Why do so many businesses continue to face stockouts, excess inventory, or unpredictable buying cycles—even when they have experienced teams and structured processes in place? The answer is simple: traditional procurement planning relies too heavily on fragmented data, manual judgement, and delayed insights. In a supply chain environment where demand shifts overnight and supplier risks can emerge without warning, old methods no longer offer the control or clarity that modern businesses need.

Procurement planning today is no longer just about purchasing the right materials at the right time. It has evolved into a strategic discipline that connects demand forecasting, supplier performance, budgeting, and inventory optimization. To keep up, companies need systems that bring speed, accuracy, and foresight into every procurement decision. This is where digital transformation becomes essential—and ERP systems take center stage.

ERP systems consolidate procurement, inventory, finance, and production data into a single, real-time environment, making it possible to plan proactively instead of reactively. By automating routine tasks, strengthening coordination across teams, and using predictive analytics to anticipate future requirements, ERP platforms help organizations move toward smarter, data-driven procurement. The result is a more resilient, cost-efficient, and predictable supply chain.

Deskera ERP strengthens this advantage even further with its mobile-first workflows, AI-powered assistant David, real-time inventory visibility, automated approvals, and integrated MRP capabilities. Designed for manufacturers, distributors, and growing businesses, Deskera enables teams to manage procurement cycles with speed, accuracy, and confidence. With its advanced reporting dashboards and seamless supplier communication, it empowers organizations to plan better and adapt faster.

What Is Procurement Planning?

Procurement planning is the strategic process of determining what materials or services a business needs, when they are needed, and who is best suited to supply them. It lays the foundation for acquiring goods efficiently by clearly outlining requirements, quantities, delivery timelines, and supplier expectations. Instead of relying on last-minute decisions, procurement planning brings structure and foresight into the purchasing process.

At its core, procurement planning uses data, analytics, and regular KPI reviews to evaluate performance and improve purchasing decisions. It involves close collaboration between multiple departments—production, finance, inventory, and procurement—to ensure that the business secures high-quality materials at the right cost. Activities such as requesting proposals, researching vendors, negotiating prices, and managing approval workflows are all part of creating a well-defined plan.

A strong procurement plan helps organizations avoid stockouts, reduce excess inventory, and eliminate emergency orders that raise costs and disrupt operations. By understanding material utilization rates, supplier capabilities, transport considerations, and supply-demand dynamics, businesses can forecast their needs more accurately and prepare for potential risks.

Ultimately, procurement planning ensures that every purchasing decision supports the company’s broader goals—cost efficiency, operational continuity, and consistent product quality. It creates a transparent, predictable roadmap for acquiring goods and services, enabling teams to work in alignment and maintain smooth operations across the supply chain.

Key Components of Procurement Planning

An effective procurement plan provides a structured roadmap for how an organization will acquire goods and services. While each plan may vary depending on the project or business needs, the following core components are essential for ensuring clarity, compliance, and smooth execution.

1. Clear Definition of Requirements

Before any purchasing activity begins, businesses must outline what they need, in what quantity, and at what level of quality. This includes technical specifications, material grades, service scopes, and budget limits. Well-defined requirements prevent ambiguity and reduce the chances of delays or rework.

2. Contract Type and Procurement Method

Every procurement plan must specify the type of contract to be used—fixed-price, cost-reimbursable, framework agreements, or time-and-materials contracts. The plan should also outline the procurement method, such as open bidding, restricted tendering, or negotiated procurement, depending on the organization’s policies and the complexity of the purchase.

3. Supplier Selection and Management Strategy

Procurement planning identifies the number of suppliers involved, criteria for evaluating them, and how they will be managed throughout the contract. This may include:

- Prequalified vendors

- Supplier onboarding steps

- Risk assessments

- Backup or alternate suppliers for critical materials

A strong supplier strategy helps minimize disruptions and ensures reliable delivery.

4. Performance Metrics and KPIs

The plan must define how supplier performance will be measured, including KPIs such as delivery timelines, product quality, cost adherence, lead time reliability, and responsiveness. Having these metrics in place promotes transparency and ensures accountability throughout the partnership.

5. Delivery Schedules and Lead Time Alignment

A procurement plan outlines the planned delivery or implementation dates, ensuring materials arrive in sync with the project timeline or production schedule. This alignment avoids bottlenecks, idle time, and emergency purchases. It also considers supplier lead times and any buffer stock required to mitigate risk.

6. Compliance with Organizational and Regulatory Standards

A robust procurement plan ensures that all purchases meet internal policies, industry standards, and legal requirements. This includes quality certifications, environmental guidelines, safety protocols, and regulatory frameworks specific to the organization or sector.

