In today’s fast-paced business environment, inventory efficiency can make or break profitability. Companies across industries are realizing that disconnected systems and data silos lead to costly inefficiencies, poor visibility, and missed opportunities. In fact, the global inventory management software market is projected to reach $4.8 billion by 2029, reflecting how essential seamless integration has become in managing modern supply chains. As businesses expand, integrating inventory processes into a single, unified system is no longer optional—it’s a strategic necessity.

Inventory distortions such as overstocks and stock-outs continue to be a major global concern, costing businesses an astonishing $1.8 trillion in 2020. These inefficiencies not only strain working capital but also erode customer trust when demand isn’t met accurately. Research shows that simply reducing stock-outs and overstocks can lower inventory costs by up to 10%, underscoring the importance of having real-time insights and synchronization across all inventory touchpoints.

This is where Enterprise Resource Planning (ERP) systems play a crucial role. ERP systems serve as the backbone of seamless inventory integration—bringing together data from procurement, warehousing, sales, and accounting into one centralized platform. By doing so, they eliminate manual data entry errors, enhance supply chain visibility, and empower decision-makers with real-time analytics. The result is a smarter, more agile inventory process that supports operational excellence and sustainable growth.

Among the many ERP solutions available today, Deskera ERP stands out for its comprehensive, user-friendly, and intelligent design. It offers real-time inventory tracking, automated reorder alerts, and AI-driven demand forecasting to help businesses stay one step ahead. With built-in MRP, accounting, and sales modules, Deskera ERP ensures every department operates in sync—making it easier to achieve true inventory harmony. Whether you’re a small business or a growing enterprise, Deskera ERP helps you transform your inventory operations from reactive to proactive.

What is Inventory Integration and Why Does It Matters?

Inventory integration refers to the seamless connection of inventory data across all business functions—such as procurement, sales, accounting, and warehouse management—into a unified, centralized system. Instead of operating in silos, each department shares real-time information, ensuring that every team works with the same accurate data. For instance, when a sales order is placed, the ERP system instantly updates stock levels, triggers a reorder if needed, and reflects the change in financial records. This level of synchronization minimizes manual work and enhances overall operational efficiency.

In traditional setups, inventory management often relies on disconnected systems or spreadsheets, which can easily lead to data inconsistencies, duplicate entries, and stock discrepancies. Without integration, businesses struggle to get a real-time view of inventory levels, leading to challenges such as delayed shipments, stockouts, or overstocking. These inefficiencies not only hurt productivity but also increase carrying costs and reduce profitability over time.

By contrast, an integrated inventory system powered by ERP software offers end-to-end visibility and automation. It streamlines the flow of information, enabling businesses to track stock movements, forecast demand accurately, and align inventory decisions with sales and procurement strategies. This unified approach also strengthens collaboration between departments, helping organizations respond swiftly to market changes or supply chain disruptions.

Ultimately, inventory integration matters because it forms the foundation of efficient, data-driven business operations. It ensures that inventory is always aligned with demand, reduces waste, and supports better financial planning. For growing businesses, adopting ERP-based inventory integration isn’t just a technological upgrade—it’s a strategic investment in agility, accuracy, and long-term success.

Challenges in Managing Disconnected Inventory Systems

Managing inventory across multiple disconnected systems or spreadsheets is a common challenge for growing businesses. When departments operate in isolation, information silos emerge, leading to errors, inefficiencies, and missed opportunities.

Disconnected inventory systems prevent organizations from achieving real-time visibility, accurate reporting, and streamlined operations—making it difficult to maintain control over stock and meet customer demand. Below are the key challenges that businesses face without integrated inventory management.

1. Data Silos and Lack of Visibility

When inventory data is stored in separate systems, each department has only a partial view of stock levels. Warehouse, sales, and accounting teams may track inventory independently, creating data silos that block company-wide insights. This fragmentation can lead to inaccurate forecasting, delayed decision-making, and poor inventory planning. ERP inventory management solves this by centralizing data, ensuring all teams work with consistent, real-time information.

