What’s the secret to keeping customers happy while ensuring smooth operations? The answer often lies in effectively managing lead time. In inventory management, lead time is one of the most critical factors influencing everything from stock levels to customer satisfaction.

Shorter lead times help businesses keep products on shelves, meet customer demand quickly, and respond swiftly to market changes. But without understanding and optimizing lead time, businesses may struggle with stockouts, excess inventory, or, worse, a breakdown in customer trust.

Lead time refers to the total time it takes from ordering materials or products to the point when they’re available for use or sale. In today’s fast-paced, customer-centric market, minimizing lead time is more important than ever, as shorter lead times can boost operational efficiency, reduce storage costs, and ultimately improve profit margins.

Lead time management doesn’t just involve speeding up delivery; it encompasses every stage of the supply chain, including production, order processing, and logistics. Each of these factors can either extend or shorten lead time, impacting a business’s ability to meet its goals.

Effectively managing lead time requires a clear understanding of each stage in the process, along with the right tools and technology to track, forecast, and optimize inventory. This is where Deskera ERP comes into play.

Deskera ERP offers a comprehensive suite of tools designed to help businesses streamline operations, automate order processing, and monitor lead times in real time. With Deskera, companies can reduce manual work, gain valuable insights into their inventory cycles, and make proactive decisions to reduce lead times and improve overall efficiency.

In this article, we’ll dive deeper into what lead time is, how it affects inventory management, and the strategies businesses can use to manage it effectively. By optimizing lead times, businesses can enhance their inventory processes, minimize waste, and ultimately provide better service to customers.

What is Lead Time in Inventory Management?

Lead time in inventory management is the total time it takes from the moment an order is placed with a supplier until the inventory is available for use or sale. It includes all the steps involved in procuring materials, processing orders, manufacturing products, and transporting them to the final destination.

Lead time plays a vital role in inventory planning because it directly impacts how quickly a business can replenish stock, meet customer demand, and maintain smooth operations.

In inventory management, lead time is often broken down into several components, including order processing time, production time, and delivery time. Each of these factors contributes to the total lead time, influencing a business’s ability to forecast demand, set reorder points, and avoid stockouts.

For instance, a longer lead time requires a higher level of safety stock to prevent running out of inventory, while a shorter lead time allows businesses to respond more flexibly to changes in demand.

Understanding lead time is essential for efficient inventory control because it directly affects key decisions around stock levels, reorder frequency, and supplier selection. Companies with shorter lead times are better positioned to meet customer expectations, especially in industries where quick turnaround is critical.

By accurately calculating and managing lead time, businesses can balance inventory costs with customer satisfaction, reduce waste, and avoid the risks associated with overstocking or understocking.

In short, lead time in inventory management serves as a measure of a company’s responsiveness to demand and adaptability to market changes. Optimizing lead time can significantly improve a company’s overall efficiency, reduce costs, and help build a more agile and competitive business.

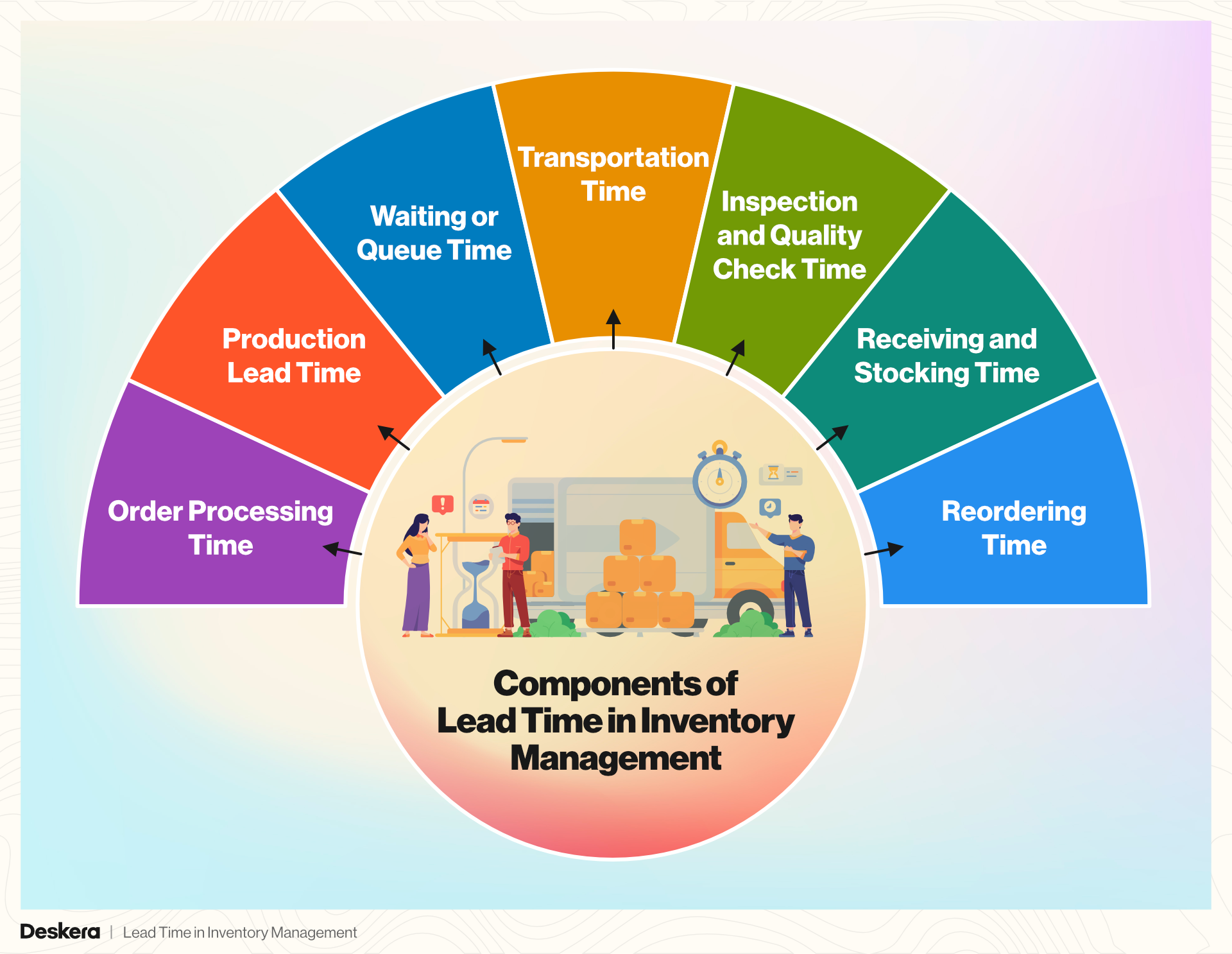

Components of Lead Time in Inventory Management

Lead time in inventory management is made up of several components, each contributing to the total time required to receive, produce, or deliver a product. Breaking down lead time into its components allows businesses to analyze and optimize each part, improving overall efficiency and responsiveness.

Here are the key components of lead time:

1. Order Processing Time

- Description: This is the time taken to create, approve, and process an order within the company. It starts when a need for stock is identified and ends when the order is formally placed with a supplier.

- Importance: Faster order processing reduces the initial lead time component, enabling companies to get orders moving sooner. Streamlining this step can help improve responsiveness to demand.

