Food production has become a $2 trillion industry and companies are always looking to find new and innovative ways to produce food. While there are many factors to consider, one of the most important is finding the right ingredients. Choosing the wrong ingredients can lead to a product that is not enjoyable to eat or even dangerous.

In today’s guide, we’ll discuss thoroughly about selecting the best ingredients for food production and related concepts. Let’s take a look at the table of content below:

- Importance of Selecting the Best Ingredients for Food Production

- Understanding the Importance of Quality Ingredients

- Identifying the Best Ingredients

- How to Meet Highest Standard to Obtain the Best Ingredients Food Production?

- Common Mistakes to Avoid When Selecting Ingredients

- Frequently Asked Questions (FAQs) Associated with Selecting Best Ingredients for Food Production

- Wrapping Up

- How Deskera Can Assist You?

Let's get started!

Importance of Selecting the Best Ingredients for Food Production

Selecting the best ingredients for food production is crucial for several reasons. First and foremost, the quality of ingredients used in food production has a direct impact on the taste and flavor of the final product.

Consumers expect high-quality ingredients in the food they purchase, and using low-quality ingredients can lead to customer dissatisfaction, poor reviews, and reduced sales.

In addition to taste and flavor, selecting the best ingredients is also important for ensuring that the food produced is packed with essential nutrients. Consumers are becoming increasingly health-conscious, and many are seeking healthier options when it comes to food. By using fresh, high-quality ingredients, producers can enhance the nutritional value of their products.

Food safety is another critical factor to consider when selecting ingredients. Using high-quality ingredients can reduce the risk of foodborne illnesses by ensuring that the final product is free from contaminants such as bacteria, pesticides, or chemicals.

Finally, selecting the best ingredients is essential for ensuring customer satisfaction. Consumers expect high-quality ingredients in the food they purchase, and using low-quality ingredients can lead to customer dissatisfaction, poor reviews, and reduced sales.

To produce food that is not only delicious but also wholesome, secure, and satisfying for consumers, the best ingredients must be used. By employing high-quality ingredients, producers can enhance the nutritional value of their products, reduce the risk of foodborne illnesses, enhance the taste and flavor profile of their products, and ultimately raise consumer satisfaction.

Understanding the Importance of Quality Ingredients

Using high-quality ingredients in food production is crucial as it has a significant impact on taste and flavor, nutrition and health, food safety, and consumer satisfaction.

The use of fresh, high-quality ingredients can enhance the flavor profile of the dish, making it more enjoyable for consumers.

Moreover, it can help to ensure that the food produced is packed with essential nutrients, reducing the risk of foodborne illnesses and ultimately increasing customer satisfaction.

Thus, understanding the importance of quality ingredients is essential for producing delicious, nutritious, and safe food products. Let’s discuss in detail further:

Impact on Taste and Flavor

The quality of ingredients used in food production has a significant impact on taste and flavor. Here's a more detailed explanation:

- Freshness: Fresh ingredients have a more robust and distinct flavor compared to older or stale ingredients. For instance, using fresh herbs in recipes such as salads, soups, or sauces can enhance the flavor profile of the dish, making it more enjoyable for consumers. Similarly, using fresh fruits and vegetables in smoothies or juices can add a burst of flavor to the final product.

- Quality: The quality of ingredients also plays a crucial role in taste and flavor. High-quality ingredients are often more flavorful and aromatic than low-quality ingredients. For example, using high-quality, aged cheese in pizza or pasta dishes can provide a more distinct and complex flavor profile, making the dish more enjoyable for consumers.

- Seasonal variations: The flavor profile of ingredients can also vary depending on the season in which they are harvested. For instance, tomatoes harvested in the summer are often sweeter and more flavorful than those harvested in the winter. Thus, selecting seasonal ingredients can enhance the flavor profile of the dish and make it more appealing to consumers.

- Region: The region in which ingredients are grown can also have an impact on taste and flavor. For example, coffee beans grown in Ethiopia have a different flavor profile compared to those grown in South America. Similarly, spices such as cumin, cinnamon, or cardamom can have a unique flavor profile depending on where they are sourced from.