2. Manual Data Entry and Human Errors

Disconnected systems often require repetitive manual data entry across spreadsheets or standalone software. This increases the risk of human errors, such as duplicate records, miscounted stock, or incorrect order fulfillment. Even minor mistakes can cascade, causing delays, misplaced shipments, and inaccurate financial reporting—ultimately affecting profitability and operational efficiency.

3. Stock Discrepancies and Inefficient Replenishment

Without real-time inventory synchronization, businesses struggle with overstocking or stockouts. Inventory imbalances not only increase carrying costs but also lead to missed sales opportunities. Decisions become reactive rather than proactive, and replenishment is often delayed, creating disruptions in the supply chain.

4. Poor Cross-Departmental Coordination

Independent systems make collaboration between departments difficult. Procurement may not have visibility into changing sales trends, while finance may not track inventory movements promptly. This lack of coordination slows processes, causes miscommunication, and reduces overall efficiency. Integrated systems ensure that all teams operate with shared, real-time data, improving workflow and responsiveness.

5. Limited Reporting and Decision-Making Capability

Disconnected inventory systems often cannot generate comprehensive, data-driven reports. Consolidating data from multiple platforms is time-consuming, which limits the ability to analyze inventory trends, optimize stock levels, or make informed decisions. Businesses spend more time gathering information than acting on insights, reducing agility and competitiveness.

6. Increased Operational Costs

Inefficiencies from disconnected systems directly drive up costs. Excess safety stock, emergency orders to cover stockouts, and repeated manual reconciliations all contribute to higher operational expenses. Without a unified system, companies struggle to optimize inventory carrying costs, labor, and logistics.

7. Difficulty in Regulatory Compliance

Industries like pharmaceuticals, food, and chemicals require accurate tracking of product movements, batch numbers, and expiration dates. Disconnected systems make compliance reporting cumbersome and prone to error, increasing the risk of regulatory penalties or recalls.

8. Slow Response to Market Changes

Disconnected inventory systems prevent businesses from reacting quickly to fluctuations in demand or supply chain disruptions. Lack of real-time data makes it challenging to adjust stock levels, leading to missed opportunities, delays in fulfilling orders, and lost revenue.

9. Challenges in Scaling the Business

As businesses grow, managing multiple systems becomes increasingly complex. Adding new products, locations, or sales channels magnifies inefficiencies, causing bottlenecks that limit scalability. Integrated inventory management via ERP ensures a scalable framework, allowing growth without operational chaos.

This comprehensive look at inventory challenges clearly shows why ERP inventory management systems are critical for achieving seamless integration, operational efficiency, and real-time visibility across the organization.