2. Production Lead Time

- Description: For businesses that manufacture products, production lead time is the time needed to complete the manufacturing process from start to finish. This includes procuring raw materials, assembling parts, quality control, and final packaging.

- Importance: Efficient production processes reduce production lead time, allowing companies to fulfill orders faster and reduce stock holding costs for finished goods.

3. Waiting or Queue Time

- Description: Waiting time is the period when an order or product is on hold, either in line for production or waiting for further processing. This often occurs due to resource availability, scheduling, or batch production practices.

- Importance: Reducing waiting time can significantly lower lead time. Businesses can address this by optimizing production schedules or investing in additional resources.

4. Transportation Time

- Description: Transportation time is the period required to move goods from one location to another. This could include shipping from a supplier to a warehouse, transporting finished goods from production facilities, or delivering products to customers.

- Importance: Optimizing transportation time by selecting faster carriers or more efficient routes can reduce lead time, enabling quicker restocking and improving customer satisfaction.

5. Inspection and Quality Check Time

- Description: After receiving or producing products, companies often inspect items to ensure they meet quality standards. This quality control step can take additional time but is essential for maintaining product quality.

- Importance: Although quality checks are necessary, efficient inspection processes can minimize delays. Automation or well-trained teams can speed up this phase without compromising quality.

6. Receiving and Stocking Time

- Description: Once goods arrive at the company’s location, they must be unloaded, inspected (if necessary), and added to inventory. This component of lead time covers the handling and stocking of items in the warehouse or storage facility.

- Importance: Efficient receiving processes allow products to be made available for use or sale faster, reducing lead time and improving inventory turnover.

7. Reordering Time

- Description: For recurring orders, reordering time refers to the internal process of identifying reorder points, triggering a new order, and completing the necessary paperwork or system entries.

- Importance: By optimizing reorder processes, companies can reduce the time it takes to initiate a new order, which is particularly useful for high-demand or fast-moving items.

Each of these components contributes to the total lead time and offers opportunities for improvement. By focusing on reducing each element, businesses can achieve shorter, more reliable lead times, improving overall efficiency and ensuring a consistent supply of products.

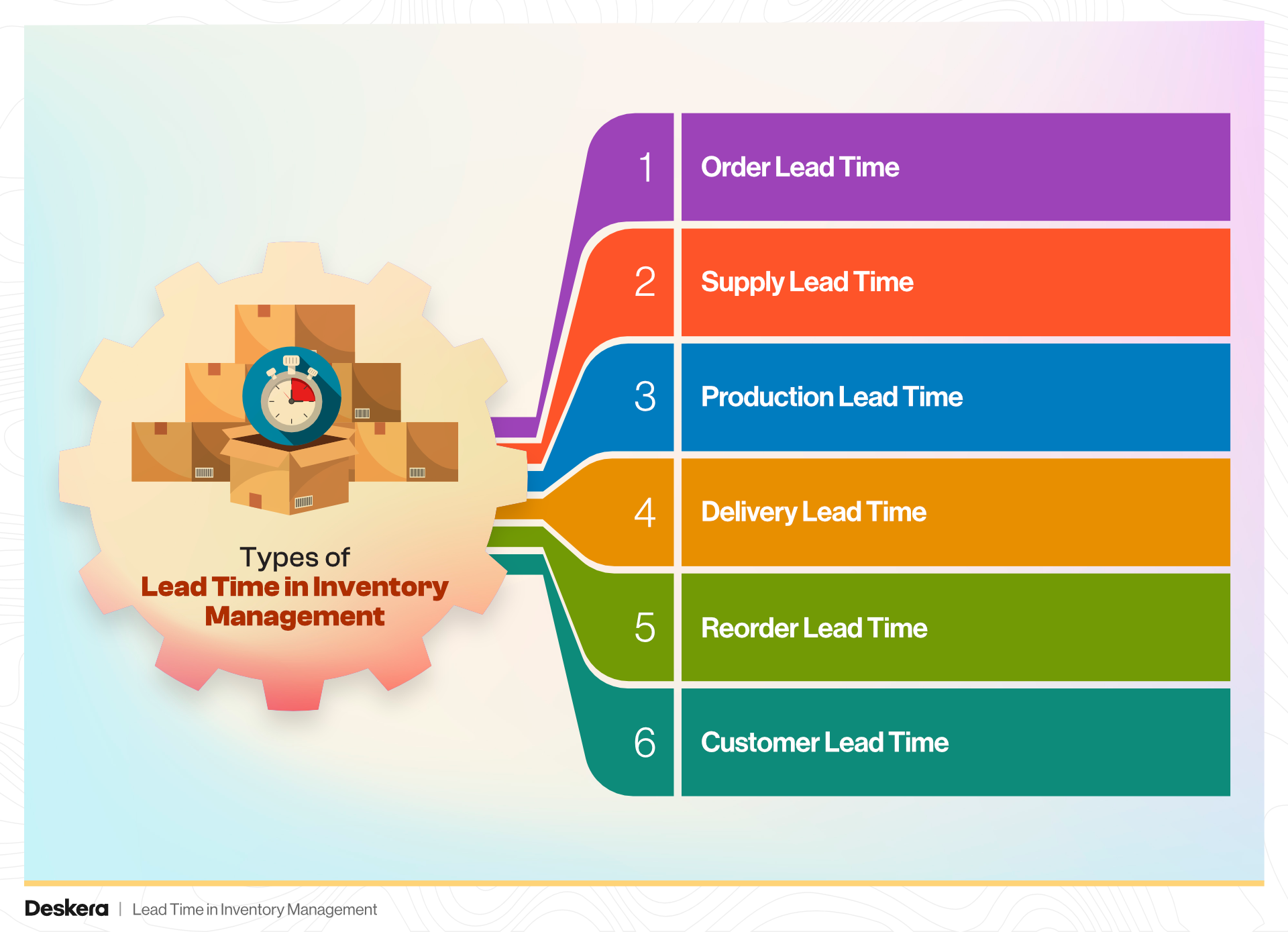

Types of Lead Time in Inventory Management

In inventory management, lead time can be categorized into several types, each affecting different aspects of the supply chain and impacting how efficiently a business can manage its stock. Understanding these types of lead time helps companies better forecast, plan inventory, and maintain smooth operations.

Here are the primary types of lead time in inventory management:

1. Order Lead Time

- Definition: Order lead time refers to the period from placing an order with a supplier until the moment it’s confirmed or acknowledged. This is the initial phase of lead time and can vary depending on supplier responsiveness and order processing efficiency.

- Importance: Faster order processing can help reduce overall lead time, allowing companies to receive their inventory sooner.

2. Supply Lead Time

- Definition: Supply lead time is the time it takes for suppliers to prepare and dispatch ordered materials or goods. This phase includes the supplier’s internal processing, such as gathering materials, assembling products, and packaging.

- Importance: This type of lead time depends heavily on the supplier's production capacity and reliability. Shorter supply lead times enable businesses to maintain lower stock levels and quickly respond to customer demand.

3. Production Lead Time

- Definition: Production lead time is the duration required to manufacture a product from start to finish. It includes time spent on procuring raw materials, assembly, quality checks, and packaging within the company’s own operations.

- Importance: Efficient production processes reduce production lead time, which helps companies fulfill orders faster and keep up with customer demand, especially for made-to-order items.

