What is the secret to running a seamless supply chain that consistently meets customer demands while minimizing costs? The answer lies in mastering supply chain inventory management.

Efficiently managing supply chain inventory ensures that the right products are available at the right time, in the right quantities, and at the right cost, making it a critical component of any successful business.

Supply chain management (SCM) involves the coordinated efforts of sourcing, production, and distribution processes to deliver goods to consumers efficiently. By integrating various functions such as procurement, logistics, and inventory control, SCM aims to maximize customer value while minimizing operational costs.

However, managing inventory within the supply chain comes with significant challenges. Balancing inventory levels to avoid stockouts or overstocking, predicting demand accurately, and managing supplier relationships are just a few hurdles businesses face. These challenges can lead to inefficiencies, increased costs, and customer dissatisfaction if not addressed properly.

This is where effective supply chain inventory control plays a pivotal role. By optimizing inventory control processes, businesses can reduce waste, improve cash flow, and ensure product availability. In turn, this leads to enhanced operational efficiency, cost savings, and ultimately, business success.

When it comes to optimizing supply chain processes, Deskera ERP stands out as a comprehensive solution. With advanced features like real-time inventory tracking, automated order management, and AI-driven demand forecasting, Deskera ERP empowers businesses to streamline their supply chain operations. This all-in-one platform helps companies maintain optimal inventory levels, reduce costs, and enhance overall efficiency.

What is Supply Chain Inventory Control?

Supply chain inventory control is the process of managing and regulating the flow of goods, materials, and products within a supply chain to ensure they are available in the right quantities, at the right time, and at the right locations. It involves balancing supply and demand to avoid issues such as stockouts, overstocking, and excess holding costs.

Effective supply chain inventory control includes practices like accurate demand forecasting, real-time inventory tracking, and the strategic placement of safety stock. By optimizing these processes, businesses can reduce waste, minimize costs, improve customer satisfaction, and enhance overall efficiency across the supply chain.

Key Components of Supply Chain Inventory Control

Supply chain inventory control comprises several key components that work together to ensure effective management of inventory across the supply chain:

- Demand Forecasting: Predicting future customer demand is crucial for maintaining optimal inventory levels. Accurate forecasting helps businesses plan production, procurement, and replenishment activities, reducing the risk of stockouts or overstocking.

- Inventory Tracking and Visibility: Real-time tracking of inventory levels across various locations (warehouses, distribution centers, retail stores) is essential for effective inventory control. It allows businesses to monitor stock levels, track the movement of goods, and make informed decisions about replenishment and distribution.

- Reorder Point and Safety Stock: Establishing reorder points and maintaining safety stock ensures that inventory is replenished before it runs out. Safety stock acts as a buffer against demand fluctuations or supply chain disruptions, helping to prevent stockouts and maintain service levels.

- Lead Time Management: Understanding and managing lead times—the time taken for inventory to be replenished from suppliers—is critical for maintaining adequate inventory levels. Shortening lead times or accurately accounting for them in inventory planning can improve responsiveness and reduce the need for excess inventory.

- Inventory Turnover Ratio: This metric measures how often inventory is sold and replaced over a specific period. A higher turnover ratio indicates efficient inventory management, while a lower ratio may suggest overstocking or slow-moving inventory.

- Just-in-Time (JIT) Inventory: JIT is an inventory control strategy where materials and products are ordered and received only as they are needed in the production process, minimizing inventory holding costs and reducing waste.

- Supplier Relationship Management: Strong relationships with reliable suppliers are essential for ensuring timely deliveries and consistent quality. Good supplier management helps in negotiating favorable terms, securing better lead times, and reducing the risk of supply chain disruptions.

- Inventory Audits and Reviews: Regular audits and reviews of inventory levels help identify discrepancies, outdated stock, and inefficiencies in the inventory control process. This ensures that inventory records are accurate and that inventory levels are optimized.

By effectively managing these components, businesses can achieve a balanced and efficient supply chain inventory control system that supports their overall operational goals.

The Role of Supply Chain Inventory Control in the Overall Supply Chain Process

Supply chain inventory control plays a critical role in ensuring that the overall supply chain process functions smoothly and efficiently. Here’s how it impacts various aspects of the supply chain:

- Balancing Supply and Demand: Effective inventory control ensures that there is a proper balance between supply and demand. By maintaining optimal inventory levels, businesses can prevent stockouts that could disrupt customer satisfaction and avoid overstocking that ties up capital and increases holding costs.

- Enhancing Efficiency: By optimizing inventory levels and implementing strategies such as just-in-time (JIT) inventory, businesses can reduce excess inventory and minimize waste. This leads to a more streamlined supply chain, with fewer bottlenecks and interruptions in production or distribution.

- Improving Cash Flow: Proper inventory control helps manage cash flow by minimizing excess inventory and reducing carrying costs. This allows businesses to allocate financial resources more effectively, invest in other areas of the business, and improve overall profitability.

- Facilitating Smooth Operations: Accurate inventory control supports smooth operations by ensuring that materials and products are available when needed. This reduces delays in production and distribution, improves order fulfillment rates, and enhances customer satisfaction.

