The COVID-19 pandemic was the most disruptive incident in the history of the modern supply chain, causing 4,200 interruptions in the first nine months of 2020, according to Resilinc's Eventwatch risk monitoring system.

All firms should now get ready for large supply chain disruptions to happen more frequently, lasting at least one month every 3.7 years, according to McKinsey's predictions.

The industries of food and drink are changing. They are aggressively investing in technological solutions to streamline and automate their supply chain and inventory management procedures so that they can deliver precisely what is needed to meet client demand regardless of the operational environment.

However, more intelligent technologies are needed when supply networks disintegrate, and calculations get more complex. Even when the pandemic subsides, persistent supply chain issues necessitate routine inspection, and more onerous geographic and regulatory obstacles make it harder to stay on course.

In today’s article, we’ll study how food and beverage companies can build a more resilient post pandemic food and beverage supply chain. This will allow them to respond more effectively when a pandemic threatens society as a whole.

Before we dive in, let’s take a look at the table of content:

- Food and Supply Industry

- Supply Chain Disruption Caused by COVID-19

- Factors Driving Supply Chain Management Changes

- Building and Strengthening Supply Chain Resilience

- Digital Transformation for a Resilient Supply Chain: Managing Disruption

- Gain a Holistic View of ERP for your Supply Chain

- Utilizing Automation, Monitoring, and Notifications to Decrease Manual Purchase

- Improve your Procedures

- The New E-Commerce Requirements

- Conclusion

- How Deskera Can Assist You?

Let's get started!

Food and Supply Industry

The food and supply industry is a broad term that encompasses a wide range of businesses involved in the production, distribution, and sale of food and related supplies.

This industry includes food manufacturers, wholesalers, retailers, distributors, supermarkets and grocery stores, convenience stores, restaurants, caterers, and foodservice companies.

In addition, the industry also includes businesses that provide supplies, such as packaging, cleaning products, equipment, and other materials needed in the food industry.

Food and beverage suppliers are in a unique position to help prevent shortages during an outbreak. They have the ability to predict demand, stockpile materials, and improve distribution networks. In addition, they can work with retailers and food service providers to ensure that products are available when consumers need them most.

Supply Chain Disruption Caused by COVID-19

The global food supply network became less adaptive as a result of the outbreak. Only 23% of consumer goods companies, including producers of food and beverages, are currently confident in the resilience of their supply chains, according to a Capgemini survey.

The COVID-19 pandemic has had a profound impact on global supply chains. Disruptions to the supply chain have caused significant delays in the production and delivery of goods and services, with businesses across industries facing significant losses as a result.

Companies have experienced supply chain disruptions due to travel restrictions, factory shutdowns, limited access to raw materials, and shortages of personnel.

In addition, the pandemic has caused a sharp rise in the demand for some goods, including food, personal protective equipment, and medical supplies. This has led to an increased strain on supply chains as businesses struggle to meet the demand.

As the pandemic continues, the disruption of global supply chains will likely continue, making it essential for businesses to develop strategies to minimize the supply chain disruptions.

Broken links in the food supply chain are causing more damage and disruption:

Harvests: Crops in the fields are wilting as spring approaches. Asparagus farmers in Europe, for instance, are critically short handed because migrant workers from Eastern Europe are either unable to reach their farms due to border restrictions or are just afraid to risk getting sick.

Logistics: In the meantime, moving food is quickly turning into a logistical headache. Transferring fresh goods overseas is very complicated and expensive due to restrictions at border crossings and on-air freight.

Processing: Food processing facilities are scaling back or closing down as a result of containment measures or workforce shortages, and their suppliers are scrambling to change their production. For instance, Canadian poultry farmers chose to reduce their output by 12.6%.

Go-to-market: Companies (like soft drink producers) who traditionally sell a sizable portion of their output through out-of-home channels are seeing a fall in sales.

Sourcing: Despite having good sales numbers, supermarkets are understaffed and underperforming. Due to difficulties in finding ingredients, products manufactured from a range of ingredients are becoming harder to produce and, as a result, are disappearing from store shelves.

Factors Driving Supply Chain Management Changes

Following, we’ve discussed several factors that are driving changes in supply chain management. Let’s learn:

1. Technological Advancements:

Technology has been a major driving force in the transition of supply chain management. Advances in technology such as the internet of things, robotics, artificial intelligence, big data, and blockchain have enabled more efficient and automated processes, allowing for more efficient and effective supply chain management.