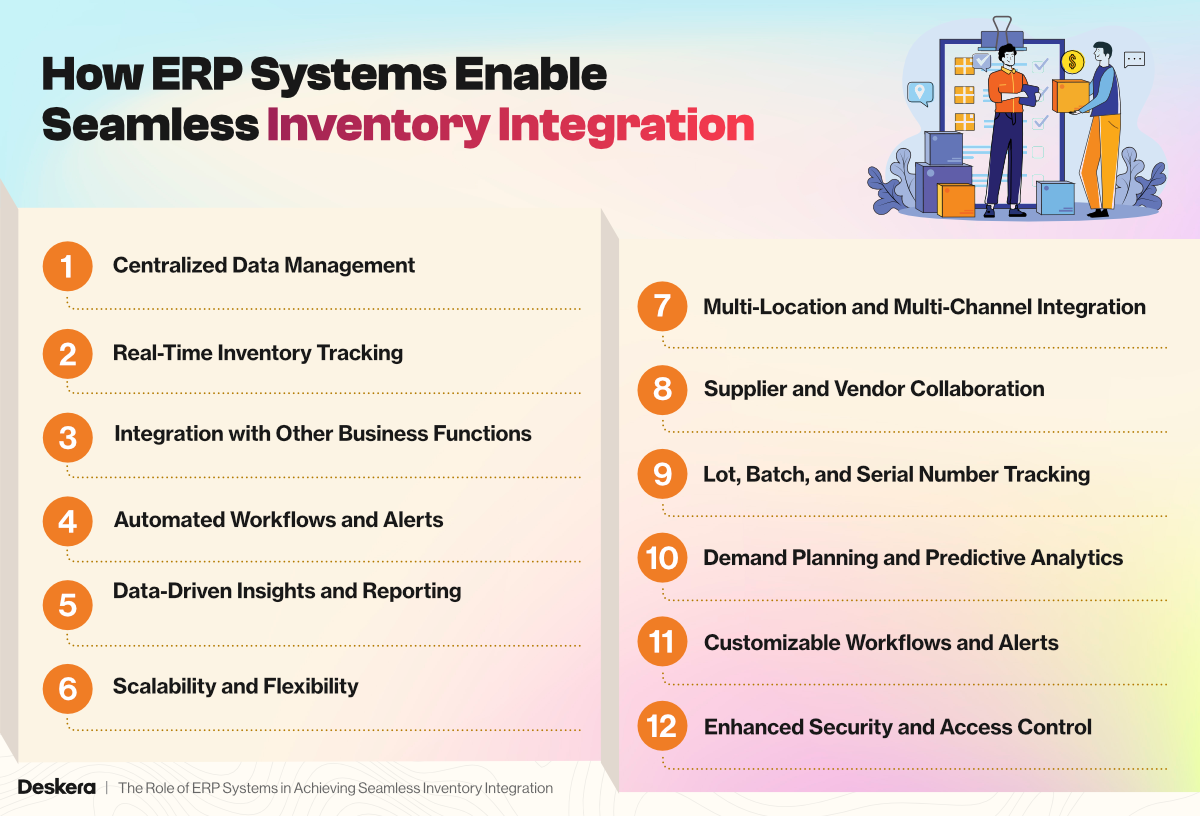

How ERP Systems Enable Seamless Inventory Integration

ERP systems act as the backbone of modern inventory management, connecting multiple business functions into a single, centralized platform. By integrating inventory with procurement, sales, accounting, and warehouse operations, ERP systems eliminate silos, reduce errors, and provide real-time visibility.

This not only streamlines day-to-day operations but also supports data-driven decision-making, cost reduction, and improved customer satisfaction. Below are the key ways ERP systems achieve seamless inventory integration.

1. Centralized Data Management

ERP systems unify all inventory-related data in one central repository. Whether it’s stock levels, purchase orders, sales orders, or supplier details, every piece of information is accessible across departments.

This centralization reduces duplicate entries, ensures consistency, and allows managers to make informed decisions without relying on manual reconciliation. ERP inventory management ensures that teams work with a single source of truth, improving efficiency and accuracy.

2. Real-Time Inventory Tracking

Integrated ERP systems provide real-time visibility into inventory levels across all locations. Businesses can monitor stock movements, track warehouse transactions, and manage reorder points instantly.

This reduces the risk of stockouts or overstocking, supports accurate demand forecasting, and enables businesses to respond quickly to market changes. Real-time tracking also enhances customer satisfaction by ensuring products are available when needed.

3. Integration with Other Business Functions

ERP systems connect inventory with other critical business functions such as sales, procurement, production, and accounting. For example:

- Sales orders automatically update stock levels.

- Purchase orders are generated when inventory hits reorder points.

- Accounting records reflect real-time inventory valuation.

This cross-functional integration improves collaboration, reduces delays, and ensures all teams operate on the same data set.

4. Automated Workflows and Alerts

Modern ERP solutions enable automation of repetitive tasks, such as reordering stock, generating purchase requests, or sending notifications for low inventory. Automated alerts help prevent stockouts, reduce manual oversight, and streamline day-to-day operations. Businesses can focus on strategic planning instead of manual inventory management.