7. Budgeting and Cost Control Measures

Effective procurement planning includes detailed cost estimates, price benchmarks, and budget allocations. It also considers potential cost fluctuations, economic conditions, and negotiation opportunities to ensure financially sound decisions.

8. Risk Assessment and Mitigation Measures

A strong procurement plan evaluates potential risks—supplier failures, shipping delays, geopolitical disruptions, or quality issues—and outlines strategies to manage them. This may involve safety stock, alternate suppliers, contractual penalties, or contingency plans.

9. Impact on Project Scope, Resources, and Constraints

The plan should explain how the new goods or services will affect the overall project or operational constraints. This includes evaluating storage requirements, resource availability, workforce needs, integration with existing systems, and any changes to timelines.

10. Documentation and Procurement Workflow

A procurement plan defines the entire workflow—from creating purchase requisitions to obtaining approvals and issuing purchase orders. This ensures consistency and transparency in documentation, helping teams stay aligned and audit-ready.

Types of Procurement Planning

Procurement planning isn’t a one-size-fits-all approach. Depending on the nature of the project, the scale of operations, and the organization’s goals, different types of procurement planning are used. Each type helps businesses align their purchasing activities with timelines, budgets, and operational needs.

1. Project-Based Procurement Planning

Used for specific projects with defined start and end dates—such as construction, IT implementation, or product launches.

- Focuses on detailed timelines, budget allocation, and technical specifications.

- Ensures materials or services arrive exactly when required in the project schedule.

- Ideal for one-time or high-value purchases.

2. Category-Based Procurement Planning

This type groups purchases into categories—such as raw materials, office supplies, packaging, or machinery—and plans procurement for each category.

- Supports standardization of supplier contracts.

- Helps identify savings opportunities across similar spend areas.

- Often used by medium and large enterprises to manage spend more strategically.

3. Strategic (Long-Term) Procurement Planning

This focuses on high-level, long-term goals such as building supplier partnerships, reducing costs, or improving supply chain resilience.

- Involves demand forecasting, supplier performance analysis, and contract strategy.

- Helps businesses handle market volatility and long-term capacity needs.

- Ideal for organizations looking to future-proof their sourcing decisions.

4. Operational (Short-Term) Procurement Planning

Covers day-to-day or weekly procurement needs based on current production schedules or sales orders.

- Ensures uninterrupted supply of essential materials.

- Relies on real-time data from inventory, production, and sales.

- Typically involves recurring purchases and replenishment orders.

5. Single vs. Multiple Supplier Procurement Planning

Depending on risk levels and material criticality, procurement planning may involve:

- Single-supplier planning: Useful when quality, consistency, or specialized capability is needed.

- Multi-supplier planning: Reduces dependency risk and ensures backup sources. This type ensures a balance between reliability and supply chain resilience.

6. Centralized Procurement Planning

A single procurement team manages all purchasing activities across the organization.

- Promotes bulk purchasing, standardized policies, and negotiation advantages.

- Ideal for companies looking to improve compliance and reduce costs.

7. Decentralized Procurement Planning

Individual departments or locations manage their own procurement decisions.

- Allows faster decision-making and flexibility.

- Works well for multi-location businesses with varied needs or local suppliers.

8. Emergency or Contingency Procurement Planning

Used when unexpected events—supplier failure, sudden demand spikes, or supply chain disruptions—require immediate action.

- Ensures continuity during crises.

- Often involves backup suppliers, safety stock provisions, and emergency budgets.

9. Green or Sustainable Procurement Planning

Focused on eco-friendly, ethical, and socially responsible sourcing.

- Prioritizes low-impact materials, ethical suppliers, and waste reduction.

- Aligns procurement decisions with sustainability goals and ESG mandates.

Importance of Procurement Planning

Procurement planning is one of the most influential levers businesses can use to control costs, stabilize supply, and achieve operational efficiency.

Without a proper plan in place, organizations often face higher expenses, poor supplier performance, stockouts, excess inventory, and frequent project delays.

A well-structured procurement plan ensures that every purchasing decision is strategic, predictable, and aligned with organizational goals.

1. Guides Smarter Purchasing Decisions

Procurement planning helps businesses decide what to buy, when to buy, and from which suppliers. By analyzing demand, inventory levels, and supplier capabilities, planners can avoid overstocking, understocking, and last-minute rush purchases. This alignment ensures that procurement supports production, sales, and project requirements seamlessly.

2. Sets Realistic Timelines and Expectations

One of the key roles of procurement planning is to align internal expectations with what is practically achievable. Many teams expect requirements to be fulfilled on short notice, but procurement cycles involve supplier negotiations, lead times, contract approvals, and delivery schedules. A well-defined plan makes timelines visible, preventing unrealistic demands and ensuring smoother workflows.

