The global food safety testing market is expected to reach $24.6 billion by 2022, driven by increased demand for food safety and quality.

Food manufacturing is an essential industry that provides us with a steady supply of food products that we depend on every day. However, the quality, safety, and consistency of these products can vary greatly between manufacturers, which is why measuring the effectiveness of food manufacturing is critical.

Measuring the effectiveness of food manufacturing helps to identify areas for improvement and optimize the production process.

The challenge with measuring effectiveness lies in the complexity of the food manufacturing process, which involves many stages and variables. From sourcing ingredients to packaging and distribution, each step of the process can impact the final product.

Measuring effectiveness requires identifying key performance indicators (KPIs) that can help assess different aspects of the process, such as production efficiency, product quality, and safety.

Therefore, it is crucial to ensure that the food manufacturing process is effective and efficient. By measuring effectiveness, food manufacturers can optimize their processes and deliver safe, high-quality products to consumers.

In this article, we will explore the different methods and tools used to measure the effectiveness of food manufacturing and the importance of doing so in today's world.

- Importance of Effective Food Manufacturing

- Key Performance Indicators (KPIs) for Measuring Efficiency of Food Manufacturing

- Significance of Measuring Food Production KPIs

- Production Efficiency KPIs in Food Manufacturing Sector

- Product Quality KPIs

- Safety KPIs

- Continuous Improvement

- Common Tools for Measuring Effectiveness in Food Manufacturing

- Key Challenges in Measuring Effectiveness

- Future Trends in Measuring Effectiveness of Food Manufacturing

- How can ERP and MRP Systems Ensure Efficient Food Manufacturing?

- How can Deskera Help You?

- Key Takeaways

- Related Articles

Importance of Effective Food Manufacturing

Effective food manufacturing plays a crucial role in ensuring the safety, quality, and accessibility of food products, and is essential for meeting the growing demand for food worldwide, addressing issues of food security and nutrition, and supporting the sustainable development of the food industry.

Effective food manufacturing is important for several reasons, including:

- Meeting Quality Standards: Effective food manufacturing ensures that products consistently meet quality standards and comply with regulations. This is essential for ensuring that the products are safe for consumers and meet their expectations.

- Improving Efficiency: Effective food manufacturing processes help improve efficiency by reducing waste, minimizing downtime, and optimizing inventory levels. This helps manufacturers produce products more efficiently, reducing costs and increasing profitability.

- Enhancing Customer Satisfaction: Effective food manufacturing processes help manufacturers produce high-quality products that meet customer expectations. This is essential for building customer loyalty and promoting repeat business.

- Promoting Safety: Effective food manufacturing processes promote safety by reducing the risk of workplace accidents and ensuring that products are safe for consumers. This is essential for protecting the health and wellbeing of employees and consumers.

- Staying Competitive: Effective food manufacturing processes help manufacturers stay competitive by producing high-quality products more efficiently than their competitors. This is essential for staying ahead in a competitive market and achieving long-term success.

Key Performance Indicators (KPIs) for Measuring Efficiency of Food Production

Key Performance Indicators (KPIs) are measurable values that demonstrate how well an organization is achieving its goals. There are several key performance indicators (KPIs) that can be used to measure the efficiency of food production. These KPIs provide a way to assess how well a food manufacturing company is performing in terms of productivity, quality, safety, and profitability. Some common KPIs for measuring the efficiency of food production include:

Production Yield

Production yield is one of the key performance indicators (KPIs) used to measure the efficiency of food production. It represents the ratio of the actual amount of finished product that is produced to the amount of raw materials or ingredients that are used in the production process.

In other words, production yield measures how much of the raw materials are transformed into usable finished products, which is a critical factor in determining the efficiency of food production.

To calculate production yield, the amount of raw materials or ingredients that are used in the production process is divided by the amount of finished product that is produced. For example, if a company uses 1000 kilograms of raw materials to produce 800 kilograms of finished product, the production yield would be 80% (800 divided by 1000).

A high production yield indicates that the production process is efficient and effective in transforming raw materials into finished products, while a low production yield suggests that there is waste or inefficiencies in the process that need to be addressed.

Measuring production yield is essential for food manufacturers to identify areas for improvement and optimize their production processes. By tracking production yield over time and comparing it to industry benchmarks, companies can monitor their efficiency and make data-driven decisions to improve their processes, reduce waste, and increase profitability.

Overall Equipment Effectiveness (OEE)

Overall Equipment Effectiveness (OEE) is used to measure the efficiency of equipment used in the food production process. OEE is a composite metric that takes into account three key factors: equipment availability, performance efficiency, and product quality.

The first factor, equipment availability, measures the percentage of time that equipment is available for production. This includes both scheduled and unscheduled downtime due to maintenance, repairs, changeovers, and other factors. Equipment availability is an important measure of the reliability of production equipment and the effectiveness of maintenance programs.

The second factor, performance efficiency, measures the rate at which equipment operates compared to its maximum potential speed. This takes into account factors such as setup time, startup time, and slow running speeds. Performance efficiency is an important measure of the effectiveness of equipment utilization and the efficiency of the production process.

The third factor, product quality, measures the percentage of products that are produced within quality specifications. This takes into account factors such as product defects, rework, and scrap. Product quality is an important measure of the effectiveness of quality control programs and the overall performance of the production process.

By combining these three factors, OEE provides a comprehensive measure of the efficiency of production equipment and the effectiveness of the production process. A high OEE score indicates that equipment is being utilized effectively and efficiently, while a low OEE score suggests that there are opportunities for improvement in one or more of the three factors.

