The global market for sustainable furniture is projected to grow at a CAGR of 6.5% between 2020 and 2027, driven by increasing consumer demand for eco-friendly products. (Source: Allied Market Research)

In a survey of over 5,500 consumers across six countries, 81% of respondents said they would be willing to pay more for products that are made sustainably or ethically. (Source: Statista)

Closed-loop manufacturing can reduce production waste by up to 90% and decrease the use of virgin materials by up to 50%. (Source: The Ellen MacArthur Foundation)

These statistics demonstrate the growing consumer demand for sustainable furniture, the potential economic benefits of closed-loop manufacturing, and the environmental advantages of using sustainable materials in production.

Closed-loop manufacturing is an innovative approach to sustainable production that aims to reduce waste, minimize material and energy use, and promote the reuse and recycling of materials.

In the furniture manufacturing industry, closed-loop manufacturing can play a vital role in improving the environmental performance of production, enhancing resource efficiency, and supporting economic viability.

Considering that closed-loop manufacturing is a promising solution for sustainable furniture manufacturing, this article will help you understand it better by covering the following topics:

- Introduction to Closed-Loop Manufacturing

- What is Sustainable Furniture Manufacturing?

- Closed-Loop Manufacturing: A Solution for Sustainable Furniture Manufacturing

- Advantages of Closed-Loop Manufacturing for Furniture Manufacturing

- Challenges and Limitations of Closed-Loop Manufacturing in Furniture Manufacturing

- Key Elements of Closed-Loop Manufacturing for Furniture Manufacturing

- Examples of Closed-Loop Manufacturing in Furniture Manufacturing

- Designing for Closed-Loop Manufacturing in Furniture Manufacturing

- Implementing Closed-Loop Manufacturing in Furniture Manufacturing

- Benefits of Circular Supply Chain for Furniture Manufacturing

- Tools and Technologies for Closed-Loop Manufacturing in Furniture Manufacturing

- Metrics for Assessing the Success of Closed-Loop Manufacturing in Furniture Manufacturing

- Policies and Regulations for Promoting Closed-Loop Manufacturing in Furniture Manufacturing

- Future Trends in Closed-Loop Manufacturing in Furniture Manufacturing

- How can Deskera Help You with Furniture Manufacturing?

- Key Takeaways

- Related Articles

Introduction to Closed-Loop Manufacturing

Closed-loop manufacturing, also known as closed-loop production, is a manufacturing approach that aims to create a sustainable and efficient production system by minimizing waste and maximizing the use of resources. It involves integrating various components of the production process, such as design, production, and recycling, to create a continuous loop of material and information flow.

The closed-loop manufacturing process starts with the design phase, where the product is designed with sustainability in mind. The production phase involves using the most efficient processes and technologies to manufacture the product while minimizing waste and emissions. Once the product is used and reaches the end of its life, it is recycled, and the materials are reused in the production of new products.

The closed-loop manufacturing approach is an essential component of the circular economy, which aims to minimize waste and promote the sustainable use of resources.

By implementing closed-loop manufacturing, companies can reduce their environmental impact, increase resource efficiency, and create more sustainable products. Additionally, closed-loop manufacturing can result in cost savings by reducing waste and optimizing the use of resources.

What is Sustainable Furniture Manufacturing?

Sustainable furniture manufacturing is the process of creating furniture in a way that minimizes negative impacts on the environment while maximizing the social and economic benefits for all stakeholders involved. This includes reducing waste, energy consumption, and pollution, as well as using sustainable materials and production methods.

Sustainable furniture manufacturing involves several key practices, including:

- Using sustainable materials: This includes using materials that are renewable, recycled, or repurposed, such as bamboo, reclaimed wood, and recycled plastic.

- Minimizing waste: This involves reducing waste in the manufacturing process, such as using computer-aided design (CAD) to optimize material usage, recycling and repurposing waste materials and implementing closed-loop manufacturing systems.

- Reducing energy consumption: This involves implementing energy-efficient technologies and practices, such as using renewable energy sources like solar and wind power and optimizing manufacturing processes to reduce energy consumption.

- Using non-toxic and eco-friendly materials: This includes using non-toxic adhesives, paints, and finishes and avoiding materials that contain harmful chemicals.

- Prioritizing fair labor practices: This includes providing fair wages, safe working conditions, and opportunities for training and career development for workers involved in the manufacturing process.

- Material selection: Choosing materials that are eco-friendly, renewable, and non-toxic is crucial in sustainable furniture manufacturing. Examples include bamboo, reclaimed wood, recycled plastic, and organic fabrics.

- Design for Sustainability: Furniture designs are developed to maximize functionality, minimize environmental impact, and optimize production efficiency. This includes using Computer-Aided Design (CAD) and other modeling software to reduce waste and material usage.

- Social Responsibility: Ensuring that workers involved in the manufacturing process are treated fairly, paid fair wages, provided safe working conditions, and given opportunities for career development.

- Product lifecycle: Ensuring that the furniture produced has a long lifespan, can be repaired and recycled at the end of its life, and does not harm the environment.

Overall, sustainable furniture manufacturing aims to create furniture that is environmentally friendly, socially responsible, and economically viable.

By adopting sustainable practices, furniture manufacturers can reduce their environmental impact, meet the growing demand for sustainable products, and contribute to a more sustainable future.

Closed-Loop Manufacturing: A Solution for Sustainable Furniture Manufacturing

Closed-loop manufacturing is a sustainable production process that focuses on reducing waste, minimizing material and energy use, and promoting the reuse and recycling of materials.

In the furniture manufacturing industry, closed-loop manufacturing can help reduce the environmental impact of production, improve resource efficiency, and enhance the economic viability of furniture manufacturing.

Closed-loop manufacturing in furniture manufacturing involves the use of sustainable materials, such as recycled and renewable materials, and the adoption of sustainable production processes, such as modular design, digitalization, and additive manufacturing. These practices can help furniture manufacturers reduce waste, optimize resource use, and improve the environmental performance of their products.

In addition to environmental benefits, closed-loop manufacturing can also provide economic benefits to furniture manufacturers. By reducing waste and optimizing resource use, manufacturers can lower their operating costs and improve their competitiveness. Closed-loop manufacturing can also help manufacturers meet increasing consumer demand for sustainable products and enhance their brand reputation.

To fully realize the potential of closed-loop manufacturing in furniture manufacturing, it is important for manufacturers to collaborate with suppliers, customers, and other stakeholders to develop sustainable supply chains and promote the adoption of sustainable practices.

It is also important for governments and industry organizations to implement policies and regulations that support closed-loop manufacturing and promote sustainable production practices.

Overall, closed-loop manufacturing is a solution for sustainable furniture manufacturing that can help reduce the environmental impact of production, improve resource efficiency, and enhance the economic viability of furniture manufacturing.

By adopting sustainable practices and collaborating with stakeholders, furniture manufacturers can develop sustainable supply chains and products that meet the needs of consumers and promote a circular economy.

Advantages of Closed-Loop Manufacturing for Furniture Manufacturing

Closed-loop manufacturing can offer several advantages for furniture manufacturing, including:

Resource Efficiency

Resource efficiency is a significant advantage of closed-loop manufacturing for furniture manufacturing. Closed-loop manufacturing optimizes the use of resources by reducing waste, recycling materials, and minimizing the need for virgin materials.

By doing so, furniture manufacturers can achieve several benefits:

- Cost Savings: Closed-loop manufacturing reduces the need for virgin materials, which can be expensive to acquire. By using recycled materials, furniture manufacturers can reduce their raw material costs and thus improve their gross profits.

- Reduced Environmental Impact: Closed-loop manufacturing helps to reduce the environmental impact of furniture manufacturing by minimizing waste and reducing the use of non-renewable resources. This helps to mitigate the negative impacts of furniture production on the environment.