Hence, the use of high-quality, fresh ingredients in food production can enhance the taste and flavor profile of the final product. The seasonality and region of the ingredients used can also impact the flavor profile, making it more unique and appealing to consumers.

Thus, selecting the best ingredients for food production is essential for ensuring that the final product is not only delicious but also enjoyable for consumers.

Impact on Health and Nutrition

The quality of ingredients used in food production has a significant impact on the nutritional value of the final product. Here's a more detailed explanation:

- Nutrient content: High-quality ingredients are often richer in nutrients compared to low-quality ingredients. For example, fresh vegetables and fruits that are not over-ripe contain more vitamins, minerals, and fiber compared to older or processed varieties. Similarly, whole grains, nuts, seeds, and legumes are packed with essential nutrients such as protein, fiber, and healthy fats.

- Processing: The processing of ingredients can also impact their nutritional value. Processing methods such as canning, freezing, or dehydration can reduce the nutritional value of the ingredients. On the other hand, fresh or minimally processed ingredients retain more of their natural nutrients.

- Pesticides and chemicals: The use of pesticides and chemicals in farming can also impact the nutritional value of the final product. Consuming foods that have been treated with pesticides and chemicals can be harmful to human health. Using organic, non-GMO, or locally sourced ingredients can help reduce exposure to these harmful substances.

- Food allergies and sensitivities: The quality of ingredients is also crucial for individuals with food allergies or sensitivities. Using high-quality ingredients that are free from allergens and contaminants can help reduce the risk of adverse reactions.

Ultimately, the use of high-quality, fresh ingredients in food production can enhance the nutritional value of the final product. Fresh and minimally processed ingredients are packed with essential nutrients, while avoiding harmful substances such as pesticides and chemicals.

Using high-quality ingredients can also help individuals with food allergies or sensitivities to safely consume the product.

Thus, selecting the best ingredients for food production is essential for ensuring that the final product is not only delicious but also nutritious and safe for consumers.

Impact on Food Safety

The quality of ingredients used in food production has a significant impact on food safety. Here's a more detailed explanation:

- Contamination: Using low-quality or contaminated ingredients can lead to foodborne illnesses. Contaminated ingredients can include those that are contaminated with harmful bacteria, viruses, or toxins. For example, using contaminated meat or poultry can lead to the spread of Salmonella or E. coli, while using contaminated produce can lead to the spread of foodborne illnesses such as Norovirus.

- Shelf life: The shelf life of ingredients also plays a role in food safety. Using ingredients that have passed their expiration date or are no longer fresh can lead to the growth of harmful bacteria, which can cause foodborne illnesses.

- Processing: The processing of ingredients can also impact food safety. Improper processing methods can lead to the spread of harmful bacteria, viruses, or toxins. For example, using unclean equipment or not following proper cooking temperatures can lead to the spread of foodborne illnesses.

- Storage: Proper storage of ingredients is also crucial for food safety. Using ingredients that have not been stored properly can lead to the growth of harmful bacteria. For example, using dairy products that have not been refrigerated can lead to the spread of harmful bacteria such as Listeria.

In sum, using top-notch components in food production is essential for food safety. The danger of foodborne infections can be decreased by using fresh, uncontaminated components, adhering to proper processing procedures, and properly storing ingredients.

In order to produce food that is not only delicious and nutritious but also safe for consumers, it is crucial to choose the best components.

Impact on Consumer Satisfaction

The quality of ingredients used in food production has a significant impact on consumer satisfaction. Here's a more detailed explanation:

- Taste and flavor: Using high-quality ingredients can significantly enhance the taste and flavor of the final product. For example, using fresh herbs and spices can add depth and complexity to a dish, while using low-quality or processed ingredients can result in a bland or artificial taste.

- Texture: The texture of the final product can also be impacted by the quality of ingredients used. For example, using high-quality flour can result in a light and fluffy cake, while using low-quality flour can result in a dense and heavy texture.

- Appearance: The appearance of the final product can also be impacted by the quality of ingredients used. For example, using fresh and vibrant vegetables can make a dish look more appetizing, while using wilted or discolored vegetables can make a dish look unappetizing.

- Brand reputation: Using high-quality ingredients can help establish a positive reputation for a brand or business. Consumers are more likely to trust and return to a brand that consistently produces high-quality products.