- Optimizing Resource Utilization: By maintaining optimal inventory levels, businesses can better utilize their resources, including warehouse space, labor, and transportation. This leads to more efficient use of assets and a reduction in operational costs.

- Enabling Better Decision-Making: Real-time inventory data provides valuable insights into inventory levels, demand patterns, and supplier performance. This information supports informed decision-making, allowing businesses to respond quickly to market changes and operational challenges.

- Strengthening Supplier Relationships: Effective inventory control often involves close coordination with suppliers. By managing inventory levels and lead times effectively, businesses can build stronger relationships with suppliers, negotiate better terms, and ensure timely deliveries.

In summary, supply chain inventory control is integral to the overall supply chain process. It ensures that inventory levels are aligned with demand, supports efficient operations, enhances cash flow, and contributes to better decision-making, ultimately leading to a more responsive and profitable supply chain.

Benefits of Effective Supply Chain Inventory Control

The benefits of effective supply chain inventory control are:

Improved Customer Satisfaction

- Description: By maintaining optimal inventory levels, businesses can ensure that products are available when customers need them, leading to timely order fulfillment and reduced stockouts.

- Benefits: Enhances customer experience, fosters loyalty, and strengthens brand reputation.

Reduced Holding Costs

- Description: Effective inventory control minimizes the amount of inventory held at any given time, thereby reducing costs associated with storage, insurance, and obsolescence.

- Benefits: Lowers operational expenses and improves overall profitability.

Enhanced Cash Flow

- Description: By optimizing inventory levels and reducing excess stock, businesses can free up capital that can be invested in other areas of the business.

- Benefits: Improves liquidity, supports business growth, and enhances financial stability.

Increased Operational Efficiency

- Description: Streamlined inventory management processes, such as accurate demand forecasting and real-time tracking, lead to smoother operations and reduced disruptions.

- Benefits: Boosts productivity, reduces lead times, and minimizes bottlenecks in the supply chain.

Better Inventory Visibility

- Description: Effective inventory control provides real-time visibility into stock levels, locations, and movements, enabling more informed decision-making and proactive management.

- Benefits: Enhances accuracy in inventory records, improves coordination, and supports strategic planning.

Lower Risk of Stockouts and Overstocks

- Description: Accurate forecasting and timely replenishment help prevent situations where inventory is either too low or too high, reducing the risk of lost sales or excessive holding costs.

- Benefits: Ensures product availability, avoids sales losses, and maintains a balanced inventory.

Optimized Resource Utilization

- Description: Efficient inventory management allows for better use of resources such as warehouse space, labor, and transportation, leading to cost savings and improved operational effectiveness.

- Benefits: Enhances overall efficiency and reduces waste.

Enhanced Supplier Relationships

- Description: Effective inventory control involves close collaboration with suppliers, leading to better communication, timely deliveries, and improved supply chain reliability.

- Benefits: Strengthens partnerships, secures favorable terms, and enhances supply chain performance.

Increased Competitive Advantage

- Description: Businesses with effective inventory control can respond more quickly to market changes, adapt to demand fluctuations, and provide superior service compared to competitors.

- Benefits: Enhances market position, improves customer satisfaction, and drives business growth.

Data-Driven Decision-Making

- Description: Accurate inventory data and analytics provide valuable insights into inventory performance, trends, and areas for improvement, supporting informed decision-making.

- Benefits: Enables strategic planning, optimizes inventory management practices, and enhances overall decision-making.

By leveraging these benefits, businesses can achieve greater efficiency, improve financial performance, and build stronger relationships with customers and suppliers.

Challenges in Supply Chain Inventory Control and Effective Solutions

Some of the challenges that you will encounter in supply chain inventory control and how you can solve them are:

1. Inaccurate Demand Forecasting

- Challenge: Misestimating future demand can lead to stockouts or overstocking, affecting customer satisfaction and operational efficiency.

- Solution: Implement advanced forecasting tools and techniques, such as predictive analytics and machine learning, to improve forecast accuracy. Regularly review and adjust forecasts based on real-time data and market trends.

2. Poor Inventory Visibility

- Challenge: Lack of real-time visibility into inventory levels and movements can result in discrepancies, delays, and inefficiencies.

- Solution: Use technologies like barcode scanning, RFID, and IoT sensors to provide real-time inventory tracking. Integrate inventory management systems with other business functions for a comprehensive view.

3. Excess Inventory and Obsolescence

- Challenge: Holding excessive inventory can increase carrying costs and lead to obsolescence, especially for perishable or trend-sensitive items.

- Solution: Adopt inventory optimization techniques such as Just-in-Time (JIT) and Economic Order Quantity (EOQ) to reduce excess stock. Implement safety stock management to protect against uncertainties.

4. Stockouts and Supply Chain Disruptions

- Challenge: Unplanned stockouts due to supply chain disruptions or inaccurate inventory levels can lead to lost sales and customer dissatisfaction.