4. Delivery Lead Time

- Definition: Delivery lead time is the time required to transport goods from the supplier (or production facility) to the company’s warehouse or retail location. This period can vary based on shipping method, distance, and logistical factors.

- Importance: Fast and reliable delivery is crucial for maintaining consistent stock levels and minimizing delays. Companies can often reduce this lead time by using local suppliers or optimized shipping routes.

5. Reorder Lead Time

- Definition: Reorder lead time is the interval between the moment a company places a reorder with a supplier and the arrival of that order. It combines several other lead times, including order, supply, and delivery lead times.

- Importance: Managing reorder lead time is critical for setting appropriate reorder points to avoid stockouts. Businesses can adjust reorder points based on seasonal demand, market conditions, and supplier performance.

6. Customer Lead Time

- Definition: Customer lead time is the period from when a customer places an order until they receive the product. This includes all stages in the supply chain, from production to delivery.

- Importance: Customer lead time is essential for customer satisfaction, as it represents how quickly a business can fulfill orders. Shorter customer lead times can enhance the customer experience, improve customer retention, and provide a competitive edge.

By managing and optimizing these different types of lead times, companies can achieve better inventory control, respond faster to market changes, and improve overall customer satisfaction. Each type of lead time requires specific strategies, whether by enhancing supplier relationships, streamlining production, or optimizing delivery logistics.

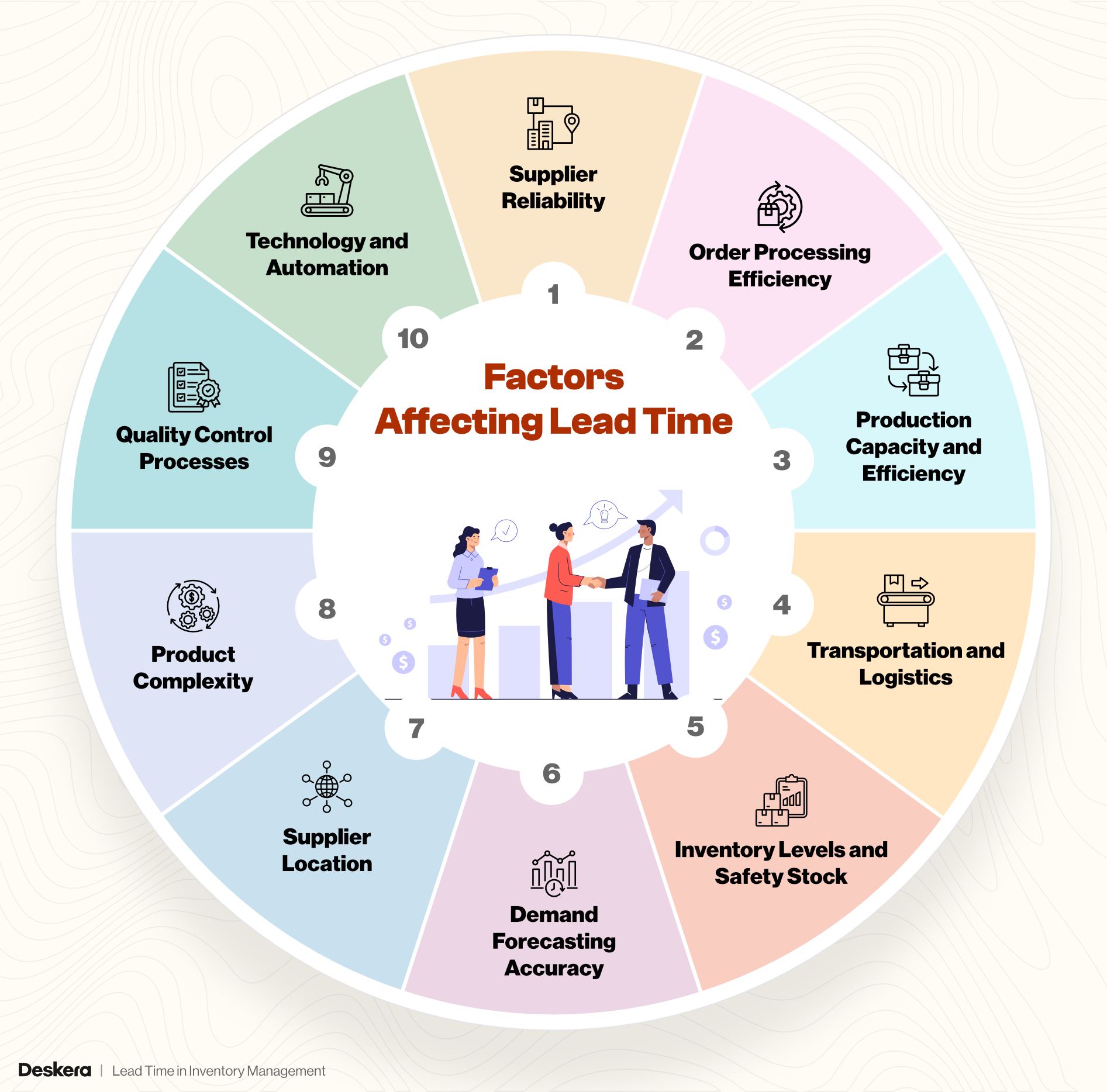

Factors Affecting Lead Time

Several factors influence lead time in inventory management, affecting how quickly a business can receive, produce, and deliver goods. Understanding these factors is essential for optimizing lead time, improving inventory control, and meeting customer expectations.

Here are the key factors that can impact lead time:

1. Supplier Reliability

- Description: The consistency and dependability of suppliers play a crucial role in determining lead time. Reliable suppliers with efficient processes can fulfill orders more quickly and consistently.

- Impact: Unreliable suppliers or those prone to delays can increase lead time, leading to stockouts and unmet customer demand. Partnering with dependable suppliers or building strong supplier relationships can help reduce lead time.

2. Order Processing Efficiency

- Description: This includes the time taken to process an order internally—from creating a purchase request to finalizing and sending the order to the supplier.

- Impact: Slow order processing can add days to lead time. Streamlining this step through automation or process improvements can significantly reduce delays.

3. Production Capacity and Efficiency

- Description: For businesses that manufacture products, production lead time depends on their capacity and operational efficiency. Factors like machine downtime, labor availability, and production bottlenecks impact the time required to complete production.

- Impact: Efficient production systems shorten lead times, while inefficiencies or capacity constraints can extend lead time and delay order fulfillment.

4. Transportation and Logistics

- Description: Transportation lead time depends on the shipping method, route, distance, and external factors like weather or political conditions.

- Impact: Choosing faster or more reliable shipping options can reduce delivery lead time. However, relying on international suppliers or complex logistics can increase lead time due to customs, border control, or carrier delays.

5. Inventory Levels and Safety Stock

- Description: Having appropriate levels of safety stock helps businesses maintain smooth operations during lead time fluctuations. Insufficient safety stock can increase the risk of stockouts if lead times extend unexpectedly.

- Impact: Higher safety stock levels act as a buffer against lead time variability, while low or inadequate safety stock can create delays and order fulfillment issues.

6. Demand Forecasting Accuracy

- Description: Accurate demand forecasting helps businesses plan inventory and reorder schedules more effectively, reducing the likelihood of rushed orders.

- Impact: Poor forecasting leads to overstocking or understocking, which affects lead time. Businesses can mitigate this by using demand planning tools that provide accurate forecasts and help align reorder schedules with actual demand.