- Improved Reputation: By adopting sustainable practices and reducing their environmental impact, furniture manufacturers can improve their reputation and appeal to environmentally conscious consumers, encouraging returning customers and customer loyalty.

- Increased Efficiency: Closed-loop manufacturing can help to improve the efficiency of furniture manufacturing by optimizing material usage, reducing waste, and minimizing manufacturing costs.

- Promotes Circular Economy: Closed-loop manufacturing promotes a circular economy by creating a closed loop of material and information flow, where waste is minimized, and resources are maximized.

Overall, resource efficiency is an essential benefit of closed-loop manufacturing for furniture manufacturing. By optimizing resource usage and reducing waste, furniture manufacturers can achieve cost savings, reduce their environmental impact, improve their reputation, increase efficiency, and contribute to a more sustainable future.

Environmental Sustainability

Environmental sustainability is a significant advantage of closed-loop manufacturing for furniture manufacturing. Closed-loop manufacturing minimizes waste, reduces the use of non-renewable resources, and helps to mitigate the negative impacts of furniture production on the environment.

By doing so, furniture manufacturers can achieve several benefits:

- Reduced Carbon Footprint: Closed-loop manufacturing can help to reduce the carbon footprint of furniture production by minimizing waste, using renewable energy sources, and reducing the use of non-renewable resources.

- Reduced Environmental Impact: Closed-loop manufacturing helps to reduce the environmental impact of furniture production by minimizing waste, reducing emissions, and using eco-friendly materials.

- Compliance with Regulations: Closed-loop manufacturing practices can help furniture manufacturers comply with environmental regulations and standards, ensuring that they operate within legal limits.

- Improved Reputation: By adopting sustainable practices and reducing their environmental impact, furniture manufacturers can improve their reputation and appeal to environmentally conscious consumers.

- Contribution to a Sustainable Future: Closed-loop manufacturing contributes to a more sustainable future by creating a closed loop of material and information flow, where waste is minimized and resources are maximized.

Overall, environmental sustainability is an essential benefit of closed-loop manufacturing for furniture manufacturing. By minimizing waste, reducing the use of non-renewable resources, and mitigating the negative impacts of furniture production on the environment, furniture manufacturers can achieve cost savings, improve their reputation, and contribute to a more sustainable future.

Cost Savings

Cost savings is a significant advantage of closed-loop manufacturing for furniture manufacturing. Closed-loop manufacturing minimizes waste, optimizes resource usage, and reduces the need for virgin materials, which can lead to several cost savings, including:

- Reduced Raw Material Costs: Closed-loop manufacturing uses recycled materials, which can be less expensive than virgin materials, leading to cost savings for furniture manufacturers.

- Reduced Waste Disposal Costs: Closed-loop manufacturing minimizes waste, reducing the need for waste disposal and associated costs.

- Improved Efficiency: Closed-loop manufacturing can help to improve the efficiency of furniture manufacturing by optimizing material usage and minimizing production costs, leading to cost savings.

- Reduced Energy Costs: Closed-loop manufacturing can help to reduce energy costs by using renewable energy sources, which are typically less expensive than non-renewable sources.

- Reduced Transportation Costs: Closed-loop manufacturing can help to reduce transportation costs by using locally sourced recycled materials, reducing the need for transportation of raw materials.

Overall, cost saving is an essential benefit of closed-loop manufacturing for furniture manufacturing. By reducing raw material costs, waste disposal costs, improving efficiency, using renewable energy sources, and reducing transportation costs, furniture manufacturers can achieve significant cost savings, leading to increased net profit ratio and competitiveness.

Better Product Quality

Better product quality is an advantage of closed-loop manufacturing for furniture manufacturing. Closed-loop manufacturing processes are designed to minimize waste and optimize resource usage, leading to several benefits that can result in better product quality, including:

- Consistent Material Quality: Closed-loop manufacturing uses recycled materials that are sorted and processed to ensure consistent material quality. This leads to better product quality as the use of consistent material helps to minimize product defects, which will also lead to improved customer retention.

- Enhanced Design Capabilities: Closed-loop manufacturing processes can help furniture manufacturers to experiment with new designs and concepts, leading to better product quality through improved design capabilities.

- Reduced Waste: Closed-loop manufacturing processes help to minimize waste by recycling materials, leading to better product quality as fewer materials are wasted during production.

- Streamlined Production Processes: Closed-loop manufacturing processes help to optimize production processes, leading to better product quality as production processes become more streamlined and efficient.

- Enhanced Durability: Closed-loop manufacturing processes can result in furniture products that are more durable, as recycled materials can often be stronger than virgin materials.

Overall, better product quality is an important advantage of closed-loop manufacturing for furniture manufacturing. By using recycled materials, optimizing production processes, and reducing waste, furniture manufacturers can improve the consistency, design, durability, and overall quality of their products.

Reduced Waste

Reduced waste is a significant advantage of closed-loop manufacturing for furniture manufacturing. Closed-loop manufacturing minimizes waste by recycling materials, optimizing material usage, and reducing the need for virgin materials.

This can lead to several benefits that can result in reduced waste, including:

- Minimize Material Waste: Closed-loop manufacturing processes use recycled materials and minimize the amount of material waste generated during production, leading to reduced waste.

- Reduced Environmental Impact: Closed-loop manufacturing helps to reduce the environmental impact of furniture manufacturing by reducing waste and emissions.

- Lower Landfill Waste: Closed-loop manufacturing processes help to reduce the amount of waste sent to landfills, leading to reduced landfill waste and associated environmental impact.

- Reduced Resource Consumption: Closed-loop manufacturing minimizes resource consumption by using recycled materials and optimizing material usage, leading to reduced waste and lower resource consumption.

- Improved Sustainability: Closed-loop manufacturing helps to promote sustainability by reducing waste and conserving resources, which can improve the long-term viability of furniture manufacturing.

Overall, reduced waste is an essential benefit of closed-loop manufacturing for furniture manufacturing. By minimizing waste and promoting sustainability, furniture manufacturers can reduce their environmental impact, conserve resources, and improve their long-term viability.

Enhanced Reputation

Enhanced reputation is an advantage of closed-loop manufacturing for furniture manufacturing. Closed-loop manufacturing helps furniture manufacturers to demonstrate their commitment to sustainability, environmental responsibility, and circular economy principles.

This can lead to several benefits that can enhance a furniture manufacturer's reputation, including:

- Improved Brand Image: Closed-loop manufacturing can help to improve a furniture manufacturer's brand image by demonstrating their commitment to sustainability and environmental responsibility.

- Enhanced Customer Perception: Closed-loop manufacturing can enhance customer perception of a furniture manufacturer by demonstrating their commitment to sustainable practices, leading to increased customer loyalty and satisfaction.

- Competitive Advantage: Closed-loop manufacturing can provide a competitive advantage for furniture manufacturers by demonstrating their commitment to sustainability and environmental responsibility, leading to increased market share and net profit.

- Increased Stakeholder Engagement: Closed-loop manufacturing can lead to increased stakeholder engagement as stakeholders, including investors, employees, and customers, become more interested in sustainable practices.

- Improved Regulatory Compliance: Closed-loop manufacturing can help furniture manufacturers to comply with environmental regulations and demonstrate their commitment to sustainability, leading to improved regulatory compliance and reduced regulatory risk.

Overall, enhanced reputation is an essential benefit of closed-loop manufacturing for furniture manufacturing.

By demonstrating their commitment to sustainability and environmental responsibility, furniture manufacturers can improve their brand image, customer perception, competitiveness, stakeholder engagement, and regulatory compliance, leading to increased profitability and long-term success.

Compliance with Regulations

Compliance with regulations is an advantage of closed-loop manufacturing for furniture manufacturing. Furniture manufacturers are subject to a range of environmental regulations, such as waste disposal regulations, emissions regulations, and material usage regulations.

