Have you ever wondered why suppliers often ask you to order a certain minimum quantity—even when you don’t really need that much stock? The answer lies in the concept of Minimum Order Quantity (MOQ), a key purchasing and supply chain term that can make or break your inventory strategy. MOQ determines how much you must buy upfront, and understanding it is crucial for maintaining healthy margins and ensuring smooth operations.

MOQ isn’t just about numbers—it’s a balancing act between supplier economics and buyer flexibility. For businesses, a well-defined MOQ can streamline production, reduce waste, and ensure predictable revenue. For buyers, however, high MOQs can lead to added costs, excess inventory, and cash flow challenges. This is why mastering MOQ is essential whether you’re a manufacturer, wholesaler, retailer, or eCommerce brand.

In today’s competitive landscape, optimizing MOQ is no longer optional. It directly affects your working capital, inventory levels, procurement strategy, and long-term profitability. With supply chains becoming more dynamic and customer demand more unpredictable, businesses need smarter ways to calculate, negotiate, and manage MOQs effectively.

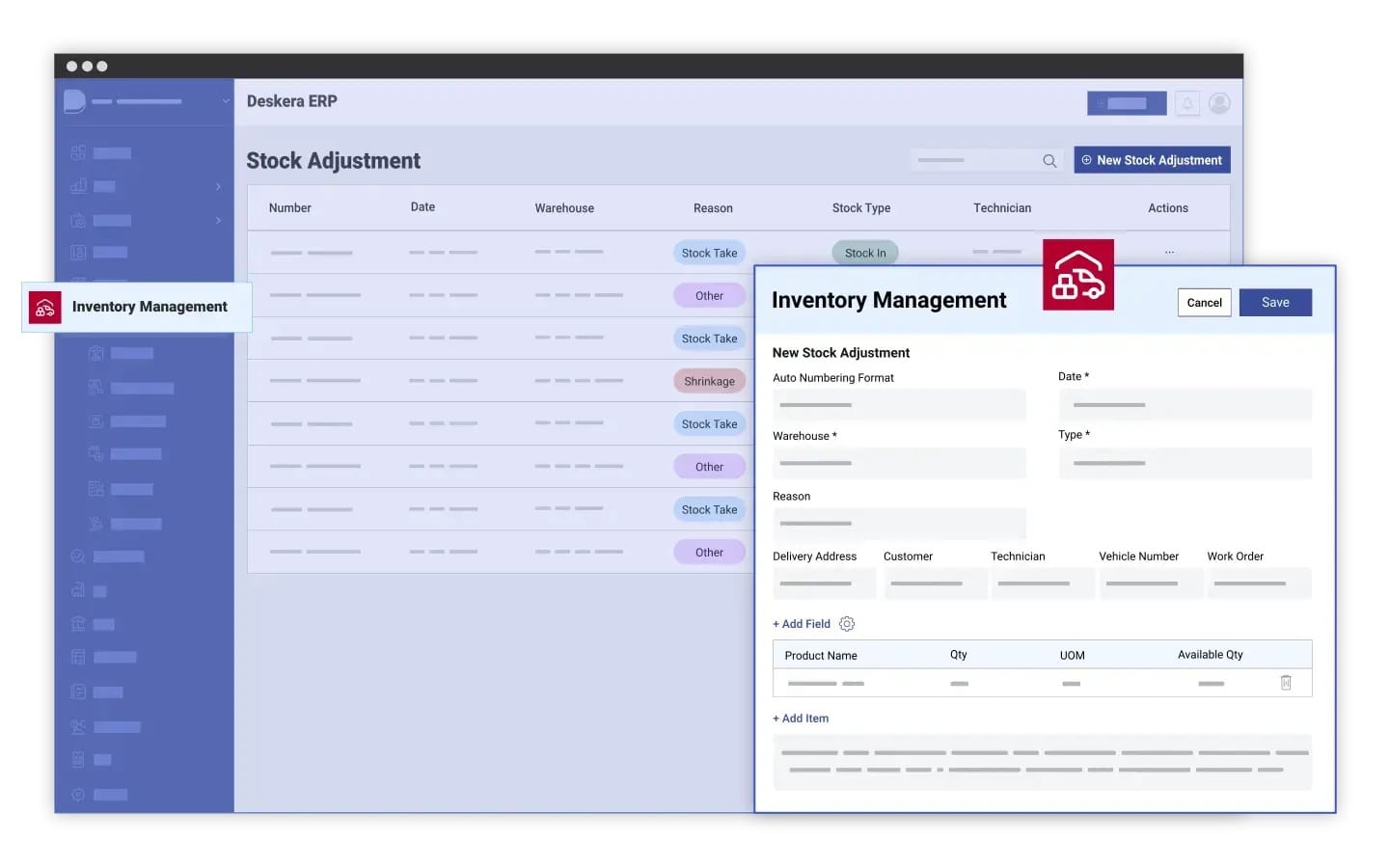

That’s where Deskera ERP becomes a powerful advantage. With real-time inventory visibility, automated demand forecasting, smart replenishment alerts, and integrated supplier management, Deskera helps businesses strike the perfect balance between cost efficiency and order flexibility. Its AI Assistant, David, provides instant insights to support faster, more informed decisions—ensuring your MOQ strategy works for you, not against you.

What Is Minimum Order Quantity (MOQ)?

Minimum Order Quantity (MOQ) refers to the smallest number of units—or the minimum monetary value—a supplier is willing to sell in a single transaction. In simple terms, it is the fewest units a buyer must purchase to place an order. While a retail store may happily sell you one item at a time, manufacturers, wholesalers, and suppliers typically require bulk orders to maintain efficiency and profitability.

Suppliers set MOQs to ensure that the costs of production, materials, labor, and logistics are covered. Every order involves setup costs—such as preparing machinery, sourcing raw materials, packaging, and administrative work. By establishing an MOQ, suppliers protect themselves from unprofitable transactions and keep operations streamlined. Depending on the business model and product type, MOQs can be based on units, order value, or even weight.

