Have you ever wondered why so many manufacturing businesses struggle to maintain profitability despite having steady sales? The answer often lies in poor visibility and control over costs. Manufacturing involves multiple moving parts—from raw material sourcing to labor, overhead, and production expenses. Without a dedicated system to track and analyze these costs, businesses risk inefficiency, errors, and lost revenue. That’s where manufacturing accounting software steps in as a game-changer.

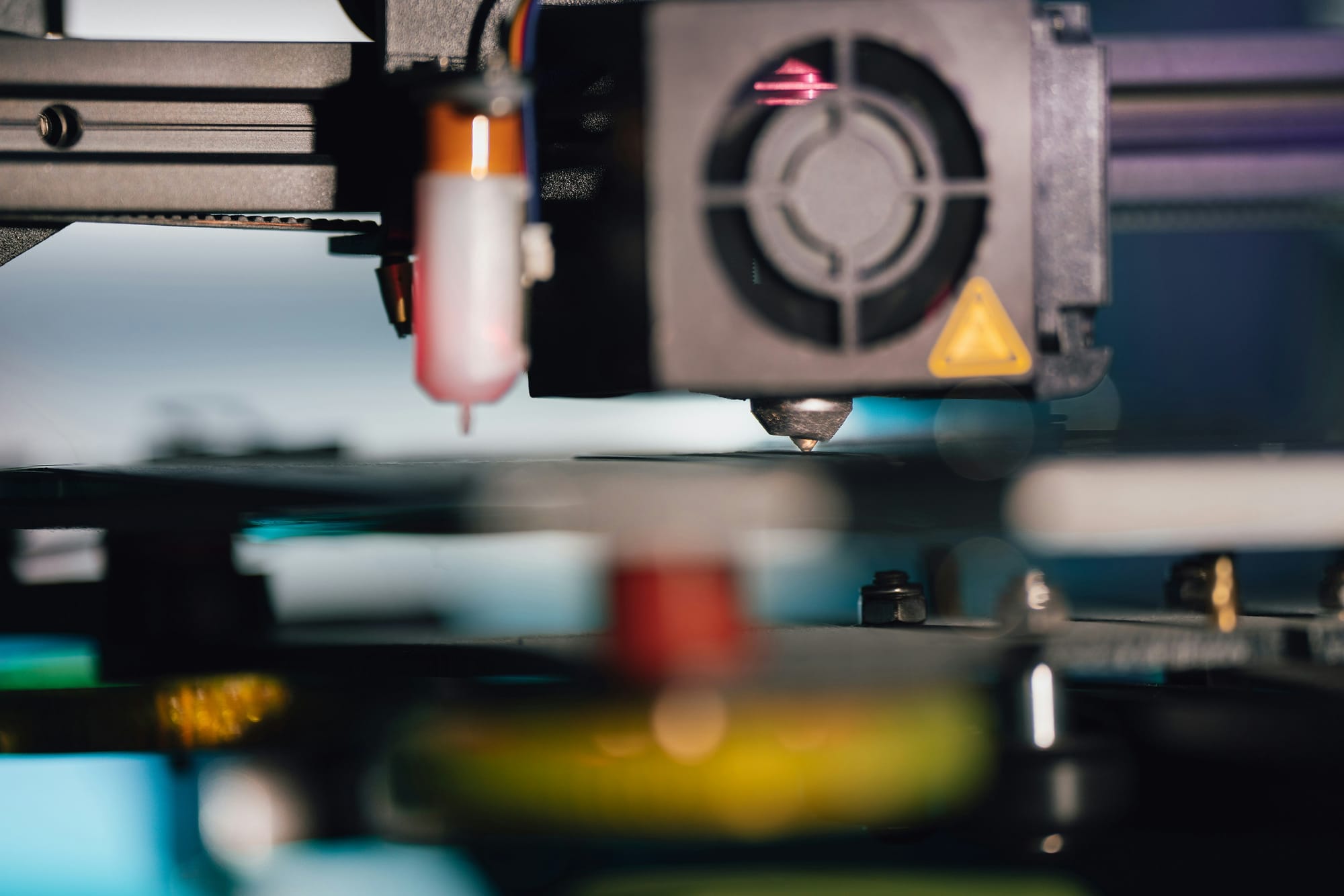

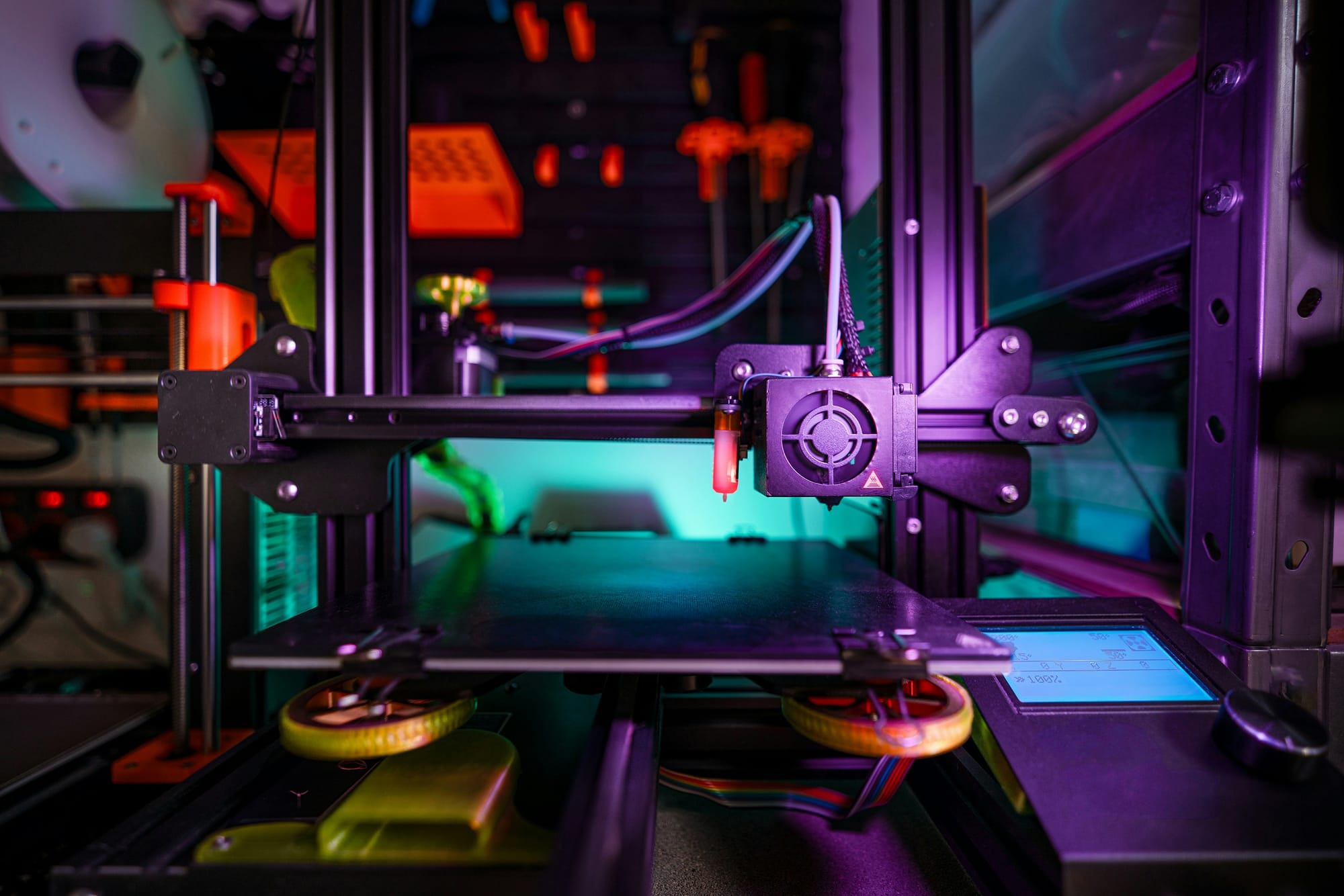

Unlike traditional accounting tools, manufacturing accounting software is designed to handle the complexities of production, inventory, and job costing. It not only records financial data but also provides actionable insights into how resources are being utilized on the shop floor. By integrating accounting with manufacturing processes, businesses can make smarter decisions, optimize operations, and protect their margins in a competitive market.

Today, modern solutions go beyond simple bookkeeping. They provide real-time dashboards, AI-driven forecasting, automated reporting, and seamless integration with ERP and MRP systems. This means business leaders no longer need to rely on guesswork when making decisions about production costs, inventory control, or profit planning. Instead, they gain access to precise data that drives efficiency and growth.