Closed-loop manufacturing can help furniture manufacturers to comply with these regulations and avoid regulatory penalties. This can lead to several benefits that can result from compliance with regulations, including:

- Reduced Regulatory Risk: Closed-loop manufacturing can help furniture manufacturers to reduce their regulatory risk by ensuring compliance with environmental regulations, avoiding regulatory penalties, and maintaining a positive relationship with regulators.

- Improved Environmental Performance: Compliance with environmental regulations can help furniture manufacturers to improve their environmental performance by reducing emissions, conserving resources, and minimizing waste.

- Enhanced Corporate Social Responsibility: Compliance with environmental regulations can help furniture manufacturers to demonstrate their commitment to corporate social responsibility and sustainability.

- Improved Stakeholder Engagement: Compliance with environmental regulations can help furniture manufacturers to engage with stakeholders, including customers, employees, and investors, who are interested in sustainable practices.

- Reduced Costs: Compliance with environmental regulations can help furniture manufacturers to avoid regulatory penalties, fines, and legal fees, which can reduce costs and improve profitability.

Overall, compliance with regulations is an essential benefit of closed-loop manufacturing for furniture manufacturing.

By complying with environmental regulations, furniture manufacturers can improve their environmental performance, enhance their corporate social responsibility, engage with stakeholders, reduce costs, and maintain a positive relationship with regulators, leading to increased profitability and long-term success.

Challenges and Limitations of Closed-Loop Manufacturing in Furniture Manufacturing

Closed-loop manufacturing is a sustainable manufacturing approach where waste and resources are minimized through recycling and reusing materials in the production process.

While closed-loop manufacturing offers many benefits, including reducing the environmental impact of manufacturing and reducing costs, it also faces challenges and limitations, especially in furniture manufacturing. Some of these challenges and limitations include:

Material Selection

Material selection is a significant challenge and limitation of closed-loop manufacturing in furniture manufacturing. Closed-loop manufacturing relies on the availability of recyclable or reusable materials, and not all materials used in furniture manufacturing can be easily recycled or reused.

For example, furniture manufacturers commonly use composite materials that are made up of multiple layers of different materials, such as wood veneers, laminates, and plastics.

These composite materials can be difficult to disassemble and separate into their individual components, making them challenging to recycle or reuse. As a result, furniture manufacturers may need to select different materials or modify their product designs to make them more compatible with closed-loop manufacturing.

In addition to the challenges of recycling composite materials, there may be limitations on the availability of recycled materials. Depending on the location and infrastructure of recycling facilities, it may be challenging to source enough high-quality recycled materials to meet production needs.

This can limit the ability of furniture manufacturers to implement closed-loop manufacturing in certain product categories or at certain production volumes.

Overall, material selection is a critical factor that needs to be carefully considered when implementing closed-loop manufacturing in furniture manufacturing. Manufacturers may need to make changes to their product designs or select different materials to ensure that their products can be easily recycled or reused and that there is a reliable supply of recycled materials available.

Quality Control

Quality control is another challenge and limitation of closed-loop manufacturing in furniture manufacturing. Closed-loop manufacturing involves using recycled materials in the production process, which can result in lower-quality finished products.

Recycled materials may have variations in their composition and quality, depending on factors such as the source of the materials and the recycling process used. These variations can result in differences in the performance and appearance of finished products. Additionally, recycled materials may be more susceptible to defects, such as cracks, warping, or discoloration, which can further affect product quality.

Maintaining consistent product quality can be challenging in closed-loop manufacturing, as manufacturers need to manage the variability of recycled materials and ensure that their products meet the required specifications and standards. This requires careful monitoring and testing of materials and products at various stages of the production process.

To address quality control challenges in closed-loop manufacturing, furniture manufacturers may need to invest in specialized testing equipment, adopt more rigorous quality control procedures, or modify their product designs to better accommodate variations in recycled materials. They may also need to work closely with recycling facilities to ensure that recycled materials meet the required quality standards.

Limited Recycling Infrastructure

Limited recycling infrastructure is another significant challenge and limitation of closed-loop manufacturing in furniture manufacturing. Closed-loop manufacturing relies on the availability of recycled or reusable materials, and the infrastructure for recycling these materials may not be available in all regions or for all types of materials.

In some areas, there may be limited recycling facilities or inadequate collection and sorting systems for certain materials. This can make it difficult for furniture manufacturers to source enough high-quality recycled materials to meet their production needs.

Additionally, transportation costs can be high for moving recycled materials to and from recycling facilities, which can further limit the feasibility of closed-loop manufacturing.

To address the challenge of limited recycling infrastructure, furniture manufacturers may need to collaborate with local governments and waste management organizations to improve recycling facilities and infrastructure. This could include investing in new recycling technologies, expanding collection and sorting systems, and developing new markets for recycled materials.

Furniture manufacturers may also need to consider alternative approaches to closed-loop manufacturing, such as using more easily recycled materials or implementing design strategies that minimize waste and promote recyclability.

This could involve redesigning products to be more modular, using materials that are easier to disassemble and recycle, or developing new recycling technologies that can process more challenging materials.

Cost

Cost is a significant challenge and limitation of closed-loop manufacturing in furniture manufacturing. Implementing closed-loop manufacturing can require significant investment in new equipment, facilities, and processes, which can add to production costs. Additionally, the availability and quality of recycled materials can be variable, which can also affect the cost of production.

In some cases, the cost of producing products using closed-loop manufacturing may be higher than traditional manufacturing methods, which can make it difficult for furniture manufacturers to compete in the market. Consumers may not be willing to pay a premium for products made from recycled materials, which can further limit the market for closed-loop furniture manufacturing.

To address cost challenges in closed-loop manufacturing, furniture manufacturers may need to explore ways to optimize their production processes and reduce waste. This could involve implementing lean manufacturing techniques, such as just-in-time production or reducing setup times, to improve efficiency and reduce costs.

Furniture manufacturers may also need to collaborate with recycling facilities to ensure a reliable supply of high-quality recycled materials at a reasonable cost. This could involve investing in new recycling technologies or developing new partnerships to increase the availability of recycled materials.

Finally, furniture manufacturers may need to consider alternative business models that can support the cost of closed-loop manufacturing, such as offering products as a service or implementing circular economy principles that prioritize durability, repairability, and reuse.

Design Limitations

Design limitations are another challenge and limitation of closed-loop manufacturing in furniture manufacturing. Closed-loop manufacturing relies on the availability of recyclable or reusable materials, and product design can have a significant impact on the ability to recycle or reuse materials.

For example, furniture products may be designed with composite materials that are difficult to disassemble and separate into their individual components, making them challenging to recycle or reuse. Additionally, products may be designed with non-recyclable components, such as adhesives, paints, or coatings, which can further limit the recyclability of the product.

To address design limitations in closed-loop manufacturing, furniture manufacturers may need to consider alternative product designs that prioritize recyclability and reuse. This could involve using more easily recyclable materials, such as natural materials or materials that are easier to disassemble and separate, or redesigning products to be more modular and easier to repair.

Furniture manufacturers may also need to collaborate with designers and architects to develop new product designs that are compatible with closed-loop manufacturing.

This could involve exploring new materials, such as biodegradable or compostable materials, or developing new manufacturing processes that can produce products with fewer non-recyclable components.

Finally, furniture manufacturers may need to educate consumers about the benefits of closed-loop manufacturing and the importance of selecting products that are designed for recyclability and reuse.

By raising awareness and promoting sustainable design principles, furniture manufacturers can help create a market for closed-loop products and support the transition to a more sustainable, circular economy.

Sorting and Processing

The sorting and processing of recycled materials is another significant challenge and limitation of closed-loop manufacturing in furniture manufacturing. The quality of recycled materials can vary depending on the source and the processing method used, and it can be challenging to ensure that recycled materials meet the required standards for use in furniture manufacturing.

