Ever wondered why your stock levels look accurate on paper but never match what’s actually on the shelves? The answer lies in one critical factor many businesses overlook: inventory visibility. Without a clear, real-time view of where your inventory is, how fast it moves, and what’s needed next, even well-run operations can experience delays, stockouts, excess stock, and frustrated customers.

Inventory visibility is the foundation of efficient supply chain management. It provides end-to-end transparency—from suppliers and warehouses to retail shelves and customer deliveries. When businesses know exactly what they have and where it is, decision-making becomes faster, demand planning becomes smarter, and overall operational efficiency improves dramatically. In a world where speed and accuracy define competitiveness, real-time visibility is no longer optional.

However, achieving this level of visibility is not always easy. Many companies struggle with siloed systems, manual spreadsheets, fragmented data, and outdated processes that limit their ability to see the whole picture. These blind spots often lead to poor forecasting, fulfillment delays, rising costs, and an inability to respond quickly to market changes. Improving inventory visibility is therefore one of the most powerful ways to strengthen supply chain readiness and future-proof operations.

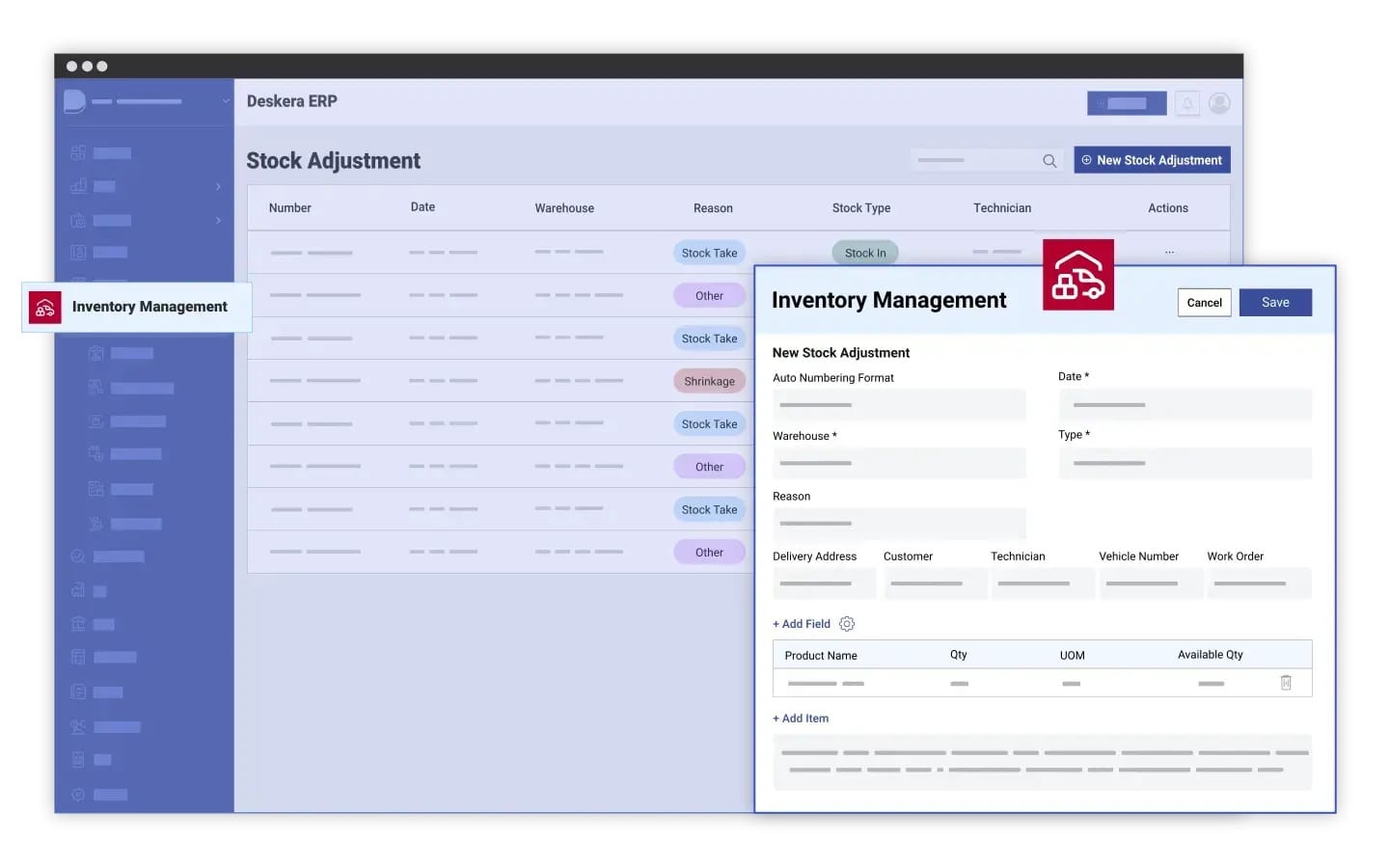

This is where a modern ERP system like Deskera ERP becomes invaluable. Deskera ERP consolidates inventory data from multiple locations, automates stock updates in real time, and offers advanced insights through its integrated modules. Its built-in mobile app and AI-powered predictions help businesses minimize errors, improve planning accuracy, and keep operations running smoothly. By providing a single source of truth, Deskera ERP enables companies to achieve the high level of visibility needed to grow efficiently and confidently.

What Is Inventory Visibility?

Inventory visibility is the ability to track, monitor, and access accurate, real-time information about your stock—its location, quantity, status, and movement at every stage of the supply chain. It goes far beyond basic stock counting. True visibility means knowing exactly what you have, where it is, and what’s available to sell or use in production at any given moment.

At its core, inventory visibility connects all types of stock—raw materials, work-in-progress (WIP), and finished goods—across warehouses, production floors, retail stores, distribution centers, and even items in transit. This end-to-end transparency helps businesses allocate resources better, avoid production delays, prevent stockouts and overstocks, and reduce unnecessary carrying costs. With clear visibility, teams can identify slow-moving or obsolete stock early and make smarter replenishment and procurement decisions.

Modern supply chains rely heavily on technology to achieve this level of accuracy and speed. Tools like barcode scanning, RFID, IoT sensors, cloud-based WMS/ERP systems, and demand forecasting ensure that inventory data updates continuously and automatically. This not only reduces manual errors but also helps teams coordinate cross-location transfers, streamline fulfillment, and answer availability questions instantly.

