Efficient chemical manufacturing is crucial for the success and profitability of any company in the industry. The ability to optimize your manufacturing processes can not only save time and money, but it can also improve product quality and consistency.

However, achieving maximum efficiency in chemical manufacturing is not always straightforward. It requires a deep understanding of the processes involved, as well as a commitment to continuous improvement.

In this article, we'll provide you with practical tips and strategies to help you optimize your chemical manufacturing processes and increase your efficiency.

Here is all that we cover on this page:

- Importance Of Chemical Manufacturing Efficiency

- Evaluate Your Current Manufacturing Process

- Streamline Process Steps

- Improve Efficiency Through Process Changes

- Effective Use of Energy and Raw Materials

- Training and Education

- Conclusion

- How can Deskera Help You?

- Key Takeaways

- Related Articles

Importance of Chemical Manufacturing Efficiency

Efficiency is a critical factor in chemical manufacturing because it directly impacts a business's profitability and competitiveness. There are several reasons why efficiency is important in chemical manufacturing.

First, efficiency helps to reduce costs. By minimizing waste, improving the use of resources, and increasing productivity, businesses can reduce their overall manufacturing costs. This can help improve profit margins, lower prices, and make products more competitive.

Second, efficiency helps to improve product quality. When processes are streamlined and optimized, it's easier to ensure that products meet quality standards and are consistent from batch to batch. This can lead to higher customer satisfaction and a better reputation for the business.

Third, efficiency helps to reduce environmental impact. By minimizing waste and resource consumption, businesses can reduce their carbon footprint and positively impact the environment. This is important not only from a social responsibility perspective but also from a regulatory compliance perspective, as governments worldwide are increasingly focused on environmental issues.

Finally, efficiency helps businesses to stay competitive in a fast-paced and ever-changing industry. By continually improving their manufacturing processes and adopting new technologies and practices, businesses can stay ahead of the curve and meet the evolving needs of their customers. This can help to ensure long-term success and sustainability.

The idea is to identify and evaluate the current process to achieve the desired outcomes. The next sections of this post will take us through the entire process of determining areas that require optimization. Also, we shall look into the ways that can help improve overall efficiency.

Evaluate Your Current Manufacturing Process

Evaluating your current chemical manufacturing process is an essential first step toward optimizing your operations for maximum efficiency. This involves thoroughly examining the various stages of your manufacturing process, from raw material sourcing to final product delivery. You need to identify potential bottlenecks, areas of waste, and other inefficiencies that may hinder your production capacity and profitability.

By carefully evaluating your current process, you can gain valuable insights into the areas that require improvement and prioritize your efforts to achieve the greatest impact. This analysis can help you to identify opportunities to streamline your operations, increase production speed, and enhance product quality. This can ultimately lead to increased profits and a more competitive position in the market.

Determine Areas that Require Optimization

In chemical manufacturing processes, it is essential to identify the areas that require optimization to ensure efficient and cost-effective production. Optimization can help in reducing waste, minimize production costs, improve product quality, and maximize yield. Here are some key areas that require optimization in a chemical manufacturing process:

- Raw Material Usage: One critical area that requires optimization is the amount of raw material used in the production process. Efficient utilization of raw materials can help in reducing costs and minimize waste.

- Energy Consumption: Another critical area that requires optimization is energy consumption during manufacturing. By minimizing energy consumption, manufacturers can reduce production costs and minimize their carbon footprint.

- Production Time: The time taken to manufacture a product is another area that requires optimization. Manufacturers can improve production efficiency and reduce costs by reducing production time.

- Process Control: Process control is another area that requires optimization in chemical manufacturing. Manufacturers can improve product quality and minimize waste by ensuring that all the production parameters are within the required specifications.

- Maintenance and Upkeep: Proper maintenance and upkeep of equipment and machinery are crucial to ensure the smooth running of a chemical manufacturing process. Regular maintenance can help in minimizing downtime, increase equipment lifespan, and minimize the chances of breakdowns.

Analyze Current Process Constraints and Limitations

Analyzing the current process constraints and limitations is an essential step in improving the efficiency and effectiveness of a chemical manufacturing process. This involves identifying any bottlenecks or limitations that prevent the process from operating at optimal levels. Here are some key aspects to consider when analyzing the current process constraints and limitations in a chemical manufacturing process:

- Capacity Constraints: Capacity constraints refer to the maximum production capacity of a process. The availability of equipment, resources, or space can limit this. It is important to identify these constraints and work towards increasing production capacity, either by adding more equipment or optimizing existing resources.

- Raw Material Availability: The availability of raw materials can also be a constraint in a chemical manufacturing process. It is important to ensure a reliable and consistent supply of raw materials to avoid any disruptions in the production process.

- Processing Time: Processing time can be a constraint if it is longer than the desired production time. Analyzing the process steps can help identify areas where time can be saved, such as through process simplification or by using more efficient equipment.

- Quality Control: Quality control is critical in a chemical manufacturing process, and it is essential to ensure that the process meets the required quality standards. Identifying any limitations in the quality control process can help in optimizing the process and improve the overall product quality.