Sorting and processing recycled materials can also be a complex and time-consuming process, which can add to production costs and reduce efficiency.

In some cases, the processing methods required to prepare recycled materials for use in furniture manufacturing may be more energy-intensive than using new materials, which can reduce the environmental benefits of closed-loop manufacturing.

To address sorting and processing challenges in closed-loop manufacturing, furniture manufacturers may need to work closely with recycling facilities to ensure a reliable supply of high-quality recycled materials. This could involve developing partnerships with specific recycling facilities or investing in new recycling technologies that can produce higher-quality recycled materials.

Furniture manufacturers may also need to consider alternative approaches to sorting and processing, such as implementing modular product designs that allow for easier disassembly and sorting of materials. Additionally, implementing lean manufacturing techniques can help optimize production processes and reduce waste, which can further improve the efficiency of sorting and processing.

Finally, furniture manufacturers may need to educate consumers about the importance of recycling and the value of closed-loop manufacturing. By increasing awareness and promoting sustainable consumption habits, furniture manufacturers can help create a market for closed-loop products and support the transition to a more sustainable, circular economy.

Transportation

Transportation is another challenge and limitation of closed-loop manufacturing in furniture manufacturing. Closed-loop manufacturing often involves recycling and reusing materials from various sources, which can require the transportation of materials from different locations.

Transportation can add to the carbon footprint of closed-loop manufacturing, particularly if materials are transported long distances. Additionally, transportation can be expensive, which can add to the production costs of closed-loop manufacturing.

To address transportation challenges in closed-loop manufacturing, furniture manufacturers may need to explore alternative approaches to sourcing recycled materials. This could involve developing partnerships with local recycling facilities or using materials that are available closer to the manufacturing site.

Furniture manufacturers may also need to consider alternative transportation methods, such as using electric or hybrid vehicles or implementing logistics strategies that prioritize efficiency and reduce the distance traveled.

Additionally, furniture manufacturers may need to explore the use of digital technologies, such as 3D printing, to reduce the need for transportation of materials and finished products.

Finally, furniture manufacturers may need to educate consumers about the environmental impacts of transportation and promote sustainable consumption habits, such as selecting products that are produced locally or using alternative transportation methods for product delivery.

By raising awareness and promoting sustainable transportation practices, furniture manufacturers can help reduce the carbon footprint of closed-loop manufacturing and support the transition to a more sustainable, circular economy.

Market Demand

Market demand is another challenge and limitation of closed-loop manufacturing in furniture manufacturing. Closed-loop manufacturing requires a significant investment in technology, equipment, and processes, which can result in higher production costs compared to traditional manufacturing methods.

To justify these costs, furniture manufacturers need to be able to sell their products at a competitive price point, which can be challenging if there is limited market demand for sustainable, closed-loop products.

Consumers may be unwilling to pay a premium for products that are produced using closed-loop manufacturing methods, especially if they are not aware of the environmental benefits of these products.

To address market demand challenges in closed-loop manufacturing, furniture manufacturers may need to invest in marketing and education campaigns that promote the benefits of closed-loop manufacturing and sustainable consumption.

This could involve highlighting the environmental benefits of closed-loop products, such as reduced waste and energy consumption, or promoting the social and ethical benefits of sustainable production, such as supporting local communities and promoting fair labor practices.

Furniture manufacturers may also need to collaborate with other stakeholders, such as designers, architects, and retailers, to develop new sustainable product lines and create a market for closed-loop products.

This could involve exploring new distribution channels, such as online marketplaces or pop-up shops, or partnering with retailers that prioritize sustainability and closed-loop production methods.

Finally, furniture manufacturers may need to consider alternative business models, such as leasing or subscription services, that can help offset the higher production costs of closed-loop manufacturing and create new revenue streams.

By exploring new business models and collaborating with stakeholders to create demand for closed-loop products, furniture manufacturers can help support the transition to a more sustainable, circular economy.

Production Scale

Production scale is another challenge and limitation of closed-loop manufacturing in furniture manufacturing. Closed-loop manufacturing often requires specialized equipment and processes, which can be expensive and difficult to scale up for mass production.

For smaller furniture manufacturers, it may be challenging to achieve the economies of scale necessary to make closed-loop manufacturing economically feasible. Additionally, smaller manufacturers may not have the resources or expertise to invest in the necessary technology and equipment required for closed-loop manufacturing.

To address production scale challenges in closed-loop manufacturing, furniture manufacturers may need to collaborate with other manufacturers or suppliers to achieve greater economies of scale.

This could involve developing partnerships with other companies to share technology, equipment, or expertise or exploring new business models, such as joint ventures or strategic alliances, that can help spread the costs and risks of closed-loop manufacturing.

Furniture manufacturers may also need to consider alternative approaches to production that are more scalable and efficient. This could involve developing modular product designs that can be easily assembled or disassembled or using digital technologies, such as 3D printing, to produce customized products on demand.

Finally, furniture manufacturers may need to consider the role of government policies and regulations in promoting closed-loop manufacturing and supporting the transition to a more sustainable, circular economy.

By working with policymakers to create a supportive regulatory environment for closed-loop manufacturing, furniture manufacturers can help overcome production scale challenges and accelerate the transition to a more sustainable future.

Key Elements of Closed-Loop Manufacturing for Furniture Manufacturing

Closed-loop manufacturing (CLM) is a manufacturing system that aims to reduce waste, improve resource efficiency, and create a circular economy by keeping materials and products in use for as long as possible. Here are some key elements of closed-loop manufacturing for furniture manufacturing:

- Design for sustainability: Designing furniture with sustainability in mind is a critical element of CLM. Furniture designers need to consider the entire lifecycle of the product, from sourcing materials to end-of-life disposal. This involves using sustainable materials, reducing waste in the manufacturing process, and designing products that can be easily disassembled and recycled.

- Efficient use of resources: CLM requires efficient use of resources such as energy, water, and raw materials. This involves optimizing production processes to minimize waste, using renewable energy sources where possible, and minimizing water usage through recycling and reuse.

- Material reuse and recycling: CLM involves creating closed-loop systems for materials, where waste is minimized, and materials are recycled and reused. This requires implementing recycling programs for materials such as wood, metal, and fabric and finding ways to reuse waste materials in the manufacturing process.

- Supply chain management: A closed-loop system requires careful management of the supply chain to ensure that materials are sourced sustainably and that waste is minimized throughout the supply chain. This involves working with suppliers to implement sustainable practices and monitoring the supply chain for any waste or inefficiencies.

- End-of-life management: CLM involves taking responsibility for the end-of-life of products by implementing programs for product take-back, refurbishment, and recycling. This includes designing products that can be easily disassembled and recycled and working with customers to ensure that products are properly disposed of at the end of their useful life.

By implementing these key elements, furniture manufacturers can move towards a more sustainable and circular manufacturing system, reducing waste and creating a more sustainable future.

Examples of Closed-Loop Manufacturing in Furniture Manufacturing

Here are some examples of closed-loop manufacturing in furniture manufacturing:

- Material recycling: Furniture manufacturers can recycle materials such as wood, metal, and fabric and use them to create new products. For example, a furniture company could collect old furniture from customers, dismantle it, and reuse the materials to create new products.

- Circular design: Furniture manufacturers can design products with circularity in mind, making them easily disassembled and recyclable at the end of their useful life. For example, a company could design a sofa with modular components that can be easily replaced or recycled as needed.

- Upcycling: Furniture manufacturers can upcycle materials to create new products, giving new life to old materials that would otherwise be discarded. For example, a company could use reclaimed wood from old buildings to create new furniture pieces.

- Zero-waste production: Furniture manufacturers can aim for zero-waste production, where all materials are used and nothing is discarded. For example, a company could use sawdust and wood scraps from the manufacturing process to create new products, such as particleboard or composite wood products.