2. Globalization:

Globalization has also played a key role in the transition of supply chain management. As international trade has increased, organizations have had to become more agile and responsive to changing demands for products and services, which has resulted in the need for more efficient supply chain management.

3. Increased Pressure from Customers:

Customers are increasingly demanding more from their suppliers, which has led to organizations having to become more efficient and responsive in their supply chain management. This has also led to a greater focus on customer service, as organizations strive to meet customer demands.

Now more than ever, people want food that is fresh, additive-free, and has origins that can be tracked. They also favor local goods more and more.

4. Cost Reduction:

As organizations try to remain competitive, they have to reduce costs wherever possible. This has led to a focus on supply chain management, which has allowed organizations to reduce costs by streamlining processes and improving efficiency.

5. Alteration of Trade Conditions

- International trade is being slowed down by COVID-19 and associated containment measures in addition to global trade conflicts and resulting political tensions.

- Increased demand for online delivery: With people staying at home due to the pandemic, the demand for online delivery services has surged. This has increased the need for warehouses and distribution centers to manage the demand.

- Shifting production: Businesses are relocating their manufacturing operations to nations with lower labor costs and less regulation.

- Increased automation: Companies are looking for ways to reduce manual labor and increase automation in their supply chains. This could lead to the use of robots and other technology to help reduce costs and improve efficiency.

- Stronger traceability: Companies are looking for ways to better food traceability supply chains to ensure quality and reduce the risk of contamination. This could result in the adoption of blockchain and other technologies to help maintain transparency and traceability.

- Shortened lead times: Lead times are being shortened, and inventory levels are being optimized, by businesses. This could lead to the adoption of predictive analytics and other technologies to better plan and manage inventory.

6. Strict Rules & Standards:

The outbreak will raise concerns about food safety, adding to the regulatory pressure.

- Government Mandating Food Safety Certifications: Governments and organizations may require food industry players to have certain food safety certifications before they can operate. This will ensure that all food handlers and suppliers are following the necessary guidelines to produce safe food.

- Strict Traceability Requirements: Governments may require food companies to have strict traceability and transparency requirements to ensure that the food they are providing is safe and of the highest quality.

- Increased Use of Technology: The food industry is likely to continue to embrace and use technology to improve food safety. This includes the use of sensors, scanners, and other automated systems to monitor food quality and safety.

- Enhanced Food Labeling: Food labeling will become more important in order to ensure that consumers know what they are buying and consuming. Governments may enforce stricter labeling requirements to ensure that consumers are aware of any potential allergens and other food safety issues.

7. Sustainability Requirements & Legislation:

The impetus behind the transition to a society free of carbon emissions (such as the EU's Green Deal) might be slowed by COVID-19. However, it also offers a chance to hasten the transition to a more sustainable economy.

In response to the pandemic, the EU has adopted a number of measures to help protect the environment and promote sustainability, such as:

• Supporting renewable energy sources, with a €750 billion Recovery Plan that includes the European Green Deal and the Just Transition Mechanism

• Investing in green infrastructure, including the EU’s Nature-Based Solutions

• Establishing a new European Climate Pact to support the move towards carbon neutrality

• Seeking to close the circular economy gap with the European Circular Economy Action Plan

• Strengthening the EU’s energy efficiency targets

• Introducing new regulations on emissions trading

• Launching the European Green Digital Transformation Strategy to reduce carbon emissions in the digital sector

• Adopting the European Sustainable Finance Action Plan to reduce financial risk and support the transition to a low-carbon economy

At a national level, many countries are also introducing their own sustainability initiatives, such as the UK’s Green Industrial Revolution and France’s “Ecological Transition” plan.

Governments are also introducing economic incentives to encourage businesses to invest in sustainable practices, such as tax breaks and subsidies. In some countries, new laws and regulations are being introduced to encourage businesses to use renewable energy sources and reduce their carbon footprint.

Governments are also encouraging companies to spend money on the development of clean energy sources. This helps businesses to save money in the long run and become more competitive in the global market.

Finally, governments are offering financial incentives to businesses so they can switch to more environmentally friendly production and consumption practices. These incentives include grants, loans, and other forms of financial support.