3. Enables Strategic Thinking and Market-Driven Decisions

Procurement planning encourages a strategic approach by combining data from sales forecasts, market research, historical consumption, and supplier insights. This helps organizations select the right procurement methods, define contract strategies, and create long-term sourcing plans. Instead of tactical buying, businesses move toward proactive, strategic purchasing.

4. Promotes Collaboration Across Stakeholders

A procurement plan brings together cross-functional teams—procurement, finance, operations, technical experts, and sometimes even suppliers—to discuss requirements, risks, and constraints. This collaboration ensures shared understanding, reduces miscommunication, and allows experts to provide input on specifications, timelines, and compliance needs.

5. Improves Time Management and Reduces Cycle Time

Planning helps organizations estimate how long each procurement activity will take—from supplier identification to contract awarding. This visibility enables faster decision-making, prevents delays, and increases procurement efficiency. When supported by digital tools, companies can automate approvals, reduce paperwork, and significantly shorten procurement lead times.

6. Enhances Cost Savings and Financial Control

Strategic procurement planning directly contributes to cost optimization. By forecasting needs early, organizations can:

- Negotiate better prices

- Compare supplier rates

- Consolidate similar requirements into single contracts

- Reduce tail spend

- Avoid emergency purchases

This proactive approach leads to measurable savings and stronger budget discipline.

7. Identifies and Mitigates Procurement Risks

Through advanced planning, businesses can uncover risks such as supply disruptions, compliance gaps, inaccurate requirements, or supplier failures. Risk mitigation strategies—alternate suppliers, safety stock plans, compliance checks, and clearer specifications—can be put in place before issues occur.

8. Strengthens Supplier Relationships and Sourcing Strategy

Forecasting procurement needs allows companies to engage with suppliers early, negotiate favorable terms, and build long-term partnerships. Strong supplier relationships lead to:

- Better pricing

- Priority during shortages

- Reliable delivery schedules

- Improved quality compliance

This strengthens the overall supply chain and reduces operational uncertainty.

9. Ensures Better Quality of Procured Goods and Services

Procurement planning involves setting clear quality specifications, performance criteria, and approval workflows. This ensures that suppliers meet required standards and that procured materials enhance, rather than hinder, operational efficiency. Regular performance tracking further improves supplier accountability.

10. Improves Transparency and Accountability

A documented procurement plan increases visibility into spending, sourcing decisions, timelines, and performance metrics. This reduces the risk of fraud, favoritism, and irregularities. Stakeholders can track progress, identify gaps, and audit procurement activities easily.

11. Supports Sustainability and Ethical Sourcing

Modern procurement planning integrates sustainability goals, such as choosing eco-friendly materials, compliant suppliers, and energy-efficient products. This not only appeals to conscious customers but also strengthens brand reputation and supports long-term ESG objectives.

12. Facilitates Better Budgeting and Resource Allocation

With procurement planned in advance, businesses can allocate funds more effectively, avoid cash flow disruptions, and schedule purchases throughout the year. This supports stronger treasury management and long-term financial stability.

13. Ensures Successful Project Execution

Projects rely heavily on timely procurement. A well-structured plan ensures that all materials, services, and equipment arrive when needed—preventing delays, cost overruns, or scope changes. Procurement planning, therefore, becomes a foundational part of project success.

Challenges in Procurement Planning

Procurement planning may seem straightforward on paper, but in practice, it is one of the most complex and coordination-heavy activities within supply chain management. Multiple teams, fluctuating market conditions, supplier constraints, and unpredictable demand often make planning difficult.

Below are the major challenges organizations commonly face.

1. Inaccurate or Unreliable Demand Forecasts

Without accurate demand forecasting, procurement teams struggle to determine what to buy, when to buy it, and in what quantity. Volatile customer demand, seasonality, and inconsistent sales data often lead to overstocking, stockouts, or last-minute rush orders.

2. Limited Visibility Across Inventory, Suppliers, and Workflows

Many organizations operate in silos—procurement, production, warehouse, and finance use separate systems or spreadsheets. This lack of integrated visibility makes it difficult to track:

- Real-time inventory levels

- Supplier lead times

- Pending purchase orders

- Consumption patterns

As a result, procurement plans often become reactive rather than strategic.

3. Poor Supplier Performance and Unpredictability

Even the best plan can fail if suppliers miss deadlines, ship poor-quality materials, or change prices without notice. Supplier risks—financial instability, capacity issues, geopolitical disruptions, or logistics problems—affect procurement timelines and can delay entire projects.

4. Long and Complex Approval Processes

Procurement often involves multiple approvals for requisitions, budgets, contracts, and compliance checks. Manual workflows cause delays, lost documents, and bottlenecks, making it difficult to stick to planned timelines.