Inventory visibility ultimately acts as a pillar of effective supply chain management, ensuring that procurement, planning, allocation, and fulfillment teams all work from the same source of truth. When businesses have real-time insight into every unit of stock, they gain the agility to meet fluctuating customer demand, maintain operational continuity, and boost overall profitability.

Components of Inventory Visibility

Effective inventory visibility is built on several interconnected components that work together to deliver complete, real-time insight into stock levels, movement, and availability. These components ensure that every team—from procurement to fulfillment—has accurate, actionable data to make better decisions and prevent disruptions.

1. Real-Time Inventory Tracking

Real-time tracking uses barcode scanners, RFID tags, and IoT sensors to monitor products as they move through the supply chain. These tools automate updates, eliminate manual errors, and can even capture environmental conditions like temperature or humidity for sensitive goods. Continuous tracking ensures that inventory data stays current across all stages—from receiving to storage to dispatch.

2. Multi-Location Synchronization

Modern supply chains operate across multiple warehouses, factories, retail outlets, and distribution centers. Multi-location synchronization unifies all inventory data into a centralized, cloud-based system. This ensures that teams—whether onsite or remote—have instant access to accurate stock levels, transfer details, and order statuses across all facilities and channels.

3. Inventory Reconciliation

Discrepancies between physical counts and digital records can lead to shrinkage, stockouts, or overstocks. Automated reconciliation tools detect mismatches early, enabling teams to correct errors, identify damaged or missing stock, and maintain the integrity of inventory data. This helps reduce financial loss and improves confidence in system-generated insights.

4. Automated Alerts and Notifications

Smart alert systems notify stakeholders when inventory metrics fall outside acceptable thresholds—such as low stock, delayed shipments, or rising fulfillment times. These proactive notifications allow teams to respond before issues escalate, preventing production interruptions and improving order accuracy.

5. Mobile Access and On-the-Go Updates

Mobile devices, handheld scanners, and tablets give warehouse staff, production teams, and managers the ability to check availability, process transfers, and update stock records from anywhere. This keeps operations fast, reduces miscommunication, and ensures every update is captured in real time.

6. Reporting and Analytics

Dashboards and analytics tools convert raw inventory data into meaningful insights using metrics like turnover rates, carrying costs, demand patterns, and order accuracy. Advanced analytics and scenario modeling help managers identify slow-moving items, detect risk areas, optimize purchasing, and forecast future needs.