Building and Strengthening Supply Chain Resilience

What can players in the food industry do to make their supply chains responsible and robust in the post-outbreak era? The following should guide solutions:

1. Increase Transparency:

Food sector players should strive to increase transparency in their supply chains by implementing traceability systems that track the production, distribution, and storage of food products. This will make it possible to immediately identify and deal with any potential issues.

2. Enhance Collaboration:

Food sector players should strive to foster collaboration between suppliers, manufacturers, distributors, and retailers to ensure that the supply chain is adequately monitored and maintained. This could involve developing shared systems for tracking and monitoring data, as well as identifying and mitigating risks across the supply chain.

3. Adopt Digital Technologies:

Food sector players should also consider adopting digital technologies to streamline and automate processes in the supply chain. To increase the effectiveness and precision of supply chain operations, this can include the use of IoT, blockchain, AI, and other digital solutions.

4. Increase Supply Chain Visibility:

Food sector players should strive to increase visibility across the supply chain to help ensure that the quality and safety of food products is maintained. This can involve looking for possible problems in the supply chain using methods like predictive analytics, data analytics, and machine learning.

5. Implement Sustainability Initiatives:

Food sector players should strive to implement sustainability initiatives to ensure that their supply chains are both responsible and resilient. This can be achieved through sustainable sourcing and transparent supply chains, reducing food waste, promoting eco-friendly packaging, investing in renewable energy sources, and adopting sustainable agricultural practices.

Additionally, businesses should focus on developing innovative solutions to reduce their environmental impact, such as utilizing solar energy and developing new technologies to reduce food waste.

Finally, companies should partner with environmental organizations, governments, and other stakeholders to ensure that their initiatives are successful.

6. Go-to-Market Versatility:

Go-to-market versatility refers to the ability of a company to adjust its approach to selling products and services to different customer segments. This can include changing the value proposition, pricing, marketing messages, sales channels, or other aspects of the approach.

Companies that have go-to-market versatility are better able to adjust to the changing needs of customers and the market and can more quickly respond to opportunities.

To fully recover from COVID-19, which is anticipated to take 12 to 18 months, communities had to close their existing go-to-market channels like pubs and restaurants.

As a result, companies must invest in omnichannel capabilities, with a focus on online and digital solutions. The fungibility of the commodity between channels should also be taken into account.

7. End-to-End Supply Chain Management:

Working with a bigger pool of vendors, particularly local ones, and maintaining larger strategic supplies are two options that firms might consider as it becomes harder for them to find items and materials.

Risks are spread out by a large product selection, but maintenance is more expensive. By streamlining recipes and/or removing problematic items, the portfolio can be made leaner and easier to manage, which lowers risk and expenses.

In addition, it would free up time and funds to devote to the creation of novel, ground-breaking products that combine a healthy way of life with minimal environmental harm.

In the interim, it is essential to invest in your relationships with supply chain partners. After COVID-19, supplier and customer loyalty and resilience will be crucial for the continued success of the business.

Digital Transformation for a Resilient Supply Chain: Managing Disruption

To manage disruption, companies must digitize their supply chain. It would help to create a resilient infrastructure that is capable of withstanding shocks and responding quickly and effectively to potential disruptions.

This can be done through the adoption of digital technologies. It includes blockchain and artificial intelligence, as well as embracing digital tools such as cloud computing, data analytics, and IoT solutions.

Using blockchain can help companies create an immutable and secure record of all transactions that take place in the supply chain. This can help them track stock levels, the movement of goods, and the progress of orders. Moreover, it can also reduce the need for manual processes, increasing efficiency and reducing costs.

Artificial intelligence can help companies predict potential disruptions and provide proactive insights into supply chain risks. Companies can use AI to recognize patterns in data, such as customer demand, and use that information to plan for potential disruptions.

Cloud computing can help companies store and manage large amounts of data, increasing scalability and agility when responding to disruptions. Data analytics can give companies real-time insights into their supply chain and help them identify weak points or areas of risk.

IoT solutions can help companies track shipments in real time and provide up-to-date information about the status of goods and orders.

By embracing digital technologies, companies can make smarter decisions, improve their operations, and increase efficiency. Data analytics can help companies to identify opportunities for cost reduction, as well as ways to improve customer service, and gain a competitive edge in the marketplace.