- Product take-back programs: Furniture manufacturers can implement product take-back programs, where customers can return old products to the manufacturer for recycling or refurbishment. For example, a company could offer customers a discount on a new piece of furniture if they return their old furniture for recycling.

By implementing closed-loop manufacturing practices, furniture manufacturers can reduce waste, conserve resources, and create a more sustainable and circular economy.

Designing for Closed-Loop Manufacturing in Furniture Manufacturing

Designing for closed-loop manufacturing in furniture manufacturing involves designing products that can be easily disassembled, recycled, or reused at the end of their useful life.

Here are some design principles for closed-loop manufacturing in furniture manufacturing:

- Use of sustainable materials: Designers should use sustainable materials, such as FSC-certified wood or recycled metal, in their designs. These materials should be chosen for their durability, ease of recycling, and ability to be reused or repurposed.

- Modular design: Designers should consider modular design, where furniture pieces can be easily disassembled, and the individual components can be reused or recycled. This can allow for more flexibility in design and can extend the life of the product.

- Design for disassembly: Designers should consider how the product will be disassembled at the end of its life. This involves designing products that can be easily taken apart and sorted into their respective materials for recycling.

- Multi-functional design: Designers should consider multi-functional design, where furniture pieces can be used for multiple purposes. This can extend the life of the product and reduce the need for additional products.

- Design for durability: Designers should consider the durability of the product, designing it to last as long as possible. This can reduce the need for replacement and extend the life of the product.

- Design for recyclability: Designers should consider the recyclability of the product, designing it with materials that can be easily recycled or repurposed at the end of its life.

By designing for closed-loop manufacturing, furniture designers can create products that are sustainable, durable, and able to be reused or recycled at the end of their useful life, thereby reducing waste and creating a more circular economy.

Implementing Closed-Loop Manufacturing in Furniture Manufacturing

Implementing closed-loop manufacturing in furniture manufacturing involves taking a holistic approach to sustainability, including sourcing sustainable materials, optimizing production processes to minimize waste, and implementing end-of-life management programs.

Here are some steps for implementing closed-loop manufacturing in furniture manufacturing:

- Conduct a sustainability assessment: Before implementing closed-loop manufacturing, furniture manufacturers should conduct a sustainability assessment to understand the environmental impact of their current operations. This assessment should include an evaluation of the entire supply chain, from raw materials sourcing to end-of-life disposal.

- Source sustainable materials: Furniture manufacturers should source sustainable materials, such as FSC-certified wood or recycled metal, and work with suppliers to ensure sustainable practices throughout the supply chain. This can involve setting sustainability criteria for suppliers and auditing suppliers for compliance.

- Optimize production processes: Furniture manufacturers should optimize production processes to minimize waste and maximize resource efficiency. This can involve implementing lean manufacturing techniques, such as reducing inventory and optimizing production flow, and using renewable energy sources, such as solar or wind power.

- Implement material reuse and recycling programs: Furniture manufacturers should implement material reuse and recycling programs to reduce waste and create a closed-loop system. This can involve recycling programs for materials such as wood, metal, and fabric and finding ways to reuse waste materials in the manufacturing process.

- Design for disassembly and end-of-life management: Furniture manufacturers should design products for disassembly and end-of-life management, ensuring that products can be easily disassembled and recycled or reused at the end of their useful life. This can involve implementing product take-back programs, refurbishment programs, and designing products with circularity in mind.

- Engage with customers: Furniture manufacturers should engage with customers to promote sustainable practices and encourage end-of-life product management. This can involve educating customers on the benefits of sustainable furniture and providing resources for the responsible disposal of products.

By implementing closed-loop manufacturing practices, furniture manufacturers can reduce waste, conserve resources, and create a more sustainable and circular economy.

Benefits of Circular Supply Chain for Furniture Manufacturing

Circular supply chains can bring several benefits to furniture manufacturing. A circular supply chain is a closed-loop system that aims to reduce waste and optimize resource use by recovering and reusing materials and products. Here are some of the benefits of circular supply chains for furniture manufacturing:

- Reduced Environmental Impact: Circular supply chains can significantly reduce the environmental impact of furniture manufacturing. By reusing materials, companies can reduce the need for virgin resources, which can help to conserve natural resources and reduce greenhouse gas emissions.

- Improved Product Quality: Furniture made from recovered and reused materials can be of high quality, especially if companies implement design for circularity principles in their products. This can improve the durability and lifespan of furniture, reducing the need for replacements and saving costs in the long run.

- Enhanced Brand Reputation: Companies that adopt circular supply chains can benefit from improved brand reputation. Consumers are increasingly aware of the environmental impact of products they buy, and circular supply chains can demonstrate a company's commitment to sustainability.

- Increased Efficiency: Circular supply chains can lead to increased efficiency and cost savings. By recovering and reusing materials, companies can reduce the amount of waste generated, optimize resource use, and improve supply chain resilience.

- New Business Opportunities: Circular supply chains can create new business opportunities for furniture manufacturers. By recovering and reusing materials, companies can create new revenue streams, such as remanufacturing or refurbishment services.

- Increased customer loyalty: Customers are increasingly concerned with sustainability and may choose to purchase products from companies that demonstrate a commitment to environmental responsibility. Implementing a circular supply chain can increase customer loyalty and attract new buyer personas who value sustainability.

- Extended product life: By designing products with circularity in mind and implementing end-of-life management programs, furniture manufacturers can extend the life of their products and reduce the need for replacement. This can reduce the environmental impact of furniture production and create a more sustainable economy.

In conclusion, circular supply chains can bring significant benefits to furniture manufacturing, including reduced environmental impact, improved product quality, enhanced brand reputation, increased efficiency, and new business opportunities.

As circularity becomes more critical to achieving sustainability goals, furniture companies that adopt circular supply chains can gain a competitive advantage and improve their bottom line.

Tools and Technologies for Closed-Loop Manufacturing in Furniture Manufacturing

Closed-loop manufacturing is a sustainable manufacturing approach that involves the use of tools and technologies to optimize resource efficiency, minimize waste, and reduce the environmental impact of the manufacturing process.

In furniture manufacturing, there are several tools and technologies that can be used to implement closed-loop manufacturing. Here are a few examples:

Computer-Aided Design (CAD) Software

Computer-aided design (CAD) software is a tool and technology that can be used in closed-loop manufacturing to improve the design and production process for furniture manufacturing. Here are some examples of how CAD software can be used in closed-loop manufacturing for furniture manufacturing:

- Design Optimization: CAD software can be used to optimize the design of furniture products, taking into account factors such as material efficiency, ergonomics, and aesthetics. CAD software can help designers create 3D models of furniture products, allowing them to visualize and test the design before production. This can help reduce material waste and improve product quality.

- Material Optimization: CAD software can be used to optimize the use of materials in furniture manufacturing. By analyzing the design and production process, CAD software can help manufacturers identify opportunities to reduce material waste and optimize resource efficiency.

- Customization: CAD software can be used to create customized furniture products that meet the specific needs and preferences of customers. By creating 3D models of furniture products, designers can make modifications to the design quickly and easily, allowing for greater customization.

- Production Planning: CAD software can be used to plan and schedule the production process for furniture manufacturing. By creating digital models of furniture products, manufacturers can estimate the time and resources required for production, allowing them to optimize production schedules and reduce the risk of errors.

- Collaboration: CAD software can be used to facilitate collaboration between designers, engineers, and manufacturers in the furniture manufacturing process. By sharing digital models and designs, stakeholders can provide feedback and make modifications in real time, reducing the risk of miscommunication and errors.

By using CAD software in closed-loop manufacturing, furniture manufacturers can improve the design and production process, reduce material waste, optimize resource efficiency, and create high-quality, customized products that meet the needs of customers.

