Factories are an intrinsic part of the development of a country. They not only help produce goods from raw materials, but also provide employment to the locals. With that said, it is essential to lay some ground rules for such establishments to follow so that they function efficiently.

With that in mind, the Government of India has enacted the Factories Act, 1948, which was amended in 1950. This act lists the guidelines that factories and similar establishments must follow to ensure overall safety of the premises, goods and the workers inside.

The state of Haryana doesn’t specifically have its own Factory Rules, therefore borrows from The Punjab Factory Rule for provision of guidelines to run its factories. Under this rule, Haryana prescribes a Form 7 (FA) that requires the factory manager to maintain a record of cleanliness on the factory premises. In this form, the particulars pertaining to lime washing, whitewashing, painting, etc. are recorded.

It is mandatory for the factory staff to maintain this register in order for the factory to stay compliant with the Punjab Factory Rules.

In order to understand the role of Form 7, record of lime washing, painting, etc. in a factory, let’s cover the following topics:

- What are the Punjab Factory Rules?

- What is Form 7 (FA), Record of Lime Washing, Painting, etc.?

- Various Fields in Form 7 Record of Lime Washing, Painting, etc.

- Column 1: Part of the Factory

- Column 2: Parts lime washed, painted, varnished, or oiled

- Column 3: Treatment done to the part, whether lime washed, painted, varnished or oiled

- Columns 4, 5 and 6: Date, Month and Year on which lime washing, painting, varnishing or oiling was carried out (According to the English Calendar)

- Column 7: Remarks

- Rule 18 of The Punjab Factory Rules

- Section 11.1 of The Factories Act, 1948

- Wrapping Up

- Key Takeaways

What are the Punjab Factory Rules?

The Punjab Factory Rules provide guidelines for the establishment, licensing, functions and operation of factories in the territories that fall under the States of Punjab as of November the 1st, 1956. Under this Act, the entities wishing to establish a factory will find the guidelines, procedures and forms pertaining to the following, to name a few:

- Submission and approval of factory plans

- Application for registration of factory and grant of license

- Provisions and guidelines for renewal and transfer of factory license

- Appointment of inspecting authority, on-premises doctors and surgeons

- Provisions and rules for records of lime washing, whitewashing, painting, etc. (in Rule 18) for form 7

- Waste disposal guidelines

- Guidelines for ventilation, air movement, temperature and provision of thermometers

- Factory lighting

- Water supply, drinking water standards and guidelines for cleanliness of water storage reservoir

- Amenities like water coolers and latrines

- Drainage requirements and guidelines

- Site safety and precautions to be observed

Many other provisions exist within this Act that helps the factories run properly and operate safely. With respect to Form 7 record of lime washing, painting, etc., the Punjab Factory Rules prescribe Rule 18 to be followed. Let’s look at Rule 18 of this Act in detail.

What is Form 7 (FA), Record of Lime Washing, Painting, etc.?

The form 7, record of lime washing, painting, etc. is, as it says, a record of the timeline during which such activities were carried out in a factory. It is mandatory for the factory manager or any appointed authority to maintain this register.

The government of Haryana requires factory owners to keep a register of their lime washing, whitewashing, colour washing, painting and other activities in the factory in order to officially measure their compliance with the Punjab Factory Rules.

It is of dire importance to observe these cleanliness guidelines laid down by the Factories Act because of the potential risks the working environment poses to the health workers.

In particular, dilapidated conditions of factory walls could prove to be hazardous and potentially cause respiratory problems in the workers. Periodic cleaning, repainting, whitewashing and regular maintenance of walls help create a decent interior environment for the shop floor workers.

Additionally, the compliances that are related to worker health safety are met by keeping a register of the mandated whitewashing and limewashing activities.

For the factories that deal with handling chemicals, perishable items or producing end products that are sensitive to surrounding hygiene, maintaining form 7 record of lime washing, painting, etc. is of dire importance.

Various Fields in Form 7 Record of Lime Washing, Painting, etc.

Form 7 record of lime washing, painting, etc. is basically a record of the times when a factory underwent maintenance and cleanliness activity as prescribed under Rule 18 and Section 11.1 of the Punjab Factory Rules and the Factories Act of 1948.

