meets customer requirements.

Companies need to have the appropriate infrastructure to collect and store big data in chemical manufacturing. This includes hardware such as sensors, data storage systems, analytical tools, and software to manage and analyze the data.

In addition, companies need to clearly understand what data to collect and how it will be used to improve processes and ensure safety and quality.

Predictive Maintenance Using Big Data in Chemical Manufacturing

Predictive maintenance is analyzing data to identify potential issues and predicting when maintenance should be performed to avoid unplanned downtime. In chemical manufacturing, this approach is becoming increasingly popular because it can help reduce equipment failure costs, improve productivity, and enhance safety.

One way to implement predictive maintenance is by using big data analytics, which involves collecting and analyzing large amounts of data from various sources to gain insights into equipment performance.

Here are some key points on how predictive maintenance using Big Data can benefit chemical manufacturing:

Improved Equipment Reliability

Big data analytics can be used to monitor and analyze equipment performance data in real time, allowing for the early detection of potential equipment failures. This can help to avoid costly unscheduled downtime and improve overall equipment reliability.

Enhanced Safety

By monitoring equipment performance in real-time, big data analytics can help to identify potential safety hazards and provide early warning of potential incidents. This can help to prevent accidents and ensure a safer work environment for employees.

Cost Reduction

Predictive maintenance can reduce maintenance costs by allowing for more efficient use of maintenance resources. Companies can avoid costly equipment repairs and replacements by identifying potential issues before they become major problems.

Increased Productivity

With predictive maintenance, companies can optimize their maintenance schedules to minimize downtime and maximize equipment uptime. This can help to increase overall production output and improve productivity.

Better Asset Management

Big data analytics can provide a wealth of information on equipment performance and help identify asset optimization opportunities. This can include identifying which equipment is underutilized or overutilized and providing insight into the best ways to optimize equipment utilization.

Future Trends for Big Data in Chemical Manufacturing

Here are some future trends for Big Data in Chemical Manufacturing:

Artificial Intelligence and Machine Learning

Chemical manufacturers invest in AI and machine learning to analyze and interpret Big Data. With AI algorithms, chemical companies can identify patterns and anomalies in data, detect product defects, and predict equipment failures before they occur.

Cloud Computing

Cloud computing allows companies to store and analyze large amounts of data cost-effectively and efficiently. Using cloud-based platforms, chemical manufacturers can access their data from anywhere, collaborate with teams across the globe, and run complex simulations and modeling to optimize operations.

Internet of Things (IoT)

IoT refers to the network of connected devices that collect and share data. IoT sensors monitor equipment, temperature, pressure, and other environmental conditions in chemical manufacturing. This data can be analyzed to optimize production processes and reduce downtime.

Real-Time Data Analysis

Technological advancements have made real-time data analysis more accessible for chemical manufacturers. Real-time data analysis enables companies to monitor production processes in real time, identify deviations from normal operating conditions, and take corrective action to prevent issues from occurring.

Data Security

As chemical companies collect and store large amounts of sensitive data, ensuring the security of that data becomes increasingly important. In the future, chemical manufacturers will continue to invest in data security measures, such as encryption and firewalls, to protect their data from cyber threats.

How Deskera Can Assist You?

Deskera MRP allows you to closely monitor the manufacturing process. From the bill of materials to the production planning features, the solution helps you stay on top of your game and keep your company's competitive edge.

Deskera ERP and MRP system can help you:

- Manage production plans

- Maintain Bill of Materials

- Generate detailed reports

- Create a custom dashboard

Deskera ERP is a comprehensive system that allows you to maintain inventory, manage suppliers, and track supply chain activity in real-time, as well as streamline a variety of other corporate operations.

Deskera Books enables you to manage your accounts and finances more effectively. Maintain sound accounting practices by automating accounting operations such as billing, invoicing, and payment processing.

Deskera CRM is a strong solution that manages your sales and assists you in closing agreements quickly. It not only allows you to do critical duties such as lead generation via email, but it also provides you with a comprehensive view of your sales funnel.

Deskera People is a simple tool for taking control of your human resource management functions. The technology not only speeds up payroll processing but also allows you to manage all other activities such as overtime, benefits, bonuses, training programs, and much more. This is your chance to grow your business, increase earnings, and improve the efficiency of the entire production process.

Conclusion

Leveraging big data in chemical manufacturing can significantly improve various aspects of the production process. Chemical manufacturers can optimize their operations, reduce costs, and improve product quality by collecting and analyzing vast amounts of data from various sources.

The use of big data analytics tools can help identify patterns and trends in production data, leading to better decision-making and improved efficiencies. Additionally, big data can aid in process monitoring and predictive maintenance, allowing for timely and proactive interventions before equipment failures occur.

Overall, big data can be a game-changer in the chemical manufacturing industry, providing a competitive advantage to those who embrace it. As technology advances and more data becomes available, the opportunities for leveraging big data will only continue to grow.

Key Takeaways

- Big data can improve chemical manufacturing by optimizing operations, reducing costs, and improving product quality.

- The use of big data analytics tools can identify patterns and trends in production data, leading to better decision-making and improved efficiencies.

- Big data can help in process monitoring and predictive maintenance, allowing for timely and proactive interventions before equipment failures occur.

- Implementing big data in chemical manufacturing can provide a competitive advantage to those who embrace it.

- Technology advancements have made more data available, providing opportunities for leveraging big data to grow.

- The successful implementation of big data in chemical manufacturing requires a strong data governance framework, including data privacy and security protocols.

- Skilled personnel are needed to manage and analyze the data for successful implementation effectively.

Related Articles