Downtime

Downtime refers to the amount of time that production equipment is not operational due to various reasons such as maintenance, repairs, changeovers, breakdowns, and other factors. Measuring downtime helps food manufacturers to identify and address issues that are causing production delays, lower productivity, and higher costs.

There are two types of downtime: planned and unplanned. Planned downtime occurs when production equipment is intentionally shut down for scheduled maintenance or repairs. Unplanned downtime occurs when equipment unexpectedly stops working due to breakdowns, faults, or other issues.

Tracking downtime is important because it helps to identify areas where productivity can be improved. By measuring the frequency and duration of downtime, food manufacturers can identify equipment that is prone to breakdowns, assess the effectiveness of maintenance programs, and identify opportunities to optimize the production process.

Reducing downtime can have significant benefits for food manufacturers. It helps to increase productivity, reduce production costs, and improve the overall efficiency of the production process. By minimizing downtime, food manufacturers can increase their output, improve their delivery times, and increase their customer satisfaction.

Customer Complaints

Customer complaints are a measure of product quality and customer satisfaction. Tracking the number and type of complaints can help identify areas for improvement in product quality and customer service, and ultimately help food manufacturers to improve their efficiency.

There are many types of customer complaints in the food industry, such as complaints about product quality, taste, texture, packaging, labeling, and safety. By tracking these complaints, food manufacturers can identify patterns and trends in customer feedback, and address issues that are negatively impacting their customer satisfaction.

Measuring customer complaints is important because it provides a direct feedback loop between the customer and the food manufacturer. By listening to customer feedback and addressing their concerns, food manufacturers can improve their products and processes, and increase their customer satisfaction.

Reducing customer complaints can have significant benefits for food manufacturers. It helps to increase customer loyalty, reduce product returns, and improve brand reputation. By delivering high-quality products and addressing customer concerns quickly and effectively, food manufacturers can improve their efficiency and competitiveness in the market.

Waste Reduction

Waste reduction refers to the amount of waste generated during the production process, including raw materials, packaging materials, and finished products that do not meet quality standards. Measuring waste reduction helps food manufacturers to identify and address inefficiencies in their production processes, which can lead to cost savings, increased productivity, and improved environmental sustainability.

There are several types of waste in the food industry, including product waste, packaging waste, and energy waste. Product waste occurs when food products are spoiled, damaged, or not up to quality standards, and must be discarded.

Packaging waste refers to the waste generated from the use of packaging materials, such as cardboard boxes, plastic wrap, and other materials used for shipping and handling. Energy waste occurs when energy is used inefficiently during the production process, such as through the use of outdated equipment or inefficient lighting.

Reducing waste is important because it helps to minimize costs associated with waste disposal, reduce the environmental impact of food production, and improve the efficiency of the production process. By measuring the amount of waste generated and identifying areas for improvement, food manufacturers can implement strategies to reduce waste and increase their overall efficiency.

Employee Productivity

Employee productivity refers to the amount of output produced by each employee during a given period of time. Measuring employee productivity helps food manufacturers to identify and address issues that may be impacting their workforce, such as inadequate training, low morale, or inefficient work practices.

There are several factors that can impact employee productivity in the food industry, such as the complexity of the production process, the quality of training and support provided to employees, and the availability of resources and equipment. By measuring employee productivity, food manufacturers can identify areas for improvement and implement strategies to increase productivity and efficiency.

Increasing employee productivity can have significant benefits for food manufacturers. It can help to increase output, reduce labor costs, and improve the overall efficiency of the production process. By providing employees with the tools, resources, and support they need to be successful, food manufacturers can increase employee morale and job satisfaction, leading to improved productivity and reduced turnover rates.

Sensory Evaluation

Sensory evaluation measures the quality of products based on sensory attributes such as taste, texture, and aroma. A high score in sensory evaluation indicates that the manufacturing process is effective in producing products with desirable sensory qualities.

It refers to the process of evaluating the sensory properties of food products, including taste, texture, aroma, and appearance. Sensory evaluation helps food manufacturers to ensure that their products meet quality standards and customer expectations.

There are several methods of sensory evaluation, including trained panel tests and consumer taste tests. Trained panel tests involve a group of trained evaluators who assess the sensory properties of food products using standardized procedures. Consumer taste tests involve a group of consumers who evaluate food products based on their personal preferences and perceptions.

Measuring sensory evaluation is important because it provides a direct assessment of the quality of food products. By evaluating the sensory properties of their products, food manufacturers can identify areas for improvement and make adjustments to their processes to ensure that their products meet quality standards and customer expectations.

Improving sensory evaluation can have significant benefits for food manufacturers. It can help to increase customer satisfaction, reduce product returns and waste, and improve brand reputation. By consistently producing high-quality products with desirable sensory properties, food manufacturers can increase their efficiency and competitiveness in the market.

Compliance with Regulatory Standards

Compliance with regulatory standards measures whether the manufacturing process meets local and national regulatory requirements. A high level of compliance indicates that the manufacturing process is effective in producing safe and high-quality products.

It refers to the extent to which food manufacturers adhere to regulations and standards set by government agencies, such as the Food and Drug Administration (FDA), the United States Department of Agriculture (USDA), and other regulatory bodies.

Regulatory standards in the food industry cover a wide range of areas, including food safety, labeling, packaging, and production processes. Food manufacturers must comply with these regulations to ensure that their products are safe for consumers and meet quality standards.

Measuring compliance with regulatory standards is important because it helps to ensure that food manufacturers are producing safe and high-quality products. By complying with regulations and standards, food manufacturers can avoid costly fines, legal action, and damage to their brand reputation.

Improving compliance with regulatory standards can have significant benefits for food manufacturers. It can help to increase consumer confidence in their products, reduce the risk of product recalls and liability, and improve their overall efficiency and profitability.