7. Location Awareness

Knowing exactly where each item is stored—whether on a shelf, in a bin, in a retail display, or in transit—reduces time wasted during picking, improves route planning inside warehouses, and enhances space utilization. Location awareness ensures accurate and timely order fulfillment.

8. Stock Level Accuracy

Precise, continuously updated stock counts prevent overstocking, stockouts, and emergency purchasing. Accurate stock levels improve purchasing decisions, reduce carrying costs, and keep order promises reliable.

9. Status Tracking

Inventory status indicates whether stock is available, reserved, in transit, under inspection, or awaiting replenishment. Clear status visibility helps teams plan production, manage fulfillment, and allocate stock effectively across channels.

10. Movement Tracking

Tracking the movement history of inventory—shipping times, transfer routes, transit durations—helps businesses manage lead times, anticipate delays, and avoid bottlenecks. Movement data also improves traceability and supports better demand planning.

Together, these components create a unified and transparent inventory ecosystem, enabling businesses to operate with greater efficiency, accuracy, and agility. If you'd like, I can also turn this into a shorter list, a more formal version, or an SEO-optimized section.

How Does Inventory Visibility Work?

Inventory visibility works by connecting people, processes, and technology to create a real-time, unified view of stock across the entire supply chain. It relies on integrated systems—such as ERPs, WMS platforms, POS systems, and tracking hardware—to capture every movement of inventory from procurement to fulfillment.

These systems continuously sync data across locations, enabling businesses to automate replenishment, optimize picking routes, reduce errors, and respond instantly to demand changes. Below are the key components that explain how inventory visibility functions in day-to-day operations.

1. Real-Time Data Capture at Every Touchpoint

Inventory visibility begins the moment products enter the supply chain. Teams use barcode scanners, RFID tags, IoT sensors, and digital receiving tools to record item details accurately. This ensures that from the point of receipt, the system maintains trustworthy, error-free data that flows through purchasing, production, storage, and distribution.

2. Centralized Inventory Management Systems

Systems like ERP and WMS consolidate data from multiple warehouses, production lines, retail outlets, and sales channels. This centralization eliminates data silos and ensures that every team—from procurement to finance—operates from the same up-to-date information. It supports accurate forecasting, planning, and real-time decision-making.

3. Mobile Scanning and On-the-Go Updates

Warehouse and fulfillment teams use handheld scanners, tablets, and mobile apps to update stock movements instantly. Whether picking, transferring, packing, or adjusting stock, these real-time updates help maintain high accuracy and prevent discrepancies between physical and digital records.

4. Automated Workflows and Replenishment

Integrated systems automate tasks like reordering, safety stock triggers, pick-path optimization, and allocation across locations. This reduces human effort, speeds up fulfillment, and ensures inventory is replenished before shortages occur. Automation also helps streamline returns, damaged goods tracking, and cycle count scheduling.

5. Inventory Control Methods and Classification

Businesses use structured methods such as FIFO, LIFO, ABC analysis, or batch tracking to manage inventory efficiently. These methods ensure better control, reduce expired or obsolete stock, and help teams prioritize high-value or fast-moving items for better visibility and planning.

6. Routine Cycle Counts and Audits

Regular cycle counts, spot checks, and periodic audits validate system records. This ongoing reconciliation helps detect discrepancies, prevent shrinkage, and maintain accurate stock data. Strong audit discipline ensures inventory visibility remains reliable over time.

7. Continuous Cross-Location Synchronization

Inventory visibility is sustained through real-time synchronization between warehouses, distribution centers, in-transit shipments, retail outlets, and online channels. Cloud-based systems ensure that stock updates made in one location reflect everywhere instantly, enabling smarter allocation and faster customer response.

Impact of Poor Inventory Visibility

Poor inventory visibility creates blind spots that quickly ripple across operations, customer experience, and financial performance. When businesses lack accurate, real-time insight into stock levels and movement, decisions are driven by assumptions rather than data—leading to inefficiencies, rising costs, and lost revenue.

1. Overstocking and Capital Misallocation

Without clear visibility into actual inventory levels and demand, businesses often overestimate requirements and overstock. Excess inventory ties up working capital, increases storage and insurance costs, and limits cash available for growth initiatives. Over time, this misallocation weakens financial flexibility and profitability.