In short, using high-quality ingredients in food preparation can significantly affect customer satisfaction. High-quality components can increase the ultimate product's flavor, texture, and appearance, improving the consumer's satisfaction.

Moreover, high-quality ingredients can help a brand's reputation by encouraging customer loyalty and trust. The greatest ingredients must be chosen for food preparation in order to please clients and build a successful business.

Identifying the Best Ingredients

Identifying the best ingredients for food production can be a complex process, but here are some general guidelines:

A. Determining the Required Characteristics

Determining the required characteristics of ingredients for food production can help ensure that the final product meets specific standards and requirements. Here are some key characteristics to consider:

- Flavor: As previously mentioned, flavor is a crucial characteristic of ingredients as it directly impacts the taste of the final product. Ingredients should have a natural and authentic flavor, free from any off-flavors or artificial additives.

- Texture: The texture of ingredients can also impact the texture of the final product. For example, if making a cake, the flour should have a fine texture to ensure the cake is light and fluffy.

- Nutritional Value: The nutritional value of ingredients is essential, especially for health-conscious consumers. Ingredients should be high in nutrients and low in harmful components like cholesterol, saturated fats, or added sugars.

- Shelf Life: The shelf life of ingredients is a significant factor in determining their suitability for food production. Ingredients with a longer shelf life can help reduce waste and maintain consistency in the final product.

- Appearance: The appearance of ingredients can impact the overall visual appeal of the final product. For example, when selecting fruits and vegetables, it is essential to choose those with an even color and without any blemishes.

- Sustainability: The sourcing of ingredients is crucial, and it is important to consider factors such as sustainability, ethical sourcing, and fair trade practices when selecting ingredients.

- Food safety: Food safety is a critical characteristic of ingredients, and it is essential to ensure that they are free from harmful bacteria or contaminants.

Identifying the properties of components that are necessary for food manufacturing methods is essential for guaranteeing that the finished product complies with particular criteria and regulations.

While choosing ingredients, it's important to take into account aspects like flavor, texture, nutritional content, shelf life, appearance, sustainability, and food safety.

By taking into account these elements, you may produce a finished good that not only fits your standards but also tastes great.

B. Evaluating Ingredient Suppliers

Evaluating ingredient suppliers is essential for ensuring that the ingredients used in food production meet the required quality standards. Here are some factors to consider when evaluating ingredient suppliers:

- Quality: The quality of the ingredients provided by the supplier is critical. It is essential to ensure that the supplier provides high-quality ingredients that meet specific standards, such as organic or non-GMO products. Research the supplier's quality control processes and read reviews from other customers to ensure that their products meet your standards.

- Traceability: Traceability is crucial for ensuring the safety and quality of ingredients. It is essential to ensure that the supplier can trace the ingredients back to their source and provide information on the origin, production, and handling of the products.

- Sustainability: Sustainability is an important factor to consider when evaluating ingredient suppliers. Ensure that the supplier is committed to sustainable sourcing practices, such as ethical and fair trade practices, and reducing their environmental impact.

- Cost: Cost is an important factor when evaluating ingredient suppliers. Ensure that the supplier provides competitive prices while maintaining high-quality products.

- Communication: Good communication is essential for a successful supplier relationship. Ensure that the supplier is responsive and transparent in their communication and can provide clear and accurate information on their products.

- Flexibility: Flexibility is important when working with ingredient suppliers, as it allows for changes in production requirements or unexpected events. Ensure that the supplier is willing to work with you to accommodate changes and can provide alternative options if necessary.

- Food safety: Food safety is critical when working with ingredient suppliers. Ensure that the supplier has strict food safety protocols in place, such as proper handling and storage, and can provide documentation of their food safety regulations practices.

In end, it is critical to assess ingredient suppliers to make sure that the components used in food manufacturing adhere to the necessary quality requirements.

Moreover, when choosing a supplier, it's important to take into account aspects like quality, traceability, sustainability, pricing, communication, flexibility, and food safety. You may create a productive supplier relationship that assures high-quality ingredients for your food production needs by taking these aspects into account.