The form has the following fields:

|

Part of the Factory, eg. Name of the Room |

Parts lime washed, painted, varnished, or oiled, eg. Walls, ceilings, woodwork, etc. |

Treatment done to the part, whether lime washed, painted, varnished or oiled |

Date on which lime washing, painting, varnishing or oiling was carried out (According to the English Calendar) |

Month in which lime washing, painting, varnishing or oiling was carried out (According to the English Calendar) |

Year in which lime washing, painting, varnishing or oiling was carried out (According to the English Calendar) |

Remarks |

|

|

|

|

Date |

Month |

Year |

|

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Column 1: Part of the Factory

A factory isn’t a single room or a hall. It is comprised of various parts, floors, wings, rooms, annexes and structures that may either be adjacent and connected or scattered and disjointed. While recording the details in form 7 record of lime washing, painting, etc. it is necessary to specifically mention which parts of the factory got these jobs done.

For example, if a factory has three sheds to store raw material in the raw material zone, then in this field, then in the entry you would need to mention the shed number or ID and the factory zone where it is located.

Column 2: Parts lime washed, painted, varnished, or oiled

This column in form 7 record of lime washing, painting, etc. helps you record the specifics of the items that were painted in the part of the factory recorded previously in column one. For example, if the part of factory mentioned was Shed 1 of the raw material zone, then in column 2 you would need to capture exactly what was painted in Shed 1.

An example of the details that go in this column can be the ID numbers of shelves kept in the shed that were painted, or the furniture housed there, or details of which walls were whitewashed (like east wall or north wall), etc. You would also need to mention which floors were covered.

Column 3: Treatment done to the part, whether lime washed, painted, varnished or oiled

Column three is required to be filled with information pertaining to the kind of treatment applied to the part specified in column 2. Not all components of a factory are the same – they can’t all be painted or lime washed. Based on the material requirement, the whitewashing / colour washing, painting and lime washing requirements change. Column 3 helps the factory manager capture this detail.

For example, if shelf number 1 through 20 of shed 1 in the raw material zone were oiled, column three would record “oiled” for this particular part. If there was whitewashing done on the east wall but colour washing on the south wall, the same particulars would be recorded in different rows with specific detail.

Columns 4, 5 and 6: Date, Month and Year on which lime washing, painting, varnishing or oiling was carried out (According to the English Calendar)

The Factories Act mandates certain periodic timeline at which such maintenance activities should be carried out. It depends from state to state – for Haryana, the Act determines that lime washing, colour washing, whitewashing or painting, oiling, etc. should be done at least once every fourteen months. It is for this reason that columns 4, 5 and 6 record the exact date when these activities are carried out at a factory.

It helps the appointed authority measure compliance of the factory.

Column 7: Remarks

This column is dedicated to recording any special events or incidents that occurred owing to which certain changes were needed to made to the cleanliness schedule. Even if the cleanliness schedule gets postponed for some reason, the details and reasons need to be recorded in this column.

For example, if the factory remains closed due to unavailability of raw material or labour which causes it to miss the maintenance, it can be recorded in the remarks column. Even if there is a delay in acquiring the requisite material (whitewash, paint, varnish etc.) – it needs to be recorded.

Another detail that goes into this column is the detail of any special treatment done besides the ones specified in the Act (like pest control or termite treatment to the woodwork).

Rule 18 of The Punjab Factory Rules

For all the factories established in Haryana, the Punjab Factory Rules apply to the processes, operations and functions for ensuring compliance. Especially where form 7, record of lime washing, painting, etc. is concerned, the Act is very clear.

Under the rule no. 18 of these Factory Rules, it has been clearly specified that form 7 be used to record all the details of the cleanliness protocol mentioned in the Act. Quoting the same from the Factory Rules:

“18. RECORD OF WHITE-WASHING ETC., [Section 11(1)]. —The record of dates on which white-washing, colour washing, varnishing, etc., are carried out shall be entered in a register maintained in Form No. 7.”

It, thus, can be considered as a matter of compliance to maintain a register with the form 7, record of lime washing, painting, etc. duly filled out.

Section 11.1 of The Factories Act, 1948

Form 7 record of lime washing, painting, etc. hails from section 11.1 of the Factories Act, 1948. This section in the Act determines the standard of cleanliness to be observed on premises at specific intervals of time to ensure health and safety of the workers employed therein. Let’s cover the specifics of this section.