2. Stockouts and Lost Sales

Poor visibility makes it difficult to anticipate shortages, resulting in frequent stockouts. When customers can’t find the products they need, sales are lost and trust erodes. In competitive markets, repeated stockouts can permanently push customers toward competitors and damage brand loyalty.

3. Inefficient Fulfillment and Higher Labor Costs

When inventory data is unreliable, warehouse teams spend extra time searching for items, resolving discrepancies, and correcting errors. This slows order fulfillment, increases labor costs, and often leads to expedited shipping to meet deadlines. The result is higher operational expense and reduced efficiency.

4. Inaccurate Demand Forecasting

Limited visibility into historical and real-time inventory trends undermines demand forecasting. Businesses struggle to align production and procurement with actual demand, leading to overproduction or shortages. These forecasting errors disrupt planning cycles and directly impact revenue and margins.

5. Increased Holding and Obsolescence Costs

Excess inventory caused by poor visibility drives up carrying costs, including warehousing, insurance, and handling. It also increases the risk of spoilage, damage, or obsolescence—especially for perishable, seasonal, or fast-changing products—forcing markdowns and write-offs.

6. Data Errors and Inventory Discrepancies

Manual data entry and delayed updates introduce inaccuracies that compound over time. Discrepancies between physical stock and system records reduce trust in inventory data, complicate audits, and create downstream issues in planning, fulfillment, and financial reporting.

Overall, poor inventory visibility doesn’t just disrupt day-to-day operations—it weakens customer relationships, inflates costs, and limits a business’s ability to scale efficiently.

Benefits of Inventory Visibility

Inventory visibility is essential for maintaining accurate stock data and ensuring smooth operations across the supply chain. It helps businesses reduce errors, make faster decisions, and align purchasing, production, and fulfillment activities. With real-time insights, companies can prevent disruptions, improve customer satisfaction, and boost overall efficiency.

1. Reduces Stockouts and Overstocks

Effective visibility ensures businesses maintain optimal stock levels by identifying shortages and excesses before they affect operations. Teams can proactively adjust orders, redistribute inventory across locations, and avoid tying up capital in slow-moving items. This balance reduces waste, prevents lost sales, and strengthens supply chain reliability end-to-end.

2. Improves Demand Forecasting

With accurate historical and real-time data, businesses can better understand sales trends and consumption patterns. Visibility enables more precise forecasting, reduces guesswork, and helps companies plan procurement and production with confidence. This leads to fewer surprises, smoother operations, and improved inventory turnover throughout the year.

3. Enables Smarter Resource Allocation

Strong visibility helps businesses allocate inventory efficiently across warehouses, retail outlets, and fulfillment centers. Teams can identify where stock is needed most, reduce transfer delays, and optimize delivery routes. This strategic distribution minimizes operational disruptions, shortens lead times, and enables faster order fulfillment during peak demand.

4. Strengthens Omnichannel Management

For retailers and ecommerce businesses, visibility ensures accurate stock levels across online stores, marketplaces, and physical locations. It prevents overselling, supports flexible fulfillment options like BOPIS, and synchronizes inventory across all channels. This unified view strengthens customer trust and ensures seamless experiences across touchpoints.

5. Enhances Customer Experience

When businesses know exactly what they have and where it is, customers receive accurate delivery promises and timely updates. Visibility reduces delays, prevents canceled orders, and ensures that products are consistently available. This reliability increases customer satisfaction, boosts repeat purchases, and strengthens long-term brand loyalty.

6. Lowers Supply Chain Costs

With clear insights into inventory movement and performance, businesses can identify wasteful practices and unnecessary expenses. Visibility helps reduce storage costs, minimize spoilage and obsolescence, and streamline labor-intensive manual tasks. Over time, these efficiencies significantly lower operational costs and improve profit margins.

7. Boosts Operational Efficiency

Real-time data reduces manual effort, eliminates duplication, and speeds up workflows across warehouse and production teams. Visibility helps employees locate items faster, resolve discrepancies quickly, and perform tasks with greater accuracy. This leads to smoother processes, fewer errors, and a more productive supply chain environment.

8. Improves Order Accuracy

Accurate visibility ensures that inventory records match physical stock, reducing the likelihood of incorrect shipments. Teams can confidently fulfill orders based on real-time availability, preventing backorders and split deliveries. Consistent accuracy strengthens customer trust, reduces return rates, and ensures a more efficient fulfillment process.