Overall, compliance with regulatory standards is an important KPI for measuring the efficiency of food production because it provides insight into the level of regulatory compliance within a company.

Measuring and tracking these KPIs over time can help food manufacturing companies identify areas for improvement, optimize their processes, and increase efficiency and profitability.

Significance of Measuring Food Production KPIs

Measuring Key Performance Indicators (KPIs) in food production is significant for several reasons. First and foremost, KPIs provide a measurable and objective way to assess the efficiency, quality, and safety of the manufacturing process. By measuring KPIs, food manufacturers can identify areas for improvement, optimize their production process, and achieve their goals more effectively.

For instance, measuring production yield KPIs can help manufacturers assess the effectiveness of their supply chain management, inventory control, and production process. By identifying areas of waste and inefficiency, they can optimize their process to minimize costs, maximize yields, and reduce waste.

Similarly, measuring sensory evaluation KPIs can help manufacturers evaluate the quality of their products and ensure that they meet or exceed customer expectations. By identifying sensory attributes that are essential to customers, manufacturers can optimize their process to produce products with desirable qualities that customers are willing to pay for.

KPIs related to compliance with regulatory standards are also significant as they help manufacturers ensure that their products meet legal requirements and are safe for consumption. By complying with regulatory standards, manufacturers can reduce the risk of liability, protect their brand reputation, and avoid costly recalls.

Overall, measuring KPIs in food production is significant because it helps manufacturers optimize their production process, reduce costs, improve product quality and safety, and meet regulatory requirements. KPIs provide a reliable and objective way to assess performance and make data-driven decisions to achieve the desired outcomes.

Production Efficiency KPIs in Food Manufacturing Sector

Production efficiency refers to how well a manufacturing process utilizes its resources to produce output. It is a measure of the effectiveness of the production process in converting raw materials and resources into finished goods. Production efficiency can be calculated by comparing the actual output of a process to its expected output, given the resources and time available.

In food manufacturing, production efficiency can be measured using various metrics, including the following:

- Overall Equipment Effectiveness (OEE): OEE measures the overall efficiency of the production process, taking into account equipment availability, performance, and quality. A high OEE indicates that the production process is efficient, and equipment is being used effectively.

- Production Cycle Time: Production cycle time measures the time it takes to produce a unit of product from the beginning to the end of the production process. A low production cycle time indicates that the manufacturing process is efficient and can produce products quickly.

- Throughput: Throughput measures the number of units produced per unit of time. A high throughput indicates that the manufacturing process is efficient and can produce a large number of products in a short period.

- Capacity Utilization: Capacity utilization measures the percentage of the production capacity that is being utilized. A high capacity utilization indicates that the manufacturing process is efficient and can produce products with minimal waste.

- Changeover Time: Changeover time measures the time it takes to switch from one product to another in the production process. A low changeover time indicates that the manufacturing process is flexible and can adapt quickly to changing customer demands.

- First Pass Yield: First Pass Yield measures the percentage of products that meet quality standards on the first attempt. A high first pass yield indicates that the manufacturing process is effective in producing high-quality products with minimal waste.

- Lead Time: Lead time measures the time it takes to fulfill an order from the time it is received until the product is delivered. A low lead time indicates that the manufacturing process is efficient and can deliver products quickly.

Improving production efficiency can lead to cost savings, increased productivity, and improved customer satisfaction. By measuring production efficiency regularly, food manufacturers can identify bottlenecks in the production process and implement improvements to increase output and reduce waste.

Product Quality KPIs

Product quality refers to the degree to which a product meets or exceeds the expectations of customers. In the context of food manufacturing, product quality is a crucial factor as it directly affects customer satisfaction, brand reputation, and sales.

Product quality can be evaluated based on various factors such as taste, texture, appearance, nutritional value, and safety. In food manufacturing, product quality can be measured using various metrics, including the following:

- Microbiological testing: This is a test that checks for the presence of harmful bacteria and other microorganisms in food products.

- Chemical analysis: This is a test that evaluates the chemical composition of a food product to ensure it meets regulatory standards and label claims.

- Customer Satisfaction: This measures how satisfied customers are with the product and can help identify opportunities to improve quality.

- First Pass Yield: This measures the percentage of products that pass quality control on the first attempt, indicating how effectively the production process is producing quality products.

- Complaints and Returns: This measures the number of customer complaints or returns due to quality issues and can help identify areas for improvement.

- Sensory Evaluation: Sensory evaluation measures the sensory attributes of the product, such as taste, texture, and aroma. A high score on sensory evaluation indicates that the product has desirable sensory qualities that meet or exceed customer expectations.

- Microbiological Testing: Microbiological testing measures the presence and concentration of microorganisms in the product, such as bacteria, yeast, and mold. Low levels of microorganisms indicate that the product is safe for consumption and meets regulatory requirements.

- Foreign Matter Contamination: Foreign matter contamination measures the presence of any foreign objects in the product, such as metal fragments, plastic, or glass. Low levels of foreign matter contamination indicate that the product is safe for consumption and meets regulatory requirements.

- Nutritional Content: Nutritional content measures the nutritional value of the product, such as calories, fat, protein, and vitamins. A high nutritional value indicates that the product is healthy and meets the nutritional needs of customers.

- Shelf Life: Shelf life measures the time that the product can be stored before it spoils or loses its quality. A longer shelf life indicates that the product has a longer lifespan and can be stored for an extended period without losing its quality.

- Compliance with Labeling Regulations: Compliance with labeling regulations measures whether the product labeling meets regulatory requirements, such as listing ingredients, nutritional information, and allergens. Compliance with labeling regulations ensures that the product is safe for consumption and meets legal requirements.