- Solution: Maintain safety stock levels and establish robust supplier relationships to ensure timely deliveries. Use real-time tracking and automated reorder systems to address potential disruptions promptly.

5. Inefficient Inventory Management Processes

- Challenge: Manual or outdated inventory management processes can lead to errors, inefficiencies, and increased operational costs.

- Solution: Implement modern inventory management software and automation tools to streamline processes, reduce manual errors, and enhance efficiency. Regularly review and refine inventory policies.

6. High Holding Costs

- Challenge: High carrying costs due to excess inventory can impact profitability and tie up capital that could be used elsewhere.

- Solution: Optimize inventory levels using data-driven strategies to minimize holding costs. Implement inventory turnover analysis and adjust stock levels based on demand patterns.

7. Inconsistent Data and Reporting

- Challenge: Inaccurate or inconsistent data can lead to poor decision-making and ineffective inventory control.

- Solution: Use integrated inventory management systems and data analytics tools to ensure accurate and consistent reporting. Conduct regular audits to verify data accuracy.

8. Supplier Reliability Issues

- Challenge: Unreliable suppliers can cause delays, affect inventory levels, and disrupt supply chain operations.

- Solution: Build strong relationships with suppliers, establish clear communication channels, and monitor supplier performance. Consider diversifying suppliers to reduce dependency on a single source.

9. Lack of Coordination Across Departments

- Challenge: Poor coordination between inventory management and other departments (e.g., sales, procurement) can lead to misalignment and inefficiencies.

- Solution: Implement integrated systems such as ERP to facilitate cross-departmental communication and ensure alignment in inventory management practices.

10. Rapid Market Changes

- Challenge: Sudden changes in market conditions, trends, or consumer preferences can impact inventory management and forecasting accuracy.

- Solution: Stay agile by continuously monitoring market trends and consumer behavior. Use flexible inventory management strategies and adjust plans as needed to respond to market changes.

By addressing these challenges with effective strategies, businesses can enhance their supply chain inventory control, improve operational efficiency, and better meet customer demands.

Common Supply Chain Inventory Control Models

The common supply chain inventory control models are:

Just-in-Time (JIT) Inventory:

- Description: This model aims to minimize inventory levels by ordering and receiving goods only as they are needed in the production process. The goal is to reduce holding costs and inventory waste.

- Benefits: Lower inventory carrying costs, reduced waste, and improved cash flow.

- Challenges: Requires accurate demand forecasting and reliable supplier performance. Vulnerable to supply chain disruptions.

Economic Order Quantity (EOQ):

- Description: EOQ is a formula used to determine the optimal order quantity that minimizes the total cost of inventory, including ordering and holding costs.

- Benefits: Balances ordering and holding costs to find the most cost-effective order size.

- Challenges: Assumes constant demand and lead time, which may not always reflect real-world variability.

Reorder Point (ROP) Model:

- Description: This model sets a specific inventory level at which a new order should be placed to replenish stock before it runs out. The reorder point is based on lead time and demand rates.

- Benefits: Prevents stockouts by triggering timely reordering.

- Challenges: Requires accurate data on lead times and demand to set effective reorder points.

Safety Stock Model:

- Description: Safety stock involves maintaining additional inventory as a buffer to protect against uncertainties in demand or supply. The amount of safety stock is calculated based on historical data and variability.

- Benefits: Reduces the risk of stockouts due to demand fluctuations or supply chain disruptions.

- Challenges: Increases holding costs and requires careful calculation to balance safety stock levels.

ABC Analysis:

- Description: This model categorizes inventory into three groups (A, B, and C) based on their importance and value. "A" items are high-value and low-quantity, "B" items are moderate in both value and quantity, and "C" items are low-value and high-quantity.

- Benefits: Focuses management efforts on high-value items and optimizes inventory control based on item importance.

- Challenges: Requires regular reassessment of inventory classification to remain effective.

Vendor-Managed Inventory (VMI):

- Description: In VMI, the supplier takes responsibility for managing and replenishing inventory levels at the customer's location. The supplier monitors inventory levels and makes decisions about restocking.

- Benefits: Reduces inventory management burden on the customer and improves supply chain collaboration.

- Challenges: Relies on trust and communication between the supplier and customer, and requires integrated systems for visibility.

Drop Shipping:

- Description: Drop shipping involves the retailer transferring customer orders directly to the supplier, who then ships the products directly to the customer. The retailer does not handle the inventory or shipping.

- Benefits: Eliminates the need for inventory storage and reduces overhead costs.

- Challenges: Less control over inventory and shipping processes, potential for longer delivery times.

Each of these models offers distinct advantages and challenges, and the choice of model often depends on factors such as business size, industry, and specific inventory needs.

Strategies for Supply Chain Inventory Optimization

The strategies for supply chain inventory optimization are:

Accurate Demand Forecasting

- Description: Utilize advanced forecasting techniques and tools to predict future demand as accurately as possible. This includes analyzing historical sales data, market trends, and seasonal variations.

- Benefits: Helps in planning inventory levels effectively, reducing stockouts and overstock situations.

- Tools: Statistical models, machine learning algorithms, and demand forecasting software.