Additionally, data analytics can help businesses identify potential issues before they become serious problems and highlight areas where processes could be improved.

Gain a Holistic View of ERP for your Supply Chain

ERP for supply chain management gives organizations the ability to track and manage the flow of goods, services, and information from vendors, customers, and other partners within the entire supply chain.

It helps to reduce costs, improve customer service, and increase efficiency. ERP also enables you to gain a holistic view of the supply chain, as it integrates all the different components of the supply chain, from order processing and inventory management to shipping and delivery.

ERP also allows you to manage the entire supply chain in one system, making it easier to analyze and optimize the entire process.

Additionally, ERP provides the ability to monitor and analyze performance, forecast demand, and identify trends and opportunities. This allows you to make strategic decisions that can improve operational efficiency, reduce costs, and increase customer service.

ERP also helps to reduce the complexity of the supply chain, as it simplifies processes and streamlines communication. Lastly, ERP offers the visibility and control required to guarantee adherence to rules and industry standards.

The larger supply chain and other operational areas are combined with dashboards and monitoring tools in an ERP solution. Leaders have the foresight and visibility necessary to respond immediately rather than too late when issues do develop.

ERP enables managers to develop new recipes and BOMs, follow legal requirements, trace lots ahead and backward, make use of EDI capabilities, and automatically produce documentation. Management is possible as a contract manufacturer, co-packer, or producer through a range of business models.

Even when best practices are applied throughout all departments, siloed planning leads to fragmented data systems, erroneous information, and misconceptions.

Also, ERP offers centralized supply chain visibility, organizational transparency, and a single integrated source of real-time data.

This software provides effective scheduling and planning based on precise, recent data.

Strong supply chain management is ensured through effective invoicing and procedures with complete data visibility, which are independent of disruptive external pressures.

In numerous manufacturing sectors, maintaining regulatory and compliance data requires cross-departmental integration and visibility.

Utilizing Automation, Monitoring, and Notifications to Decrease Manual Purchase

With the help of an ERP solution, businesses may avoid spending excessive amounts of money, placing oversized or little orders, and placing them at the wrong time. It increases the accuracy of demand forecasts using past trends.

As more suppliers are added, it maintains a business organized. Software decreases risks by accelerating or automating the process of selecting the finest providers at the appropriate moment.

If a supplier is located in a pandemic hotspot or a snowfall alert zone, orders are transferred to a supplier who is not at risk. Furthermore, ERP keeps track of and coordinates any alterations to a job with suppliers so that, in the case that job specifications change, a quick transition to the best provider is possible.

Relying on a small set of suppliers—some of which may be understaffed or use few raw material suppliers—is a fruitless tactic given the additional disruptions that are projected in the upcoming years.

These ERP tools enable automation of your supplier network diversification and emergency planning. The key to minimising the effects of interruptions and improving supply chain resilience is having visibility and insights into suppliers' performance over time. This enables continuous, steady progress.

Improve your Procedures

Your business can become more efficient in a number of ways with a system created exclusively for the food and beverage industry.

Advanced trace and recall features enable rapid recall responses by allowing the origin of packaging and raw ingredients to be tracked. The automatic regulatory compliance features do away with the need for human records and data storage in various systems.

In order to determine the most economical solutions, forecasting tools allow for the examination of various production scenarios as conditions change.

Real-time costing tools analyze margins in real-time and proactively change prices, while transportation optimization systems assess logistics to create more economical delivery schedules.

The New E-Commerce Requirements

During the pandemic, the breakdown of e-commerce served as a stark example of how, during the previous ten years, the food supply chain changed from being a linear system to one with several nodes branching out in diverse ways.

If and when supplies are refilled and made available to customers, it is difficult to predict with accuracy how any bottleneck at any one of the nodes might affect distribution, fulfillment, or delivery, let alone the impact on product quality.

In order to meet evolving customer expectations during the past 10 years, it will be crucial to comprehend the increasing complexity of the e-commerce supply chain revolution.

At the very least, the pandemic has shown that consumers have accepted online grocery shopping as a permanent trend.

Even though it is projected that most customers would still occasionally visit physical stores in the future, omnichannel shoppers are quite likely to predominate.

Furthermore, 75% of consumers plan to order groceries online in the future, according to a survey by the Consumer Brands Association, which found that 47% of consumers have already done so for pickup or delivery.