MOQs vary widely across industries. For example, a manufacturer creating custom-designed goods may set a high MOQ to justify production setup, while a wholesaler might only require a minimum purchase value to optimize shipping and storage costs. In the retail supply chain, both manufacturers and wholesalers typically use MOQs, especially when selling in bulk to the next stage of the distribution channel.

To understand how MOQs work, consider a simple example: A wholesaler sells widgets at $100 each and sets an MOQ of 100 units. This means buyers must place an order worth at least $10,000 to transact. Even if a buyer needs only 50 units, they must purchase 100 because that is the minimum threshold for the supplier to turn a profit. This practice helps maintain sales margins, manage inventory, and reduce operational expenses.

In essence, MOQ is a critical procurement concept that influences pricing, inventory planning, working capital, logistics, and supplier relationships—making it essential for businesses to understand and manage effectively.

Types of Minimum Order Quantity

Minimum Order Quantities can vary widely depending on industry, supplier capabilities, buying patterns, and cost structures. Broadly, MOQs can be classified into simple MOQs, complex MOQs, supplier-set MOQs, and brand-set MOQs. Each type serves a different purpose and helps businesses balance operational efficiency with profitability.

1. Simple Minimum Order Quantity

A simple MOQ refers to a straightforward minimum threshold—either in units or order value—that a buyer must meet to place an order. This is often used by businesses that don’t function like traditional retailers but still need to maintain a fixed minimum level of stock.

For example, a bike dealer purchases bikes in bulk from the manufacturer but sells them individually to customers. The dealer maintains a simple MOQ to ensure that each purchase aligns with cash flow constraints and the economic realities of their target market. In this model, the MOQ is easy to understand, easy to communicate, and directly linked to a basic cost structure.

2. Complex Minimum Order Quantity

Complex MOQs involve multiple variables such as price tiers, product mix, packaging requirements, and quality standards. Businesses like grocery store owners or chemists face these challenges daily. A chemist, for instance, must stock dozens of medicines, each with different brand options, price points, and minimum order sizes.

In such cases, the retailer manages several MOQs simultaneously while ensuring availability across diverse product categories. Complex MOQs help retailers balance customer demand, regulatory requirements, and storage limitations while avoiding overstocking or understocking essential items.

3. Supplier-Set MOQs

Supplier-set MOQs are the most common type and are established by suppliers to ensure cost efficiency and profitability. These MOQs account for production setup costs, material sourcing, packaging, labor, and administrative expenses.

For instance, consider a supplier manufacturing candles. Producing just 15 units may cost $400 in materials and labor, yet selling them at $7 each brings in only $105—far below break-even. If the buyer instead orders 40 units, the supplier benefits from bulk raw material pricing, reducing production costs to around $150. Selling 40 candles at $5 each yields $200, ensuring the production run is viable and profitable.

Supplier-set MOQs protect suppliers from loss-making orders and help them maintain smooth, efficient operations across large or repeated production runs.

4. Brand-Set MOQs

Brands can also establish their own MOQs, usually for wholesale clients, distributors, or retail partners. While less common than supplier-set MOQs, brand-set MOQs ensure that each order justifies the costs of production, fulfillment, packaging, and logistics.

For example, a brand may require retailers to place a minimum purchase order of 50 units or a minimum value of $500 to qualify as a wholesale customer. These MOQs help maintain consistent sales volumes, stronger partnerships, and predictable revenue for the brand.

Factors That Influence Minimum Order Quantity (MOQ)

Minimum order quantity isn’t a random number. It’s shaped by a combination of operational, financial, and strategic factors that determine how much a supplier must sell to remain profitable. Understanding these influences not only helps buyers negotiate better but also allows businesses to align purchasing decisions with their inventory strategy and cash flow realities.

1. Raw Materials and Sourcing Constraints

Raw materials play one of the biggest roles in determining MOQs. Suppliers often face their own upstream MOQs when sourcing components, fabrics, polymers, metals, or ingredients.

- Upstream MOQs: Manufacturers of raw materials rarely keep inventory on hand; they begin production only after receiving an order—usually with a minimum quantity. This forces suppliers to adopt MOQs that match or exceed what they must purchase from their own vendors.

- Shelf life: Perishables (e.g., food ingredients) and semi-perishables (e.g., cosmetics, chemicals) naturally require carefully managed MOQs to reduce expiry risks. Even durable goods (electronics, fashion items) may become obsolete quickly.

- Cost and scarcity: Limited or seasonal materials, such as specialty metals or rare ingredients, typically come with higher MOQs to justify procurement.

Impact: The more complex, scarce, or perishable the raw materials, the higher the MOQ.

2. Production Costs and Manufacturing Efficiency

A large portion of MOQ is driven by the economics of production.

- Setup costs: Machine calibration, tooling, mould creation, printing plates, and labor setup require time and expense. Larger batches help distribute these fixed costs.

- Batch size requirements: Automated facilities often run efficiently only at scale. High-speed machines need continuous operation, making small runs unprofitable.

- Customization: Customized products—engraving, unique formulations, branded packaging—almost always require higher MOQs to justify setup labor and tooling.

Impact: The more complex or capital-intensive the production process, the higher the MOQ.

3. Order Volume and Supplier Scale

The size and business model of the supplier influences MOQ levels significantly.

- High-volume manufacturers rely on mass production and economies of scale, so they typically set high MOQs. Example: packaging factories printing 50,000+ units per run.

- Smaller, boutique suppliers are more flexible and may accommodate lower MOQs to attract niche or startup buyers.

- Buyer segmentation: Suppliers selling to big-box retailers may adopt high MOQs; those targeting small retailers or D2C brands usually keep MOQs lower.

Impact: Large suppliers with automated operations usually require higher MOQs; smaller suppliers often remain flexible.

4. Market Demand and Competitive Conditions

Market dynamics also determine how strict or flexible a supplier can afford to be.

- High-demand products often have lower MOQs because batches sell faster and suppliers can rely on continuous volumes.

- Niche or low-demand products require higher MOQs to break even.

- Economic cycles: During demand booms, suppliers may raise MOQs; during downturns, they lower them to win more customers.

Impact: Strong market demand typically results in more flexible MOQs, while niche markets drive MOQ upward.