Additionally, using CAD software can help furniture manufacturers stay competitive in the market by reducing production costs and improving product quality.

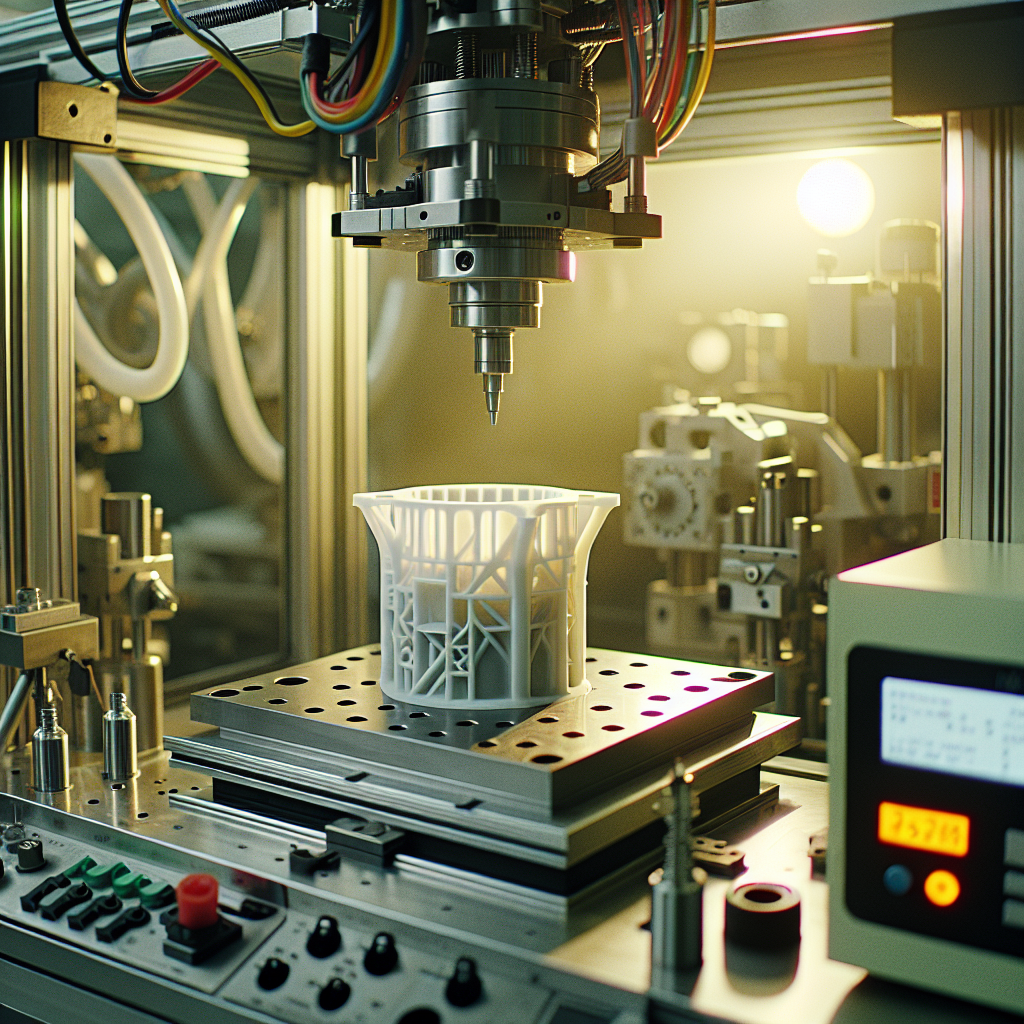

3D Printing

3D printing is a tool and technology that can be used in closed-loop manufacturing to improve the production process for furniture manufacturing. Here are some examples of how 3D printing can be used in closed-loop manufacturing for furniture manufacturing:

- Rapid Prototyping: 3D printing can be used to create rapid prototypes of furniture products, allowing designers and manufacturers to test and refine the design quickly and efficiently. This can help reduce the time and cost associated with traditional prototyping methods.

- Customization: 3D printing can be used to create customized furniture products that meet the specific needs and preferences of customers. By creating digital models of furniture products, designers can modify the design quickly and easily, allowing for greater customization.

- Spare Parts and Replacement Parts: 3D printing can be used to create spare parts and replacement parts for furniture products, reducing the need for excess inventory and reducing waste.

- Sustainable Material Usage: 3D printing can be used to optimize material usage by printing furniture products with minimal waste. Additionally, 3D printing can use sustainable materials, such as recycled plastics or biodegradable materials, reducing the environmental impact of furniture manufacturing.

- Production of Complex Structures: 3D printing can be used to produce complex structures and shapes that are difficult or impossible to produce using traditional manufacturing methods. This allows for greater design flexibility and can lead to innovative and unique furniture products.

By using 3D printing in closed-loop manufacturing, furniture manufacturers can improve the production process, reduce waste, and optimize resource efficiency.

Additionally, using 3D printing can help furniture manufacturers stay competitive in the market by reducing production costs and improving product quality.

CNC Machines

Computer Numerical Control (CNC) machines are a tool and technology that can be used in closed-loop manufacturing to improve the production process for furniture manufacturing.

Here are some examples of how CNC machines can be used in closed-loop manufacturing for furniture manufacturing:

- Precision Manufacturing: CNC machines can produce furniture products with a high level of precision and accuracy, ensuring consistent quality and reducing the risk of errors.

- Material Efficiency: CNC machines can optimize the use of materials in furniture manufacturing, reducing waste and increasing resource efficiency.

- Customization: CNC machines can be used to create customized furniture products that meet the specific needs and preferences of customers. By using digital designs, CNC machines can quickly and efficiently create unique furniture products.

- Automation: CNC machines can be programmed to perform repetitive tasks automatically, reducing the need for manual labor and improving production efficiency.

- Reduced Lead Times: CNC machines can reduce the lead time required for furniture production, as they can create furniture products quickly and efficiently. This can help furniture manufacturers respond quickly to changing customer demands and market trends.

By using CNC machines in closed-loop manufacturing, furniture manufacturers can improve the production process, reduce waste, and optimize resource efficiency.

Additionally, using CNC machines can help furniture manufacturers stay competitive in the market by reducing production costs and improving product quality.

IoT Sensors

Internet of Things (IoT) sensors are a tool and technology that can be used in closed-loop manufacturing to improve the production process for furniture manufacturing.

Here are some examples of how IoT sensors can be used in closed-loop manufacturing for furniture manufacturing:

- Inventory Management: IoT sensors can be used to track inventory levels in real time, reducing the risk of stockouts and excess inventory. This can help furniture manufacturers optimize inventory levels and reduce waste.

- Asset Tracking: IoT sensors can be used to track the location and status of furniture products throughout the production process, ensuring that products are produced and shipped on time.

- Predictive Maintenance: IoT sensors can be used to monitor the performance of machinery and equipment in the production process, identifying potential maintenance issues before they cause downtime.

- Quality Control: IoT sensors can be used to monitor the quality of furniture products in real-time, identifying defects and ensuring that products meet customer requirements.

- Energy Efficiency: IoT sensors can be used to monitor energy usage in the production process, identifying opportunities to reduce energy consumption and optimize resource efficiency.

By using IoT sensors in closed-loop manufacturing, furniture manufacturers can improve the production process, reduce waste, and optimize resource efficiency. Additionally, using IoT sensors can help furniture manufacturers stay competitive in the market by reducing production costs and improving product quality.

Recycling and Waste Management Systems

Recycling and waste management systems are tools and technologies that can be used in closed-loop manufacturing to improve the sustainability and resource efficiency of furniture manufacturing.

Here are some examples of how recycling and waste management systems can be used in closed-loop manufacturing for furniture manufacturing:

- Material Recycling: Furniture manufacturers can implement recycling programs to collect and recycle materials such as wood, metal, and plastics. By recycling materials, furniture manufacturers can reduce waste and reuse resources in the production process.