9. Increases Agility and Resilience

With real-time visibility, businesses can quickly respond to disruptions such as supplier delays, demand spikes, or transportation issues. Teams can reroute inventory, adjust production plans, and prevent stockouts before they occur. This agility improves resilience and protects revenue during unexpected changes in supply or demand.

10. Supports Better Decision-Making

Inventory visibility provides leaders with reliable, consolidated data for strategic planning. It helps forecast inventory needs, identify performance gaps, and optimize purchasing decisions. With clearer insight into trends and movement, businesses make faster, more informed decisions that support long-term operational and financial goals.

11. Boosts Profitability and Cash Flow

By minimizing waste, reducing excess inventory, and improving turnover, visibility directly enhances profitability. Better control over stock reduces carrying costs and frees up cash for growth-focused initiatives. Over time, the cumulative benefits—fewer errors, better planning, and faster fulfillment—translate into stronger, more predictable cash flow.

Key Challenges in Achieving Inventory Visibility

Achieving accurate inventory visibility is not just a technology issue—it also involves process alignment, data discipline, and organizational readiness. Many businesses struggle with outdated systems, manual workflows, and fragmented data, which create blind spots across the supply chain. Below are the most common challenges that prevent companies from gaining reliable, real-time inventory visibility.

1. Legacy Systems and Technology Limitations

Older ERP, ecommerce, or inventory platforms often lack real-time tracking and integration capabilities. These systems were not designed for multi-location or omnichannel operations, making it difficult to sync inventory data accurately. As a result, updates are delayed, visibility is fragmented, and decision-making relies on outdated information.

2. Manual Processes and Human Errors

Manual inventory tracking, spreadsheet-based updates, and physical counts are time-consuming and error-prone. Miscounts, missed entries, and delayed updates quickly lead to discrepancies between physical stock and system records. These errors reduce data reliability and make it difficult to maintain optimal stock levels across locations.

3. Data Silos Across Systems and Teams

When inventory, sales, procurement, and logistics systems are not integrated, data gets trapped in silos. Different teams may work with conflicting numbers, causing delays, misaligned decisions, and poor customer experiences. Lack of end-to-end visibility also makes it harder to trace inventory movement across partners and channels.

4. Inaccurate or Unrecorded Inventory Changes

Unrecorded losses due to theft, damage, spoilage, or breakage weaken inventory accuracy. Without automated reconciliation or regular audits, these discrepancies go unnoticed and compound over time. This results in unreliable planning, unexpected stockouts, and excess safety stock added as a buffer.

5. Inefficient Warehouse Layouts and Processes

Disorganized warehouses with poor labeling, inconsistent bin sizes, and inefficient product placement reduce visibility at the ground level. When staff struggle to locate items quickly, picking errors increase and inventory counts become unreliable. Physical inefficiencies directly undermine system-level inventory accuracy.

6. Lack of Real-Time Tracking Capabilities

Without barcode scanning, RFID, or mobile devices, inventory updates are often delayed until the end of a shift or day. This lag creates blind spots, especially in fast-moving environments. Real-time visibility becomes impossible when stock movement is not captured at the moment it occurs.

7. Poor Demand Planning and Reactive Management

Limited visibility forces teams to react after problems arise rather than preventing them. Managers receive late notifications of shortages or delays, leaving little room for corrective action. This reactive approach leads to speculative ordering, excess inventory, and frequent firefighting across operations.

8. Scalability Challenges as the Business Grows

As order volumes increase and new warehouses, products, or sales channels are added, inventory systems must scale seamlessly. Many businesses outgrow their initial tools, leading to performance issues, slower updates, and increased complexity. Poor scalability limits long-term visibility and operational agility.

9. High Cost of Modernization and Integration

Upgrading inventory systems involves software, hardware, integration, training, and ongoing maintenance costs. For small and mid-sized businesses, this investment can feel intimidating. However, delaying modernization often results in higher long-term costs through inefficiencies, lost sales, and excess inventory.

10. Resistance to Change and Low Adoption

Even the best systems fail without user adoption. Employees may resist new tools or processes due to lack of training or fear of disruption. Poor change management slows implementation, reduces data quality, and delays ROI—preventing businesses from fully realizing the benefits of inventory visibility.

Strategies to Improve Inventory Visibility

Improving inventory visibility requires a combination of the right technology, streamlined processes, and cross-functional alignment. The following strategies help businesses gain accurate, real-time insight into inventory across locations, channels, and supply chain partners—enabling faster decisions and more resilient operations.