5. Supplier Strategy and Business Model

MOQs also reflect strategic decisions made by the supplier.

- Filtering buyers: High MOQs help suppliers target only large, profitable customers and reduce administrative overhead.

- Profitability goals: Suppliers selling low-margin products often require high MOQs to make each batch financially viable.

- Relationship-based flexibility: Trusted, long-term buyers may receive lower MOQs or special terms.

Impact: MOQs act as a strategic tool to maximize margin and manage customer mix.

6. Logistics, Shipping, and Storage Considerations

MOQ levels can be influenced by transportation and warehousing efficiency.

- Container optimization: Many MOQs are aligned with container sizes or pallet loads to maximize shipping efficiency.

- Freight economics: Bulk shipping reduces cost per unit, encouraging higher MOQs.

- Storage limitations: Suppliers with limited warehouse capacity may set lower MOQs, whereas those with large facilities sometimes require larger orders.

Impact: Efficient logistics often encourage higher MOQs, especially for international shipments.

7. Seasonality and Production Cycles

Products that follow seasonal trends often have fluctuating MOQ requirements.

- Peak season: MOQs may increase to capitalize on demand (e.g., holiday packaging, winter apparel).

- Off-season: Suppliers may lower MOQs to keep factories running.

- Inventory turnover pressures: Seasonal items require quick sell-through; suppliers adjust MOQs accordingly.

Impact: MOQs change based on seasonal forecasting and factory utilization needs.

8. Geographic Location and Import/Export Conditions

Location and regulatory environments can shape MOQ decisions.

- Customs, duties, and taxes may make small shipments unprofitable.

- Distance from the buyer affects shipping container economics.

- Regional manufacturing norms (e.g., China’s preference for large-scale production) can dictate higher MOQs.

Impact: Suppliers far from buyers or operating under strict import/export rules often adopt higher MOQs.

9. Product Type and Complexity

Different products naturally demand different MOQ strategies.

- High-complexity items (machinery parts, electronics, engineered goods) usually require high MOQs due to setup costs.

- Low-complexity items (simple packaging, standard apparel) tend to have lower MOQs.

Impact: The more complex the product design, the higher the MOQ.

How to Calculate Minimum Order Quantity (Step-by-Step Guide)

Calculating the Minimum Order Quantity (MOQ) is not a one-size-fits-all process. It varies significantly by industry, product type, cost structure, and market demand. Moreover, MOQs are dynamic, not static—changes in raw material prices, production expenses, and supplier constraints may require regular recalibration to stay profitable.

This is why businesses increasingly rely on inventory management and ERP platforms to calculate MOQs more accurately. Integrated systems bring together real-time data from finance, procurement, production, and supply chain operations to give suppliers precise insights into costs and demand patterns.

Although there is no single universal formula for MOQ, businesses can use a structured approach to determine a profitable and operationally feasible MOQ.

Below is a practical step-by-step process to guide you through setting the right MOQ for each product.

1. Determine Total Production Costs

Start by identifying how much it costs to produce one unit of your product. This includes:

- Raw materials

- Packaging

- Labor

- Storage and handling

- Administrative and marketing overhead

Understanding your true cost per unit helps ensure that your MOQ supports healthy profit margins and covers all variable and fixed expenses tied to production.

2. Factor In Supplier and Material Requirements

If you work with upstream suppliers, consider their minimum purchase rules or material constraints. For example:

- Do you need to buy raw materials in specific lot sizes?

- Does the supplier require a minimum value or unit purchase?

- Do you need to store excess materials before production?

These constraints directly influence your break-even point and should be considered before setting an MOQ.

3. Analyze Market Demand

Evaluate demand using historical data and forecasting tools. Key considerations include:

- Seasonal fluctuation

- Customer buying frequency

- Competition and market conditions

- Lead times for procurement and production

For example, if demand typically averages 500 units per cycle, setting an MOQ of 5,000 would be unrealistic and could harm buyer relationships.

4. Calculate Holding and Carrying Costs

Inventory storage costs—refrigeration, temperature control, warehousing space, insurance, and spoilage risk—significantly affect the ideal MOQ. High carrying costs often push suppliers to set higher MOQs to ensure faster turnover and avoid long-term storage.

5. Find the Break-Even Point

Break-even analysis helps you understand how many units must be sold to cover total costs without incurring losses. Any MOQ you set should sit above the break-even point while remaining aligned with customer demand. For example:

- Selling 50 units may not cover production costs

- Producing 500 units may reduce cost per unit and ensure profitability

This balance is essential for sustainable operations.

6. Set the MOQ Based on All Inputs

Once you have a clear picture of costs, demand, supplier constraints, and break-even numbers, establish an MOQ that:

- Covers expenses

- Maintains profitability

- Matches buyer capacity

- Supports healthy inventory turnover

You can also use incentives—such as bulk discounts or instalment options—to encourage larger orders from buyers when introducing new MOQs.

7. Review and Adjust Regularly

MOQs should be flexible and reviewed periodically. Supply chain fluctuations, raw material price changes, seasonal demand, and buyer behavior may require adjustments. Many businesses also use different MOQs for different seasons or product lines to stay responsive to market conditions.

Why Do Suppliers Use Minimum Order Quantities?

Suppliers don’t set Minimum Order Quantities (MOQs) to complicate the buying process—they set them to ensure that every transaction remains profitable, sustainable, and operationally efficient.

MOQs are a strategic safeguard that helps suppliers balance production economics with market demand. Whether a supplier is producing fresh holiday turkeys or manufacturing thousands of identical components, MOQs help them protect their margins and streamline operations.

1. Managing Production Costs

Every production run carries fixed costs, such as:

- Machine setup

- Labor

- Raw materials

- Packaging

For small orders, these setup costs can quickly exceed the revenue generated. MOQs ensure that suppliers produce and sell enough units to justify the cost of manufacturing. This is especially crucial in industries where production lines are designed for mass volume.

By batching orders in larger quantities, suppliers spread setup expenses across more units, reducing the cost per product and avoiding loss-making transactions.