- Waste Reduction: Waste is a common issue in chemical manufacturing processes and can be a significant constraint if not managed effectively. It is important to identify the source of waste and work towards reducing it, either through process optimization or by implementing waste reduction initiatives.

Streamline Process Steps

Streamlining process steps is a critical aspect of optimizing a chemical manufacturing process. Manufacturers can reduce costs, increase production efficiency, and improve product quality by simplifying and optimizing process steps. Here are some key steps to streamline process steps in chemical manufacturing:

- Map out the process: The first step in streamlining process steps is to map out the entire process. This involves identifying each step in the production process and evaluating their impact on the overall process. Once the process is mapped out, it is easier to identify areas where steps can be simplified or eliminated.

- Identify redundant or non-value-added steps: After mapping out the process, it is important to identify any redundant or non-value-added steps. These are steps that do not contribute to the overall value of the product or process and can be eliminated or streamlined.

- Evaluate equipment and tools: The equipment and tools used in the production process can significantly impact the process steps. Evaluating these tools can help identify areas where they can be improved or replaced with more efficient alternatives.

- Optimize process flow: By optimizing the flow of the production process, manufacturers can reduce wait times, minimize handling, and improve the overall efficiency of the process. This can be achieved through the use of lean manufacturing principles, such as implementing a just-in-time system or improving the layout of the manufacturing plant.

- Implement automation: Automation can help to streamline process steps by reducing the need for manual intervention. Automating certain aspects of the production process can help reduce errors, increase efficiency, and improve overall product quality.

Effective Use of Energy and Raw Materials

Effective use of energy and raw materials is crucial in chemical manufacturing because it significantly impacts the industry's economic and environmental sustainability. First and foremost, it helps to reduce costs in chemical manufacturing.

By using energy and raw materials more efficiently, manufacturers can reduce their energy bills and raw material costs, improving the financial viability of the business. Effective use of energy and raw materials can also help to reduce waste and increase efficiency, resulting in improved production capacity, higher product quality, and reduced environmental impact.

Additionally, it helps to minimize the use of non-renewable resources, reducing the industry's carbon footprint and contributing to a more sustainable future. In short, the effective use of energy and raw materials is a win-win for both businesses and the environment, making it an essential consideration for chemical manufacturers looking to improve their competitiveness, sustainability, and profitability.

Achieving effective use of energy and raw materials in chemical manufacturing requires a holistic approach that takes into account the entire manufacturing process.

Reduce Energy Consumption

One approach to reducing energy consumption is to optimize the manufacturing process. This involves analyzing the various stages of production and identifying areas where energy can be saved. For example, optimizing the reaction conditions, such as temperature and pressure, can reduce the energy required to carry out the reaction. Using more efficient equipment, such as heat exchangers and pumps, can also reduce energy consumption.

Another approach is to use alternative energy sources. For example, using renewable energy sources such as solar or wind power can reduce the reliance on fossil fuels and lower energy costs. Some chemical manufacturers have also implemented combined heat and power (CHP) systems that generate both electricity and heat, reducing the facility's overall energy consumption.

Finally, it's important to consider the entire life cycle of the chemicals being produced. Optimizing the production process and reducing energy consumption can minimize the environmental impact of the chemicals. Additionally, using renewable energy sources and implementing energy-efficient practices can help make the manufacturing process more sustainable.

Optimize Raw Materials Usage

Raw materials are the building blocks of chemical products, and optimizing their usage can have a significant impact on the efficiency and cost-effectiveness of the manufacturing process.

Material efficiency is a strategy you can use which involves maximizing the amount of material that is converted into the final product. This can be achieved through process optimization and the use of advanced technologies.

Next, ensure that the process design of the manufacturing process can also have a significant impact on raw material usage. By designing the process to use raw materials more efficiently, manufacturers can reduce the amount of waste generated and improve the overall efficiency of the process.

Finally, supply chain optimization is essential in optimizing raw materials usage. By working closely with suppliers, manufacturers can identify ways to reduce the amount of raw material needed and improve the efficiency of the supply chain.

Recover and Reuse Materials

Recovering and reusing materials refers to the process of extracting valuable materials or components from waste streams generated during a chemical manufacturing process and then repurposing them for further use. This approach is an effective way to optimize chemical manufacturing processes, reduce waste and environmental impact, and increase the efficiency of the overall production process.

This technique can provide a number of benefits. First, it can help to reduce the amount of waste generated during production, which can save on disposal costs and minimize the environmental impact of the manufacturing process.

Second, by repurposing materials that might otherwise be discarded, manufacturers can reduce their dependence on virgin raw materials, which can help to reduce costs and conserve natural resources.

For example, recovering solvents, catalysts, and other chemicals can reduce the need for new purchases and allow for more precise manufacturing process control. Additionally, reusing materials can help to improve product quality and consistency, as well as reduce the risk of contamination or variability in the final product.

Training and Education

Educating staff is essential if you look forward to optimizing chemical manufacturing processes for maximum efficiency. This is because employees are the backbone of any manufacturing operation, and their knowledge, skills, and experience are critical to achieving the desired outcomes. There are several reasons why training and education are important for improving chemical manufacturing efficiency.