5. Fragmented Communication Among Stakeholders

Procurement relies heavily on coordination between operations, finance, production, and suppliers. Miscommunication—unclear specifications, outdated requirement sheets, or inconsistent priority levels—leads to errors, delays, and misaligned expectations.

6. Difficulty Managing Lead Times and Delivery Schedules

Lead times vary across suppliers, materials, and geographies. Inaccurate lead time data or sudden disruptions make it challenging to align procurement timelines with production schedules or project milestones. This often forces teams into emergency buying, raising costs.

7. Budget Constraints and Cost Fluctuations

Rising material costs, currency fluctuations, freight rate changes, and unexpected surcharges can derail procurement budgets. Without real-time cost visibility and forecasting, planners struggle to optimize spend and negotiate effectively.

8. Compliance and Regulatory Requirements

Procurement needs to meet organizational standards, industry certifications, and legal regulations. Ensuring that suppliers follow compliance rules—quality standards, sustainability mandates, safety norms—adds extra workload and increases planning complexity.

9. Lack of Standardized Procurement Policies and Processes

Many companies have inconsistent procurement practices across departments or locations. This leads to:

- Duplicate purchases

- Poor documentation

- Inconsistent vendor evaluation

- Difficulties in consolidation and negotiation

Standardization is essential for scaling procurement operations efficiently.

10. Difficulty Tracking Supplier Contracts and Performance Metrics

Procurement teams frequently struggle with:

- Monitoring contract expiration dates

- Reviewing performance KPIs

- Managing multi-supplier relationships

- Ensuring adherence to SLAs

Without structured tracking, supplier management becomes reactive and fragmented.

11. Unplanned Procurement Requests (Ad-Hoc Buying)

Departments often raise urgent requests that were not considered during planning. These unplanned purchases disrupt budgets, inflate costs, and weaken the reliability of the overall procurement strategy.

12. Limited Use of Technology and Analytics

Many organizations still rely on spreadsheets or outdated systems that cannot support real-time analysis or predictive planning. This results in:

- Slow decision-making

- Errors in data entry

- Poor forecasting accuracy

- Inability to perform long-term planning

How ERP Systems Enable Efficient Procurement Planning

ERP systems play a transformative role in modern procurement planning by eliminating guesswork, improving visibility, and enabling smarter, data-driven decisions. Instead of managing procurement through spreadsheets, emails, or disconnected tools, ERP platforms centralize all purchasing activities—from demand forecasting to vendor management—into a single, integrated ecosystem. This empowers procurement teams to plan proactively, reduce costs, and ensure materials flow smoothly through the supply chain.

1. Centralized Visibility Across Inventory, Purchasing, and Suppliers

ERP systems consolidate data from production, warehouse, finance, and procurement into one platform. With real-time visibility into stock levels, consumption trends, pending POs, and supplier lead times, businesses can create procurement plans that are accurate, timely, and aligned with operational needs.

2. Accurate Demand Forecasting and Data-Driven Planning

Modern ERPs use analytics, historical consumption patterns, and sales forecasts to predict future material requirements. This helps procurement teams:

- Avoid stockouts and overstocking

- Optimize purchasing schedules

- Align procurement with production planning

Data-driven forecasting ensures procurement becomes strategic rather than reactive.

3. Automated Purchase Requisitions and Workflows

ERP systems automate manual tasks such as creating requisitions, routing approvals, and generating purchase orders. This reduces administrative effort and ensures that every request follows the correct workflow. Automated alerts also prevent delays by notifying teams of pending approvals or expiring contracts.

4. Seamless Supplier Management and Performance Tracking

ERPs store supplier profiles, pricing, contract details, certifications, and performance KPIs in one place. This makes it easier to:

- Compare vendors

- Monitor reliability

- Track lead times and quality metrics

- Manage multi-supplier relationships

With real-time supplier data, companies can choose the best partners and negotiate with confidence.

5. Real-Time Cost Tracking and Budget Control

ERP systems help procurement teams monitor budgets, track purchase costs, and analyze spending patterns. Real-time visibility into price fluctuations, landed costs, and cost variances allows businesses to control procurement expenses and avoid budget overruns.

6. Integration With Production and Inventory Planning

One of the biggest strengths of ERP systems is the ability to integrate procurement planning with:

- MRP (Material Requirements Planning)

- Production scheduling

- Inventory replenishment

This ensures organizations purchase the right materials at the right time, supporting uninterrupted production and optimal inventory levels.

7. Improved Contract Compliance and Audit Readiness

ERPs ensure that procurement activities follow predefined policies and compliance guidelines. They automatically track:

- Contract terms

- Expiration dates

- Approved vendor lists

- Regulatory requirements

This minimizes compliance risks and ensures transparency in every procurement cycle.