2. Improving Inventory and Storage Efficiency

MOQs help suppliers avoid overproduction and reduce the risk of unsold inventory. Producing in quantities aligned with customer buying patterns minimizes storage costs and reduces the chance of spoilage, damage, or obsolescence—particularly for perishable or seasonal items. For example, suppliers of refrigerated food might require full truckload orders to ensure efficient use of temperature-controlled logistics.

3. Reducing Operational and Logistics Costs

Handling small, fragmented orders increases shipping, packaging, and administrative costs. MOQs streamline logistics by encouraging bulk orders, which:

- Lower per-unit shipping costs

- Reduce handling and packing time

- Make transportation more efficient

This standardization results in smoother operations and higher productivity across the supply chain.

4. Ensuring Cash Flow Stability and Higher Profit Margins

MOQs play a key role in keeping cash flow predictable. Since each order meets a minimum profitability threshold, suppliers are able to:

- Secure consistent revenue

- Avoid tying up capital in slow-moving inventory

- Maintain liquidity for future production

Many suppliers also offer discounts for quantities above the MOQ, incentivizing larger purchases and increasing overall profit margins.

5. Strengthening Inventory Control and Forecasting

Bigger, predictable orders make demand forecasting more accurate. With MOQs in place, suppliers can:

- Plan production schedules more effectively

- Optimize raw material purchases

- Reduce stockouts and overstocks

This contributes to better resource allocation and prevents capital from being locked into inventory that doesn’t move.

6. Supporting Long-Term Operational Sustainability

Ultimately, MOQs help suppliers build a stable and scalable business model. By ensuring that every order contributes meaningfully to revenue and operational efficiency, suppliers can focus on profitable customer relationships instead of spreading resources across numerous small, low-value transactions.

How Minimum Order Quantity (MOQ) Impacts Inventory

Minimum Order Quantity (MOQ) has a direct and significant influence on inventory management—both for suppliers who set the MOQ and for buyers who must meet it.

The size of the MOQ determines how much stock suppliers must produce or hold and how much buyers must store, sell, or manage within their cash flow constraints. These decisions shape carrying costs, inventory turnover, warehousing needs, and overall supply chain efficiency.

Impact of MOQ on Sellers (Suppliers & Manufacturers)

Suppliers must align their MOQs with production capacity, market demand, and cost structures. The MOQ they set determines:

- How much inventory they must produce and store

- How often they need to place internal or external orders

- Working capital tied up in raw materials or finished goods

A higher MOQ often means more stock sitting in warehouses, while a lower MOQ means increased frequency of production runs and administrative effort.

Impact of MOQ on Buyers (Retailers, Brands, Distributors)

For buyers, MOQs influence:

- How much inventory they must purchase at once

- How much cash gets tied up in stock

- Whether they can sell or use the required quantity quickly enough

If the MOQ is too high relative to demand, buyers may struggle with overstocking, storage costs, or product expiration (especially for perishables or trend-based items). In contrast, a lower MOQ gives buyers more flexibility but may come at a higher cost per unit.

High Minimum Order Quantity (High MOQ)

A high MOQ requires buyers to purchase (and suppliers to produce) large quantities in a single batch. This creates a distinct set of inventory implications:

For Suppliers

- Higher inventory holdings: They must produce larger batches, often stocking more finished goods.

- Better economies of scale: Bulk production lowers per-unit costs.

- Lower administrative load: Fewer but larger orders reduce frequency of paperwork, procurement, and logistics.

- Risk of obsolescence: Products—especially seasonal, style-based, or tech items—may become outdated if demand slows.

- Longer lead times: Larger batch production may extend manufacturing and delivery timelines.

For Buyers

- More warehouse space needed: They must store larger volumes, which increases holding costs.

- Greater working capital required: A high MOQ ties up significant cash in inventory.

- Risk of unsold stock: Particularly if the product is perishable, trend-driven, or has unpredictable demand.

- Potential bulk savings: Larger orders often mean discounted pricing, improving margins if products sell consistently.

High MOQs are more common in industries with low-margin products, where suppliers depend on volume to stay profitable.

Low Minimum Order Quantity (Low MOQ)

Low MOQs allow for smaller purchase volumes, which impacts inventory in different ways.

For Suppliers

- Lower inventory storage: Less finished goods are held, increasing turnover.

- Higher administrative costs: More frequent orders require more coordination and resources.

- Increased pressure on sales teams: They may need to manage many smaller customers and more frequent negotiations.

- Less bulk purchasing power: Suppliers may lose some economies of scale.

For Buyers

- Greater flexibility: They can order closer to demand and avoid overstocking.

- Lower holding costs: Warehousing and carrying costs drop due to smaller volumes.

- Lower risk of obsolescence or spoilage: Especially helpful for fast-changing or perishable products.

- Potentially higher per-unit pricing: Smaller quantities may cost more per unit.

Low MOQs are typical for high-margin products, where suppliers can remain profitable even with small batches.

High MOQ vs. Low MOQ: Impact Summary

Benefits of Minimum Order Quantity (MOQ)

Minimum order quantity isn’t just a purchasing requirement—it’s a strategic lever that benefits both suppliers and buyers when implemented thoughtfully. From cost efficiency to improved forecasting, MOQs can streamline operations and strengthen supplier–buyer relationships.

Below is a detailed look at how MOQ creates value across the supply chain.

Benefits for Suppliers

1. Improved Cash Flow

An effectively set MOQ ensures that every order contributes meaningfully to revenue. Since each transaction meets a minimum profitability threshold, suppliers enjoy predictable, healthier cash flow. This stability helps them budget production, manage overheads, and reinvest confidently in operations.

2. Lowered Inventory Costs

Instead of producing large batches without confirmed demand, suppliers can trigger production only when buyers commit to ordering the minimum profitable quantity. This reduces the need for excess warehouse space, lowers holding costs, and minimizes the risk of unsold or aging inventory.

3. Better Profit Margins

MOQs allow suppliers to price and produce strategically. Larger orders reduce per-unit production costs and maximize economies of scale—especially for manufacturers with high setup costs. Suppliers can also adjust MOQ levels to optimize margin, maintain profitability, and remain competitive.