First, training and education help employees understand the importance of their role in manufacturing. When employees are knowledgeable about the business's overall goals and the expected outcomes, they are more likely to take ownership of their work and strive for excellence. This can help to improve the quality and consistency of products, reduce errors and downtime, and ultimately improve the efficiency of the manufacturing process.

Second, training and education can help employees to develop new skills and knowledge that can be applied to their work. This is particularly important in the rapidly-evolving field of chemical manufacturing, where new technologies and practices are constantly emerging.

By providing regular training and education opportunities, businesses can ensure that their employees are up-to-date on the latest best practices, safety protocols, and technologies. This can help improve the manufacturing process's efficiency by reducing errors, improving communication and collaboration, and leveraging the latest tools and techniques.

Finally, training and education can help to foster a culture of continuous improvement within a manufacturing organization. By encouraging employees to think critically, identify areas for improvement, and propose solutions, businesses can tap into the collective knowledge and experience of their workforce. This can lead to innovative new approaches to manufacturing, reduced waste and downtime, and increased overall efficiency.

By investing in their employees, businesses can improve quality, reduce errors, and promote a culture of continuous improvement that can help drive success for years.

Conclusion

By implementing a variety of strategies, such as improving equipment maintenance, streamlining production workflows, and leveraging data analytics, manufacturers can identify and address bottlenecks in their processes, reduce downtime, and increase throughput.

In addition to these process-focused strategies, it's also important to consider the environmental impact of chemical manufacturing processes. By incorporating sustainable practices such as recovering and reusing materials, minimizing waste, and conserving resources, businesses can not only improve their bottom line but also reduce their carbon footprint and positively impact the planet.

Overall, optimizing chemical manufacturing processes is an ongoing process that requires ongoing evaluation and adjustment. By continually seeking out opportunities for improvement and adopting new technologies and practices, businesses can achieve their productivity, profitability, and sustainability goals.

How can Deskera Help You?

Deskera's integrated financial planning tools help investors plan and track their investments more effectively. It can help investors make more accurate and timely decisions.

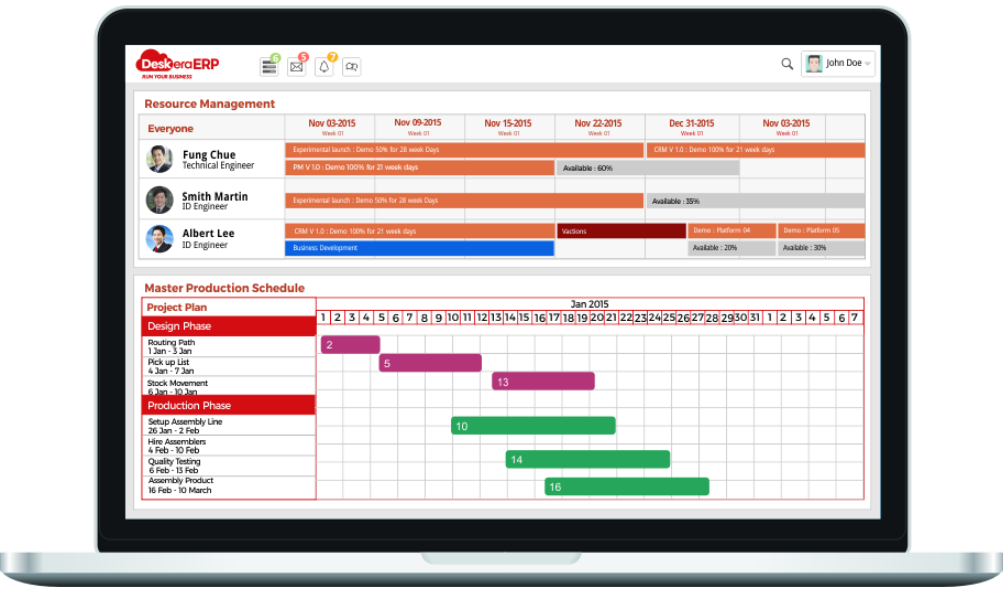

Deskera MRP monitors the manufacturing process in real time. From the bill of materials to the production planning features, the solution helps you stay on top of your game and maintain your company's competitive edge.

Deskera Books can assist you in automating your accounting and lowering business risks. Deskera simplifies invoice creation by automating many other procedures, reducing your team's administrative workload.

Deskera also offers integrated applications to help businesses manage their finances, inventory, and operations. Other business aspects include human resources (Deskera People), customer relationship management (Deskera CRM), and Deskera ERP.

Key Takeaways

- Efficiency is a critical factor in chemical manufacturing because it directly impacts a business's profitability and competitiveness.

- Determining areas for optimization and analyzing constraints are some of the ways to evaluate the current manufacturing process.

- Streamline process steps by mapping out the steps, identifying and eliminating the unnecessary steps, and

- Ensure effective use of resources and raw materials. Reduce energy consumption and reuse materials to achieve higher efficiency.

- Educating staff is essential if you look forward to optimizing chemical manufacturing processes for maximum efficiency.

Related Articles