Safety KPIs

Safety in the context of food manufacturing refers to the implementation of measures that ensure the food products produced are safe for consumption. This includes the implementation of food safety management systems, compliance with relevant regulations, and ensuring the hygienic production of food products.

Safety in food manufacturing involves the prevention of any physical, chemical, or biological hazards that could cause harm to the consumer. This includes ensuring proper labeling of food products, preventing contamination during production, and implementing proper storage and transportation practices.

Food safety is a critical aspect of the food manufacturing industry, as any foodborne illness outbreaks can lead to significant health risks for consumers, as well as damaging the reputation and financial health of the company.

Therefore, ensuring the safety of food products is a top priority for food manufacturers, and safety KPIs are used to measure the effectiveness of the safety measures implemented in the production process.

It can be assessed through the following metrics:

- Recordable Incident Rate (RIR): This measures the number of workplace injuries or illnesses per 100 employees and can help identify areas for improvement in workplace safety.

- Near Misses: This measures the number of incidents that could have resulted in injury or illness but were avoided, helping to identify potential safety hazards.

- Compliance: This measures how well the production process complies with safety regulations, ensuring that employees and consumers are protected from harm.

- Training: This measures the effectiveness of employee training programs in promoting safety and reducing accidents.

- Compliance with Regulatory Requirements: Compliance with regulatory requirements measures whether the company meets legal requirements related to food safety, such as maintaining proper storage temperatures, ensuring equipment is clean and sanitized, and following good manufacturing practices.

- Number of Incidents: The number of incidents measures the number of safety incidents that occur, such as accidents or injuries. A low number of incidents indicates that the company has an effective safety program in place.

- Audit Performance: Audit performance measures the company's performance in internal or external safety audits. A high audit score indicates that the company is effectively managing safety risks.

- Employee Training: Employee training measures the extent to which employees are trained on safety procedures and practices. A high percentage of employees trained indicates that the company values safety and is investing in training to ensure safety protocols are followed.

- Hazard Analysis and Critical Control Points (HACCP) Compliance: HACCP is a food safety management system that helps identify and prevent hazards. Compliance with HACCP measures whether the company is following HACCP procedures and implementing them effectively to prevent safety incidents.

- Product Recall Rates: Product recall rates measure the number of products recalled due to safety concerns. A low product recall rate indicates that the company is effectively managing safety risks and ensuring that products are safe for consumption.

By measuring these Safety KPIs, food manufacturers can identify potential safety risks, improve safety procedures, and prevent incidents from occurring.

Continuous Improvement

Continuous improvement is a crucial aspect of the food manufacturing industry. It involves continuously seeking ways to improve processes, products, and services, with the ultimate goal of increasing efficiency, reducing waste, and improving customer satisfaction.

Continuous improvement in food manufacturing refers to the ongoing effort to improve the efficiency, quality, and safety of food production processes. It involves a systematic approach to identify and eliminate waste, reduce defects, increase productivity, and enhance customer satisfaction.

Here are some of the key reasons why continuous improvement is important in food manufacturing:

- Process optimization: This involves analyzing the food manufacturing process and identifying areas for improvement, such as reducing the time it takes to produce a product or minimizing the amount of waste generated.

- Quality Assurance: Continuous improvement helps ensure that products consistently meet or exceed customer expectations in terms of quality, taste, and nutritional value. By continually seeking to improve processes, manufacturers can identify areas for improvement and optimize their operations to produce higher quality products.

- Cost Reduction: Continuous improvement helps identify areas where costs can be reduced by reducing waste, improving efficiency, and increasing productivity. This not only helps reduce production costs but also makes products more affordable for customers.

- Regulatory Compliance: The food manufacturing industry is highly regulated, and continuous improvement helps ensure that manufacturers comply with ever-changing regulations. By staying up-to-date with regulatory changes, manufacturers can avoid costly fines and reputational damage.

- Innovation: Continuous improvement encourages innovation by encouraging manufacturers to explore new methods, technologies, and ingredients. This can help manufacturers develop new products and services that meet emerging customer needs, differentiate themselves from competitors, and stay ahead of market trends.

- Employee Engagement: Continuous improvement encourages employee engagement by involving employees in the process of identifying and implementing improvements. This not only helps improve morale and job satisfaction but also helps ensure that the improvements are sustainable and effective.

Common Tools for Measuring Effectiveness in Food Manufacturing

There are various tools and techniques available for measuring effectiveness in food production. Here are some common tools that are widely used in the industry:

Statistical Process Control (SPC)

Statistical Process Control (SPC) is a statistical method that is used in manufacturing to monitor and control production processes. It involves the use of statistical tools to measure and analyze the performance of a manufacturing process over time.

SPC can be used to identify trends, detect abnormalities, and take corrective actions to ensure that the manufacturing process is operating within the desired specifications.

In food manufacturing, SPC can be used to monitor and control various production processes, such as temperature, humidity, pH, and other factors that affect product quality and safety. SPC can also be used to identify sources of variability in the manufacturing process, such as equipment malfunction or operator error.

The benefits of using SPC in food manufacturing include improving product quality and consistency, reducing waste, and increasing efficiency. By monitoring and controlling production processes, food manufacturers can ensure that their products meet the desired specifications and are safe for consumption.

Some of the statistical tools used in SPC include control charts, which are used to track the performance of a process over time, and process capability analysis, which is used to measure the ability of a process to produce products that meet the desired specifications.

Overall, SPC is a powerful tool for measuring the effectiveness of food manufacturing processes. By analyzing data and identifying sources of variability, food manufacturers can improve product quality, reduce waste, and increase efficiency, ultimately leading to a more profitable and sustainable business.