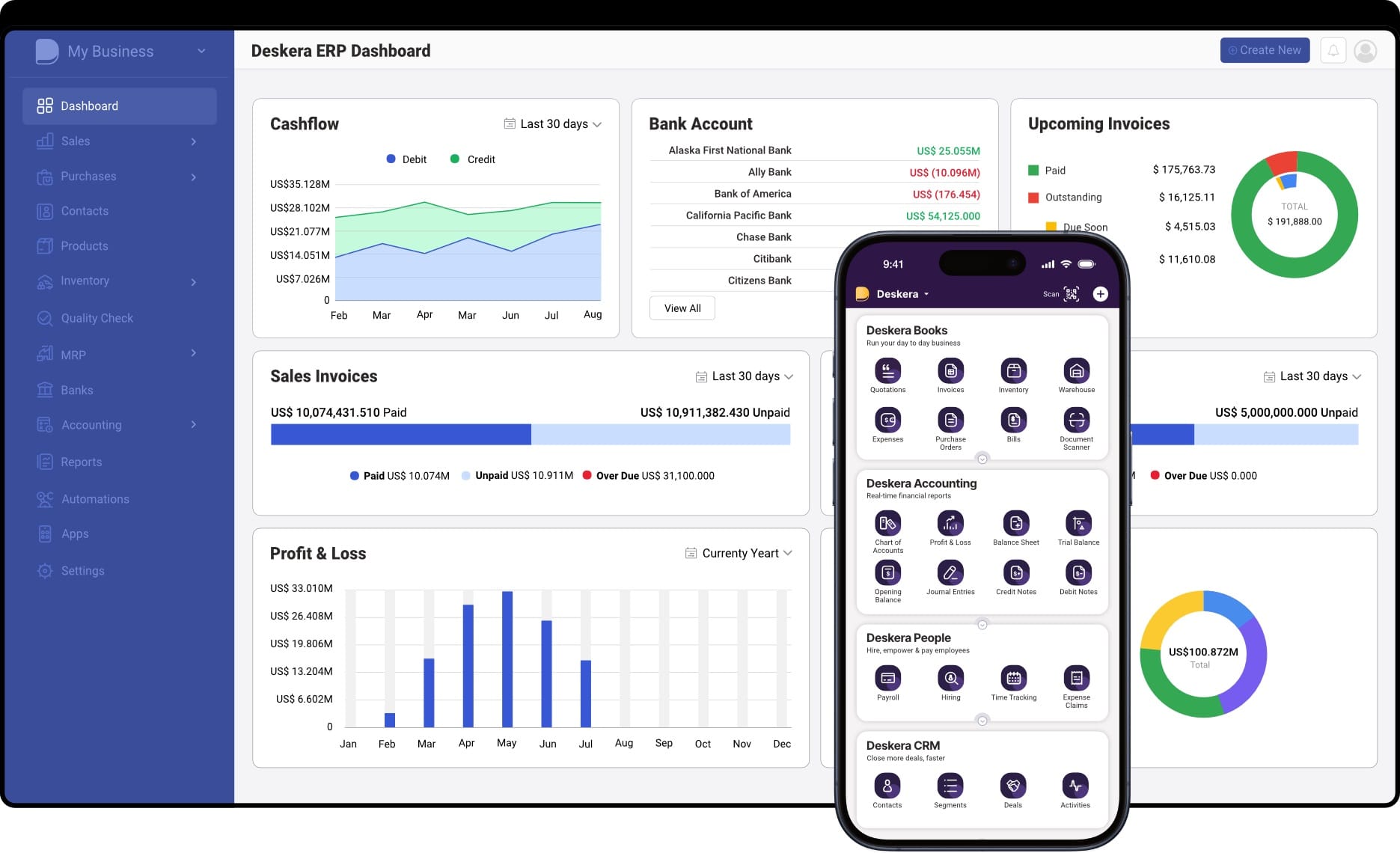

One such powerful solution is Deskera Manufacturing ERP, an all-in-one platform built for manufacturers. Deskera brings together accounting, inventory, production planning, MRP, demand forecasting, and even AI-driven assistance through its smart assistant, David. With mobile accessibility and advanced reporting templates, it helps manufacturers gain complete financial clarity while streamlining operations.