8. Enhanced Risk Management and Scenario Planning

Advanced ERPs provide tools to evaluate supplier risks, estimate the impact of delays, and run what-if analyses. Procurement teams can simulate different supply scenarios and adjust purchasing strategies to mitigate disruptions.

9. Faster Decision-Making With Real-Time Dashboards

ERP dashboards present procurement insights in a visual, easy-to-understand format. Teams can instantly view:

- Pending purchase orders

- Supplier scorecards

- Spend analysis

- Inventory status

These insights accelerate decision-making and improve the overall responsiveness of procurement operations.

10. Reduced Manual Errors and Improved Data Accuracy

By automating data entry and syncing information across departments, ERPs eliminate inconsistencies and reduce human errors that often lead to procurement delays or incorrect orders.

How ERP Systems Support Predictive Procurement Planning

Predictive procurement planning goes beyond responding to current needs—it anticipates future demand, supplier risks, and market changes before they disrupt operations.

Modern ERP systems play a central role in enabling this shift from reactive to predictive procurement by using real-time data, analytics, and automation to forecast needs accurately and optimize purchasing strategies.

1. Advanced Forecasting Using Historical and Real-Time Data

ERP systems collect and analyze data across sales, inventory, production, and supplier performance. By identifying patterns in material consumption, seasonality, and customer demand, ERPs produce highly accurate forecasts that help procurement teams plan ahead instead of relying on manual estimates.

2. Predictive Alerts for Stockouts, Delays, and Excess Inventory

ERP platforms use intelligent algorithms to flag potential issues before they occur. For example:

- Low inventory alerts based on consumption trends

- Anticipated stockouts due to rising demand

- Overbuying risks when inventory builds beyond forecasted needs

These predictive insights allow teams to take timely action, preventing last-minute orders and unplanned costs.

3. Supplier Performance Monitoring and Risk Prediction

A predictive ERP continuously tracks supplier KPIs—lead times, defect rates, pricing changes, and delivery reliability. If a supplier starts showing early signs of delays or declining performance, the ERP alerts procurement teams, enabling:

- Early mitigation

- Backup supplier planning

- Negotiation for better terms

This ensures procurement strategies remain resilient and informed.

4. Scenario Planning and What-If Analysis

Predictive procurement planning requires flexibility. ERP systems help teams simulate different supply scenarios such as:

- Sudden demand spikes

- Supplier shutdowns

- Cost fluctuations

- Long lead-time orders

This allows planners to choose strategies that are cost-effective and risk-aware before committing to purchase decisions.

5. AI-Driven Recommendations for Optimal Ordering

Modern ERPs with built-in AI capabilities suggest:

- The best time to order

- Optimal order quantities

- Supplier alternatives

- Cost-saving opportunities

These predictive recommendations streamline planning and enhance decision quality.

6. Dynamic Replenishment Based on Real-Time Consumption

ERP systems constantly update inventory balances based on real-time usage. Instead of fixed reorder points, predictive ERP models adjust purchasing triggers based on actual consumption, production needs, seasonality, and external factors—keeping inventory lean and operations uninterrupted.

7. Predictive Cost and Budget Forecasting

Market-driven price changes, freight variations, and economic shifts impact procurement budgets. ERPs help predict cost trends and provide forward-looking spend forecasts, enabling procurement teams to:

- Prepare accurate budgets

- Lock in favorable contracts

- Avoid unexpected cost spikes

8. Integration With MRP for Predictive Production Needs

Predictive procurement becomes more powerful when integrated with MRP (Material Requirements Planning). The ERP calculates future material requirements based on:

- Planned production schedules

- Work orders

- BOM (Bill of Materials)

This ensures procurement is always aligned with upcoming manufacturing activities.

9. Predictive Supplier Capacity Insights

ERPs track supplier workloads and order histories to estimate whether they can handle upcoming demand. This helps procurement teams avoid bottlenecks and maintain continuity even during peak seasons.

10. Improved Agility and Faster Course-Correction

With predictive insights, procurement teams can detect issues earlier, adjust plans faster, and respond proactively instead of waiting for problems to surface. This agility is critical in volatile supply chain environments.

Best Practices to Maximize ERP Success in Procurement

Maximizing the value of an ERP system requires more than just implementation—it demands a purposeful strategy, disciplined execution, and continuous optimization. When procurement teams follow best practices, ERP becomes a powerful engine for cost efficiency, predictive planning, and stronger supplier performance.

1. Start With Clean, Standardized Procurement Data

ERP systems are only as strong as the data that feeds them.

Standardizing item codes, supplier records, SKUs, pricing terms, and contract details ensures smooth procurement workflows and accurate reporting.

Tip: Conduct a data cleansing exercise before integrating procurement modules.