4. Streamlined Operations & Reduced Production Costs

Producing in bulk is more efficient than running multiple small batches. Larger runs reduce labor inefficiencies, machine downtime, and packaging overhead. Suppliers also benefit from bulk purchasing of raw materials, which typically results in better terms and lower unit costs.

5. Tighter Inventory Control

MOQs help suppliers synchronize production with demand. This leads to better forecasting, optimized production scheduling, and smoother utilization of resources. It also ensures inventory moves consistently through the supply chain instead of stagnating in storage.

6. Sustainable Business Model

By preventing unprofitable small orders, MOQs help suppliers build a stable operating model. Predictable demand, controlled production costs, and efficient resource allocation together support long-term business sustainability and growth.

Benefits for Buyers

1. Economies of Scale & Bulk Savings

Although MOQs may require larger purchases, buyers often benefit from the lower per-unit costs that come with bulk buying. Even with added warehousing expenses, the overall savings can increase profit margins or make products more competitively priced in the market.

2. Better Inventory Freshness

Suppliers who operate with clearly defined MOQs tend to produce only as needed. Buyers receive fresher stock—especially important for perishable or seasonal goods—reducing the likelihood of spoilage or obsolescence.

3. Improved Inventory Management

With predictable order quantities, buyers can plan stock levels more efficiently. MOQs encourage buyers to evaluate demand more accurately, preventing both overstocking and stockouts. This leads to better cash flow utilization and reduced operational inefficiencies.

4. Improved Supplier Relationships

MOQ negotiations prompt deeper collaboration between buyers and suppliers. When MOQ exceeds a buyer’s economic order quantity (EOQ), suppliers may offer compromises such as order splitting, phased delivery, or shared purchasing with other clients. This strengthens long-term partnerships and improves communication.

5. Increased Bargaining Power

When buyers commit to larger, consistent purchase volumes, they often gain leverage during supplier negotiations. This can lead to better pricing, priority production slots, and more favorable payment terms.

Benefits for Both Parties

1. Streamlined Operations

MOQs create structure. Suppliers can standardize production runs and logistics, while buyers reduce the number of orders placed, cutting down administrative workloads and shipping costs.

2. Reliable Demand Forecasting

Predictable orders benefit manufacturers and distributors alike. Suppliers can negotiate better deals with their own vendors, optimize capacity planning, and lower the risk of stock-related disruptions.

3. Revenue Predictability

Since MOQ ensures minimum revenue per order, suppliers operate with greater financial confidence. Buyers also gain stability by knowing what quantities—and costs—to expect in future procurement cycles.

4. Reduced Risk of Returns and Cancellations

Bulk orders typically involve more committed buyers. This reduces the odds of last-minute cancellations or returns, protecting both supplier margins and operational efficiency.

Challenges of Minimum Order Quantities (MOQs) and How to Overcome Them

While minimum order quantities bring structure and efficiency to supply chains, they also present several challenges—especially for small businesses, startups, and brands with unpredictable demand. Understanding these challenges and knowing how to mitigate them is essential for maintaining cash flow, managing inventory efficiently, and building sustainable supplier relationships.

1. High Initial Costs

The Challenge: High MOQs require buyers to commit to large orders, which means significant upfront investment. For businesses with limited capital, this can be financially draining and may prevent them from diversifying their product range.

How to Overcome It:

- Negotiate Flexible Terms: Many suppliers are open to reduced MOQs for new partnerships or long-term clients.

- Consider Tiered MOQ Agreements: Order smaller quantities initially and scale up as demand stabilizes.

- Leverage Group Purchasing: Collaborate with other small businesses to split bulk orders and reduce individual costs.

2. Risk of Overstocking and Deadstock

The Challenge: When demand is uncertain, committing to high MOQs increases the chances of overstocking. Excess inventory ties up capital, increases carrying costs, and heightens the risk of deadstock—particularly for seasonal, fast-changing, or perishable items.

How to Overcome It:

- Use Demand Forecasting Tools: Inventory management systems (like Deskera ERP) help predict demand based on real-time data.

- Order in Phases: Request staggered deliveries to reduce storage stress and disperse sales risk over time.

- Optimize Product Mix: Start with your fastest-moving SKUs to minimize the chance of slow inventory piling up.

3. Cash Flow Constraints

The Challenge: Bulk purchasing to meet MOQ ties up working capital that could otherwise be used for marketing, product expansion, or operations. This creates liquidity issues and delays ROI.

How to Overcome It:

- Use Inventory Financing: Some banks and fintech platforms offer short-term financing for bulk inventory purchases.

- Renegotiate Payment Terms: Ask suppliers for extended payment windows or milestone-based payments.

- Track Sell-Through Rates: Make data-backed decisions on how quickly inventory converts into revenue.

4. Limited Flexibility for Small Businesses

The Challenge: High MOQs can limit product testing, reduce flexibility, and prevent smaller companies from working with high-quality manufacturers that prefer larger clients.

How to Overcome It:

- Start with Smaller Suppliers: Many mid-tier or local manufacturers offer more flexible MOQs.

- Offer Long-Term Contracts: Suppliers may agree to lower MOQs if you commit to repeated orders.

- Provide Forecast Transparency: Share expected order patterns to build trust and encourage flexibility.

5. Potential Waste in Perishable or Trend-Based Industries

The Challenge: In categories like food, cosmetics, or fashion, surplus stock can expire, become outdated, or lose market value before it’s sold. High MOQs accelerate this risk.

How to Overcome It:

- Shorten Reorder Cycles: More frequent, smaller orders prevent build-up of perishable inventory.

- Improve SKU Rationalization: Focus on high-demand, quick-turnover products.

- Use Clearance Channels: Flash sales, bundles, or outlet platforms can help move near-expiry stock.

6. Lost Sales Opportunities

The Challenge: High MOQs may deter customers—especially small retailers or budget-conscious buyers—who cannot purchase in bulk. This narrows market reach and reduces sales potential.

How to Overcome It:

- Introduce Multiple Pricing Tiers: Let smaller buyers purchase lower quantities at slightly higher margins.