7. Supplier Location

- Description: The geographical distance between a business and its suppliers affects transportation time, customs clearance, and overall lead time.

- Impact: Sourcing from local suppliers can reduce lead time, while using overseas suppliers can lead to longer lead times due to shipping and regulatory processes.

8. Product Complexity

- Description: Complex products with multiple components may require more time to assemble and inspect, impacting production and delivery times.

- Impact: Simplifying product designs or standardizing components can reduce lead time, while custom or intricate products may extend production and quality assurance times.

9. Quality Control Processes

- Description: Quality checks and inspections are necessary to ensure product standards but can add to lead time, particularly if issues arise that require rework or adjustments.

- Impact: Efficient quality control processes ensure product reliability without causing excessive delays. Streamlining or optimizing quality control can help reduce lead time.

10. Technology and Automation

- Description: Automation in order processing, inventory management, and logistics can help reduce manual handling times and eliminate bottlenecks in lead time.

- Impact: Using ERP or inventory management software, like Deskera ERP, can improve visibility and tracking, allowing for faster order processing, real-time monitoring, and more responsive lead time management.

By understanding and addressing these factors, businesses can better manage lead time, reducing delays and ensuring a consistent supply of products to meet customer demand. Proactive measures, such as optimizing processes and investing in technology, can significantly improve lead time efficiency.

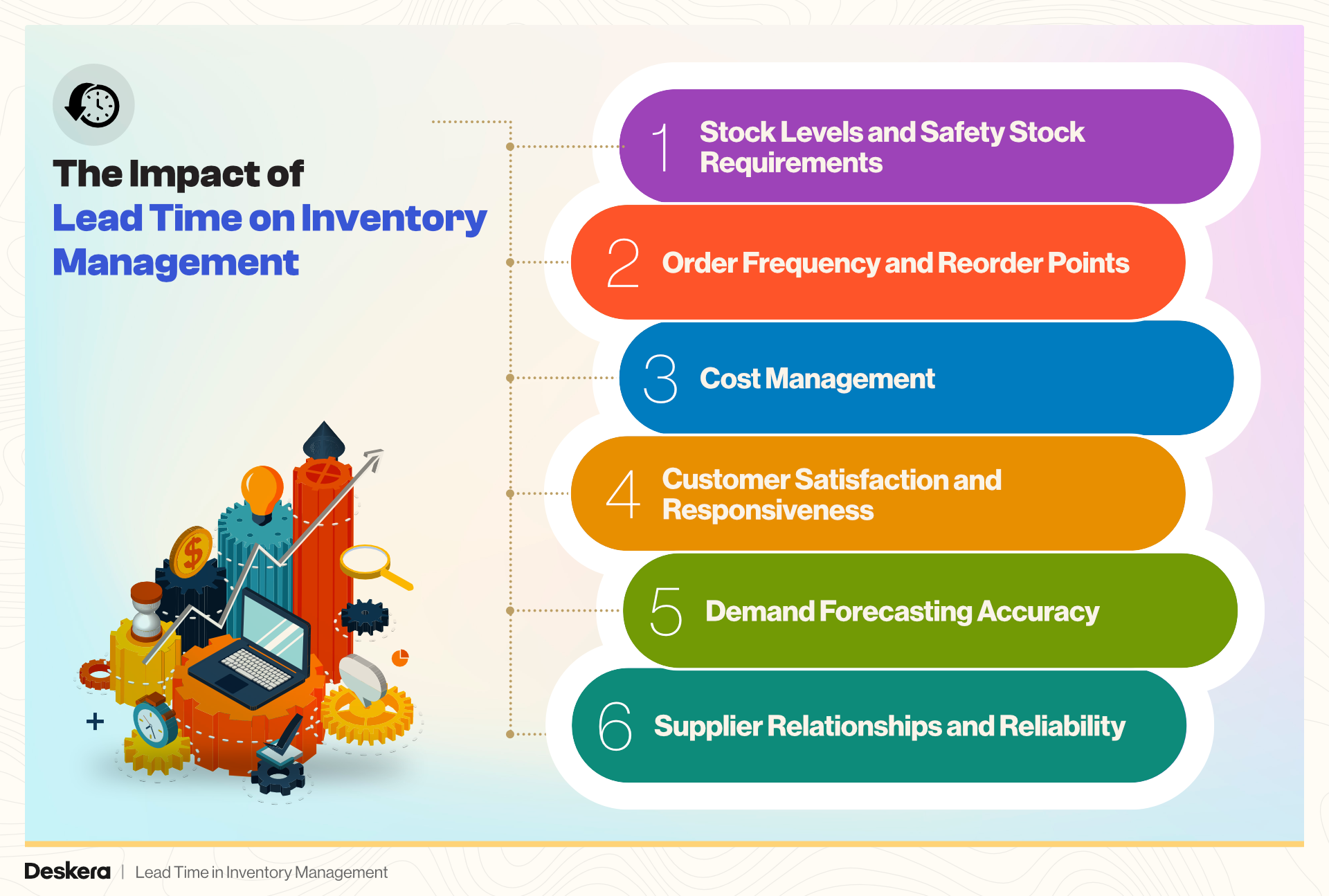

The Impact of Lead Time on Inventory Management

Lead time has a substantial impact on inventory management, influencing how businesses plan, store, and reorder stock to meet customer demand. Efficient lead time management is essential for maintaining optimal inventory levels, reducing costs, and ensuring that products are available when needed.

Here are some key ways that lead time affects inventory management:

1. Stock Levels and Safety Stock Requirements

- Impact: Longer lead times often require businesses to maintain higher levels of safety stock to prevent stockouts. When lead times are unpredictable or lengthy, companies must hold additional inventory to cover the gap, which increases carrying costs. Conversely, shorter and more consistent lead times allow for reduced safety stock, enabling businesses to keep inventory levels lean.

- Example: A retail company with a lead time of several weeks for popular products may need to order more in advance to avoid stockouts during high-demand periods, resulting in higher storage costs.

2. Order Frequency and Reorder Points

- Impact: Lead time directly influences reorder points, which indicate when new orders should be placed to avoid stockouts. The longer the lead time, the earlier a business must reorder to ensure continuous availability of stock. A short lead time allows companies to place orders closer to the time they actually need the inventory, providing greater flexibility and reducing the risk of overstocking.

- Example: A business with a reliable 3-day lead time can reorder items closer to depletion, while a 3-week lead time requires early ordering, making accurate demand forecasting critical.

3. Cost Management

- Impact: Managing lead time effectively helps control both direct and indirect costs. Extended lead times can lead to higher costs due to increased safety stock, additional warehousing needs, and potential obsolescence risks if demand fluctuates. Shorter lead times reduce these carrying costs and minimize the risk of excess inventory.

- Example: By reducing lead time, a business can free up storage space, lower handling expenses, and avoid holding outdated products that may become obsolete or unsellable.

4. Customer Satisfaction and Responsiveness

- Impact: Lead time affects a business’s ability to meet customer expectations, especially in industries where quick order fulfillment is crucial. Shorter lead times enhance responsiveness, enabling businesses to fulfill orders faster, maintain higher service levels, and build customer loyalty. Conversely, long lead times may lead to delays, stockouts, and backorders, which can negatively impact customer satisfaction and retention.