5. Data-Driven Insights and Reporting

ERP systems offer powerful dashboards, analytics, and customizable reports that provide actionable insights into inventory performance. Businesses can identify slow-moving items, optimize stock levels, forecast demand, and evaluate supplier performance. Inventory integration software powered by ERP enables decision-makers to act proactively, rather than reactively, improving operational efficiency and reducing inventory costs.

6. Scalability and Flexibility

As businesses grow, ERP systems scale to accommodate new products, warehouses, or sales channels without disrupting existing operations. Unlike disconnected systems, ERP maintains seamless integration across locations, supporting expansion while maintaining accuracy, efficiency, and visibility.

7. Multi-Location and Multi-Channel Integration

Modern businesses often operate across multiple warehouses, retail outlets, or e-commerce channels. ERP systems provide centralized inventory control across all locations and channels, ensuring consistent stock information, avoiding duplication, and enabling smooth omnichannel operations.

8. Supplier and Vendor Collaboration

Integrated ERP systems allow direct communication and data sharing with suppliers. Businesses can share forecasts, track deliveries, and automate purchase orders. This strengthens supplier relationships, reduces lead times, and prevents stock shortages.

9. Lot, Batch, and Serial Number Tracking

For industries such as pharmaceuticals, food, and electronics, tracking inventory by lot, batch, or serial number is crucial for quality control and compliance. ERP systems enable precise tracking, making recalls or audits faster and more reliable.

10. Demand Planning and Predictive Analytics

Advanced ERP systems use historical sales data and AI-powered algorithms to provide demand forecasting. This allows businesses to anticipate market trends, adjust inventory levels proactively, and reduce waste or overstocking.

11. Customizable Workflows and Alerts

ERP systems allow businesses to customize workflows, approvals, and alerts according to their unique operational processes. For example, automatic notifications for low stock, expired items, or pending approvals streamline operations and prevent costly errors.

12. Enhanced Security and Access Control

ERP systems provide role-based access, ensuring that sensitive inventory and financial data is accessible only to authorized personnel. This improves data security while maintaining transparency for operational decisions.

Benefits of Inventory Integration Through ERP Systems

Implementing an ERP system to integrate inventory processes brings multiple advantages that go beyond simple stock management. By connecting procurement, warehouse, sales, and finance, ERP systems create a synchronized ecosystem that improves efficiency, reduces costs, and enhances overall business performance. Below are the key benefits of seamless inventory integration through ERP.

1. Improved Accuracy and Reduced Human Errors

Manual inventory management is prone to errors that can lead to stock discrepancies, miscounted items, and financial mismatches. ERP inventory management automates data entry and synchronizes information across departments, significantly reducing human errors. This ensures accurate stock levels, precise reporting, and reliable financial records.

2. Enhanced Collaboration Between Departments

An integrated system connects teams from sales, procurement, warehouse, and accounting. Everyone works with the same real-time data, improving coordination and decision-making. This cross-departmental visibility ensures that stock levels are aligned with orders, reducing delays and improving operational efficiency.

3. Increased Operational Efficiency

ERP systems automate repetitive inventory tasks such as reorder notifications, stock adjustments, and reporting. By reducing manual intervention, businesses save time and labor costs, allowing staff to focus on higher-value activities. Automated workflows also accelerate order fulfillment, making operations smoother and more predictable.

4. Optimized Inventory Costs

By providing accurate, real-time inventory insights, ERP systems help businesses reduce overstocking and stockouts, which can lower inventory costs by up to 10%. Better demand forecasting, inventory planning, and procurement decisions help control carrying costs and reduce waste.

5. Streamlined Order Fulfillment and Customer Satisfaction

Integrated inventory management ensures products are available when and where they are needed. Accurate stock data allows for faster order processing, on-time delivery, and fewer backorders, improving customer satisfaction and brand reputation.

6. Better Financial Reporting and Compliance

ERP systems automatically update accounting records based on inventory movements. This provides accurate financial reporting, simplifies audits, and ensures compliance with regulatory requirements. Businesses can track inventory valuation, cost of goods sold, and other key financial metrics in real time.

