According to a report by Allied Market Research, the global food processing equipment market is expected to reach $91.8 billion by 2025, growing at a CAGR of 6.7% from 2018 to 2025. This growth is driven by the increasing demand for processed foods and the adoption of automated food processing equipment.

Food manufacturing is an essential part of the global food supply chain, responsible for producing the vast array of processed foods we see in supermarkets today. From the traditional techniques of baking bread and fermenting cheese to the cutting-edge methods of freeze-drying and sous-vide cooking, food manufacturing has come a long way in meeting the demands of a rapidly growing population.

However, with the rise of health concerns, environmental issues, and consumer preferences, the food industry is constantly searching for better ways to produce food that is safe, nutritious, and sustainable.

In this article, we will explore the pros and cons of different food manufacturing techniques, from traditional to modern and combination methods.

We will also discuss the factors to consider when choosing a food manufacturing technique, including cost, efficiency, quality, safety, and environmental impact. Join us on this journey through the fascinating world of food manufacturing and discover the latest developments and challenges facing the industry today.

- What are Food Manufacturing Techniques?

- Importance of Food Manufacturing Techniques

- Overview of Different Food Manufacturing Techniques

- Pros and Cons of Traditional Food Manufacturing Techniques

- Pros and Cons of Modern Food Manufacturing Techniques

- Pros and Cons of Combination Food Manufacturing Techniques

- Factors to Consider When Choosing Food Manufacturing Techniques

- How can MRP and ERP Systems Enhance Food Manufacturing Process?

- How can Deskera Help You?

- Key Takeaways

- Related Articles

What are Food Manufacturing Techniques?

Food manufacturing techniques refer to the methods and processes used to transform raw agricultural materials into packaged, shelf-stable food products that are safe, nutritious, and appealing to consumers. These techniques involve a range of processes such as harvesting, cleaning, cooking, preserving, and packaging.

Food manufacturing techniques have evolved over time as food processing has become more complex, and as consumers' preferences and demands have changed. Some common food manufacturing techniques include:

- Canning: This involves sealing food in airtight containers and sterilizing them by heat treatment to preserve their shelf life.

- Freezing: This technique involves rapidly lowering the temperature of food to below freezing to prevent the growth of microorganisms and preserve the quality of the food.

- Dehydration: This involves removing moisture from foods, typically through the use of heat, to extend their shelf life and make them more portable.

- Extrusion: This technique is used to create processed foods by forcing food materials through a small opening to create a specific shape or texture.

- High-pressure processing (HPP): This is a non-thermal processing technique that uses high pressure to inactivate microorganisms in foods, while preserving their flavor, texture, and nutrients.

We shall be learning more about these methods in the upcoming sections. Overall, food manufacturing techniques play a crucial role in ensuring the safety, quality, and accessibility of food products, while also meeting consumer demands for convenience, taste, and nutrition.

Importance of Food Manufacturing Techniques

Food manufacturing techniques are essential for ensuring the safety, quality, and availability of food products. Here are some key reasons why food manufacturing techniques are important:

Food Safety

Food manufacturing techniques are essential for preventing foodborne illnesses caused by harmful bacteria, viruses, and other pathogens. Techniques such as pasteurization, irradiation, and high-pressure processing are used to kill harmful bacteria and other microorganisms, while preserving the nutritional quality and flavor of foods.

Food safety is a crucial aspect of the importance of food manufacturing techniques. Foodborne illnesses caused by harmful bacteria, viruses, and other pathogens are a significant public health concern, and food manufacturing techniques are essential for preventing contamination and ensuring that food products are safe for consumption.

Food manufacturing techniques can help to prevent foodborne illnesses in several ways including the following:

- Cleaning and sanitation: Proper cleaning and sanitation of food processing equipment, facilities, and tools are essential for preventing the growth and spread of harmful bacteria and other pathogens. Food manufacturing techniques involve rigorous cleaning and sanitizing procedures to ensure that the final product is free from contamination.

- Preservation techniques: Preservation techniques such as canning, freezing, and dehydration can help to prevent the growth of harmful bacteria and other pathogens by creating conditions that are inhospitable to their growth.

Food Preservation

Food manufacturing techniques such as canning, freezing, and dehydration help to extend the shelf life of foods and reduce food waste. This is particularly important in regions where food is scarce or in areas where transportation and storage conditions are challenging.

Nutritional Value

Food manufacturing techniques can help to preserve the nutritional value of foods by minimizing nutrient loss during processing. Techniques such as blanching, steaming, and microwaving can help to preserve the vitamins and minerals in foods.

Convenience

Food manufacturing techniques can make food more convenient for consumers to use and prepare. For example, pre-cooked or pre-packaged meals can save time for busy consumers.