- Example: An e-commerce retailer with short lead times can quickly restock popular items, ensuring customers don’t have to wait or turn to competitors, whereas long lead times might lead to order cancellations or dissatisfied customers.

5. Demand Forecasting Accuracy

- Impact: Accurate demand forecasting is essential for managing lead time effectively. Longer lead times increase the difficulty of predicting demand accurately, as businesses must account for fluctuations over extended periods. This often requires more sophisticated forecasting techniques and data analysis to anticipate customer needs over the lead time period. Shorter lead times help businesses be more responsive to real-time demand changes, reducing dependency on complex forecasts.

- Example: A manufacturer with a lead time of just a few days can adapt to demand changes quickly, while one with a month-long lead time must forecast demand far in advance, increasing the likelihood of inaccuracies.

6. Supplier Relationships and Reliability

- Impact: The reliability and efficiency of suppliers heavily influence lead time. Building strong relationships with dependable suppliers can help minimize lead times and improve consistency. When businesses work closely with suppliers, they may negotiate faster processing, streamlined communication, and prioritized orders, all of which contribute to better lead time management.

- Example: A business that collaborates closely with suppliers to expedite order processing and shipping can ensure shorter, more consistent lead times, improving inventory turnover and flexibility.

In summary, lead time is a critical factor in inventory management, affecting every aspect of the supply chain, from stock levels and order timing to customer satisfaction and cost control.

By effectively managing lead time and reducing variability, businesses can streamline their inventory processes, minimize costs, and deliver better service, gaining a competitive edge in the market.

Calculating Lead Time in Inventory Management

Calculating lead time accurately in inventory management is essential for effective stock control, meeting customer demands, and minimizing costs associated with holding excess inventory. Here’s a breakdown of how to calculate lead time and some key formulas involved:

1. Basic Lead Time Calculation

- The simplest way to calculate lead time is to measure the time between when an order is placed and when it is fully received or completed.

- Formula: Lead Time = Order Received Date - Order Placed Date

- Example: If an order is placed on January 1 and received on January 10, the lead time is 10 days.

2. Total Lead Time Calculation with Components

- To get a more accurate lead time, businesses often break it down into its components, such as order processing, production, transportation, and receiving time. The sum of these components provides the total lead time.

- Formula: Total Lead Time = Order Processing Time + Production Time + Transportation Time + Receiving Time

- Example: If order processing takes 2 days, production takes 5 days, transportation takes 3 days, and receiving takes 1 day, then the total lead time is 2 + 5 + 3 + 1 = 11 days.

3. Reorder Point Calculation (Using Lead Time)

- Lead time plays a crucial role in determining the reorder point, which is when a business should reorder stock to avoid running out of inventory.

- Formula: Reorder Point = Lead Time Demand + Safety Stock

where:

Lead Time Demand = Average daily demand ×\times× Lead time (in days)

Safety Stock is extra stock held to prevent stockouts due to variability in demand or lead time.

- Example: If a business sells 50 units per day, has a lead time of 10 days, and holds 100 units of safety stock, then the reorder point would be:

Reorder Point = (50 x 10) + 100 = 600 units

4. Lead Time Demand Calculation

- This calculation estimates how much inventory will be needed to cover demand during the lead time. It is useful for ensuring that sufficient stock is ordered to meet demand while waiting for replenishment.

- Formula: Lead Time Demand = Average Daily Demand x Lead Time

- Example: If daily demand averages 30 units and lead time is 7 days, the lead time demand would be: Lead Time Demand = 30 x 7 = 210 units

5. Cycle Time and Lead Time Relationship

- Cycle time, which refers to the time it takes to produce a product from start to finish, is closely related to lead time, especially in manufacturing. Together, they impact inventory levels and production scheduling.

- Formula for Total Lead Time with Cycle Time: Total Lead Time = Cycle Time + Order Processing Time + Transportation Time + Receiving Time

- Example: If the cycle time is 4 days, order processing is 2 days, transportation is 3 days, and receiving is 1 day, then the total lead time would be: 4+2+1+3 = 10 days

6. Adjusting Lead Time for Variability

- Lead times may vary due to factors like supplier delays or transportation issues. To manage variability, businesses often calculate an average lead time and add buffer days or safety stock.

- Adjusted Lead Time: This involves adding extra days based on historical lead time variability.

- Formula: Adjusted Lead Time = Average Lead Time + Lead Time Variability

- Example: If the average lead time is 5 days but varies by up to 2 days, the adjusted lead time would be: 5+2 = 7 days

By accurately calculating and understanding lead time, businesses can make data-driven decisions about reorder points, safety stock, and inventory levels, helping to minimize costs and improve customer satisfaction.

Lead Time Reduction Strategies

Reducing lead time is critical for improving inventory management, increasing customer satisfaction, and enhancing operational efficiency. By optimizing each component of the lead time, businesses can respond more quickly to customer demand, reduce costs, and improve overall productivity.

Here are several effective strategies to reduce lead time:

1. Streamline Order Processing

- Strategy: Automating order processing and adopting digital tools can eliminate manual steps, reduce errors, and speed up the approval process.

- Actions:

- Implement automated order entry systems.

- Use integrated software systems (e.g., ERP) to streamline communication between departments and suppliers.

- Provide real-time access to order status and stock levels to speed up decision-making.

- Impact: Faster order processing leads to quicker action on replenishment orders, reducing overall lead time.

2. Improve Supplier Relationships

- Strategy: Strong relationships with suppliers can reduce delays in sourcing and receiving materials, contributing to faster lead times.

- Actions:

- Negotiate shorter lead times with suppliers.

- Establish a preferred supplier list based on reliability and speed.

- Communicate regularly to ensure suppliers are aware of your demand forecasts.

- Impact: Reliable suppliers help to ensure faster deliveries and consistent supply of goods, which reduces waiting time.

3. Increase Inventory Visibility

- Strategy: Real-time visibility into inventory levels helps reduce stockouts and ensures that orders are fulfilled quickly without unnecessary delays.

- Actions:

- Use inventory management systems that provide real-time data on stock levels and sales.

- Implement barcoding or RFID for better tracking of goods.

- Adopt demand forecasting tools to better predict inventory needs and optimize stock levels.

- Impact: Improved visibility helps avoid overstocking or stockouts, reducing delays in production and fulfillment.

4. Leverage Technology and Automation

- Strategy: Automation tools can speed up many processes, such as production scheduling, order fulfillment, and shipping.

- Actions:

- Use automated manufacturing equipment to reduce production time.

- Invest in warehouse automation tools like conveyor systems, robotic pickers, and automated guided vehicles (AGVs).

- Implement AI and machine learning for predictive maintenance to reduce machine downtime.

- Impact: Automation can significantly reduce production and handling times, decreasing lead time across the entire process.

5. Optimize Production Scheduling

- Strategy: Efficient production scheduling ensures that resources are allocated effectively, and products are manufactured or assembled in the most efficient manner possible.

- Actions:

- Use production planning tools that prioritize orders based on deadlines, demand, and resource availability.

- Implement lean manufacturing practices to minimize waste and downtime.

- Adopt flexible production systems that can adapt to changing demand patterns.

- Impact: Optimized production scheduling leads to faster turnaround times and helps avoid bottlenecks.

6. Consolidate Shipments

- Strategy: Consolidating shipments can reduce transportation time and costs, especially when materials come from multiple suppliers.