7. Scalability and Business Growth

ERP-enabled inventory integration supports business expansion by accommodating new products, locations, and sales channels without disrupting operations. The system grows with the business while maintaining accuracy, visibility, and efficiency across all departments.

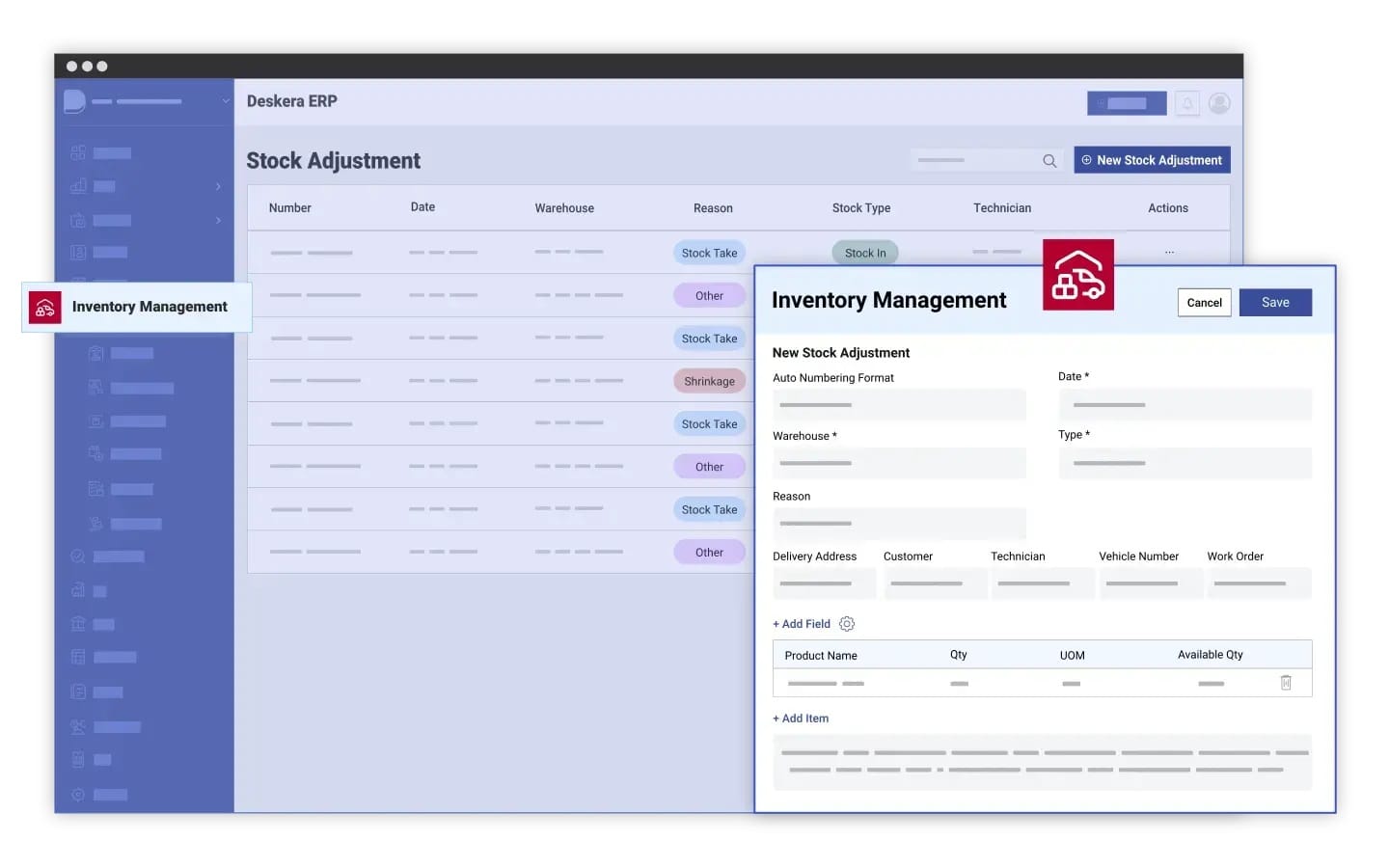

How Deskera ERP Supports Seamless Inventory Integration

Managing inventory efficiently requires more than just tracking stock—it demands real-time visibility, automated workflows, and integration across all business functions. Deskera ERP provides a comprehensive platform that empowers businesses to achieve seamless inventory integration while reducing errors, improving efficiency, and enabling data-driven decision-making.