The biggest problem is that the outbreak caused us to reach the digital age 10 years earlier than expected. But outdated manual procedures regularly cause our systems to lag. It's time to close the gap.

1. Enhanced Security:

The e-commerce industry must prioritize security measures to protect customers and their data. This includes implementing more secure payment gateways, encrypting data, and implementing two-factor authentication.

2. Personalization:

Consumers are increasingly expecting personalized experiences. E-commerce companies must focus on tailoring their product offerings, emails, website design, and more to meet individual customers’ needs and preferences.

3. Omnichannel Experiences:

Customers now expect a seamless experience across all channels. This means that e-commerce companies must integrate online and offline channels, create unified customer profiles, and provide a consistent shopping experience across all channels.

4. Contactless Shopping:

Contactless shopping is becoming increasingly important for customers. This means that e-commerce companies must enable customers to purchase items and receive them without coming into contact with anyone or anything.

5. Automation and AI:

Automation and AI can help e-commerce companies improve customer service, create personalization, and streamline operations. Companies should look into tools such as chatbots, virtual assistants, and automated marketing tools.

In a nutshell, the blueprint urges the food industry to use digital technologies to make the supply chain more transparent and responsive. Several suggestions are:

- Using sensor technology to improve temperature monitoring and other crucial and preventive control areas.

- Using online and mobile reporting resources

- Digitalizing audits and inspections

- Putting in place desirable behaviors utilizing digital tools and administrative controls

It’s the perfect time to adopt digital solutions that enable real-time visibility into how each node in the supply chain is operating. It's important to examine digital engagement much more broadly—not just for online grocery shopping, but also for in-person and mobile engagements.

Conclusion

The global pandemic has exposed how fragile the supply chain is and how vulnerable businesses can be to sudden disruption. To become more resilient and agile, businesses must embrace digital transformation.

Digital technology can help manage disruption by providing powerful tools to monitor, manage, and optimize supply chains. Companies can use data analytics and automation to anticipate and respond quickly to changing demand and supply conditions, ensuring that their operations remain stable and efficient.

Businesses can increase operational efficiency and gain visibility into their supply chains by investing in technologies like artificial intelligence, machine learning, predictive analytics, blockchain, and the Internet of Things. Automating processes such as order fulfillment and inventory management can also help reduce costs and improve efficiency.

Finally, companies should leverage digital technologies to create smarter, more collaborative supply networks, where key players can share data and insights to better anticipate and respond to disruption. This will help them build stronger, more resilient supply chains that are better equipped to weather future disruptions.