In this blog, we’ll explore everything you need to know about manufacturing accounting software and how it can transform your business.

What is Manufacturing Accounting Software?

Manufacturing accounting software is a specialized financial management system built to handle the unique complexities of manufacturing operations. Unlike standard accounting tools that focus only on general ledgers, income, and expenses, this software combines core accounting functions with manufacturing-specific features like job costing, production tracking, and inventory management. It gives manufacturers a clear and accurate picture of their financial health while connecting accounting directly with production activities.

One of its key roles is to determine the true cost of each product. By tracking raw materials, labor, machine usage, and overhead expenses in detail, the system ensures that manufacturers know exactly where their money is going at every stage of production.

It manages raw materials, works in process (WIP), and finished goods—three critical inventory types that directly impact the cost of goods sold (COGS) and profit margins. To streamline this, manufacturing accounting software supports multiple inventory valuation methods such as FIFO (First In, First Out), LIFO (Last In, First Out), and weighted average.

Beyond cost tracking, the software also automates overhead allocation—fairly distributing indirect costs like rent, depreciation, and utilities across different products. Many solutions come equipped with variance analysis tools, which highlight discrepancies between forecasts and actual results, helping manufacturers adjust quickly to maintain profitability.

Modern manufacturing accounting software goes even further by incorporating artificial intelligence (AI) and integrations with ERP, MES (Manufacturing Execution Systems), and supply chain platforms. These capabilities automate repetitive tasks such as payment reconciliation and invoice processing, reduce manual errors, and provide real-time financial insights. Dashboards and KPIs, such as unit cost and sell-through rates, empower decision-makers with the data they need to price effectively, optimize production, and stay ahead in competitive markets.

Key Features of Manufacturing Accounting Software

The global demand for manufacturing accounting software is growing rapidly, with the market projected to reach $26 billion by 2031. The reason is simple: manufacturers need accounting systems that not only track finances but also connect seamlessly with production, inventory, and supply chain operations.

Below are the most important features every manufacturer should look for:

1. Job Costing

Job costing allows manufacturers to analyze costs for each product, project, or batch in detail. It categorizes expenses into direct costs (like raw materials and labor) and indirect costs (such as overhead). Accurate job costing provides visibility into which products deliver higher returns and which need process adjustments. Advanced software also includes cost variance analysis, helping businesses detect budget overruns, waste, and inefficiencies before they erode profits.

2. Inventory Management

Effective inventory management ensures smooth production without overstocking or stockouts. Manufacturing accounting software offers real-time visibility into inventory across warehouses and production lines, with features like:

- Automated reorder points.

- Batch, lot, and serial number tracking for full traceability.

- Mobile access for on-the-go audits and stock checks.

Integration with procurement and MRP systems ensures that materials are always available when needed, reducing waste and maintaining lean operations.

3. Production Planning

Production planning aligns materials, labor, and capacity with customer demand. Key tools include:

- Gantt charts and drag-and-drop scheduling.

- Capacity planning to identify machine/labor constraints.

- “What-if” scenario modeling for demand shifts and supply chain disruptions.

By combining real-time shop floor data with financial insights, manufacturers can reduce downtime, minimize bottlenecks, and improve on-time delivery.

4. Financial Reporting and Analytics

Modern solutions go beyond bookkeeping with customizable dashboards and detailed financial reports focused on manufacturing-specific KPIs. These include:

- Cost of goods manufactured (COGM)

- Profitability by product line.

- Production cost variances.

AI-driven reporting tools can also flag anomalies, predict trends, and provide actionable insights. Consolidated reporting across business units or locations offers a complete financial overview for leadership, investors, and compliance bodies.

5. Supply Chain Management Integration

Manufacturing accounting software integrates financial data with supply chain workflows. This provides end-to-end visibility into procurement, production, and distribution.

Features like automated purchase order creation, supplier performance tracking, and demand forecasting help reduce risks and optimize sourcing. AI-powered modeling can suggest alternative suppliers or adjust orders during disruptions, making supply chains more resilient.

6. Compliance and Tax Management

Automated tax calculations, audit-ready reports, and deadline reminders help manufacturers stay compliant. Advanced platforms also support global tax laws, multi-currency transactions, and automatic updates to reflect regulatory changes. This reduces the risk of costly errors and simplifies audits across multiple jurisdictions.