- Enable Drop-shipping for Micro-Orders: Helps serve smaller clients without affecting your inventory load.

- Offer Volume Discounts: Incentivizes buyers to upgrade to higher tiers gradually.

7. Barrier to Entry for New Entrepreneurs

The Challenge: For startups, meeting high MOQs can feel prohibitive, limiting experimentation and discouraging new product launches.

How to Overcome It:

- Work With MOQs Strategically: Prioritize testing demand through pre-orders or crowdfunding.

- Choose Manufacturers Offering Sample Runs: Many provide low-volume prototyping before bulk production.

- Adopt Lean Inventory Practices: Start small, validate demand, then scale orders responsibly.

8. Higher Storage and Administrative Costs

The Challenge: Large inventory orders require additional warehouse space, higher insurance costs, and more administrative effort for monitoring and handling, especially when orders become frequent due to low MOQs.

How to Overcome It:

- Automate Inventory Management: Systems like Deskera ERP reduce manual workload and improve accuracy.

- Use 3PL Providers: Outsource warehousing and fulfillment to reduce overheads.

- Consolidate SKUs: Reducing product variations lowers storage and handling complexity.

How to Set an MOQ

Setting the right Minimum Order Quantity (MOQ) is a strategic decision that directly affects your profitability, customer satisfaction, and operational efficiency. A well-calculated MOQ helps you avoid excess inventory, streamline production, and maintain healthy cash flow—while ensuring that customers can meet your purchasing requirements.

Below are the essential steps to determine an optimal MOQ for your business:

1. Evaluate Your Production Costs

Start by calculating the minimum number of units you must produce or source to break even. Consider:

- Raw material costs

- Direct labor

- Manufacturing overheads

- Packaging and quality control

This ensures your MOQ covers all operating expenses and protects your margins.

2. Analyze Historical Sales Data

Review past sales trends to understand:

- Average order size

- Seasonal spikes and dips

- Fast-moving vs slow-moving items

This helps you avoid setting an MOQ that is misaligned with actual demand.

3. Forecast Future Demand

Use a combination of data analytics, customer behavior, and market trends to project demand. Consider:

- New product launches

- Marketing campaigns

- Economic or industry shifts

- Customer purchase frequency

Forecasting helps you set an MOQ that complements real-world demand rather than guesswork.

4. Calculate Storage and Carrying Costs

MOQs significantly influence how much stock you must carry. Evaluate:

- Warehouse rent

- Utilities and insurance

- Handling costs

- Depreciation and shrinkage

- Opportunity cost of tied-up capital

High carrying costs may require a lower MOQ to reduce financial risk.

5. Evaluate Order and Logistics Costs

Every order comes with fixed costs such as:

- Shipping and freight

- Customs duties (if importing)

- Packaging

- Administrative processing

If order costs are high, you may need a slightly higher MOQ to maintain cost efficiency.

6. Understand Lead Times and Safety Stock Levels

Longer supplier lead times often require:

- Higher safety stock

- Larger replenishment quantities

If your lead times are short and reliable, you can afford a lower MOQ.

7. Factor in Product Shelf Life

For perishables, cosmetics, electronics, and trend-driven items:

- Avoid large MOQs that increase obsolescence risk

- Consider how quickly the product loses value

Products with shorter life cycles should generally have lower MOQs.

8. Analyze Cash Flow Capacity

Before setting an MOQ, ensure your business can financially handle it. Assess:

- Available working capital

- Payment terms (e.g., advance vs credit)

- Impact on operating cash flow

Your MOQ should never strain your liquidity.

9. Review Supplier MOQs and Negotiate if Necessary

Suppliers often impose their own MOQ. If their requirement is higher than what makes sense for your business:

- Negotiate for smaller batches

- Offer longer-term contracts

- Explore mixed-batch ordering

- Consider alternative suppliers

Supplier flexibility can significantly impact your final MOQ.

10. Assess the Value of Bulk Discounts

Sometimes ordering more to meet a higher MOQ can be cost-effective if:

- Volume discounts are substantial

- Demand is stable

- Storage costs are manageable

Always compare the savings against additional carrying costs.

11. Test, Review, and Refine

Once you implement your MOQ:

- Monitor sales velocity

- Track inventory turnover

- Review customer feedback

- Adjust based on performance

MOQs are not static—they should evolve with market demand, production changes, and business growth.

14 Tips for Optimizing Minimum Order Quantity (MOQ)

Optimizing your MOQ is essential for balancing profitability, customer satisfaction, and operational efficiency. Whether you’re a buyer managing supplier-imposed MOQs or a seller setting your own thresholds, these actionable strategies will help you maximize inventory efficiency and cash flow while minimizing risk.

1. Remove Slow-Moving Products

Regularly analyze SKU performance to identify items with declining demand. Products that sell slowly increase carrying costs, consume warehouse space, and tie up capital. To optimize MOQs:

- Lower MOQs or offer promotions on slow movers

- Bundle items with best-sellers

- Explore liquidation strategies

- Discontinue unprofitable SKUs

Streamlining your product line boosts forecasting accuracy and prevents wasted inventory.

2. Improve Inventory Turnover

High MOQs often force excess inventory, so improving turnover is key. Strategies include:

- Running flash sales

- Offering product bundles

- Adding free gifts using surplus stock

- Increasing marketing efforts for specific SKUs

A faster turnover protects cash flow and reduces the risk of obsolescence.

3. Evaluate and Compare Supplier Options

Not all suppliers have the same MOQ requirements. When evaluating suppliers, compare:

- MOQ levels

- Unit pricing and tiered discounts

- Lead times

- Payment terms

- Order flexibility (mix & match options)

A supplier with a slightly higher price but a flexible MOQ may ultimately be more profitable.

4. Negotiate Creatively

If MOQs are too high, negotiate using leverage points such as:

- Ordering mixed SKUs to hit the MOQ

- Asking for leftover or canceled-order stock

- Offering longer lead times

- Committing to long-term contracts

- Requesting smaller trial batches

Negotiating terms that benefit both sides strengthens the relationship and reduces risk.