Just-in-Time (JIT) Inventory

- Description: Implement a JIT approach where inventory is ordered and received only when needed for production or sales. This minimizes inventory holding costs and reduces waste.

- Benefits: Lower carrying costs and reduced risk of obsolescence.

- Challenges: Requires reliable suppliers and accurate demand forecasting to avoid disruptions.

Safety Stock Management

- Description: Maintain a buffer of extra inventory (safety stock) to protect against demand fluctuations and supply chain disruptions. The level of safety stock is determined based on historical data and variability.

- Benefits: Reduces the risk of stockouts and ensures a higher level of service.

- Challenges: Increases holding costs and requires careful calculation to avoid excess inventory.

Economic Order Quantity (EOQ)

- Description: Use the EOQ model to determine the optimal order quantity that minimizes total inventory costs, including ordering and holding costs. The EOQ formula helps in balancing these costs.

- Benefits: Optimizes order sizes and reduces total inventory costs.

- Challenges: Assumes constant demand and lead time, which may not always be accurate.

Inventory Turnover Optimization

- Description: Monitor and improve the inventory turnover ratio, which measures how frequently inventory is sold and replaced. Strategies include promoting slow-moving items and reducing excess stock.

- Benefits: Enhances inventory efficiency and frees up working capital.

- Challenges: Requires ongoing analysis and adjustments based on sales patterns.

Vendor-Managed Inventory (VMI)

- Description: Allow suppliers to manage inventory levels at your location. The supplier monitors inventory and replenishes stock based on agreed-upon thresholds.

- Benefits: Reduces inventory management burden and improves supply chain collaboration.

- Challenges: Relies on effective communication and trust between supplier and customer.

Automation and Technology Integration

- Description: Implement inventory management systems and technologies such as real-time tracking, automated reorder systems, and AI-driven analytics to streamline inventory processes.

- Benefits: Enhances accuracy, reduces manual errors, and improves efficiency.

- Tools: Inventory management software, barcode/RFID systems, and ERP systems.

Cross-Docking

- Description: Use cross-docking to streamline the flow of goods from suppliers to customers with minimal handling and storage. Products are directly transferred from inbound to outbound transportation.

- Benefits: Reduces inventory holding time and speeds up order fulfillment.

- Challenges: Requires efficient coordination and transportation logistics.

Collaborative Planning, Forecasting, and Replenishment (CPFR)

- Description: Engage in collaborative planning and forecasting with supply chain partners to improve inventory accuracy and align supply with demand.

- Benefits: Enhances visibility and coordination across the supply chain, leading to better inventory management.

- Challenges: Requires strong partnerships and data sharing.

Regular Inventory Audits

- Description: Conduct regular audits and reviews of inventory levels to identify discrepancies, slow-moving items, and areas for improvement. Adjust inventory policies based on audit findings.

- Benefits: Ensures inventory accuracy and helps in optimizing inventory levels.

- Challenges: Time-consuming and requires thorough data analysis.

By employing these strategies, businesses can optimize their supply chain inventory, improve operational efficiency, and enhance overall performance.

Leveraging Technology for Effective Inventory Optimization

Technology plays a crucial role in optimizing inventory management by providing tools and systems that enhance accuracy, efficiency, and decision-making. Here’s how technology contributes to effective inventory optimization:

Real-Time Inventory Tracking

- Description: Technologies such as barcode scanning, RFID, and IoT devices enable real-time monitoring of inventory levels and movements. This provides up-to-date information on stock availability, location, and condition.

- Benefits: Enhances visibility, reduces discrepancies, and improves decision-making by providing accurate data on inventory status.

Automated Inventory Management Systems

- Description: Inventory management software automates tasks such as order placement, stock level monitoring, and replenishment. These systems use algorithms to manage inventory more efficiently and reduce manual errors.

- Benefits: Streamlines inventory processes, improves accuracy, and reduces administrative burden.

Advanced Forecasting Tools

- Description: Predictive analytics and machine learning models analyze historical data and market trends to forecast future demand. This helps businesses anticipate inventory needs and plan accordingly.

- Benefits: Enhances demand forecasting accuracy, reduces the risk of stockouts and overstocking, and improves inventory planning.

Enterprise Resource Planning (ERP) Systems

- Description: ERP systems integrate inventory management with other business functions such as finance, sales, and procurement. This provides a holistic view of operations and facilitates better coordination across departments.

- Benefits: Improves cross-functional collaboration, enhances data accuracy, and provides a comprehensive view of inventory and business processes.

AI and Machine Learning

- Description: AI-driven solutions analyze vast amounts of data to identify patterns and optimize inventory levels. Machine learning algorithms can predict demand fluctuations, optimize reorder points, and manage safety stock.

- Benefits: Enhances inventory control with data-driven insights, improves accuracy in forecasting, and adapts to changing market conditions.

Cloud-Based Solutions

- Description: Cloud-based inventory management systems offer scalability, flexibility, and remote access to inventory data. They support real-time updates and collaboration among distributed teams.