C. Conducting Quality Tests

Conducting quality tests is crucial for ensuring that the ingredients used in food production meet the required quality standards. Here are some quality tests that can be conducted to evaluate ingredients:

- Microbial testing: Microbial testing is essential to ensure that ingredients are free from harmful bacteria or other microorganisms. This testing involves analyzing the ingredients for the presence of pathogens, such as E.coli or Salmonella.

- Chemical testing: Chemical testing can be conducted to analyze the presence of contaminants or harmful substances in ingredients. For example, testing can be conducted for heavy metals, pesticides, or additives that may be harmful to human health.

- Physical testing: Physical testing can be conducted to evaluate the appearance and texture of ingredients. For example, testing can be conducted to evaluate the particle size of flour or the moisture content of fruits and vegetables.

- Nutritional testing: Nutritional testing can be conducted to evaluate the nutritional value of ingredients. This testing involves analyzing the ingredients for their nutrient content, such as vitamins, minerals, and macronutrients.

- Packaging testing: Packaging testing is used to evaluate the effectiveness of packaging materials in protecting food products from physical, chemical, and microbiological hazards. This includes testing for factors such as oxygen permeability, moisture transmission, and seal integrity. Packaging testing is important for ensuring that food products remain safe and of high quality throughout their intended shelf life.

- Sensory testing: Sensory testing can be conducted to evaluate the taste, smell, and texture of ingredients. This testing involves human evaluation of the ingredients to determine their sensory characteristics.

- Shelf-life testing: Shelf-life testing can be conducted to evaluate the stability and shelf life of ingredients. This testing involves storing the ingredients under various conditions to determine their shelf life and stability.

- Allergen testing: Allergen testing can be conducted to evaluate the presence of allergens in ingredients. This testing involves analyzing the ingredients for the presence of common allergens, such as nuts, wheat, or soy.

Quality testing is crucial to ensuring that the ingredients used in food production meet the required standards for quality. Microbial, chemical, physical, nutritional, sensory, and shelf-life tests are all as important to consider in addition to allergen testing. In addition, you may make sure that the ingredients used to produce food adhere to the appropriate criteria for quality, safety, and nutritional content by carrying out these tests

D. Checking for Certifications and Labeling

Checking for certifications and labeling is an essential step in selecting the best ingredients for food production. Here are some certifications and labels to look for when evaluating ingredients:

- Organic: The organic certification indicates that the ingredients were produced without the use of synthetic pesticides, fertilizers, or genetically modified organisms (GMOs). Look for the USDA organic label, which indicates that the product meets specific organic standards.

- Non-GMO: The non-GMO label indicates that the ingredients do not contain genetically modified organisms. Look for the Non-GMO Project Verified label, which verifies that the product has been independently tested for the presence of GMOs.

- Fair trade: The fair trade certification indicates that the ingredients were produced using fair labor practices and that the farmers or workers who produced the ingredients received fair compensation. Look for the Fairtrade International label or the Fair Trade Certified label.

- Kosher: The kosher certification indicates that the ingredients meet Jewish dietary laws. Look for the kosher certification symbol, such as the OU or Star-K symbol.

- Gluten-free: The gluten-free label indicates that the ingredients do not contain gluten, which is important for people with gluten sensitivity or celiac disease. Look for the gluten-free certification symbol, such as the Gluten-Free Certification Organization (GFCO) label.

- Allergen-free: The allergen-free label indicates that the ingredients do not contain common allergens, such as peanuts, tree nuts, wheat, soy, or dairy. Look for the allergen-free certification symbol, such as the Free-From label.

- Sustainable: The sustainable label indicates that the ingredients were produced using environmentally sustainable practices. Look for the Rainforest Alliance Certified label or the Marine Stewardship Council (MSC) label for sustainable seafood.

In addition to certifications and labels, it is also important to read the ingredient list and nutrition facts label to ensure that the ingredients meet your specific requirements. Furthermore, checking for certifications and labeling can help ensure that the ingredients used in food production meet the desired standards for quality, safety, and sustainability.

How to Meet Highest Standard to Obtain the Best Ingredients Food Production?