Lean Manufacturing

Lean manufacturing is a production philosophy that focuses on reducing waste and maximizing efficiency in the manufacturing process. It involves the elimination of non-value-added activities, such as overproduction, waiting time, excess inventory, defects, and unnecessary motion.

By reducing waste and increasing efficiency, lean manufacturing can help food manufacturers improve product quality and reduce costs. In food manufacturing, lean principles can be applied to various processes, such as production, inventory management, and supply chain management.

For example, lean manufacturing can help food manufacturers reduce inventory levels by producing products in smaller batches and improving the flow of materials and information throughout the supply chain.

The benefits of using lean manufacturing in food manufacturing include improving product quality, reducing waste, increasing efficiency, and reducing costs. By identifying and eliminating waste, food manufacturers can improve their competitiveness and profitability.

Some of the tools used in lean manufacturing include value stream mapping, which is used to identify waste and opportunities for improvement, and kaizen events, which are short-term improvement projects designed to eliminate waste and improve efficiency.

Total Productive Maintenance (TPM)

Total Productive Maintenance (TPM) is a tool used in manufacturing to improve the effectiveness and efficiency of equipment maintenance. TPM involves a comprehensive approach to maintenance, where everyone in the organization takes responsibility for ensuring that equipment is well-maintained and operating at peak performance.

The goal of TPM is to increase equipment uptime, reduce unplanned downtime, and improve overall equipment effectiveness.

In food manufacturing, TPM is critical for maintaining food safety and quality, as well as for improving productivity and reducing costs. TPM includes a range of activities, such as routine inspections, cleaning, and lubrication of equipment, as well as more advanced maintenance activities, such as predictive maintenance and condition monitoring.

One of the key benefits of TPM is that it helps to identify potential equipment problems before they occur, allowing manufacturers to take corrective action before equipment failure leads to unplanned downtime or product quality issues. TPM can also help manufacturers reduce maintenance costs by reducing the need for expensive repairs or equipment replacement.

To implement TPM in food manufacturing, companies must establish a culture of continuous improvement and ensure that all employees are trained on TPM principles and techniques. They must also establish a system for tracking equipment performance and maintenance activities, and regularly analyze data to identify areas for improvement.

Root Cause Analysis (RCA)

Root Cause Analysis (RCA) is a problem-solving tool used in manufacturing to identify the underlying causes of production issues or failures. The goal of RCA is to identify the root cause of a problem, rather than simply treating the symptoms, so that it can be effectively addressed and prevented from recurring.

In food manufacturing, RCA is an important tool for improving quality, productivity, and safety. By identifying the root cause of issues, manufacturers can take targeted corrective action to prevent future occurrences, reduce waste, and improve overall efficiency.

RCA typically involves a structured approach to problem-solving, including data collection, analysis, and interpretation. The process typically involves asking "why" questions to identify the underlying cause of a problem, with each answer leading to a deeper understanding of the issue until the root cause is identified.

Once the root cause is identified, manufacturers can take corrective action to address the issue, such as modifying processes or procedures, implementing new training programs, or making equipment changes. By addressing the root cause of a problem, manufacturers can prevent the issue from recurring and improve the overall effectiveness of their food manufacturing processes.

In summary, Root Cause Analysis is an effective tool for measuring the effectiveness of food manufacturing processes, helping to identify underlying issues and take targeted corrective action to improve productivity, quality, and safety.

Six Sigma

Six Sigma is a data-driven quality improvement methodology that aims to eliminate defects and minimize variability in manufacturing processes. The goal of Six Sigma is to achieve a level of performance where the probability of producing a defective product is extremely low, typically less than 3.4 defects per million opportunities.

In food manufacturing, Six Sigma can be used to improve the quality of products, reduce waste, and increase efficiency. The methodology involves a structured approach to problem-solving, which includes the Define, Measure, Analyze, Improve, and Control (DMAIC) framework.

The DMAIC process involves defining the problem, measuring the current process performance, analyzing the data to identify the root cause of the problem, implementing improvements, and controlling the process to sustain the improvements.

Six Sigma uses statistical tools and techniques to analyze data and identify opportunities for improvement. This includes process mapping, statistical process control, design of experiments, and hypothesis testing.

Key Performance Indicators (KPIs)

As already covered, the KPIs are a set of measurable metrics used to track and evaluate the effectiveness of production processes. These metrics can be tracked using software or manually, depending on the size and complexity of the manufacturing process. KPIs can include metrics related to quality, productivity, efficiency, and customer satisfaction.

By using these tools and techniques, food manufacturers can measure the effectiveness of their production processes, identify areas for improvement, and optimize their operations to produce high-quality products more efficiently. These tools and techniques help manufacturers ensure that their products consistently meet quality standards, comply with regulations, and meet customer needs.

Key Challenges in Measuring Effectiveness

The effectiveness of food manufacturing can be challenging to measure due to various factors such as the complexity of the production process, lack of standardized metrics, and the subjective nature of quality evaluation. Thus, identifying and addressing these key challenges is crucial for accurately measuring and optimizing the efficiency of food production.

Measuring the effectiveness of food manufacturing can be challenging due to a variety of factors, including:

Complex Production Processes

Complex production processes can be a major challenge in measuring the effectiveness of food manufacturing. Many food products require numerous steps and stages of processing, each with its own set of variables and potential sources of variation.

This complexity can make it difficult to identify and measure the factors that contribute to overall effectiveness.

For example, in a food manufacturing plant that produces canned soup, there may be multiple steps involved in the production process, including cooking, mixing, filling, and sealing. Each step may involve different ingredients, machinery, and quality control procedures.