2. Align Procurement, Finance, and Inventory Teams on Shared Workflows

Cross-functional alignment is essential for ERP success. When procurement works in isolation, duplicate orders, mismatched budgets, and approval delays become unavoidable.

Practice: Define unified workflows, approval hierarchies, and communication channels across all departments.

3. Leverage Automation for Requisitions, Approvals, and PO Processing

One of the biggest advantages of ERP is eliminating repetitive manual tasks.

Automating PR-to-PO cycles, supplier updates, approvals, and notifications helps reduce bottlenecks and improves accuracy.

Outcome: Faster processing times and fewer human errors.

4. Use Real-Time Dashboards for Better Decision-Making

ERP dashboards provide instant insights into spend patterns, vendor performance, inventory levels, and demand forecasts.

When procurement relies on real-time analytics, decisions become more proactive and less reactive.

Practice: Set up dashboards for KPIs like lead time, PO cycle time, contract compliance, and supplier OTIF.

5. Create Supplier Scorecards and Track Performance Consistently

ERP systems can evaluate suppliers on delivery speed, quality levels, pricing stability, and reliability.

Using structured scorecards helps identify risks early and strengthens long-term supplier partnerships.

Practice: Review supplier performance monthly or quarterly and take action when KPIs drop.

6. Build Predictive Procurement Models Using ERP Data

To achieve predictive procurement, businesses must combine ERP data with trends in sales, inventory movement, and lead times.

Use cases:

- Predicting re-order needs before stockouts

- Forecasting supplier delays

- Identifying potential cost increases

Outcome: More accurate planning and greater resilience.

7. Integrate ERP With Inventory, Production, and Accounting Systems

Procurement requires visibility across the entire supply chain. Integration ensures:

- Procurement doesn’t over-purchase

- Inventory gets updated automatically

- Finance can track budgets in real time

Practice: Avoid siloed systems—ERP should become the single source of truth.

8. Implement Role-Based Access and Approval Controls

Well-defined user permissions ensure compliance, prevent unauthorized purchases, and strengthen audit trails.

Practice: Assign procurement roles based on responsibility—requesters, approvers, buyers, auditors, etc.

9. Train Procurement Teams Continuously

ERP success is heavily influenced by user adoption. Teams must know how to navigate the system efficiently—from creating purchase requests to analyzing supplier risks.

Practice: Conduct regular refresher training sessions and update SOPs.

10. Review Procurement KPIs Regularly and Optimize Workflows

As business needs evolve, procurement workflows must evolve too. Regular KPI analysis helps identify inefficiencies such as long approval cycles or frequent emergency purchases.

Practice: Quarterly workflow audits to refine processes and eliminate bottlenecks.

11. Use Mobile ERP Capabilities for Faster On-the-Go Decisions

Modern ERP systems offer mobile apps that allow teams to approve POs, track suppliers, or view inventory insights anytime.

Outcome: Faster turnaround times and greater operational flexibility.

12. Ensure Change Management and Stakeholder Buy-In From Day One

ERP implementation impacts multiple departments. Without buy-in, adoption drops and workarounds begin.

Practice: Keep stakeholders engaged through demos, training, and continuous feedback cycles.

Business Outcomes: The ROI of ERP-Driven Procurement

When procurement becomes centralized, data-driven, and automated through an ERP system, the financial and operational benefits compound quickly.

Instead of functioning as a reactive support function, procurement transforms into a strategic driver of cost savings, efficiency, and long-term resilience. ERP-driven procurement delivers measurable ROI across multiple dimensions—cost, productivity, risk, supplier performance, and overall organizational agility.

1. Significant Cost Savings Through Better Spending Control

ERP systems provide complete visibility into spending patterns, supplier pricing, contract terms, and real-time inventory levels. This eliminates maverick purchasing, prevents duplicate orders, and strengthens negotiation power with suppliers.

Outcome: Reduced operational costs, optimized purchasing, and stronger cost discipline across departments.

2. Improved Procurement Cycle Time and Higher Productivity

Automation of PR-to-PO workflows, approvals, supplier communication, and invoice matching drastically reduces manual tasks. ERP-driven workflows shorten procurement cycles and free teams to focus on strategic analysis rather than administrative work.

Outcome: Faster procurement processing, improved on-time deliveries, and greater team productivity.

3. Increased Accuracy in Forecasting and Demand Planning

With integrated sales, inventory, and production data, ERP systems generate more reliable forecasts. This accuracy ensures businesses buy exactly what they need—no more, no less—minimizing both excess stock and shortages.

Outcome: Lower carrying costs, improved working capital efficiency, and reduced emergency purchases.

4. Stronger Supplier Performance and Reduced Supply Risks

ERPs track supplier metrics such as delivery timelines, defect rates, contract compliance, and cost variations. Businesses can identify risk-prone suppliers early, diversify options, and build stronger partnerships with reliable vendors.