- Actions:

- Coordinate shipments to consolidate multiple orders into a single delivery.

- Work with logistics partners who offer combined shipments and faster transit times.

- Use cross-docking in distribution centers to streamline inbound and outbound shipments.

- Impact: Reduced shipping time and cost can lead to faster delivery times and lower overall lead times.

7. Enhance Communication Across the Supply Chain

- Strategy: Effective communication with all stakeholders—suppliers, manufacturers, distributors, and customers—can prevent delays and improve responsiveness.

- Actions:

- Use integrated communication platforms to streamline collaboration with suppliers and customers.

- Set clear expectations with all supply chain partners regarding lead times and delivery schedules.

- Implement automated notifications and alerts to keep all parties informed of changes.

- Impact: Clear communication ensures that all steps in the process are aligned, reducing errors and delays.

8. Reduce Waiting Time with Just-in-Time (JIT)

- Strategy: Implementing a Just-in-Time inventory system ensures that materials and products are only ordered as needed, reducing unnecessary stockholding and waiting time.

- Actions:

- Establish a JIT approach to procurement, ensuring materials arrive only when they are needed in production.

- Work closely with suppliers to ensure quick replenishment cycles and shorter lead times.

- Regularly monitor lead times to adjust schedules based on actual delivery times.

- Impact: JIT reduces inventory holding costs and eliminates unnecessary waiting time between procurement and production.

9. Improve Receiving and Inspection Processes

- Strategy: Streamlining the receiving and inspection process ensures that products are quickly available for use in production or sale.

- Actions:

- Use automated tools for receiving and inspecting goods (e.g., scanners for quick inventory updates).

- Implement faster inspection protocols that allow goods to be inspected and processed simultaneously.

- Reduce the time spent on quality control checks through efficient procedures or automated testing systems.

- Impact: Faster receiving and inspection reduce the time products spend in warehouses, helping to speed up the overall lead time.

10. Implement Vendor-Managed Inventory (VMI)

- Strategy: In VMI, the supplier manages inventory levels, ensuring that the right products are available at the right time, reducing the need for constant order processing.

- Actions:

- Work with suppliers to implement a VMI system where they monitor and restock your inventory automatically.

- Share real-time data with suppliers about inventory levels and demand forecasts.

- Use collaborative planning tools to improve the accuracy of supply chain decisions.

- Impact: VMI reduces order processing time and ensures that inventory levels remain optimal, minimizing lead time.

By implementing these lead time reduction strategies, businesses can achieve faster delivery times, reduce inventory costs, and improve overall supply chain performance. The key is to optimize each component of the lead time and continuously assess the process for further improvements.

Benefits of Optimizing Lead Time

Optimizing lead time in inventory management is essential for businesses aiming to improve efficiency, reduce costs, and enhance customer satisfaction. By reducing lead time, organizations can streamline their supply chain operations and respond more effectively to market demand. Here are the key benefits of optimizing lead time:

1. Improved Customer Satisfaction

- Benefit: Faster delivery times lead to happier customers who receive products when they expect them.

- Explanation: Shorter lead times mean products are available to customers more quickly, reducing the chances of stockouts and backorders. This enhances the overall customer experience and can result in higher customer loyalty and repeat business.

- Impact: Enhanced reputation and customer retention, leading to increased sales and brand loyalty.

2. Reduced Inventory Costs

- Benefit: By optimizing lead time, businesses can reduce the need to hold large amounts of inventory.

- Explanation: Shorter lead times allow companies to implement lean inventory practices, reducing the amount of safety stock required. This decreases inventory holding costs, such as storage, insurance, and the risk of obsolete stock.

- Impact: Improved cash flow, reduced capital tied up in inventory, and a more efficient supply chain.

3. Increased Operational Efficiency

- Benefit: Streamlining lead time helps eliminate bottlenecks and inefficiencies within the supply chain.

- Explanation: By reducing the time taken for each stage of the supply chain (e.g., order processing, production, and delivery), businesses can optimize resource allocation and improve the flow of materials.

- Impact: Smoother operations, lower operational costs, and the ability to meet customer demand more effectively.

4. Better Demand Forecasting

- Benefit: Optimizing lead time helps businesses better predict demand and stock requirements.

- Explanation: With reduced lead time, companies can rely on more accurate and timely data for forecasting. This allows them to respond more swiftly to fluctuations in customer demand, avoiding both overstocking and stockouts.

- Impact: Improved decision-making, more accurate inventory levels, and better alignment with customer needs.

5. Enhanced Supplier Relationships

- Benefit: Faster lead times often rely on strong relationships with reliable suppliers.

- Explanation: When businesses work closely with their suppliers to improve lead times, it creates a mutually beneficial relationship. Suppliers who meet tighter lead times can help ensure more reliable and consistent product availability.

- Impact: Stronger collaboration with suppliers, improved quality control, and better supply chain reliability.

6. Higher Competitive Advantage

- Benefit: Companies that can deliver products more quickly have a distinct edge in the marketplace.

- Explanation: In fast-paced markets, customers value speed. Businesses that can shorten lead times without sacrificing quality gain a competitive advantage by being able to fulfill customer orders faster than their competitors.

- Impact: Increased market share, better positioning in the marketplace, and the ability to quickly capitalize on new opportunities.

7. Improved Cash Flow

- Benefit: Reducing lead time helps businesses minimize the amount of capital tied up in inventory.

- Explanation: By having shorter lead times, businesses can replenish stock more frequently without needing to hold large amounts of inventory. This reduces the need for large upfront investments in stock and allows for more efficient cash flow management.

- Impact: Better liquidity, more flexible financial management, and reduced financial strain.

8. Faster Response to Market Changes

- Benefit: A business that can reduce lead time is better positioned to react quickly to changes in market demand, trends, or disruptions.

- Explanation: With optimized lead times, businesses can make quicker adjustments to production schedules, stock levels, and order fulfillment processes. This responsiveness helps mitigate risks posed by unexpected market shifts or supply chain disruptions.

- Impact: Increased resilience to external challenges and a more adaptable business model.

9. Reduced Stockouts and Overstocking

- Benefit: Optimized lead times help businesses maintain balanced inventory levels.

- Explanation: By reducing lead time, companies can more accurately time their inventory replenishment, leading to fewer stockouts (which can lead to missed sales) and reduced risk of overstocking (which can result in excess inventory and wasted storage costs).

- Impact: A more efficient inventory management system, fewer missed sales opportunities, and lower storage costs.

10. Better Use of Resources

- Benefit: By shortening lead times, businesses can make better use of their workforce and facilities.

- Explanation: Reduced lead times require less time spent on order processing, production scheduling, and other tasks. This allows employees to focus on higher-value activities, such as improving product quality, customer service, and innovation.

- Impact: Optimized workforce productivity, better utilization of facilities, and a more streamlined operation.

Optimizing lead time offers numerous benefits, including improved customer satisfaction, reduced costs, increased efficiency, and enhanced competitiveness. By focusing on streamlining processes, improving supplier relationships, and leveraging technology, businesses can create a more responsive and cost-effective supply chain. In the long run, reducing lead time helps companies stay agile in the face of market changes, improve cash flow, and boost overall profitability.

Challenges in Managing Lead Time

Managing lead time in inventory and supply chain operations can be complex due to various internal and external factors. While optimizing lead time brings significant benefits, businesses often face challenges that can hinder their ability to reduce it effectively. Understanding these challenges is crucial for devising strategies to overcome them and improve overall supply chain efficiency.