The complexity of the production process can make it challenging to identify and measure the factors that affect effectiveness, such as production speed, product quality, and waste reduction.

In addition, the use of different equipment and technology can also contribute to complexity in food production. For example, some food manufacturers may use older equipment that is not well-suited to data collection and analysis, while others may use more advanced technologies that require specialized expertise to operate effectively.

Limited Data Availability

Limited data availability is another key challenge in measuring the effectiveness of food manufacturing. Many food manufacturing processes involve multiple variables that can impact the final product, including ingredients, temperature, humidity, and processing times. However, collecting and analyzing data on these variables can be difficult and time-consuming.

In some cases, data may not be collected at all due to a lack of resources or the absence of the necessary tools and technologies. In other cases, data may be collected but not in a format that is easily analyzed, making it difficult to identify trends or patterns.

This limited availability of data can make it challenging to accurately measure effectiveness and identify areas for improvement. Without sufficient data, it may be difficult to determine the root cause of issues such as product defects, low throughput, or poor quality.

To overcome this challenge, food manufacturers may need to invest in new data collection and analysis tools or work with external partners to gather and analyze data. This may involve implementing new technologies such as sensors, machine learning algorithms, or predictive analytics.

By improving data availability and analysis, food manufacturers can gain a better understanding of their production processes and make more informed decisions about how to improve efficiency and quality.

Cost of Implementation

Implementing an effective measurement system requires significant investment in technology, equipment, and personnel. For smaller food manufacturers or those with limited resources, these costs can be prohibitive.

One of the biggest costs associated with implementing a measurement system is the cost of technology. Advanced tools such as sensors, automated monitoring systems, and analytics software can be expensive to purchase and require specialized expertise to implement and operate. Additionally, the cost of training personnel on how to use these tools and interpret the resulting data can also be a significant expense.

Another challenge associated with cost is the need to integrate new measurement technologies and systems with existing production processes. This can require significant modifications to existing infrastructure and processes, which can add to the overall cost of implementation.

Overall, the cost of implementing an effective measurement system can be a significant barrier for food manufacturers looking to improve the efficiency and quality of their production processes.

However, by taking a strategic approach to investment and working with external partners or consultants, food manufacturers can overcome these challenges and realize long-term benefits in terms of improved efficiency, quality, and profitability.

Time and Resource Constraints

Many food manufacturing facilities operate on tight schedules and have limited resources, making it difficult to dedicate the time and personnel needed to implement an effective measurement system.

One of the biggest challenges associated with time and resource constraints is the need to balance ongoing production with the implementation of a measurement system. Shutting down production for an extended period to implement new technologies or processes can result in lost revenue and productivity, making it difficult for food manufacturers to justify the investment.

Additionally, there may be a lack of available personnel or expertise to manage and operate new measurement technologies. This can result in delays or inefficiencies in data collection and analysis, making it difficult to accurately measure the effectiveness of production processes.

To overcome these challenges, food manufacturers may need to take a phased approach to implementing a measurement system, starting with small-scale pilot projects and gradually scaling up as resources become available.

They may also need to invest in training and development programs to ensure that personnel have the necessary expertise to manage and operate new technologies and processes.

Regulatory Compliance

The food manufacturing industry is subject to strict regulations around safety and quality. Meeting these regulations can be challenging and can impact the effectiveness of production processes.

One of the biggest challenges associated with regulatory compliance is the need to keep up with constantly changing regulations and standards. This can require significant resources and expertise to ensure that the production process is consistently in compliance with the latest requirements.

Additionally, compliance with regulations and standards can require the implementation of specific measurement and monitoring systems. For example, regulations may require the monitoring of specific environmental conditions, such as temperature and humidity, to ensure that food products are stored and transported in a safe and hygienic manner.

To overcome these challenges, food manufacturers may need to invest in specialized expertise or external consulting services to ensure that their production processes are in compliance with the latest regulations and standards. They may also need to implement specialized measurement and monitoring systems to ensure that they are meeting the necessary requirements.

Overall, regulatory compliance is a significant challenge that can make it difficult for food manufacturers to measure the effectiveness of their production processes. By taking a proactive approach to compliance and investing in the necessary resources and expertise, food manufacturers can ensure that they are meeting regulatory requirements while also improving the efficiency and quality of their production processes.

Despite these challenges, measuring the effectiveness of food manufacturing is essential for ensuring the safety and quality of products, reducing costs, and promoting customer satisfaction. By addressing these challenges through investment in technology, personnel, and data analysis tools, food manufacturers can overcome these obstacles and achieve long-term success.

Future Trends in Measuring Effectiveness of Food Manufacturing

The food manufacturing industry is constantly evolving, and there are several future trends that are likely to impact how the effectiveness of food manufacturing is measured. These trends include:

Automation and Digitalization

Automation and digitalization are expected to be major future trends in measuring the effectiveness of food manufacturing processes. With the increasing availability of digital technologies such as the Internet of Things (IoT), artificial intelligence (AI), and machine learning, food manufacturers can now collect and analyze large amounts of data in real-time, providing insights into the performance of their production processes.

One key benefit of automation and digitalization is the ability to collect data from a wide range of sources, including sensors, cameras, and other monitoring devices. This data can then be analyzed using advanced analytics tools to identify patterns and trends, enabling manufacturers to optimize their production processes for maximum efficiency and quality.

Another benefit of automation and digitalization is the ability to implement predictive maintenance and quality control systems. By using machine learning algorithms to analyze data from sensors and other sources, manufacturers can identify potential issues before they occur, reducing downtime and improving product quality.

In addition, automation and digitalization can also improve the safety of food manufacturing processes. By implementing digital monitoring and control systems, manufacturers can reduce the risk of human error and ensure that production processes are consistently in compliance with safety and quality regulations.