Outcome: Better quality materials, fewer disruptions, and a more resilient supply chain.

5. Improved Budgeting, Cash Flow, and Financial Control

ERP-driven procurement connects purchasing decisions directly with financial planning. Real-time budget tracking and predictive cost analysis help companies control expenses, plan ahead, and maintain healthy cash flow.

Outcome: More accurate budgeting, fewer financial surprises, and better treasury management.

6. Higher Operational Agility and Faster Decision-Making

With instant access to real-time data—inventory status, lead times, purchase trends, supplier risks—organizations can make rapid, confident decisions. ERP systems eliminate guesswork and make procurement truly proactive.

Outcome: Agile operations capable of responding quickly to market volatility and changes.

7. Enhanced Collaboration Across Departments

Procurement, finance, production, and warehouse teams operate on a single shared platform. This eliminates communication gaps and ensures everyone works with the same source of truth.

Outcome: Smoother cross-functional workflows and fewer delays caused by misalignment.

8. Reduction in Compliance Issues and Document Errors

Automated approval hierarchies, digital audit trails, and centralized documentation ensure procurement activities follow internal and regulatory guidelines.

Outcome: Lower compliance risks, stronger audit readiness, and reduced penalties or disputes.

9. Sustainable and Ethical Purchasing Improvements

ERP systems allow businesses to track supplier ESG performance, monitor waste, and choose partners who align with sustainable goals.

Outcome: Stronger brand reputation, reduced environmental impact, and long-term business sustainability.

10. Tangible Financial ROI Within Months

When improved efficiency, cost savings, reduced risks, and optimized processes come together, organizations typically experience measurable financial returns within the first year of ERP-driven procurement.

Outcome: Better margins, improved profitability, and stronger competitive advantage.