7. Scalability

As manufacturers grow, their software must scale too. Cloud-based solutions offer flexibility for expanding operations, multiple sites, and global growth while ensuring data security. Modular systems let businesses add advanced features—such as AI-driven forecasting or advanced costing methods—without replacing the entire system.

8. Integration Capabilities

Modern manufacturers rely on multiple platforms, from ERP and CRM to e-commerce and production management tools. Seamless integration prevents data silos and ensures accurate, real-time information flows across the business.

9. Ease of Use

A user-friendly design with intuitive dashboards and role-based access reduces errors and shortens the learning curve. Many platforms also provide robust support resources—tutorials, FAQs, and communities—that empower employees to use the system effectively.

10. Advanced Automation and AI (additional feature)

AI and automation are redefining accounting in manufacturing. From automating invoice processing and payment reconciliation to predictive cost analysis, these features eliminate repetitive tasks and deliver insights at scale. AI-powered assistants (like Deskera’s David) can even provide instant answers, generate reports, and suggest corrective actions.

Together, these features give manufacturers full visibility into costs, streamlined processes, stronger compliance, and smarter decision-making—all critical for long-term profitability.

11. Budgeting and Forecasting

Budgeting and forecasting features help manufacturers plan for the future with confidence. By analyzing historical data, market trends, and current production costs, the software generates accurate financial forecasts.

This allows leaders to set realistic budgets, allocate resources effectively, and anticipate demand fluctuations. Forecasting tools also align with MRP and supply chain systems, enabling proactive planning instead of reactive decision-making.

12. Automated Reporting and Analytics

Automation takes reporting to the next level by reducing manual effort and delivering real-time insights. AI-powered tools automatically generate reports, flag anomalies, and highlight trends before they impact profitability.

Predictive analytics can forecast performance, track KPIs like unit costs and sell-through rates, and suggest corrective actions. This not only saves time but also equips managers with data-driven insights for faster, smarter decisions.

Benefits of Using Manufacturing Accounting Software

Manufacturing accounting software connects financial management with day-to-day operations, creating a single source of truth for costs, compliance, and performance. Unlike traditional accounting systems that focus only on ledgers and balances, it streamlines complex production workflows and delivers actionable insights.

Here are the key benefits manufacturers can expect:

1. Streamlined Financial Processes

Manufacturing accounting software automates routine tasks such as data entry, invoice management, reconciliation, and payroll processing. This not only reduces the administrative burden but also saves significant time for finance and operations teams.

Instead of being bogged down with repetitive work, employees can shift focus toward more strategic activities, such as analyzing profitability or planning growth initiatives. The result is a smoother, faster, and more reliable financial workflow that eliminates bottlenecks and improves efficiency.

2. Real-Time Visibility into Production Costs

One of the greatest advantages of manufacturing accounting software is the ability to track expenses in real time. From labor costs and raw material usage to energy consumption and overheads, businesses gain complete visibility into where money is being spent.

This ensures product pricing reflects actual costs while avoiding underestimations that hurt profits. By integrating operational and financial data, manufacturers can monitor costs as they occur, enabling accurate decision-making and better long-term profitability analysis.

3. Reduced Manual Errors and Better Compliance

Manual accounting processes often result in errors that can have significant financial consequences, including tax miscalculations and incorrect financial statements. Manufacturing accounting software reduces these risks by automating calculations, validations, and reconciliations.

Built-in compliance features, such as audit trails and regulatory reporting, ensure businesses meet local and global accounting standards. This not only prevents penalties but also builds trust with stakeholders and auditors. Ultimately, automation enhances financial accuracy and strengthens organizational accountability.

4. Improved Decision-Making with Data Insights

Manufacturing accounting software comes equipped with advanced analytics and reporting capabilities that transform raw financial and operational data into actionable insights. Managers can analyze cost trends, monitor production performance, and evaluate profitability across product lines, departments, or plants.

With real-time dashboards and customizable reports, decision-makers can spot inefficiencies quickly and take corrective action. This data-driven approach eliminates guesswork, empowers leaders to make smarter choices, and supports continuous improvement across both operations and finances.

5. Higher Profitability and Cost Efficiency

By uncovering hidden inefficiencies, manufacturing accounting software helps businesses control costs and maximize profit margins. It highlights areas such as excessive raw material usage, underperforming machines, or labor-intensive processes that can be optimized for better efficiency.