1. Real-Time Stock Tracking Across Multiple Locations

Deskera ERP enables businesses to monitor inventory levels across warehouses, retail outlets, and e-commerce channels in real time. Managers can instantly see stock availability, track movements, and prevent stockouts or overstocking. This multi-location visibility ensures accurate inventory data and supports smooth operations across all channels.

2. AI-Powered Demand Forecasting

With AI-driven analytics, Deskera ERP predicts demand trends based on historical data, seasonal fluctuations, and market patterns. This helps businesses optimize stock levels, plan procurement efficiently, and reduce inventory carrying costs. Proactive forecasting minimizes the risk of lost sales and excess inventory.

3. Automated Workflows and Alerts

Deskera ERP automates routine inventory processes such as reorder notifications, purchase approvals, and stock adjustments. Businesses receive alerts when inventory reaches critical levels or when discrepancies occur. These automated workflows save time, reduce human errors, and ensure timely replenishment.

4. Integration with Accounting, Sales, and MRP Modules

Deskera ERP unifies inventory management with accounting, sales, and material requirements planning (MRP) modules. Sales orders automatically update stock levels, procurement requests align with real-time demand, and accounting reflects accurate inventory valuation. This full integration enables seamless cross-departmental collaboration.

5. Batch, Serial, and Expiry Tracking

For businesses in regulated industries like pharmaceuticals, food, or electronics, Deskera ERP supports detailed tracking of lot numbers, serial numbers, and expiry dates. This ensures compliance, simplifies audits, and allows for quick recalls if necessary.

6. Mobile Accessibility for Remote Management

Deskera ERP offers mobile access, allowing managers and staff to monitor inventory, approve purchase orders, and track stock from anywhere. This flexibility enhances operational control and responsiveness, particularly for businesses with multiple locations or remote teams.

7. Data-Driven Insights and Reporting

Deskera ERP provides dashboards and reports with actionable insights into inventory performance. Businesses can identify slow-moving items, evaluate supplier performance, optimize reorder points, and make informed decisions that improve efficiency and reduce costs.

8. Scalability and Flexibility

As businesses expand, Deskera ERP scales effortlessly to accommodate new products, locations, or sales channels without disrupting existing operations. This ensures that inventory remains accurate, synchronized, and fully integrated across all departments.

Deskera ERP effectively transforms inventory management from a reactive, manual process into a proactive, intelligent system. By combining automation, real-time visibility, and cross-functional integration, it enables businesses to achieve seamless inventory integration and operational excellence.

Key Takeaways

- Seamless inventory integration is critical for modern businesses to reduce inefficiencies, prevent costly stock distortions, and stay competitive, with the global inventory management software market projected to reach $4.8 billion by 2029.

- Inventory integration connects all departments—procurement, sales, warehouse, and accounting—into a unified system, enabling real-time visibility, accurate data, and smarter decision-making.

- Disconnected systems create data silos, manual errors, stock discrepancies, compliance risks, and increased operational costs, all of which hinder efficiency and business growth.

- ERP systems centralize data, provide real-time tracking, integrate multiple business functions, automate workflows, and deliver actionable insights, making inventory management accurate, efficient, and scalable.

- Seamless inventory integration through ERP reduces errors, improves cross-departmental collaboration, optimizes inventory costs, enhances customer satisfaction, and strengthens financial reporting.

- Deskera ERP offers AI-powered demand forecasting, real-time stock visibility, automated workflows, batch and serial tracking, mobile access, and cross-functional integration, enabling businesses to achieve truly seamless inventory management.

Related Articles