1. Implement an Integrated Inventory Management System

A centralized inventory management system acts as a single source of truth for stock levels, movement, and availability. When integrated with WMS, ERP, and order management systems, it eliminates data silos, ensures real-time updates, and improves coordination across procurement, warehousing, sales, and finance teams.

2. Use Barcode, RFID, and IoT Technologies

Automated data capture technologies such as barcode scanners, RFID tags, and IoT-enabled sensors significantly improve inventory accuracy. These tools track items in real time, reduce manual errors, speed up receiving and picking, and enable condition monitoring for sensitive or perishable goods.

3. Invest in Warehouse Management Software (WMS)

A robust WMS improves visibility at the warehouse level by tracking bin locations, stock movement, picking paths, and cycle counts. Optimized layouts, clear labeling, and system-guided picking reduce search time, improve fulfillment accuracy, and strengthen overall inventory transparency.

4. Leverage ERP Platforms for End-to-End Visibility

ERP systems connect inventory data with procurement, production, sales, and accounting. This end-to-end visibility allows businesses to respond quickly to demand changes, automate replenishment, manage multi-location inventory, and maintain consistency across channels and business units.

5. Centralize Data Across Channels and Locations

Synchronizing inventory data from e-commerce platforms, retail stores, warehouses, and third-party logistics providers ensures consistent stock information everywhere. A unified view prevents overselling, reduces stock imbalances, and enables smarter allocation decisions across locations.

6. Automate Cycle Counts and Inventory Audits

Automated cycle counting improves data accuracy without disrupting operations. Frequent, system-driven counts help identify discrepancies early, reduce shrinkage, and build confidence in inventory data—freeing staff to focus on higher-value activities like fulfillment and customer service.

7. Optimize Processes and Standardize Data

Well-defined inventory processes supported by standardized product identifiers, units of measure, and data formats improve consistency across systems. Process discipline—combined with automation—ensures reliable data flows and makes inventory visibility scalable as operations grow.

8. Enable Mobile Access for Real-Time Updates

Providing mobile access to inventory tools allows teams to scan, update, and verify stock from anywhere on the warehouse floor or in transit. Mobile devices reduce delays, improve communication, and ensure decisions are always based on current information.

9. Collaborate with Suppliers and Logistics Partners

Extending visibility beyond internal systems to suppliers and logistics partners improves replenishment planning and lead-time reliability. Shared data on inventory levels, demand forecasts, and shipment status helps create a more responsive and resilient supply chain.

10. Use Analytics for Forecasting and Continuous Improvement

Advanced reporting and analytics transform raw inventory data into actionable insights. By monitoring trends such as turnover, aging stock, and demand patterns, businesses can improve forecasting accuracy, reduce excess inventory, and continuously refine inventory strategies.

Together, these strategies create a connected, data-driven inventory ecosystem that supports accuracy, agility, and long-term operational efficiency.

How to Measure the Success of Your Inventory Visibility Strategy

Measuring the success of your inventory visibility strategy goes beyond confirming system adoption—it requires tracking the right performance metrics that reflect accuracy, efficiency, and business impact. By monitoring a focused set of KPIs, businesses can assess whether visibility improvements are translating into better operational and financial outcomes.

Inventory Accuracy KPIs

- Inventory Accuracy Rate – Compares system-recorded stock levels with physical inventory

- Cycle Count Accuracy – Measures consistency between routine counts and system data

- Shrinkage Rate – Tracks losses due to theft, damage, or recording errors

Supply Chain Efficiency KPIs

- Inventory Turnover Ratio – Indicates how frequently inventory is sold and replenished

- Perfect Order Rate – Measures the percentage of error-free, on-time deliveries

- Supply Chain Cycle Time – Tracks the time taken from order placement to final delivery

Stock Availability & Service-Level KPIs

- Stockout Rate – Measures how often items are unavailable when needed

- Backorder Frequency – Indicates demand not fulfilled immediately due to shortages

- Order Fill Rate – Shows the percentage of customer demand met from available inventory

Cost & Working Capital KPIs

- Inventory Carrying Costs – Includes storage, insurance, and obsolescence expenses

- Obsolete or Slow-Moving Inventory – Identifies excess stock tying up capital

- Days Inventory Outstanding (DIO) – Measures how long inventory sits before being sold

Operational Productivity KPIs

- Picking Accuracy – Tracks correct item selection during order fulfillment

- Order Processing Time – Measures speed from order receipt to shipment

- Labor Hours per Order – Indicates workforce efficiency in inventory handling

ROI & Technology Performance KPIs

- Order Fulfillment Accuracy – Reflects improvements driven by better visibility

- Labor Efficiency Gains – Measures time saved through automation

- Inventory Visibility ROI – Compares cost savings and performance gains against system investment

This KPI set provides a comprehensive view of accuracy, efficiency, customer impact, and financial returns from your inventory visibility initiatives.