- Waste Reduction: Furniture manufacturers can implement waste reduction programs to minimize the amount of waste generated during the production process. This can include initiatives such as reducing packaging waste or using reusable containers.

- Circular Economy: Furniture manufacturers can adopt circular economy principles, which focus on creating closed-loop systems where waste is minimized, and resources are reused as much as possible. By adopting circular economy principles, furniture manufacturers can reduce their environmental impact and increase resource efficiency.

- Sustainable Packaging: Furniture manufacturers can use sustainable packaging materials, such as biodegradable or recycled materials, to reduce the environmental impact of their products.

- Life Cycle Assessment: Furniture manufacturers can use life cycle assessment (LCA) tools to evaluate the environmental impact of their products throughout their entire life cycle. By identifying areas for improvement, furniture manufacturers can optimize their production processes and reduce their environmental impact.

By using recycling and waste management systems in closed-loop manufacturing, furniture manufacturers can improve the sustainability and resource efficiency of their production processes.

Additionally, implementing these systems can help furniture manufacturers meet regulatory requirements, improve their brand reputation, and reduce costs associated with waste disposal.

Energy-Efficient Manufacturing Equipment

Energy-efficient manufacturing equipment is a tool and technology that can be used in closed-loop manufacturing to improve the energy efficiency and sustainability of furniture manufacturing.

Here are some examples of how energy-efficient manufacturing equipment can be used in closed-loop manufacturing for furniture manufacturing:

- Energy-Efficient Machinery: Furniture manufacturers can invest in energy-efficient machinery and equipment, such as motors and compressors that use less energy to operate. By using energy-efficient machinery, furniture manufacturers can reduce their energy consumption and lower their operating costs.

- Renewable Energy Sources: Furniture manufacturers can install renewable energy systems, such as solar panels or wind turbines, to generate clean energy to power their production process. By using renewable energy, furniture manufacturers can reduce their reliance on fossil fuels and lower their carbon footprint.

- Energy Monitoring Systems: Furniture manufacturers can use energy monitoring systems to track energy usage in real-time, identifying areas where energy consumption can be reduced. By monitoring energy usage, furniture manufacturers can identify opportunities to optimize their energy efficiency and reduce costs.

- Process Optimization: Furniture manufacturers can optimize their production processes to reduce energy consumption. This can include initiatives such as reducing the number of steps in the production process, using more efficient production methods or optimizing the timing of production processes to reduce idle time.

- Energy Management Systems: Furniture manufacturers can implement energy management systems to control and monitor energy usage across their production processes. By using energy management systems, furniture manufacturers can optimize their energy efficiency and reduce energy costs.

By using energy-efficient manufacturing equipment in closed-loop manufacturing, furniture manufacturers can reduce their environmental impact, lower their operating costs, and improve their sustainability.

Additionally, implementing these systems can help furniture manufacturers meet regulatory requirements, improve their brand reputation, and enhance their competitive advantage.

Automation and Robotics

Automation and robotics are tools and technologies that can be used in closed-loop manufacturing to optimize production processes, reduce waste, and improve efficiency in furniture manufacturing.

Here are some examples of how automation and robotics can be used in closed-loop manufacturing for furniture manufacturing:

- Automated Assembly: Automated assembly systems can be used to assemble furniture components quickly and accurately, reducing the time and resources required for manual assembly. Automated assembly systems can also reduce the risk of errors, resulting in higher-quality products.

- Robotics for Cutting and Shaping: Robotic arms can be programmed to cut and shape furniture components with high precision and accuracy, reducing material waste and optimizing resource efficiency. Robotics can also be used to handle and transport furniture components throughout the manufacturing process, reducing the risk of damage and improving efficiency.

- Smart Conveyor Systems: Smart conveyor systems can be used to transport furniture components and materials through the manufacturing process, optimizing the flow of materials and reducing the risk of errors. Smart conveyor systems can also be equipped with sensors and other monitoring devices to detect potential issues and optimize performance.

- Automated Finishing: Automated finishing systems can be used to apply finishes to furniture products, such as stains, paints, and varnishes, with high precision and accuracy. This reduces the risk of errors and improves efficiency in the finishing process, resulting in higher-quality products.

- Collaborative Robotics: Collaborative robots, or cobots, can be used to work alongside human workers in furniture manufacturing. Cobots can assist with tasks such as lifting heavy furniture components, reducing the risk of injury, and improving worker safety. Additionally, cobots can be programmed to perform repetitive tasks, freeing up human workers to focus on more complex tasks.

By using automation and robotics in closed-loop manufacturing, furniture manufacturers can reduce waste, improve efficiency, and optimize resource efficiency. This can result in higher quality products, reduced environmental impact, and increased competitiveness in the market.

Advanced Materials for Closed-Loop Manufacturing in Furniture Manufacturing

Closed-loop manufacturing in furniture manufacturing involves the use of sustainable materials that are recyclable, renewable, and biodegradable.

Here are some examples of advanced materials that can be used in closed-loop manufacturing for furniture manufacturing:

- Bamboo: Bamboo is a rapidly renewable material that is strong and lightweight. It is an ideal material for furniture manufacturing because it is durable, eco-friendly, and easy to work with. Bamboo can be used to make a variety of furniture products, including chairs, tables, and cabinets.

- Reclaimed Wood: Reclaimed wood is wood that has been salvaged from old buildings, barns, or other structures. It is a sustainable material that can be repurposed to create new furniture products. Reclaimed wood has a unique character and texture that cannot be replicated, making it a popular choice for furniture manufacturers.

- Recycled Plastic: Recycled plastic is a durable and lightweight material that can be used to create a wide range of furniture products. It is made from post-consumer plastic waste, such as water bottles and food containers, and can be recycled multiple times. Recycled plastic can be used to create outdoor furniture, chairs, tables, and other products.

- Bio-based Materials: Bio-based materials are made from renewable resources, such as plant-based materials, and are biodegradable or compostable. These materials are ideal for furniture manufacturing because they are eco-friendly and can be easily recycled or composted. Examples of bio-based materials include hemp, soy-based foam, and natural rubber.

- Steel and Aluminum: Steel and aluminum are strong, durable, and recyclable materials that can be used to create a variety of furniture products. These materials are long-lasting and require little maintenance, making them an ideal choice for outdoor furniture.

By using these advanced materials in closed-loop manufacturing, furniture manufacturers can reduce their environmental impact and create sustainable products that are both durable and aesthetically pleasing.

Additionally, using these materials can help furniture manufacturers meet the growing demand for sustainable and eco-friendly products in the market.

Metrics for Assessing the Success of Closed-Loop Manufacturing in Furniture Manufacturing

Assessing the success of closed-loop manufacturing in furniture manufacturing requires the use of metrics to measure the impact of the production process on the environment, resource efficiency, and economic performance.

Here are some examples of metrics that can be used to assess the success of closed-loop manufacturing in furniture manufacturing:

- Waste Reduction: The amount of waste generated during the production process is a key metric for assessing the success of closed-loop manufacturing. Furniture manufacturers can measure the amount of waste generated per unit of production and set targets for reducing waste over time.

- Material Efficiency: This metric measures the amount of material used per unit of output. The goal of closed-loop manufacturing is to maximize material efficiency, which means using as little material as possible to produce high-quality furniture.

- Resource Efficiency: The resource efficiency of the production process is another key metric for assessing the success of closed-loop manufacturing. Furniture manufacturers can measure the number of resources used per unit of production, such as water, energy, and materials, and set targets for improving resource efficiency over time.

- Recycling and Reuse: The amount of materials recycled and reused during the production process is an important metric for assessing the success of closed-loop manufacturing. Furniture manufacturers can measure the amount of materials recycled and reused and set targets for increasing the percentage of materials recycled and reused over time.