- The Act requires that factories should be kept clean from the effluvia that are generated by drains, privies or other such nuisances on premises

- That the factory shall adopt any means suitable to clean the accumulated dirt and refuse from the floors and furniture of workrooms – whether by sweeping, washing or anything that is suitable

- That the factory shall mandate the cleaning of the workroom floors at least once a week with washing, using disinfectant or other suitable material known to act on pathogens, or any other effective method

- That the factory shall provide an effective drainage system in the workrooms where processes result in wetting of the floor to a point where draining the wetness is required. Factories are also required to maintain the drainage system periodically

- All the walls, ceilings, partitions, tops of rooms, sides and tops of passages need to be:

- Varnished, revarnished or repainted once every five years in case they are not painted with water washable paint

- Where such parts have been painted with water washable paint, the factory shall have it washed once every six months, and have it repainted once every three years with one coat of same paint

- In case such factory parts have an impervious finish (like paint or varnish), the factory shall mandate cleaning with suitable / prescribed methods once every fourteen months

- For any other finishing on such factory parts, the factory shall keep them colour washed or whitewashed once every fourteen months

- That the factory shall mandate the painting or varnishing of all windows, doors, shutters and their parts, whether wooden or metallic, once every five years

- That the factory shall record all these activities in the register according to form 7, record of lime washing, painting, etc.

Wrapping Up

As a part of compliance, form 7 record of lime washing, painting, etc. must be duly filled and recorded in factory registers. In case an inspection comes up, it would be easy to have all the records handy.

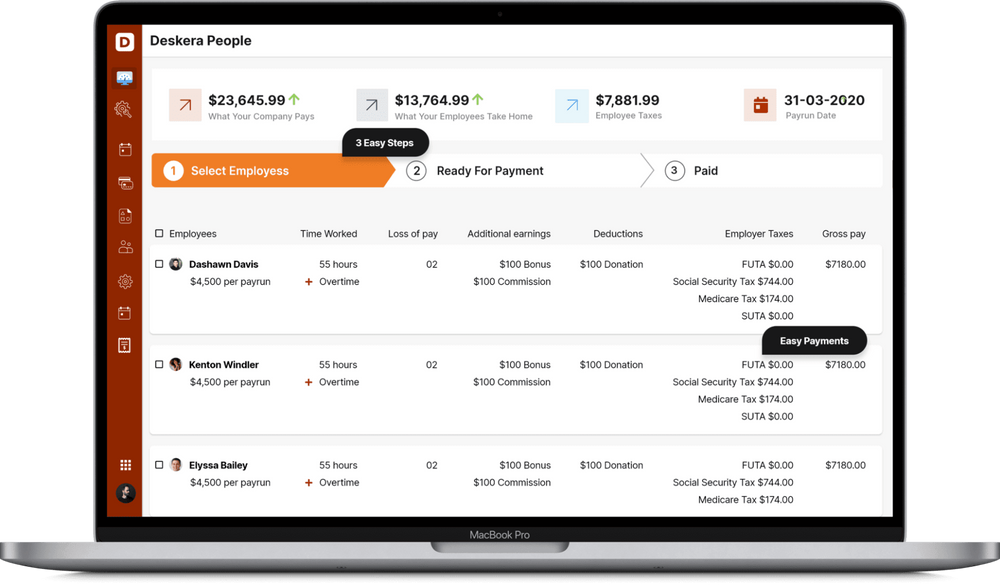

How Can Deskera Assist You?

Deskera People helps digitize and automate HR processes like hiring, payroll,leave, attendance, expenses, and more. Simplify payroll management and generate payslips in minutes for your employees.

Key Takeaways

A brief summary of the importance of form 7, record of lime washing, painting, etc.

- In accordance with the Punjab Factory Rule, all the factories in Haryana must comply with the guidelines and provisions enlisted in that rule

- Form 7 record of lime washing, painting, etc. draws from rule number 18 of the Factory Rule, in accordance with Section 11.1 of the Act

- The form is a record of maintenance activities pertaining to whitewashing, colour washing, repainting, oiling, varnishing, etc. of factory parts and components. The form carries fields that record each item in great detail

- This form is a part of compliance requirements of operational factories

Related Articles