- Benefits: Provides accessibility from anywhere, enables real-time data sharing, and scales with business growth.

Integrated Supply Chain Platforms

- Description: Platforms that integrate various aspects of the supply chain, including inventory management, procurement, and logistics, ensure seamless data flow and process coordination.

- Benefits: Enhances visibility across the supply chain, reduces lead times, and improves overall supply chain efficiency.

Data Analytics and Reporting Tools

- Description: Analytics tools generate reports and dashboards that provide insights into inventory performance, turnover rates, and trends. This helps in making informed decisions and identifying areas for improvement.

- Benefits: Offers actionable insights, tracks performance metrics, and supports strategic decision-making.

By leveraging these technologies, businesses can optimize their inventory management processes, improve efficiency, and achieve better alignment with market demands.

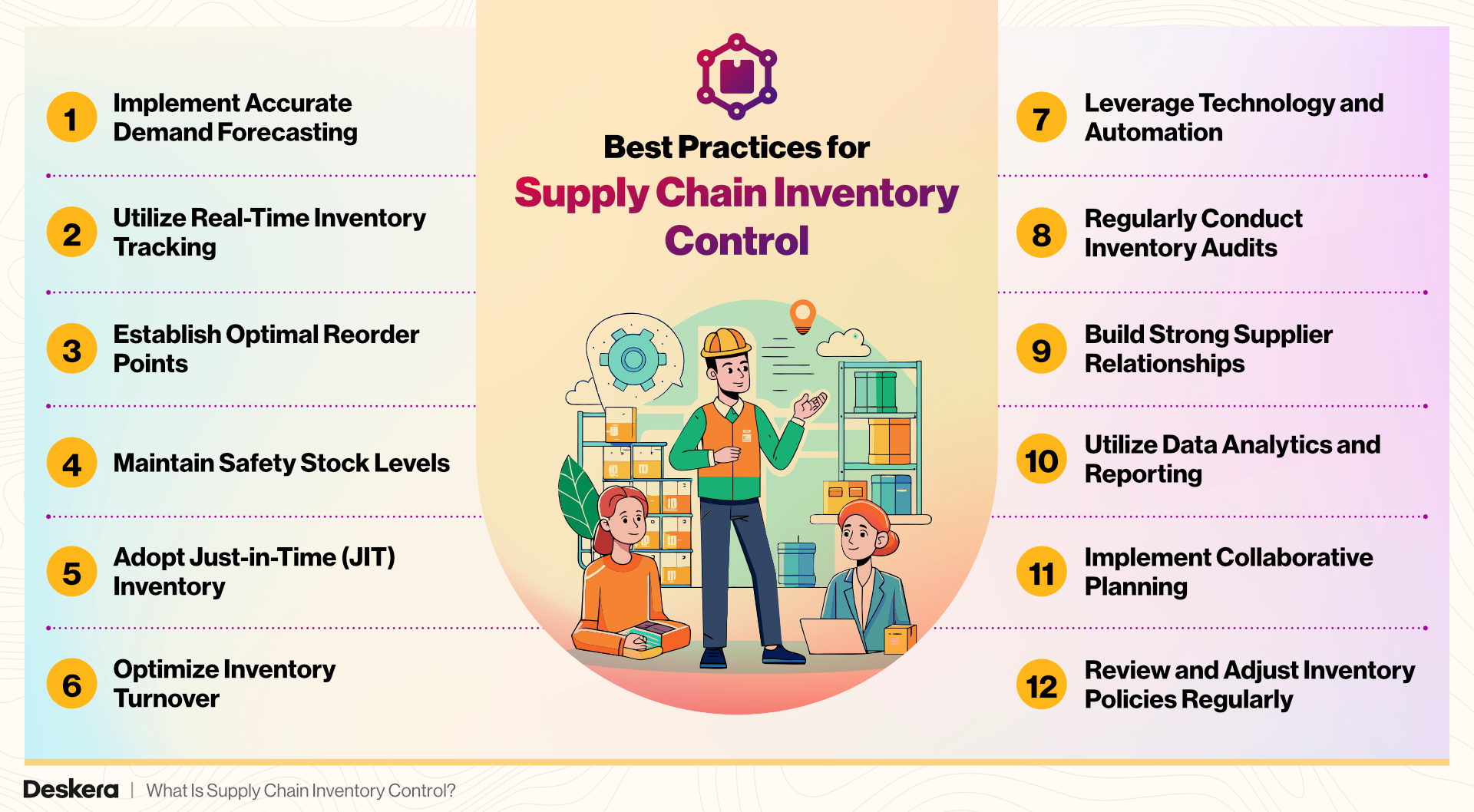

Best Practices for Supply Chain Inventory Control

Some of the best practices that you must implement to have an effective supply chain inventory control are:

Implement Accurate Demand Forecasting

- Description: Use historical data, market trends, and advanced forecasting tools to predict future demand. Regularly update forecasts to reflect changes in market conditions.

- Benefits: Helps in maintaining optimal inventory levels, reduces the risk of stockouts and overstocking.