Innovation

Food manufacturing techniques can be used to develop new and innovative food products that meet consumer demands for healthy, convenient, and sustainable foods. Techniques such as extrusion, texturization, and emulsification can be used to create new food textures, flavors, and nutritional profiles.

Overview of Different Food Manufacturing Techniques

Food manufacturing techniques involve a range of methods and processes that are used to convert raw ingredients into safe, nutritious, and appealing food products. Here's an overview of some of the most common food manufacturing techniques:

Canning

Canning is a process of preserving food by heating it to high temperatures and sealing it in airtight containers. This process kills harmful bacteria and prevents the growth of microorganisms, extending the shelf life of the food for several years. The process typically involves the following steps:

- Preparing the food: The food is cleaned, chopped, and cooked if necessary.

- Filling the jars: The jars are filled with the food and any necessary preservatives or seasonings.

- Sealing the jars: The jars are sealed with lids and bands, and then processed in a pressure canner or boiling water bath to ensure that they are free from harmful microorganisms.

Freezing

Freezing involves lowering the temperature of food products to below freezing to slow down the growth of microorganisms and enzymes that can cause spoilage. The process typically involves the following steps:

- Preparing the food: The food is cleaned, chopped, and blanched if necessary.

- Packaging the food: The food is packaged in airtight containers or freezer bags, removing as much air as possible to prevent freezer burn.

- Freezing the food: The food is placed in a freezer at a temperature of 0°F (-18°C) or below to prevent the growth of microorganisms.

Drying

Drying is a process of removing moisture from food products to inhibit the growth of microorganisms and enzymes. The process typically involves the following steps:

- Preparing the food: The food is cleaned, sliced, and blanched if necessary.

- Drying the food: The food is placed in a dehydrator or oven at a low temperature to remove moisture. Alternatively, it can be air-dried in a well-ventilated area.

- Packaging the food: The dried food is packaged in airtight containers to prevent moisture from re-entering the product.

Pasteurization

Pasteurization is a process of heating food products to a specific temperature for a set amount of time to kill harmful bacteria and microorganisms. The process typically involves the following steps:

- Heating the food: The food is heated to a specific temperature for a set amount of time to kill harmful bacteria and microorganisms.

- Cooling the food: The food is then cooled to prevent further bacterial growth.

- Packaging the food: The pasteurized food is packaged in airtight containers to prevent contamination.

Sterilization

Sterilization is a process of completely eliminating all microorganisms from food products. The process typically involves the following steps:

- Heating the food: The food is heated to a high temperature for a set amount of time to kill all microorganisms.

- Cooling the food: The food is then cooled to prevent further bacterial growth.

- Packaging the food: The sterilized food is packaged in airtight containers to prevent contamination.

High-Pressure Processing (HPP)

HPP is a non-thermal processing technique that involves applying high pressure to food products to kill harmful microorganisms while preserving their nutritional quality and flavor. The process typically involves the following steps:

- Packaging the food: The food is packaged in a flexible container.

- Applying high pressure: The packaged food is placed in a chamber and subjected to high pressure (up to 87,000 psi) for several minutes.

- Removing the pressure: The pressure is then slowly released, and the food is removed from the chamber and packaged for sale.

These are just a few of the many food manufacturing techniques used in the industry. Each technique has its unique benefits and is used depending on the specific food product and its desired characteristics.

Pros and Cons of Traditional Food Manufacturing Techniques

Traditional food manufacturing techniques have been used for centuries to produce a variety of foods. While they have many benefits, they also have some drawbacks. Here are some pros and cons of traditional food manufacturing techniques:

Pros:

- Natural and organic: Traditional food manufacturing techniques often use natural and organic ingredients, which can be healthier and more sustainable than modern alternatives.

- Preservation: Many traditional techniques, such as smoking and fermenting, are effective at preserving food without the use of artificial preservatives.

- Flavor: Traditional techniques can enhance the flavor of food, making it more enjoyable and satisfying to eat.

- Cultural significance: Traditional food manufacturing techniques are often tied to cultural traditions and can help preserve cultural heritage.

Cons:

- Time-consuming: Many traditional techniques, such as fermentation and curing, can be time-consuming and require a lot of preparation.

- Inconsistent quality: Traditional techniques can be difficult to replicate consistently, resulting in variations in taste and quality.

- Safety concerns: Traditional techniques, such as canning, may not always be safe if not done properly, increasing the risk of foodborne illnesses.

- Limited scalability: Traditional techniques may not be scalable to large-scale commercial production, limiting their use in the modern food industry.

It's important to note that traditional food manufacturing techniques are not necessarily better or worse than modern techniques. Each technique has its own advantages and disadvantages, and the choice of technique depends on the specific food product and its desired characteristics.