How Deskera ERP Helps Improve Inventory Visibility

Deskera ERP strengthens inventory visibility by unifying inventory data, automating tracking, and delivering real-time insights across the supply chain. By replacing disconnected systems and manual processes with a single, cloud-based platform, Deskera enables businesses to see exactly what stock they have, where it is, and how it’s moving—at any moment.

Centralized, Real-Time Inventory Tracking

Deskera ERP provides a single source of truth for inventory across warehouses, production units, and sales channels. Stock levels update in real time as goods are received, issued, transferred, or sold, ensuring teams always work with accurate, up-to-date data.

Multi-Location and Multi-Warehouse Visibility

Businesses can track inventory by location, bin, batch, or serial number across multiple warehouses. This visibility supports smarter allocation, faster inter-warehouse transfers, and improved order fulfillment without overstocking or shortages.

Seamless Integration with Procurement, Sales, and Production

Inventory data in Deskera ERP is tightly integrated with purchasing, manufacturing (MRP), and sales modules. This allows inventory to automatically adjust based on purchase orders, production runs, and customer orders, improving planning accuracy and reducing manual reconciliation.

Batch, Serial, and Expiry Tracking

For industries handling perishable or regulated goods, Deskera ERP supports batch-wise, serial-wise, and expiry-date tracking. This helps maintain quality control, reduce wastage, and ensure compliance while improving visibility into inventory status.

Automated Reordering and Smart Alerts

Deskera ERP enables businesses to set reorder levels and receive automated alerts when stock falls below thresholds. This proactive approach prevents stockouts and overstocking while keeping procurement aligned with real-time demand.

Advanced Reporting and Inventory Analytics

Built-in dashboards and reports provide clear visibility into key metrics such as inventory turnover, aging stock, carrying costs, and movement trends. These insights help decision-makers identify slow-moving items, optimize stock levels, and improve forecasting.

Mobile Access and Operational Flexibility

With cloud and mobile access, warehouse and operations teams can update inventory, approve transfers, and check availability on the go. This ensures consistent visibility even in fast-moving or distributed environments.

By combining real-time tracking, integrated workflows, and actionable analytics, Deskera ERP transforms inventory visibility from a reactive function into a strategic advantage, enabling better control, faster decisions, and more resilient supply chains.

Key Takeaways

- Inventory visibility is the ability to track inventory quantity, location, status, and movement in real or near real time across the entire supply chain, enabling accurate decisions and smoother operations.

- Effective inventory visibility depends on accurate tracking, location awareness, status updates, movement history, system synchronization, and analytics working together as a unified data layer.

- Inventory visibility works through connected systems—such as ERP, WMS, and scanners—that capture inventory data at every touchpoint and continuously update it for enterprise-wide access.

- Limited visibility leads to stockouts, excess inventory, higher carrying costs, inefficient fulfillment, poor forecasting, and lost customer trust, directly impacting profitability and growth.

- Inventory visibility enables businesses to maintain optimal stock levels, reduce costs, prevent stockouts and overstocking, and make faster, data-driven decisions—resulting in smoother operations, better customer satisfaction, and stronger overall supply chain performance.

- Legacy systems, manual processes, data silos, integration complexity, and resistance to change are major barriers that prevent businesses from achieving consistent, real-time visibility.

- Businesses can improve visibility by adopting ERP and WMS platforms, automating data capture with barcodes or RFID, centralizing data, optimizing warehouse processes, and collaborating across the supply chain.

- The success of inventory visibility initiatives should be measured using KPIs such as inventory accuracy, turnover, stockout rates, carrying costs, fulfillment accuracy, and overall ROI.

- Deskera ERP delivers real-time, multi-location inventory visibility by integrating inventory with procurement, sales, and production, supported by automation, smart alerts, and advanced analytics.

Related Articles