Utilize Real-Time Inventory Tracking

- Description: Employ technologies such as barcode scanning, RFID, and IoT sensors to monitor inventory levels and movements in real-time.

- Benefits: Improves visibility, accuracy, and decision-making by providing up-to-date inventory information.

Establish Optimal Reorder Points

- Description: Determine the reorder point for each inventory item based on lead time, demand variability, and safety stock levels. Set automatic triggers for reordering.

- Benefits: Prevents stockouts and ensures timely replenishment, reducing the risk of disruptions in supply.

Maintain Safety Stock Levels

- Description: Keep a buffer stock of critical items to protect against unexpected demand spikes or supply chain disruptions. Calculate safety stock based on demand variability and lead time.

- Benefits: Reduces the risk of stockouts and improves service levels, especially during periods of high demand or supply issues.

Adopt Just-in-Time (JIT) Inventory

- Description: Order and receive inventory only as needed for production or sales, minimizing holding costs and reducing waste.

- Benefits: Lowers carrying costs, improves cash flow, and reduces the risk of inventory obsolescence.

Optimize Inventory Turnover

- Description: Monitor and improve the inventory turnover ratio by identifying slow-moving items, promoting them, or adjusting order quantities.

- Benefits: Enhances inventory efficiency, reduces holding costs, and frees up working capital.

Leverage Technology and Automation

- Description: Implement inventory management systems, ERP solutions, and automation tools to streamline inventory processes, improve accuracy, and reduce manual effort.

- Benefits: Enhances efficiency, reduces errors, and provides real-time insights into inventory performance.

Regularly Conduct Inventory Audits

- Description: Perform periodic audits to reconcile physical inventory with records, identify discrepancies, and assess inventory accuracy.

- Benefits: Ensures accurate inventory records, helps detect and address issues promptly, and maintains control over inventory levels.

Build Strong Supplier Relationships

- Description: Develop and maintain reliable relationships with suppliers to ensure timely deliveries and consistent quality. Communicate inventory needs and collaborate on forecasting.

- Benefits: Enhances supply chain reliability, improves lead times, and strengthens overall inventory management.

Utilize Data Analytics and Reporting

- Description: Use data analytics tools to generate reports and dashboards that provide insights into inventory performance, trends, and key metrics.

- Benefits: Supports data-driven decision-making, helps identify areas for improvement, and tracks performance against goals.

Implement Collaborative Planning

- Description: Engage in collaborative planning, forecasting, and replenishment (CPFR) with supply chain partners to align inventory strategies and improve accuracy.

- Benefits: Enhances coordination, improves forecasting accuracy, and reduces inventory inefficiencies.

Review and Adjust Inventory Policies Regularly

- Description: Regularly review and update inventory policies and procedures based on performance data, market changes, and evolving business needs.

- Benefits: Ensures that inventory control practices remain effective and aligned with current business conditions.

By following these best practices, businesses can achieve more effective supply chain inventory control, improve operational efficiency, and enhance overall supply chain performance.

Future Trends in Supply Chain Inventory Control

As supply chain inventory management continues to evolve, several key trends are shaping the future of inventory control in supply chain management. These trends highlight the shift towards more sophisticated, technology-driven approaches to inventory management and optimization.

Increased Use of Artificial Intelligence and Machine Learning

- Description: AI and machine learning are becoming integral to supply chain inventory management. These technologies enhance predictive analytics, optimize inventory levels, and improve demand forecasting accuracy.

- Benefits: Provides more precise inventory control, reduces excess stock and stockouts, and enhances supply chain inventory optimization.

Adoption of Advanced Analytics and Big Data

- Description: The use of big data and advanced analytics is revolutionizing inventory management in the supply chain. By analyzing large volumes of data, businesses can gain deeper insights into inventory trends, customer preferences, and market dynamics.

- Benefits: Improves decision-making, enables more accurate demand forecasting, and enhances supply chain inventory control.

Growth of Cloud-Based Inventory Management Solutions

- Description: Cloud-based solutions are increasingly being used for supply chain inventory management due to their scalability, flexibility, and remote accessibility. These systems facilitate real-time inventory tracking and integration with other supply chain functions.

- Benefits: Enhances visibility, supports collaboration, and enables more efficient inventory management in supply chain management.

Integration of Internet of Things (IoT) and Real-Time Tracking

- Description: IoT devices and sensors are being employed to provide real-time tracking of inventory throughout the supply chain. This technology allows for better monitoring of stock levels, location, and condition.

- Benefits: Improves inventory accuracy, reduces discrepancies, and enhances supply chain inventory visibility.

Focus on Sustainability and Green Supply Chain Practices

- Description: There is a growing emphasis on sustainability within supply chain inventory control. Businesses are adopting practices that reduce waste, lower carbon footprints, and enhance the efficiency of inventory management.

- Benefits: Supports environmental goals, improves operational efficiency, and aligns with consumer preferences for sustainable practices.

Development of Autonomous Inventory Management Systems

- Description: Autonomous systems, including robotics and automated warehouses, are transforming inventory management. These systems handle tasks such as sorting, packing, and restocking with minimal human intervention.