Here are some common challenges in managing lead time:

1. Supplier Reliability

- Challenge: One of the biggest challenges in managing lead time is ensuring that suppliers consistently deliver goods on time.

- Explanation: Delays in the supply of materials, components, or products can extend lead times and disrupt the entire supply chain.

- Impact: Unpredictable supplier performance can lead to production delays, stockouts, or even missed customer orders, negatively affecting business operations and customer satisfaction.

2. Demand Fluctuations

- Challenge: Unpredictable fluctuations in customer demand can complicate lead time management.

- Explanation: Sudden spikes or drops in demand may require companies to adjust their inventory levels and order fulfillment processes, which can increase lead times or lead to overstocking.

- Impact: Demand variability can cause inventory shortages or surplus stock, complicating the timing of orders and leading to inefficiencies in meeting customer expectations.

3. Transportation Delays

- Challenge: Transportation issues, such as delays in shipping, customs, or accidents, can significantly affect lead time.

- Explanation: Goods that are delayed in transit, whether due to weather conditions, carrier inefficiencies, or logistical issues, lead to longer lead times and disrupt the delivery schedule.

- Impact: Delays in transportation can result in delayed product deliveries, increased shipping costs, and dissatisfied customers.

4. Inventory Management Challenges

- Challenge: Poor inventory management practices can increase lead times.

- Explanation: Without real-time visibility into inventory levels and movement, businesses may struggle to order materials on time, causing delays in production and fulfillment.

- Impact: Inefficient inventory control can lead to stockouts, overstocking, or slow restocking, all of which contribute to longer lead times.

5. Complex Production Processes

- Challenge: Complex manufacturing processes can create bottlenecks that increase lead time.

- Explanation: When production schedules are tightly packed or dependent on specialized machinery, delays in one part of the process can extend lead times across the entire system.

- Impact: Delays in production can have cascading effects on the supply chain, leading to increased inventory holding costs and customer dissatisfaction.

6. Lack of Communication Across the Supply Chain

- Challenge: Ineffective communication between suppliers, manufacturers, distributors, and retailers can lead to inefficiencies in managing lead time.

- Explanation: Poor communication results in misunderstandings, delays in decision-making, and inaccurate forecasting of inventory needs, which can disrupt the flow of goods.

- Impact: Miscommunication leads to delayed orders, unexpected shortages, and disruptions in production, all of which contribute to longer lead times.

7. Regulatory and Compliance Issues

- Challenge: Compliance with industry regulations or international standards can delay production and shipments.

- Explanation: Certain products may require certifications, inspections, or adherence to specific legal requirements, which can extend lead time.

- Impact: Regulatory delays, such as waiting for product approvals or meeting safety standards, can slow down the production and delivery processes, increasing overall lead time.

8. Limited Technology Integration

- Challenge: Insufficient integration of technology, such as enterprise resource planning (ERP) systems, can hamper lead time management.

- Explanation: Without effective technological integration across the supply chain, information may be siloed, leading to delays in order processing, inventory management, and decision-making.

- Impact: Lack of automation or real-time data sharing between departments or partners can cause delays in inventory tracking, production scheduling, and order fulfillment, ultimately extending lead time.

9. Supply Chain Disruptions

- Challenge: Natural disasters, geopolitical instability, or pandemics can disrupt supply chains and increase lead time.

- Explanation: Unexpected events, such as factory closures, border restrictions, or raw material shortages, can cause widespread disruptions that affect lead time.

- Impact: External factors outside the company's control can cause significant delays, requiring businesses to adjust quickly to maintain operations and meet customer demands.

10. Capacity Constraints

- Challenge: Limited production or storage capacity can create delays in fulfilling orders and replenishing stock.

- Explanation: When production lines or warehouses are running at full capacity, there may be insufficient resources to meet demand within the desired timeframe.

- Impact: Capacity constraints can result in longer production cycles, delayed shipments, and inability to respond quickly to spikes in demand, extending lead time.

Managing lead time is an ongoing challenge that requires careful attention to various factors within the supply chain. From supplier reliability to technological integration, businesses must navigate these hurdles to ensure timely delivery and maintain operational efficiency.

Overcoming these challenges often involves a combination of strategic planning, technology adoption, strong supplier relationships, and continuous process optimization. By addressing these challenges head-on, companies can reduce lead time, improve customer satisfaction, and stay competitive in the marketplace.