Artificial Intelligence

With the increasing availability of AI technologies, food manufacturers can now collect and analyze large amounts of data in real-time, providing insights into the performance of their production processes.

One key benefit of AI is its ability to analyze data in real-time and make predictions based on historical data. By using machine learning algorithms to analyze data from sensors and other sources, manufacturers can identify patterns and trends in their production processes, enabling them to optimize for maximum efficiency and quality.

Another benefit of AI is its ability to optimize production processes by using predictive analytics. By analyzing data from sensors and other sources, AI systems can identify potential issues before they occur, reducing downtime and improving product quality. This can lead to significant cost savings for food manufacturers.

AI can also be used to improve product quality and safety by providing real-time monitoring and control of production processes. By using AI-based systems, manufacturers can ensure that their products are consistently in compliance with safety and quality regulations, reducing the risk of product recalls and other costly issues.

Overall, AI is expected to play an increasingly important role in measuring the effectiveness of food manufacturing processes. By leveraging the latest AI technologies, food manufacturers can improve efficiency, quality, and safety, while also gaining valuable insights into their production processes.

Blockchain Technology

Blockchain technology is another future trend in measuring the effectiveness of food manufacturing processes. Blockchain is a distributed ledger technology that enables secure, transparent, and tamper-proof recording of data. In the food industry, blockchain can be used to track the movement of food products from farm to table, providing a clear picture of the entire supply chain and improving transparency and traceability.

By using blockchain technology, food manufacturers can create an unalterable record of the production and movement of their products. This can help to prevent food fraud, reduce waste, and ensure that products are of the highest quality.

Blockchain can also be used to provide consumers with more information about the products they are buying, such as where the food was grown, how it was produced, and whether it meets certain quality or sustainability standards.

One key benefit of blockchain technology is its ability to improve the efficiency of supply chain operations. By using a decentralized system that eliminates the need for intermediaries, blockchain can streamline the movement of goods and reduce the time and cost associated with supply chain management.

Another benefit of blockchain technology is its ability to improve food safety. By creating a tamper-proof record of the entire supply chain, blockchain can help to prevent foodborne illnesses by identifying the source of any contamination quickly.

Overall, blockchain technology is expected to play an increasingly important role in measuring the effectiveness of food manufacturing processes. By providing transparency, traceability, and security throughout the supply chain, blockchain can help to improve efficiency, reduce waste, and ensure that food products are safe and of the highest quality.

Sustainable Manufacturing

Sustainable manufacturing practices are likely to become more important in the food industry, with a focus on reducing waste and minimizing environmental impact. Sustainable manufacturing refers to the production of goods in an environmentally friendly and socially responsible manner.

In the food industry, sustainable manufacturing involves reducing the environmental impact of food production while maintaining high levels of quality and safety.

Sustainable food manufacturing can be achieved through a variety of methods, such as reducing waste, using renewable energy sources, and using sustainable packaging materials. By reducing waste, food manufacturers can minimize their environmental impact and reduce their costs.

Using renewable energy sources, such as solar or wind power, can help to reduce greenhouse gas emissions and promote sustainability. Using sustainable packaging materials, such as biodegradable or compostable materials, can help to reduce waste and promote recycling.

Sustainable manufacturing also involves promoting social responsibility in the food industry. This includes ensuring fair labor practices, promoting diversity and inclusion, and supporting local communities. By promoting social responsibility, food manufacturers can build trust with their customers and promote a positive image for their brand.

Overall, sustainable manufacturing is a key future trend in measuring the effectiveness of food manufacturing processes. By promoting environmental sustainability and social responsibility, food manufacturers can create high-quality products that are both safe and ethical. This can lead to increased customer loyalty and a positive impact on the environment and society as a whole.

Personalization

The trend towards personalized nutrition is likely to continue, with a focus on developing products that meet individual dietary needs and preferences. Personalization in food manufacturing refers to the ability to customize food products to meet the specific needs and preferences of individual consumers.

Advances in technology, such as artificial intelligence and machine learning, are making it possible to analyze large amounts of data and create personalized food products based on individual tastes, health needs, and dietary restrictions. Personalization in food manufacturing has several benefits.

First, it allows food manufacturers to create products that meet the specific needs and preferences of individual consumers, leading to increased customer satisfaction and loyalty.

Second, it can help to promote healthy eating habits by creating personalized diets and meal plans based on individual health needs and goals. Finally, it can help to reduce food waste by creating products that are tailored to specific consumer demand, reducing the amount of unsold food that is discarded.

Personalization in food manufacturing can be achieved through a variety of methods, such as using sensors to collect data on individual preferences and health needs, and using algorithms to create personalized food products.

As technology continues to advance, it is likely that personalization will become an increasingly important trend in the food manufacturing industry.

Overall, personalization is a key future trend in measuring the effectiveness of food manufacturing processes. By creating customized food products that meet individual consumer needs, food manufacturers can increase customer satisfaction, promote healthy eating habits, and reduce food waste.

The future of measuring the effectiveness of food manufacturing will be shaped by the use of advanced technologies, a focus on sustainability, and the increasing demand for personalized products. By staying ahead of these trends and investing in new tools and technologies, food manufacturers can continue to improve their processes and meet the evolving needs of consumers.

How can ERP and MRP Systems Ensure Efficient Food Manufacturing?

Enterprise Resource Planning (ERP) and Material Requirements Planning (MRP) systems are software solutions that can help to ensure efficient food manufacturing. These systems work by providing real-time data and insights that enable businesses to make informed decisions about production, inventory, and supply chain management.