5. Use Technology to Automate Inventory & MOQ Decisions

ERP, MRP, and inventory management systems help optimize MOQs by:

- Tracking inventory levels in real time

- Analyzing sales velocity

- Forecasting demand

- Recommending reorder quantities

- Sending alerts when stock levels drop

Technology prevents guesswork and ensures MOQs align with actual business needs.

6. Incentivize Higher Spending from Buyers

For sellers, MOQs can be optimized by encouraging customers to increase order value. You can:

- Offer volume discounts

- Introduce tiered pricing

- Set free shipping thresholds

- Create subscription bundles

- Offer “buy X, save Y” incentives

This not only pushes customers to meet your MOQ but also boosts average order value.

7. Bundle Orders to Increase Flexibility

Allow customers to reach MOQs through bundles instead of single-SKU orders:

- Mix & match colors, sizes, or variations

- Bundle slow-moving SKUs with fast-moving ones

- Create seasonal or gift bundles

Bundles improve sell-through while keeping customers satisfied.

8. Adopt Just-in-Time (JIT) Inventory Practices

Consider JIT alongside MOQs to:

- Reduce storage space requirements

- Minimize excess inventory

- Improve cash flow

- Support lean operations

JIT works best when lead times are reliable and demand forecasting is accurate.

9. Simplify Your SKU Catalog

Too many SKUs complicate forecasting and force higher MOQs. To optimize:

- Consolidate overlapping SKUs

- Limit unnecessary variations

- Prioritize best-sellers

Fewer SKUs make forecasting easier and reduce MOQ-related waste.

10. Consider Alternative Suppliers or Distributors

If a manufacturer’s MOQ is too high:

- Look for distributors with smaller order requirements

- Partner with trading companies for shared bulk purchases

- Explore local sourcing options

Working with the right supplier removes unnecessary strain on cash flow.

11. Strengthen Supplier Relationships

Strong relationships can lead to:

- More flexible MOQs

- Priority during shortages

- Better pricing

- Faster lead times

Paying on time, clear communication, and long-term commitment often result in more favorable MOQ terms.

12. Analyze Sales Data Regularly

Demand changes—your MOQs should too. Audit sales performance to:

- Identify which products need higher or lower MOQs

- Adjust purchasing strategies

- Identify trends or seasonal shifts

A data-driven approach ensures your MOQ stays aligned with market reality.

13. Negotiate Higher Spend Strategically (for Sellers)

If you’re setting MOQs as a supplier or brand:

- Implement higher MOQs for low-cost items

- Use lower MOQs for high-value items

- Adjust pricing to encourage larger orders without forcing them

This ensures profitability without alienating smaller customers.

14. Use MOQ to Drive Operational Efficiency

Smart MOQ management helps:

- Reduce order processing costs

- Streamline production batches

- Optimize warehousing

- Improve supplier coordination

It’s not just a number—it’s a strategic lever.

Common Mistakes Companies Make With MOQ

Minimum Order Quantities (MOQs) are essential for balancing production efficiency, profitability, and customer needs—but when handled poorly, they can quickly turn into costly mistakes.

Many companies, both buyers and sellers, struggle with setting or managing MOQs because they overlook critical operational, financial, or market factors.

Here are the most common mistakes businesses make with MOQs:

1. Setting MOQs Without Understanding True Demand

Many businesses set arbitrary MOQs without analyzing historical sales data, seasonality, or customer buying patterns. This often leads to:

- Overstocking

- Deadstock buildup

- Poor inventory turnover

A demand-driven approach is essential to avoid tying up capital unnecessarily.

2. Ignoring Production and Carrying Costs

Some companies set MOQs based solely on supplier requirements, without factoring in:

- Production costs

- Storage and warehousing expenses

- Holding and carrying costs

- Risk of obsolescence or depreciation

This can lead to reduced profitability even if sales remain strong.

3. Forcing High MOQs on Customers

Businesses often push high MOQs on buyers without understanding their purchasing ability or market realities. This creates several problems:

- Lost customers

- Limited market reach

- Reduced sales volume

- Strained wholesale relationships

High MOQs should always be tied to perceived value or incentives—not imposed blindly.

4. Over-Reliance on a Single Supplier

Depending on one supplier with rigid MOQ requirements is risky. If their MOQ is high, companies often:

- Overorder to meet requirements

- Lock large amounts of cash into inventory

- Lose flexibility when demand shifts

Exploring multiple supplier options or backup vendors is key for negotiating better terms.

5. Failing to Negotiate

Many companies, especially small businesses, assume MOQs are fixed. But in reality:

- MOQs can often be lowered

- SKUs can be mixed to hit a combined MOQ

- Pricing can be adjusted

- Lead times can be optimized

Avoiding negotiations means missing cost-saving opportunities.

6. Maintaining Too Many SKUs

A large SKU catalog increases the likelihood of meeting high MOQs for slow-moving items. This leads to:

- Overstocking

- Increased carrying costs

- Complex inventory management

Simplifying SKU lines improves forecasting and reduces pressure to meet unnecessary MOQs.

7. Neglecting Shelf Life or Product Lifecycle

For perishables, cosmetics, electronics, or seasonal products, high MOQs can be risky. Companies often forget to consider:

- Expiration dates

- Product obsolescence

- Version updates

- Fashion cycles

This results in wastage or deep discounting later.

8. Not Factoring in Cash Flow Implications

Even profitable products can strain cash flow when purchased in large MOQ batches. Common mistakes include:

- Ignoring opportunity cost

- Locking funds in slow-moving inventory

- Underestimating the financial impact of bulk purchases

Cash flow should be a primary factor when deciding whether to accept or set an MOQ.

9. Lack of Technology and Real-Time Data

Using spreadsheets or manual systems makes it difficult to identify when MOQs are hurting operations. Without technology, businesses often:

- Miss demand trends

- Fail to adjust MOQs in time

- Overorder due to inaccurate forecasting

ERP and inventory management tools help optimize replenishment and purchasing decisions.

10. Setting the Same MOQ for All Products

A uniform MOQ across all products is a major error. Why?