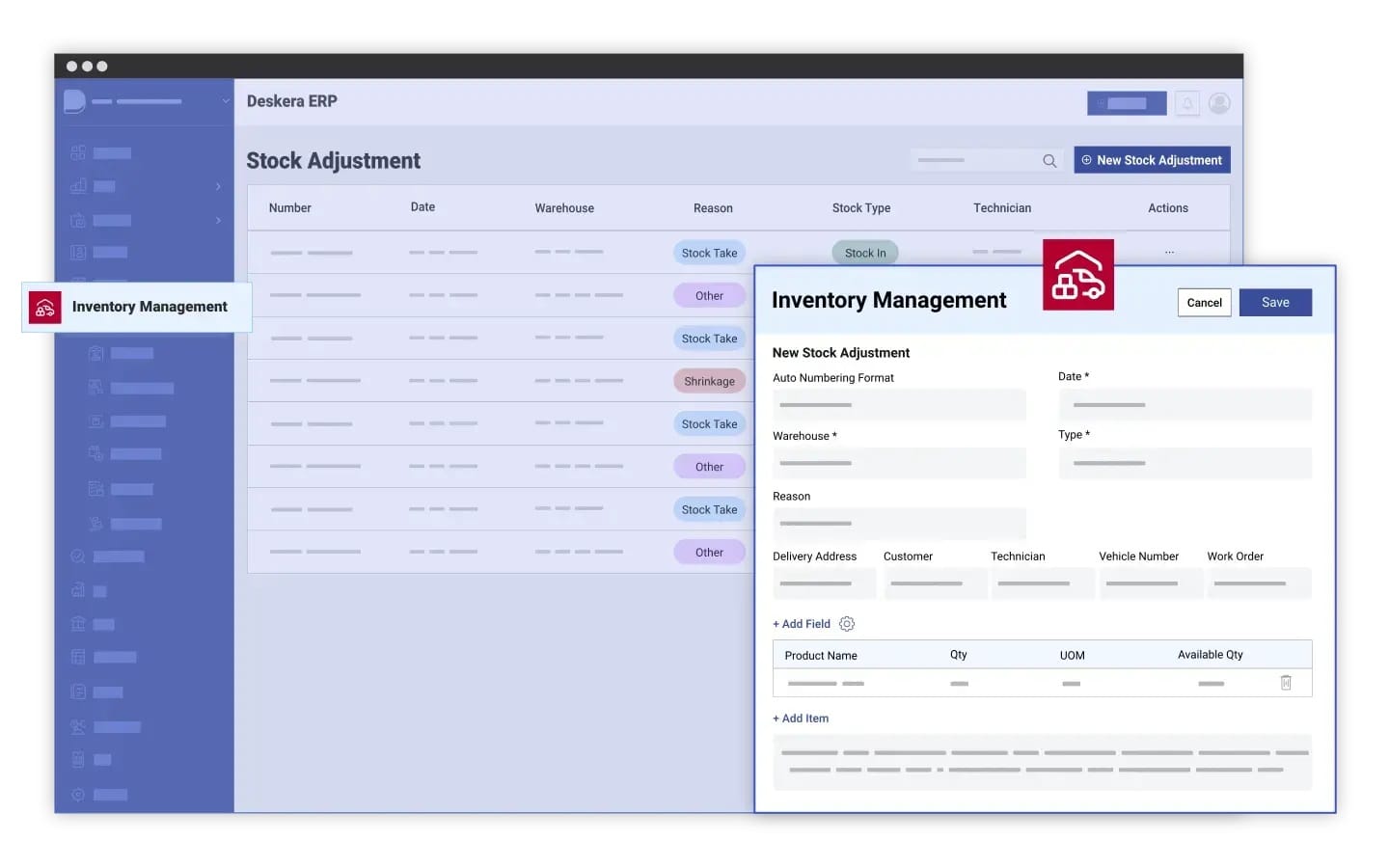

How Deskera ERP Can Help You with Reducing Lead Times in Inventory Management

Reducing lead times in inventory management is crucial for improving efficiency, minimizing costs, and meeting customer expectations. Deskera ERP offers a comprehensive suite of tools designed to help businesses streamline their supply chain processes, reduce lead times, and enhance overall operational performance.

Here’s how Deskera ERP can assist in achieving these goals:

1. Real-Time Inventory Tracking

- How It Helps: Deskera ERP provides real-time inventory tracking, allowing businesses to monitor stock levels, track product movement, and quickly identify when replenishment is needed.

- Impact on Lead Time: By having accurate, up-to-date visibility into inventory, businesses can order materials and products just in time, preventing delays in production or sales orders. This reduces the need for excessive stock holding, enabling faster responses to customer demands and reducing lead time.

2. Automated Replenishment

- How It Helps: Deskera ERP’s automated replenishment feature allows for the automatic creation of purchase orders when inventory reaches a predefined threshold.

- Impact on Lead Time: Automated ordering minimizes manual intervention, reduces errors, and ensures that materials are ordered on time. This streamlined process reduces waiting periods between order placement and delivery, helping to shorten lead times.

3. Demand Forecasting and Planning

- How It Helps: Deskera ERP utilizes historical data and analytics to help businesses forecast demand more accurately.

- Impact on Lead Time: Accurate demand forecasting enables businesses to plan their inventory needs more effectively. By predicting future demand, businesses can order the right quantity of stock in advance, reducing the risk of stockouts or overstocking, which directly helps in reducing lead times.

4. Supplier Management

- How It Helps: Deskera ERP enables businesses to manage supplier relationships, track performance, and communicate directly with vendors through its integrated platform.

- Impact on Lead Time: By monitoring supplier performance, businesses can identify the most reliable vendors and work to ensure timely deliveries. This can lead to more predictable and shorter lead times, as suppliers can be held accountable for meeting delivery schedules.

5. Production Scheduling

- How It Helps: Deskera ERP’s production planning and scheduling tools allow businesses to optimize production workflows by aligning inventory levels with manufacturing schedules.

- Impact on Lead Time: Efficient production scheduling ensures that materials and resources are available when needed, reducing delays in production cycles. This results in faster product turnaround and shorter lead times from production to delivery.

6. Order Management and Fulfillment

- How It Helps: Deskera ERP integrates order management, inventory control, and shipping functions, allowing businesses to streamline the order-to-fulfillment process.

- Impact on Lead Time: By automating the entire order management process, Deskera ERP helps businesses reduce the time spent on manual order entry, tracking, and fulfillment. This reduces processing time, ensuring faster order deliveries to customers.

7. Data-Driven Insights and Reporting

- How It Helps: Deskera ERP’s advanced reporting and analytics tools provide insights into inventory performance, order fulfillment times, and lead times.

- Impact on Lead Time: With access to detailed reports, businesses can identify areas of inefficiency in their supply chain and inventory management processes. This empowers decision-makers to take corrective actions that optimize operations and reduce lead times.

8. Integration with Other Systems

- How It Helps: Deskera ERP can be integrated with other business systems, such as e-commerce platforms, CRM, and logistics software.

- Impact on Lead Time: Seamless integration ensures that all aspects of the supply chain work together smoothly, reducing the chances of delays caused by miscommunication or manual data entry. This integrated approach minimizes lead time by improving workflow efficiency across departments.

9. Cloud-Based Access and Collaboration

- How It Helps: Deskera ERP is cloud-based, allowing for easy access from any location, enabling real-time collaboration across teams and partners.

- Impact on Lead Time: With cloud-based access, teams can make quick decisions, share updates, and collaborate on inventory management, production, and logistics from anywhere. This real-time communication and collaboration help to expedite processes and reduce delays that could otherwise extend lead times.

10. Scalable Solutions

- How It Helps: Deskera ERP offers scalable solutions that can grow with your business, accommodating changes in demand and operational complexity.

- Impact on Lead Time: As your business expands, Deskera ERP can adapt to higher volumes of transactions, more suppliers, and larger inventory needs. This scalability ensures that your lead time remains optimized, even as you scale operations.

Key Takeaways

- Lead time is the total time taken from the initiation of an order until the goods are delivered and available for use or sale. Efficient lead time management is essential for businesses to reduce costs, ensure product availability, and meet customer demands in a timely manner.

- Different types of lead time, including procurement, production, and transportation lead time, impact overall inventory management. Understanding each type helps businesses address specific delays in the supply chain to optimize performance.

- Lead time can be influenced by factors such as supplier performance, demand fluctuations, transportation delays, and production bottlenecks. Identifying and addressing these factors allows businesses to manage lead time more effectively and reduce operational delays.

- Longer lead times can result in stockouts, higher carrying costs, and reduced customer satisfaction. Shortening lead times allows for more efficient inventory control, helping businesses to reduce excess stock, improve cash flow, and meet customer demands faster.

- Lead time consists of several components, including ordering, production, and shipping. By understanding and managing each component separately, businesses can identify areas of improvement and reduce total lead time.

- Accurate lead time calculation involves adding up the time taken at each stage of the supply chain. Regularly tracking and calculating lead time ensures better visibility into inventory flow, leading to more informed decisions and improved supply chain efficiency.

- To reduce lead times, businesses can focus on strategies such as improving supplier relationships, automating inventory management, enhancing demand forecasting, and optimizing production scheduling. These strategies help minimize delays and improve responsiveness.

- Optimizing lead time offers several benefits, including improved customer satisfaction, reduced holding costs, and enhanced supply chain efficiency. By shortening lead time, businesses can operate more cost-effectively and respond to market demands with greater agility.

- Managing lead time involves challenges like supplier unreliability, transportation delays, and demand fluctuations. Addressing these challenges through better communication, technology, and planning is key to reducing lead time and ensuring smoother operations.

- Deskera ERP is a powerful tool for businesses looking to reduce lead times in inventory management. By providing real-time tracking, automating replenishment, enabling accurate forecasting, and streamlining supplier management and order fulfillment, Deskera ERP helps businesses achieve faster turnaround times and greater supply chain efficiency. With the ability to make data-driven decisions, collaborate across teams, and scale as your business grows, Deskera ERP ensures that your lead times remain competitive, ultimately leading to enhanced customer satisfaction and improved business performance.

Related Articles