How Deskera ERP Supports Efficient and Predictive Procurement Planning

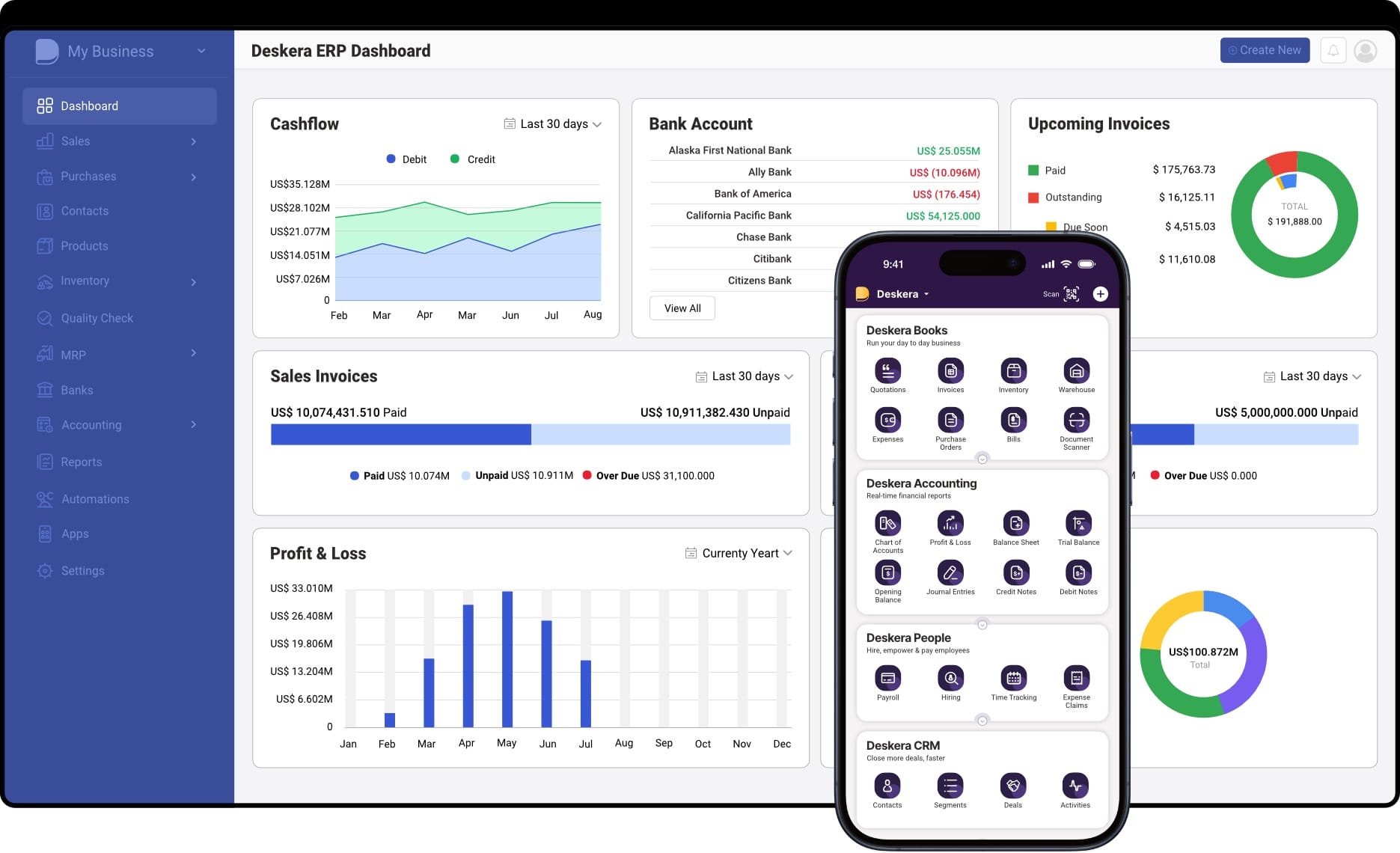

Deskera ERP brings together procurement, inventory, finance, and supplier management into one unified system, enabling businesses to manage purchasing operations with greater visibility, speed, and accuracy. Its intuitive workflows, real-time data updates, and automation capabilities help organizations eliminate procurement delays, reduce manual errors, and improve supplier collaboration.

1. Automated Purchase Requests, Approvals & Order Management

Deskera streamlines procurement workflows by automating PR creation, routing approval requests to the right stakeholders, and generating purchase orders in a few clicks. This removes bottlenecks, accelerates cycle times, and ensures full auditability.

2. Real-Time Inventory Visibility to Prevent Stockouts & Excess

Deskera gives procurement teams accurate, real-time insights into stock levels across multiple locations. This helps buyers replenish at the right time, reduce unnecessary purchases, and avoid stockouts that delay production or customer fulfillment.

3. Demand Forecasting for Predictive Procurement

With built-in demand forecasting, Deskera helps businesses anticipate future material needs based on historical data, sales trends, and lead times. This supports forward-looking procurement decisions and reduces reactive purchasing.

4. Supplier Management with Performance Insights

Deskera centralizes supplier information—including pricing, contracts, delivery history, and quality ratings. Procurement teams can compare vendors, assess performance, and choose the best supplier for cost, reliability, and speed.

5. Automated Lead-Time Alignment & Delivery Scheduling

Deskera’s planning engine automatically syncs supplier lead times with production or project schedules. This ensures materials arrive exactly when needed, preventing downtime, rush orders, and missed deadlines.

6. Controlled Procurement Budgeting & Cost Visibility

Integrated financial modules provide real-time visibility into procurement spending, committed costs, and budget utilization. This helps teams prevent overspending, negotiate better terms, and maintain financial discipline.

7. Seamless Integration Across Inventory, MRP & Finance

Deskera ERP connects procurement with MRP, sales, warehouse operations, and accounting. Every purchase decision is based on updated, accurate data, enabling better planning and eliminating communication gaps across departments.

8. Mobile Accessibility for Faster Decisions

Procurement managers can raise PRs, approve purchases, track orders, and check supplier documents on the go using Deskera’s mobile app. This keeps operations moving, even when teams are remote.

Key Takeaways

- Efficient and predictive procurement planning is no longer optional—ERP systems provide the real-time visibility, automation, and intelligence needed to eliminate guesswork and strengthen supply resilience.

- A strong procurement plan includes clear contract structures, defined performance metrics, aligned lead times, prequalified vendors, and compliance requirements—ensuring structured, risk-aware sourcing decisions.

- Different forms of procurement planning—strategic, tactical, operational, project-based, and category-based—help organizations manage both long-term sourcing strategy and day-to-day purchasing needs.

- Procurement teams often struggle with inaccurate demand data, long lead times, supplier unpredictability, compliance gaps, and siloed information—creating delays and unnecessary cost burdens.

- ERP systems streamline end-to-end procurement workflows, improve cross-department coordination, and ensure real-time inventory and supplier data, leading to faster, error-free purchasing.

- Predictive analytics within ERP platforms use historical data, trends, and lead-time insights to forecast material needs accurately, enabling proactive and data-driven procurement decisions.

- With ERP-enabled procurement, businesses experience reduced purchasing costs, fewer stockouts, faster cycle times, improved supplier performance, and better budget control—directly boosting overall ROI.

- To unlock full value, organizations should maintain clean data, standardize workflows, integrate departments, train users effectively, and continuously monitor procurement KPIs.

- Deskera ERP enhances procurement accuracy with automation, real-time inventory data, demand forecasting, supplier performance insights, and integrated financial controls—helping businesses plan smarter and buy better.

Related Articles