- Benefits: Increases efficiency, reduces labor costs, and enhances accuracy in inventory control.

Enhanced Collaborative Planning and Forecasting

- Description: Collaborative planning, forecasting, and replenishment (CPFR) are gaining traction as businesses work more closely with suppliers and partners to align inventory strategies and improve accuracy.

- Benefits: Strengthens supply chain relationships, enhances inventory accuracy, and optimizes supply chain inventory management.

Emergence of Blockchain for Supply Chain Transparency

- Description: Blockchain technology is being explored for its potential to provide transparency and traceability in supply chain operations. It ensures secure and tamper-proof records of inventory movements and transactions.

- Benefits: Enhances traceability, improves security, and supports more effective inventory control in supply chain management.

Integration of Augmented Reality (AR) and Virtual Reality (VR)

- Description: AR and VR technologies are being used for inventory management tasks such as training, warehouse layout planning, and real-time inventory visualization.

- Benefits: Improves training efficiency, aids in warehouse optimization, and enhances inventory management processes.

Focus on Agility and Resilience

- Description: The need for agile and resilient supply chains has become evident, particularly in response to disruptions and changing market conditions. Strategies are being developed to improve responsiveness and adaptability.

- Benefits: Enhances supply chain resilience, improves inventory flexibility, and supports effective management of supply chain disruptions.

By staying ahead of these trends, businesses can achieve more effective supply chain inventory control, optimize inventory management practices, and adapt to the evolving landscape of supply chain management.

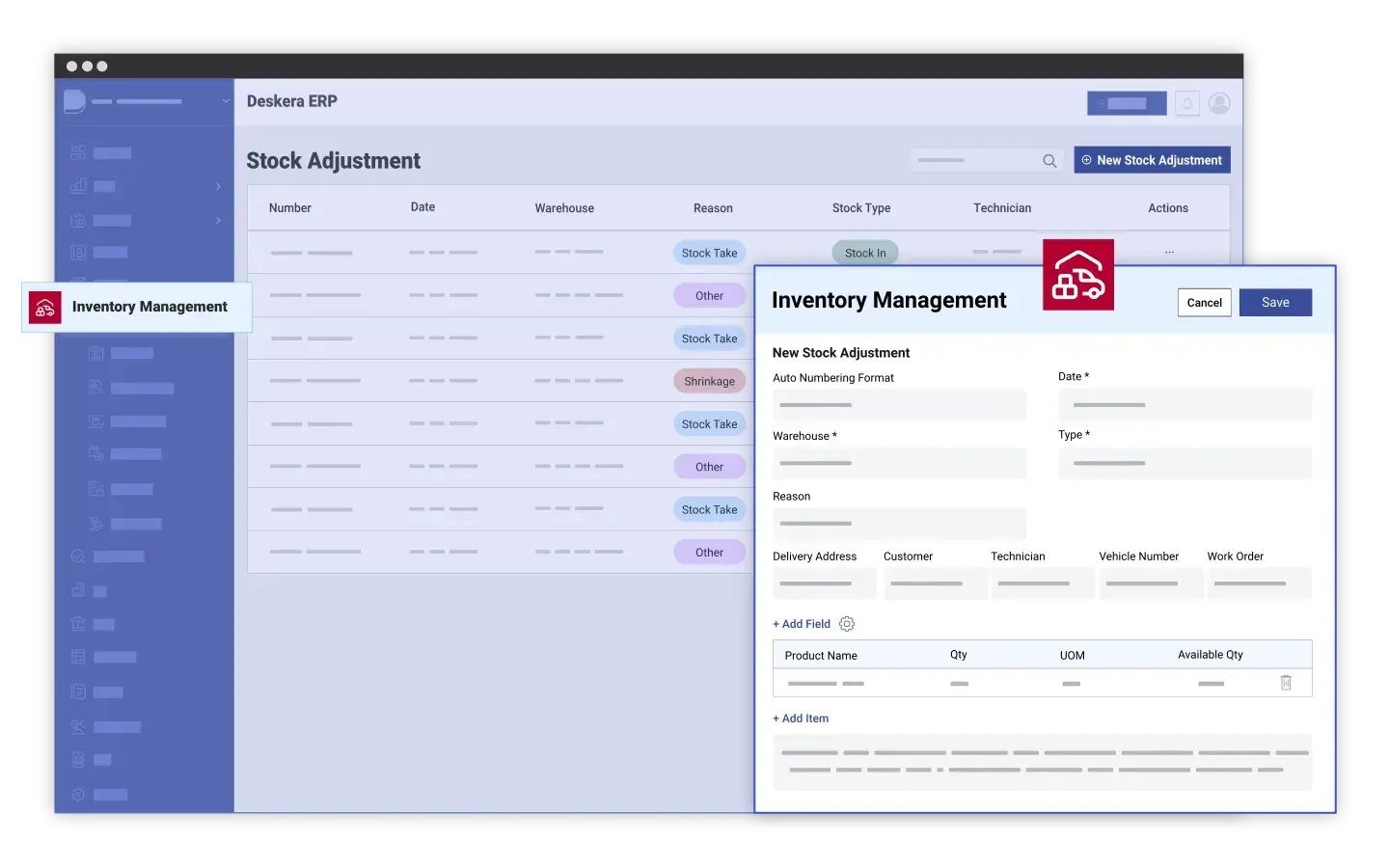

How Deskera ERP Can Enhance Supply Chain Inventory Control

Deskera ERP offers a comprehensive suite of features designed to streamline and optimize supply chain inventory control. Here’s how Deskera ERP can assist in managing your inventory more effectively:

Real-Time Inventory Tracking

- Description: Deskera ERP provides real-time visibility into inventory levels across multiple locations. This feature enables you to monitor stock movements and availability with up-to-date information.

- Benefits: Improves accuracy in inventory management, reduces stock discrepancies, and enhances overall inventory control.

Advanced Demand Forecasting

- Description: The system uses historical data and predictive analytics to forecast demand accurately. Deskera ERP integrates demand forecasting with inventory planning to ensure optimal stock levels.

- Benefits: Reduces the risk of stockouts and overstocking, improves inventory turnover, and aligns inventory with actual market demand.

Automated Replenishment

- Description: Deskera ERP automates the inventory replenishment process by setting up reorder points and automatic purchase orders based on predefined criteria.

- Benefits: Ensures timely restocking, minimizes manual intervention, and maintains optimal inventory levels.

Comprehensive Reporting and Analytics

- Description: The ERP system offers robust reporting and analytics tools that provide insights into inventory performance, turnover rates, and stock valuation.

- Benefits: Supports data-driven decision-making, helps identify trends and issues, and enhances strategic inventory management.

Integrated Supply Chain Management

- Description: Deskera ERP integrates inventory management with other supply chain functions such as procurement, sales, and finance. This holistic approach ensures seamless coordination and information flow.

- Benefits: Enhances overall supply chain efficiency, reduces errors, and improves communication between departments.

Inventory Optimization Tools

- Description: The ERP system includes tools for optimizing inventory levels, such as Economic Order Quantity (EOQ) calculations and safety stock management.

- Benefits: Improves inventory efficiency, reduces carrying costs, and enhances supply chain inventory optimization.

Supplier Management

- Description: Deskera ERP facilitates effective supplier management by tracking supplier performance, managing purchase orders, and maintaining supplier relationships.

- Benefits: Enhances supplier collaboration, ensures timely deliveries, and supports reliable inventory control.

Multi-Location Management

- Description: Deskera ERP manages inventory across multiple locations and warehouses, providing a unified view of stock levels and movements.

- Benefits: Enhances visibility, optimizes inventory distribution, and supports efficient multi-location inventory control.

Flexible and Scalable Solutions

- Description: Deskera ERP offers flexible and scalable solutions that can be tailored to meet the specific needs of your business as it grows.

- Benefits: Adapts to changing business requirements, supports future expansion, and ensures long-term inventory management effectiveness.

By leveraging these features, Deskera ERP can help you achieve more efficient supply chain inventory control, reduce costs, and improve overall operational performance.

Key Takeaways

Optimizing supply chain inventory control is pivotal for achieving operational efficiency and enhancing overall supply chain performance.

- Real-Time Visibility is Crucial: Accurate, real-time tracking of inventory levels and movements is essential for effective supply chain inventory control. It helps in reducing discrepancies and maintaining optimal stock levels.

- Effective Demand Forecasting Enhances Inventory Management: Utilizing advanced forecasting tools and data analytics improves the accuracy of demand predictions. This leads to better inventory planning and minimizes the risk of stockouts and overstocking.

- Automation Streamlines Replenishment Processes: Automated inventory replenishment systems ensure timely restocking by setting reorder points and generating purchase orders automatically. This reduces manual intervention and helps maintain balanced inventory levels.

- Integrated Systems Improve Efficiency: Integrating inventory management with other supply chain functions such as procurement, sales, and finance enhances coordination and information flow, leading to more effective supply chain operations.

- Optimization Techniques are Key to Reducing Costs: Implementing inventory optimization strategies, such as Economic Order Quantity (EOQ) and safety stock management, helps in reducing carrying costs and improving inventory turnover.

- Technology Enhances Inventory Accuracy: Leveraging technologies like barcode scanning, RFID, and real-time tracking systems improves inventory accuracy, speeds up data entry, and reduces manual errors.

- Supplier Relationships Impact Inventory Control: Strong supplier relationships and performance tracking are vital for ensuring timely deliveries and reliable inventory replenishment.

- Scalability Supports Long-Term Success: Flexible and scalable inventory management solutions can adapt to growing business needs, supporting long-term efficiency and effectiveness.

By integrating inventory management with other supply chain functions, Deskera ERP enhances operational efficiency and accuracy. Its flexible, scalable solutions ensure that businesses can adapt to growth and changing market conditions seamlessly. Embracing Deskera ERP can lead to more precise inventory control, reduced costs, and a stronger, more agile supply chain.

Related Articles