To meet the highest standards and obtain the best ingredients for food manufacturing, consider the following steps:

- Define the requirements: Determine the specific characteristics and qualities you need in the ingredients for your product, such as nutritional content, flavor, and texture.

- Identify potential suppliers: Look for reputable suppliers that meet your criteria and have a track record of delivering high-quality ingredients.

- Conduct supplier audits: Visit the supplier's facilities and conduct a thorough audit to assess their quality management systems, production processes, and ingredient sourcing practices.

- Review certifications and documentation: Check the supplier's certifications and documentation to ensure they comply with relevant food safety and quality standards.

- Perform product testing: Test the ingredients to ensure they meet your specifications and are free from contaminants and pathogens.

- Monitor and evaluate: Continuously monitor the quality of the ingredients throughout the supply chain and evaluate supplier performance to ensure consistency and quality.

- Implement sustainability practices: Choose suppliers that prioritize sustainability practices, such as ethical sourcing and environmentally friendly production processes.

By following these steps, you can ensure that you are selecting the best ingredients for food manufacturing and meeting the highest standards for quality, safety, and sustainability.

Common Mistakes to Avoid When Selecting Ingredients

When selecting ingredients for food production, there are several common mistakes that you should avoid ensuring the quality, safety, and success of your product. Some of these mistakes include:

- Focusing solely on price: While cost is an important factor to consider, selecting ingredients based solely on price can lead to lower quality, inconsistent supply, and potential safety risks.

- Not considering sustainability: Failing to consider the sustainability of ingredients can lead to negative environmental and social impacts and may not align with consumer demand for ethically sourced and environmentally friendly products.

- Not verifying supplier qualifications: Failing to verify supplier qualifications can lead to poor quality ingredients, increased risk of contamination, and potential legal liability.

- Not conducting product testing: Failing to conduct product testing can lead to inconsistencies in product quality and potential safety risks for consumers.

- Neglecting to monitor supply chain: Failing to monitor the supply chain for potential issues can result in quality and safety problems, such as contamination or spoilage.

Ultimately, to avoid these common mistakes, take a comprehensive and strategic approach to selecting ingredients that considers factors such as quality, safety, sustainability, and consumer demand.

Frequently Asked Questions (FAQs) Associated with Selecting Best Ingredients for Food Production

Following, we’ve discussed some frequently asked questions about selecting the best ingredients for food production:

Que 1: Why is it important to select the best ingredients for food production?

Ans: Selecting the best ingredients for food production is important for several reasons, including ensuring the quality, safety, and nutritional value of the final product, as well as satisfying consumer demand for high-quality foods.

Que 2: How can I identify the best ingredients for my product?

Ans: To identify the best ingredients for your product, you should determine the specific characteristics and qualities you need in the ingredients and evaluate potential suppliers based on their ability to meet your requirements.

Que 3: What factors should I consider when selecting ingredients?

Ans: When selecting ingredients, it is important to consider factors such as seasonal availability, cost, sustainability, shelf life, and packaging and transportation.

Que 4: How can I evaluate ingredient suppliers?

Ans: You can evaluate ingredient suppliers by conducting supplier audits, reviewing certifications and documentation, and performing product testing to ensure the ingredients meet your specifications.

Que 5: What should I do if I cannot find a supplier that meets my requirements?

Ans: If you cannot find a supplier that meets your requirements, consider adjusting your requirements or expanding your search to include additional suppliers or regions.

Que 6: How can I ensure the quality and safety of the ingredients throughout the supply chain?

Ans: You can ensure the quality and safety of the ingredients throughout the supply chain by continuously monitoring and evaluating supplier performance, implementing appropriate quality control measures, and conducting regular product testing.

Wrapping Up

In conclusion, selecting the best ingredients for food production is crucial for ensuring the quality and safety of the final product. The process involves researching and sourcing ingredients from reputable suppliers, assessing their nutritional content and flavor profiles, and conducting thorough testing and analysis to ensure their safety and suitability for use.

By following these guidelines and prioritizing quality and safety in ingredient selection, food producers can create products that meet the expectations and demands of consumers while also meeting regulatory standards and promoting good health.

Ultimately, the success of any food production operation relies on the careful selection and management of ingredients throughout the production process.