- Carbon Footprint: The carbon footprint of the production process is a metric for assessing the environmental impact of closed-loop manufacturing. Furniture manufacturers can measure the amount of greenhouse gas emissions generated during the production process and set targets for reducing emissions over time.

- Water Use: This metric measures the amount of water used during the production process. Closed-loop manufacturing aims to minimize water use by using water-efficient processes, recycling and reusing water, and implementing water management practices.

- Energy Use: This metric measures the amount of energy used during the production process. Closed-loop manufacturing aims to minimize energy use by using energy-efficient processes and equipment, implementing energy management practices, and using renewable energy sources.

- Product Life Cycle: This metric measures the environmental impact of furniture throughout its entire life cycle, from production to disposal. Closed-loop manufacturing aims to minimize the environmental impact of furniture by designing products for durability, recyclability, and reuse.

- Economic Performance: The economic performance of closed-loop manufacturing is a key metric for assessing the financial viability of the production process. Furniture manufacturers can measure the costs associated with the production process and set targets for reducing costs while maintaining or improving product quality.

By using these metrics to assess the success of closed-loop manufacturing in furniture manufacturing, furniture manufacturers can identify areas for improvement, set goals for reducing environmental impact and resource use, and improve their economic performance.

Additionally, tracking these metrics can help furniture manufacturers demonstrate their commitment to sustainability and enhance their competitive advantage.

Policies and Regulations for Promoting Closed-Loop Manufacturing in Furniture Manufacturing

There are various policies and regulations that can be implemented to promote closed-loop manufacturing in furniture manufacturing. Here are some examples:

- Extended Producer Responsibility (EPR): EPR policies hold manufacturers responsible for the entire life cycle of their products, including post-consumer disposal. EPR policies can encourage furniture manufacturers to design products for durability, recyclability, and reuse and to implement closed-loop manufacturing practices.

- Product Standards and Labels: Product standards and labels can encourage furniture manufacturers to design products that meet specific environmental and sustainability criteria. Standards and labels can also help consumers make informed purchasing decisions and promote the adoption of closed-loop manufacturing practices.

- Tax Incentives and Grants: Tax incentives and grants can encourage furniture manufacturers to invest in closed-loop manufacturing technologies and processes. These incentives can help offset the costs associated with transitioning to closed-loop manufacturing and promote the adoption of sustainable production practices.

- Procurement Policies: Public and private procurement policies can require the purchase of furniture products that meet specific environmental and sustainability criteria. These policies can promote the adoption of closed-loop manufacturing practices and encourage the development of sustainable supply chains.

- Environmental Regulations: Environmental regulations can require furniture manufacturers to reduce waste, minimize material and energy use, and implement closed-loop manufacturing practices. These regulations can help level the playing field for sustainable manufacturers and promote the adoption of environmentally-friendly practices.

- Voluntary Sustainability Standards: Voluntary sustainability standards can encourage furniture manufacturers to adopt closed-loop manufacturing practices and design products that meet specific environmental and sustainability criteria. These standards can also help consumers make informed purchasing decisions and promote the development of sustainable supply chains.

By implementing policies and regulations that promote closed-loop manufacturing in furniture manufacturing, governments, industry organizations, and other stakeholders can encourage the adoption of sustainable production practices, reduce environmental impacts, and enhance the economic viability of furniture manufacturing.

Future Trends in Closed-Loop Manufacturing in Furniture Manufacturing

Here are some future trends in closed-loop manufacturing in furniture manufacturing:

- Circular Economy Business Models: Furniture manufacturers will increasingly adopt circular economy business models that prioritize the use of renewable resources, reduce waste generation, and promote product reuse and recycling. These models will involve the integration of sustainable production processes, closed-loop supply chains, and product life cycle management.

- Artificial Intelligence and Machine Learning: The use of artificial intelligence and machine learning will become more prevalent in closed-loop manufacturing in furniture manufacturing. These technologies will help manufacturers optimize production processes, reduce waste, and improve resource efficiency.

- Digitalization: Digitalization will enable furniture manufacturers to collect and analyze data on their production processes, supply chains, and product life cycles. This will help manufacturers identify areas for improvement, optimize production processes, and enhance sustainability.

- Additive Manufacturing: Additive manufacturing technologies, such as 3D printing, will continue to evolve and become more prevalent in furniture manufacturing. These technologies will enable manufacturers to produce customized products, reduce waste, and optimize material use.

- Materials Innovation: Innovations in sustainable materials, such as bioplastics and biocomposites, will enable furniture manufacturers to produce products that are both durable and environmentally friendly. These materials will also help manufacturers reduce their dependence on virgin materials and promote the adoption of closed-loop manufacturing practices.

- Collaboration and Partnerships: Collaboration and partnerships between furniture manufacturers, suppliers, and other stakeholders will become more important in closed-loop manufacturing. These collaborations will enable manufacturers to develop sustainable supply chains, optimize resource use, and enhance sustainability.

Overall, the future of closed-loop manufacturing in furniture manufacturing is focused on developing sustainable production processes, reducing waste and resource use, and promoting the circular economy.

By adopting these trends and incorporating sustainable practices into their operations, furniture manufacturers can reduce their environmental impact, enhance their competitiveness, and improve their economic performance.

How can Deskera Help You with Furniture Manufacturing?

Deskera is a cloud-based software solution that offers a range of features to help streamline and optimize the furniture manufacturing process. Here are some ways Deskera MRP can help you with furniture manufacturing:

- Inventory management: Deskera can help you manage your inventory levels and track the movement of raw materials and finished goods in real-time.

- Production planning: With Deskera, you can plan and schedule your production process, track progress, and monitor resource utilization to ensure efficient production.

- Quality control: Deskera offers tools to help you manage quality control throughout the manufacturing process, from design to finishing, to ensure that your products meet the required standards.

- Sales and distribution: Deskera can help you manage your sales orders, track customer orders, and manage your distribution channels, allowing you to manage your sales process more efficiently.

- Financial management: With Deskera, you can manage your financial transactions, track expenses, and generate financial reports, giving you greater visibility into your financial performance.

- Business intelligence: Deskera provides advanced analytics and reporting capabilities, allowing you to gain insights into your business performance and make data-driven decisions.

Key Takeaways

Closed-Loop Manufacturing (CLM) is a sustainable approach to manufacturing that aims to reduce waste and environmental impact while improving efficiency and profitability.

In the context of furniture manufacturing, CLM can involve using sustainable materials, optimizing production processes, designing for disassembly and repairability, and implementing circular supply chains.

The advantages of closed-loop manufacturing for furniture manufacturing are:

- Resource Efficiency

- Environmental Sustainability

- Cost Savings

- Better Product Quality

- Reduced Waste

- Compliance with Regulations

The challenges and limitations of closed-loop manufacturing for furniture manufacturing are:

- Material Selection

- Quality Control

- Limited Recycling Infrastructure

- Cost

- Design Limitations

- Sorting and Processing

- Transportation

- Market Demand

- Production Scale

The key elements of closed-loop manufacturing for furniture manufacturing are:

- Design for sustainability

- Efficient use of resources

- Material reuse and recycling

- Supply chain management

- End-of-life management

The steps for implementing closed-loop manufacturing for furniture manufacturing are:

- Conduct a sustainability assessment

- Source sustainable materials

- Optimize production processes

- Implement material reuse and recycling programs

- Design for disassembly and end-of-life management

- Engage with customers

There are several tools and technologies that can be used to implement closed-loop manufacturing for furniture manufacturing. Some of the examples include:

- Computer-Aided Design (CAD) Software

- 3D Printing

- CNC Machines

- IoT Sensors

- Recycling and Waste Management Systems

- Energy-Efficient Manufacturing Equipment

- Automation and Robotics

The metrics for assessing the success of closed-loop manufacturing in furniture manufacturing are:

- Waste Reduction