Firstly, ERP systems provide a central database that consolidates all of the company's data and processes into a single system, making it easier to manage. This means that managers can track inventory levels, production schedules, and supply chain logistics in real-time, allowing them to optimize processes and make informed decisions. This can lead to improved production efficiency, reduced waste, and lower costs.

Secondly, MRP systems work by generating production schedules based on real-time data about inventory levels, demand, and production capacity. This ensures that the right materials are ordered in the right quantities, reducing waste and ensuring that production runs smoothly.

To summarize, here are the features of an MRP and ERP software that can help ensure efficient food manufacturing include:

- Inventory Management: Effective management of inventory through real-time tracking of materials, finished goods, and work in progress to prevent stockouts and reduce waste.

- Production Planning: Planning and scheduling production processes based on demand forecasts, lead times, and inventory levels, ensuring timely delivery of products.

- Quality Control: Ensuring the quality of raw materials, work in progress, and finished products by monitoring and tracking quality parameters at every stage of the manufacturing process.

- Traceability and Recall Management: Tracking the movement of products and raw materials throughout the supply chain to facilitate timely recalls in case of defects or safety concerns.

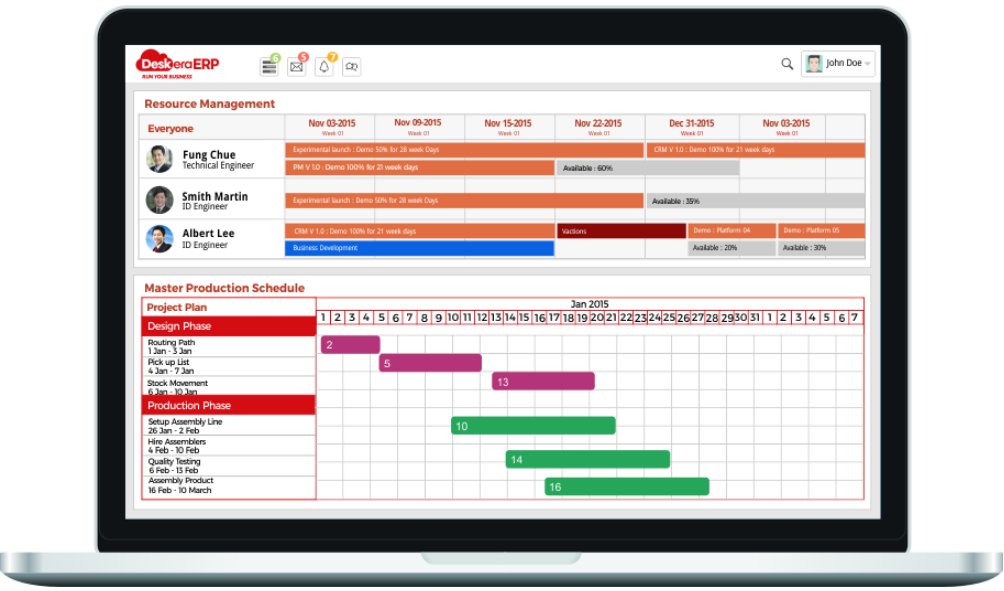

- Resource Management: Optimizing the use of resources such as labor, equipment, and energy to reduce waste and increase productivity.

- Cost Control: Analyzing the cost of production processes and identifying opportunities for cost savings through better resource utilization and process optimization.

- Reporting and Analytics: Providing real-time reporting and analytics on key performance indicators such as production efficiency, quality, and inventory levels to enable informed decision-making.

- Integration with Supply Chain Partners: Seamless integration with suppliers, distributors, and retailers to ensure smooth coordination and timely delivery of products.

How can Deskera Help You?

Deskera ERP and MRP systems help you to keep your business units organized. The system's primary functions are as follows:

- Keep track of your raw materials and final items inventories

- Control production schedules and routings

- Keep a bill of materials

- Produce thorough reports

- Make your own dashboards

Deskera's integrated financial planning tools enable investors to better plan and track their investments. It can assist investors in making faster and more accurate decisions.

Deskera Books allows you to better manage your accounts and finances. Maintain good accounting practices by automating tasks like billing, invoicing, and payment processing.

Deskera CRM is a powerful solution that manages your sales and helps you close deals quickly. It not only enables you to perform critical tasks like lead generation via email, but it also gives you a comprehensive view of your sales funnel.

Deskera People is a straightforward tool for centralizing your human resource management functions.

Key Takeaways

- Measuring the effectiveness of food manufacturing is crucial for ensuring product quality, safety, and regulatory compliance.

- Key Performance Indicators (KPIs) are essential tools for measuring effectiveness in food production.

- Production efficiency KPIs include measures such as throughput, downtime, and cycle time.

- Product quality KPIs include measures such as yield, defects, and customer satisfaction.

- Safety KPIs include measures such as accident rates, near misses, and compliance with regulatory standards.

- Continuous improvement is important for achieving long-term success in food manufacturing.

- Common tools for measuring effectiveness in food production include statistical process control, root cause analysis, and Six Sigma methodologies.

- Effective data collection and analysis are essential for measuring effectiveness in food manufacturing.

- Automation and digitalization are likely to increase in food manufacturing, leading to the collection of more data.

- Artificial intelligence and blockchain technology are likely to play a greater role in measuring effectiveness in food manufacturing.

- Sustainable manufacturing practices will become more important in the food industry.

- Key challenges in measuring effectiveness include complex production processes, limited data availability, and cost of implementation.

- Regulatory compliance is an ongoing challenge for food manufacturers.

- By staying ahead of trends and investing in new tools and technologies, food manufacturers can continue to improve their processes and meet the evolving needs of consumers.

Related Articles