Pros and Cons of Modern Food Manufacturing Techniques

Modern food manufacturing techniques have been developed to improve food production efficiency, quality, and safety. Here are some pros and cons of modern food manufacturing techniques:

Pros:

- Efficiency: Modern techniques can produce food on a large scale, allowing for greater availability and affordability.

- Consistency: Modern techniques can produce food products with consistent taste, texture, and quality.

- Safety: Modern techniques often use advanced technologies and methods to ensure food safety and reduce the risk of foodborne illnesses.

- Nutritional value: Modern techniques can be used to fortify foods with essential vitamins and minerals to improve their nutritional value.

- Innovation: Modern techniques allow for the development of new food products with unique flavors, textures, and forms.

Cons:

- Artificial ingredients: Modern techniques often rely on artificial ingredients and additives to improve flavor, texture, and shelf life, which may have negative health effects.

- Environmental impact: Modern food manufacturing techniques can have a significant environmental impact, such as producing greenhouse gas emissions and contributing to waste.

- Health concerns: Some modern techniques, such as genetic modification, raise concerns about their long-term health effects.

- Processing: Some modern techniques can involve heavy processing, which can reduce the nutritional value of food and affect its taste and texture.

It's important to note that modern food manufacturing techniques have improved the availability and quality of food for many people, but they also come with potential drawbacks. Balancing the benefits and drawbacks of modern techniques is important for creating a sustainable and healthy food system.

Pros and Cons of Combination Food Manufacturing Techniques

Combination food manufacturing techniques are a hybrid approach that combines traditional and modern techniques to achieve desired outcomes. Here are some pros and cons of combination food manufacturing techniques:

Pros:

- Preservation: Combination techniques can effectively preserve food, often without the use of artificial preservatives, by utilizing traditional preservation methods such as smoking, drying, and fermenting.

- Quality control: Combination techniques can provide greater quality control over the final product by incorporating modern testing and analysis techniques.

- Sustainability: Combination techniques can utilize local and organic ingredients, reducing the environmental impact of food production and supporting sustainable agriculture.

- Innovation: Combination techniques can lead to the development of new and unique food products with improved flavor, texture, and nutritional value.

Cons:

- Complexity: Combination techniques can be complex and require a higher level of expertise, which can make them more challenging to implement.

- Time-consuming: Combination techniques may require more time and resources compared to traditional or modern techniques alone.

- Safety concerns: Combination techniques require careful consideration of food safety, as traditional techniques may not always meet modern safety standards.

- Cost: Combination techniques may be more expensive than traditional techniques, as they require specialized equipment and knowledge.

It's important to note that combination food manufacturing techniques can offer advantages over traditional and modern techniques alone. However, it's important to carefully consider the benefits and drawbacks before implementing them to ensure the final product meets safety and quality standards.

Factors to Consider When Choosing Food Manufacturing Techniques

When choosing food manufacturing techniques, there are several factors that should be considered to ensure that the final product meets quality, safety, and economic requirements.

Here are some factors to consider:

- Product characteristics: The desired characteristics of the final product, such as texture, flavor, and nutritional value, should be considered when choosing manufacturing techniques.

- Safety: The manufacturing process should ensure the safety of the final product and minimize the risk of foodborne illness.

- Equipment and facilities: The availability of suitable equipment and facilities should be considered when choosing manufacturing techniques. The equipment and facilities should be able to meet the manufacturing requirements and ensure the safety and quality of the final product.

- Scalability: The manufacturing technique should be scalable to meet the production requirements of the business.

- Cost: The cost of the manufacturing technique should be considered, including the cost of equipment, labor, and materials.

- Sustainability: The environmental impact of the manufacturing technique should be considered, and sustainable practices should be used where possible.

- Regulatory requirements: The manufacturing technique should comply with regulatory requirements, such as food safety and labeling laws.

- Consumer preferences: Consumer preferences should be considered when choosing manufacturing techniques to ensure that the final product meets their needs and preferences.

By considering these factors, businesses can choose the most appropriate manufacturing techniques to ensure that the final product meets quality, safety, and economic requirements while also meeting consumer preferences and sustainability goals.

How can MRP and ERP Systems Enhance Food Manufacturing Process?