- Different SKUs have different demand

- Storage costs vary

- Profit margins differ

- Shelf life may not be the same

Product-specific MOQs are essential for accurate and efficient inventory planning.

11. Ignoring Market Conditions

Companies sometimes keep MOQs static even when market dynamics change, such as:

- Economic slowdowns

- Supply chain disruptions

- New competitors

- Shifts in customer preferences

MOQs should be reviewed regularly—not set once and forgotten.

12. Poor Communication With Suppliers or Buyers

Miscommunication often leads to:

- Incorrect order quantities

- Delayed production

- Misaligned expectations

- Unnecessary costs

Transparent discussions about capacity, demand, and constraints help prevent costly MOQ mistakes.

How Deskera ERP Helps Businesses Optimize MOQ and Inventory

Setting and managing the right Minimum Order Quantity (MOQ) can be complex—especially when production costs, supplier constraints, market demand, and inventory carrying costs are constantly shifting.

Deskera ERP simplifies this entire process by giving businesses real-time visibility, automated insights, and intelligent tools to optimize both MOQs and inventory levels. With its integrated modules for inventory, procurement, accounting, sales, and MRP, Deskera helps companies make data-driven decisions that reduce costs, prevent overstocking, and ensure smoother supply chain operations.

Below are the key ways Deskera ERP supports businesses in optimizing MOQs and managing inventory more efficiently:

1. Real-Time Inventory Visibility and Tracking

Deskera ERP provides live updates on stock levels, movement, and availability across warehouses. This helps businesses:

- Identify fast-moving vs slow-moving items

- Avoid overordering to meet MOQs unnecessarily

- Maintain optimal stock levels across all SKUs

- Improve stock turnover rates

With real-time insights, companies can confidently decide whether a supplier’s MOQ aligns with their actual demand.

2. Automated Demand Forecasting

Deskera’s intelligent forecasting engine analyzes historical data, sales trends, seasonality, and customer demand patterns. This allows businesses to:

- Predict how much inventory is needed before placing MOQ-based orders

- Reduce the risk of overstocking or stockouts

- Plan purchasing and production cycles with greater accuracy

Accurate demand forecasting ensures MOQs match real market requirements rather than guesswork.

3. Supplier Management and Negotiation Insights

Deskera offers a unified view of supplier performance, pricing history, lead times, and past orders. Using these insights, businesses can:

- Compare suppliers to find those with more flexible MOQs

- Negotiate better terms based on consistent data

- Consolidate orders where necessary to meet minimums

This strengthens supplier relationships and reduces dependency on inflexible vendors.

4. Automated Reorder Points and Safety Stock Calculation

The system automatically calculates optimal reorder levels and safety stock based on consumption rates and lead times. This helps businesses:

- Trigger replenishment before hitting MOQ-related shortages

- Avoid panic buying or emergency orders

- Reduce carrying costs while maintaining service levels

With automated replenishment, MOQ alignment becomes far more accurate and predictable.

5. MRP Integration for Smarter Production Planning

Deskera MRP ensures production schedules, raw material requirements, and procurement activities align with supplier MOQs. This feature helps businesses:

- Adjust production batches to meet MOQ conditions

- Reduce excess raw material purchases

- Avoid bottlenecks caused by insufficient materials

By linking MOQs to actual production needs, waste and overstock are significantly minimized.

6. Inventory Optimization Using Advanced Reporting

Deskera provides powerful, customizable inventory and procurement reports. These reports help identify:

- SKU-wise profitability

- Overstock or deadstock caused by high MOQs

- High-velocity products needing optimized MOQs

- Supplier MOQs that are too costly or inefficient

With comprehensive dashboards, companies can make strategic inventory adjustments quickly.

7. Workflow Automation for Purchasing and Procurement

Deskera automates purchase orders (POs), approvals, supplier communication, and receiving processes. This leads to:

- Accurate MOQ compliance

- Faster procurement cycles

- Fewer manual errors

- Greater consistency in operations

Automation ensures teams do not miss critical MOQ thresholds or timelines.

8. Cash Flow Management and Cost Control

Deskera’s finance and accounting modules help businesses evaluate the financial impact of MOQs. Companies can:

- Assess how MOQ purchases affect working capital

- Understand cost implications through real-time financial reports

- Maintain healthy cash flow while meeting procurement needs

This ensures capital isn’t locked in excess inventory.

9. Deskera Mobile Accessibility

Deskera’s mobile-first design allows teams to manage inventory, track stock levels, approve purchases, and monitor MOQs from anywhere. Business leaders benefit from:

- Faster decision-making

- On-the-move inventory control

- Improved responsiveness to supplier updates

This agility helps companies stay ahead in dynamic demand environments.

10. AI-Powered Assistant (DAVID) for Smarter Decisions

Deskera’s AI assistant, DAVID, provides actionable recommendations such as:

- Optimal MOQ adjustments

- Supplier-specific ordering suggestions

- Alerts for stock risks caused by high MOQs

- Real-time insights on demand changes

DAVID helps businesses make intelligent, data-backed decisions instantly.

Key Takeaways

- Understanding MOQ is essential for balancing supplier expectations with your business’s inventory, cash flow, and demand forecasting needs.

- MOQs help suppliers reduce costs and increase operational efficiency, but they require buyers to plan smartly to avoid unnecessary financial strain.

- Choosing the correct MOQ involves analyzing demand, storage capacity, cost structures, and supplier terms to ensure profitable purchasing decisions.

- Different MOQ types—based on units, value, or production batches—serve unique purposes and need to align with your product lifecycle and sales patterns.

- MOQs can secure better pricing, ensure consistent supply, and streamline operations when managed strategically.

- High upfront costs, overstocking risks, cash flow pressures, and limited flexibility can hinder growth unless businesses use forecasting, negotiation, and inventory control techniques.

- Overestimating demand, neglecting data, ignoring storage constraints, and accepting supplier MOQs blindly can result in waste, excess inventory, and financial losses.

- Deskera ERP enhances MOQ planning through real-time demand forecasting, automated inventory tracking, actionable insights, and smarter procurement workflows.

Related Articles