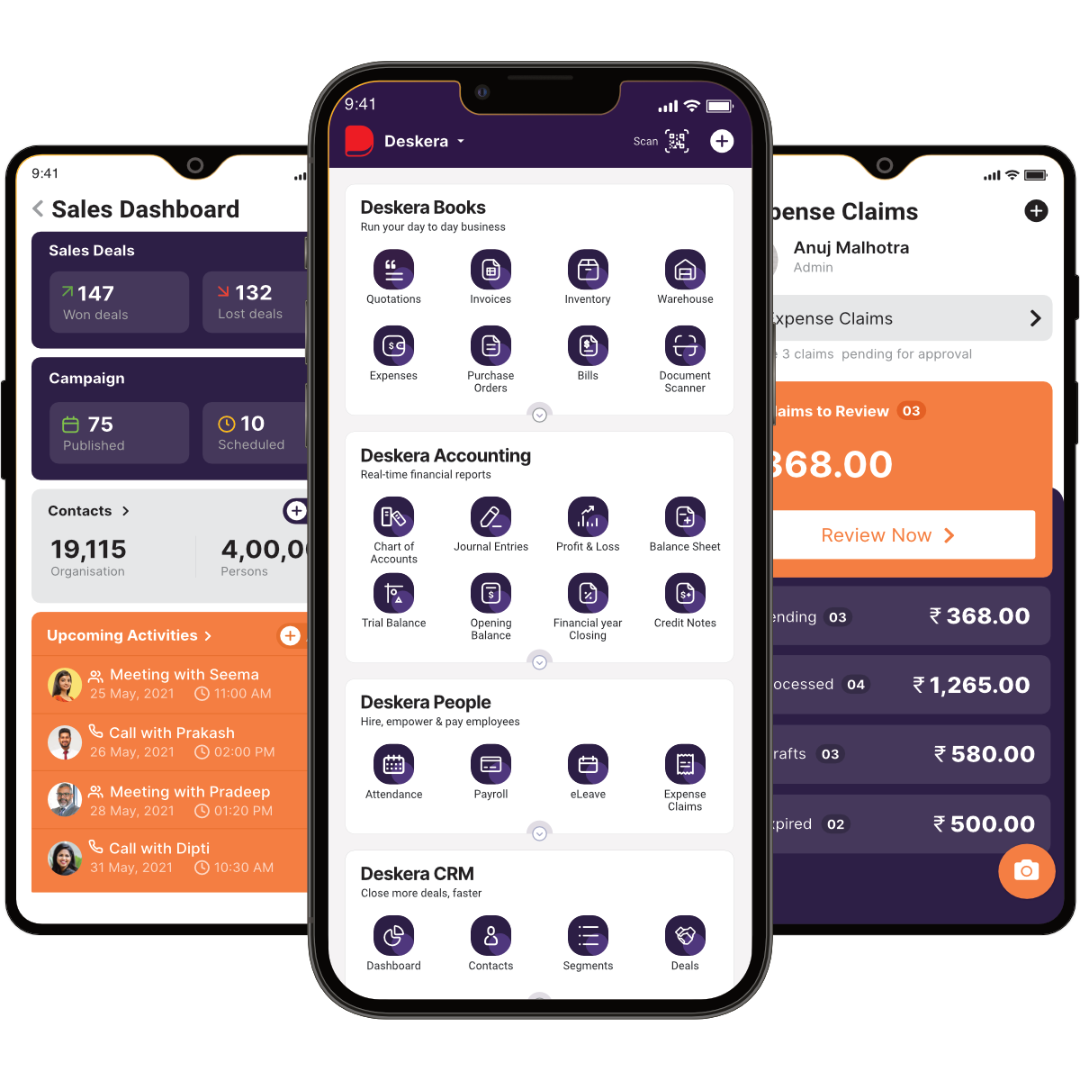

How Deskera Can Assist You?

Deskera ERP is a comprehensive system that allows you to maintain inventory, manage suppliers, and track supply chain activity in real-time, as well as streamline a variety of other corporate operations.

Deskera ERP and MRP system can help you:

- Manage production plans

- Maintain Bill of Materials

- Generate detailed reports

- Create a custom dashboard

Deskera Books enables you to manage your accounts and finances more effectively. Maintain sound accounting practices by automating accounting operations such as billing, invoicing, and payment processing.

Deskera CRM is a strong solution that manages your sales and assists you in closing agreements quickly. It not only allows you to do critical duties such as lead generation via email, but it also provides you with a comprehensive view of your sales funnel.

Deskera People is a simple tool for taking control of your human resource management functions. The technology not only speeds up payroll processing but also allows you to manage all other activities such as overtime, benefits, bonuses, training programs, and much more. This is your chance to grow your business, increase earnings, and improve the efficiency of the entire production process.

Final Takeaways

We've arrived at the last section of this guide. Let's have a look at some of the most important points to remember:

- Technology has been a major driving force in the transition of supply chain management. Advances in technology such as the internet of things, robotics, artificial intelligence, big data, and blockchain.

- Customers are increasingly demanding more from their suppliers, which has led to organizations having to become more efficient and responsive in their supply chain management. This has also led to a greater focus on customer service, as organizations strive to meet customer demands.

- Governments and organizations may require food industry players to have certain food safety certifications before they can operate. This will ensure that all food handlers and suppliers are following the necessary guidelines to produce safe food.

- Food sector players should strive to increase visibility across the supply chain to help ensure that the quality and safety of food products is maintained. This can involve looking for possible problems in the supply chain using methods like predictive analytics, data analytics, and machine learning.

- Go-to-market versatility refers to the ability of a company to adjust its approach to selling products and services to different customer segments. This can include changing the value proposition, pricing, marketing messages, sales channels, or other aspects of the approach.

- ERP provides the ability to monitor and analyze performance, forecast demand, and identify trends and opportunities. This allows you to make strategic decisions that can improve operational efficiency, reduce costs, and increase customer service.

Related Articles