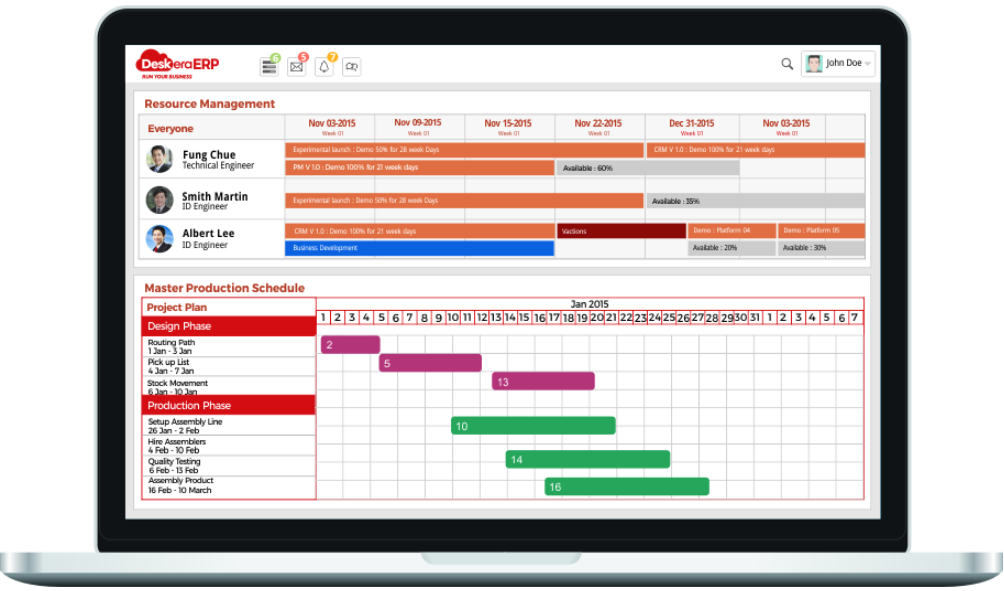

How Deskera Can Assist You?

Deskera's integrated financial planning tools allow investors to better plan their investments and track their progress. It can help investors make decisions faster and more accurately.

Deskera Books enables you to manage your accounts and finances more effectively. Maintain sound accounting practices by automating accounting operations such as billing, invoicing, and payment processing.

Deskera CRM is a strong solution that manages your sales and assists you in closing agreements quickly. It not only allows you to do critical duties such as lead generation via email, but it also provides you with a comprehensive view of your sales funnel.

Deskera People is a simple tool for taking control of your human resource management functions. The technology not only speeds up payroll processing but also allows you to manage all other activities such as overtime, benefits, bonuses, training programs, and much more. This is your chance to grow your business, increase earnings, and improve the efficiency of the entire production process.

Final Takeaways

We've arrived at the last section of this guide. Let's have a look at some of the most important points to remember:

- Food safety is another critical factor to consider when selecting ingredients. Using high-quality ingredients can reduce the risk of foodborne illnesses by ensuring that the final product is free from contaminants such as bacteria, pesticides, or chemicals.

- The use of high-quality, fresh ingredients in food production can enhance the taste and flavor profile of the final product. The seasonality and region of the ingredients used can also impact the flavor profile, making it more unique and appealing to consumers.

- The processing of ingredients can also impact their nutritional value. Processing methods such as canning, freezing, or dehydration can reduce the nutritional value of the ingredients. On the other hand, fresh or minimally processed ingredients retain more of their natural nutrients.The shelf life of ingredients also plays a role in food safety. Using ingredients that have passed their expiration date or are no longer fresh can lead to the growth of harmful bacteria, which can cause foodborne illnesses.

- Using high-quality ingredients can help establish a positive reputation for a brand or business. Consumers are more likely to trust and return to a brand that consistently produces high-quality products.

- Traceability is crucial for ensuring the safety and quality of ingredients. It is essential to ensure that the supplier can trace the ingredients back to their source and provide information on the origin, production, and handling of the products.

- Nutritional testing can be conducted to evaluate the nutritional value of ingredients. This testing involves analyzing the ingredients for their nutrient content, such as vitamins, minerals, and macronutrients.

Related Articles