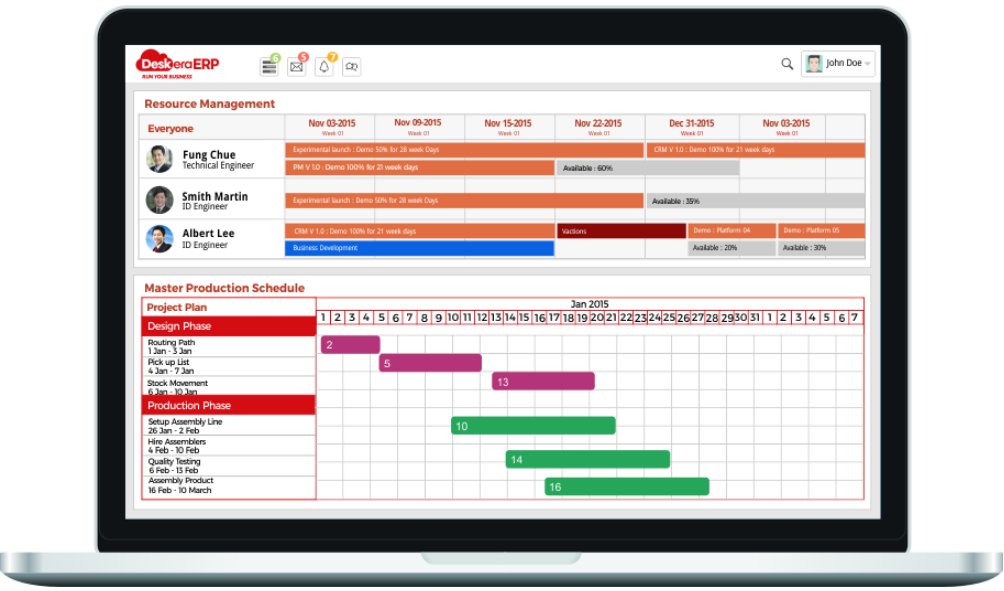

MRP (Material Requirements Planning) and ERP (Enterprise Resource Planning) systems are software solutions that can enhance food manufacturing processes by improving inventory management, production planning, and quality control. Here are some ways in which MRP and ERP systems can enhance the food manufacturing process:

Inventory management

MRP and ERP systems can help manage inventory by providing real-time inventory data, including stock levels, usage, and expiration dates. This can help businesses avoid overstocking or stock shortages, reduce waste, and improve product quality.

Production planning

MRP and ERP systems can help optimize production planning by analyzing demand, inventory levels, and production capacity to ensure that the right products are produced at the right time. This can help businesses reduce manufacturing lead times, increase production efficiency, and minimize waste.

Quality control

MRP and ERP systems can help ensure product quality by providing detailed information about the production process, including batch and lot tracking. This can help businesses identify and address quality issues quickly, reducing the risk of recalls or customer complaints.

Supply chain management

MRP and ERP systems can help manage the entire supply chain by providing real-time data on inventory levels, production schedules, and shipping. This can help businesses improve efficiency, reduce lead times, and better manage vendor relationships.

Compliance

MRP and ERP systems can help ensure regulatory compliance by providing documentation and data required for audits and inspections. This can help businesses reduce the risk of non-compliance and avoid penalties.

Overall, MRP and ERP systems can enhance the food manufacturing process by providing real-time data and analytics, improving inventory management, production planning, and quality control, and ensuring regulatory compliance.

How can Deskera Help You?

Deskera ERP and MRP systems help you to keep your business units organized. The system's primary functions are as follows:

- Keep track of your raw materials and final items inventories

- Control production schedules and routings

- Keep a bill of materials

- Produce thorough reports

- Make your own dashboards

Deskera's integrated financial planning tools enable investors to better plan and track their investments. It can assist investors in making faster and more accurate decisions.

Deskera Books allows you to better manage your accounts and finances. Maintain good accounting practices by automating tasks like billing, invoicing, and payment processing.

Deskera CRM is a powerful solution that manages your sales and helps you close deals quickly. It not only enables you to perform critical tasks like lead generation via email, but it also gives you a comprehensive view of your sales funnel.

Deskera People is a straightforward tool for centralizing your human resource management functions.

Key Takeaways

- Traditional food manufacturing techniques, such as fermentation and drying, can produce high-quality, flavorful products but may be slower and less efficient than modern techniques.

- Modern food manufacturing techniques, such as high-pressure processing and ultrasound, can produce products quickly and efficiently but may affect the texture and flavor of the final product.

- Combination techniques, which combine traditional and modern techniques, can provide the benefits of both but may require more equipment and labor.

- The choice of food manufacturing technique depends on factors such as product characteristics, safety, equipment, scalability, cost, sustainability, regulatory requirements, and consumer preferences.

- Traditional techniques can be more sustainable and environmentally friendly than modern techniques, which may rely on large amounts of energy and resources.

- Traditional techniques can also provide unique flavors and textures that may not be achievable with modern techniques.

- Modern techniques can help improve food safety and reduce the risk of foodborne illness by using methods such as pasteurization and sterilization.

- Modern techniques can also improve efficiency and reduce costs by using automated systems and high-tech equipment.

- Combination techniques can provide the benefits of both traditional and modern techniques, such as improved flavor and texture and increased efficiency.

- The choice of food manufacturing technique depends on the specific product and production requirements, and a combination of techniques may be the most effective approach. It is important to consider the pros and cons of different techniques to ensure that the final product is safe, high-quality, and meets consumer preferences.

Related Articles