Additionally, precise cost tracking allows manufacturers to set competitive yet profitable product pricing. Over time, these improvements drive higher profitability while reducing waste. In a competitive market, such cost visibility and efficiency are crucial for long-term sustainability and growth.

6. Budgeting and Forecasting Capabilities

Accurate budgeting and forecasting are critical for manufacturers dealing with volatile demand and fluctuating raw material prices. Manufacturing accounting software offers robust tools to create detailed budgets, test different financial scenarios, and forecast outcomes with greater accuracy.

This empowers businesses to plan strategically for growth, allocate resources effectively, and anticipate challenges in advance. With clear financial projections, manufacturers can respond confidently to market shifts and ensure business continuity while supporting long-term financial stability.

7. Automated Reporting and Analytics

Traditional reporting methods often take days or even weeks, delaying crucial insights. With manufacturing accounting software, businesses benefit from automated reporting that generates accurate financial statements and operational performance summaries instantly.

Customizable dashboards allow leaders to view KPIs at a glance, while scheduled reports ensure stakeholders stay informed without manual intervention. This not only speeds up month-end and year-end closing but also improves transparency, enabling faster, data-backed decisions across the organization.

8. Enhanced Inventory Control

Inventory management is a major challenge in manufacturing, with stockouts and overstocking directly impacting profitability. Manufacturing accounting software integrates seamlessly with inventory systems to track stock levels, monitor order fulfillment, and analyze turnover rates.

Automated alerts prevent shortages and excess storage costs, ensuring materials are always available when needed. Real-time visibility into inventory also helps optimize procurement and production planning. This reduces carrying costs, minimizes waste, and ensures smooth supply chain operations, driving overall efficiency.

9. Scalability and Growth Support

As manufacturers grow, so do the complexities of managing financial and operational data. Cloud-based manufacturing accounting software offers the scalability to handle multi-location operations, global transactions, and diverse product lines with ease.

Businesses can expand into new markets or add facilities without facing system limitations. The software adapts to evolving requirements, ensuring smooth expansion while maintaining financial accuracy. This flexibility supports long-term growth and allows manufacturers to scale confidently without unnecessary disruptions.

10. Better Collaboration Across Departments

Siloed data often creates miscommunication between finance, operations, sales, and supply chain teams. Manufacturing accounting software centralizes financial and operational data in one platform, ensuring all departments work with the same accurate information.

This transparency fosters collaboration, reduces delays caused by conflicting data, and improves decision-making across teams. Whether it’s production scheduling, procurement, or financial reporting, cross-functional teams can coordinate more effectively, reducing bottlenecks and driving operational excellence across the organization.

11. Stronger Customer and Supplier Relationships

Financial efficiency extends beyond internal operations to external stakeholders. By ensuring accurate costing, timely payments, and efficient invoicing, manufacturing accounting software helps businesses strengthen relationships with suppliers.

Customers benefit from competitive pricing and reliable delivery, thanks to streamlined processes. This builds trust and long-term loyalty on both ends of the supply chain. A reputation for financial reliability and efficiency positions the business as a preferred partner in competitive manufacturing markets.

12. Environmental and Sustainability Insights

Sustainability has become a priority for modern manufacturers. Advanced accounting software can track resource usage, energy consumption, and waste to identify opportunities for improvement. These insights help businesses reduce inefficiencies and adopt eco-friendly practices while lowering operational costs.

For instance, optimizing resource utilization can cut waste and decrease environmental impact. By linking financial performance with sustainability efforts, manufacturers can align profitability with social responsibility, enhancing brand reputation and meeting growing consumer expectations.

Challenges in Manufacturing Accounting Without Software

Managing finances in manufacturing is no easy task. When businesses rely solely on manual methods or outdated systems, they face several inefficiencies that hinder accuracy, decision-making, and overall growth. Without specialized manufacturing accounting software, companies often find themselves overwhelmed by errors, disconnected data, and slow reporting.

Below are some of the most pressing challenges manufacturers face when accounting is not digitized:

1. Manual Errors and Time-Consuming Bookkeeping

Traditional bookkeeping methods in manufacturing are often prone to human errors, such as data entry mistakes, miscalculations, or lost records. These small errors can lead to major discrepancies in financial reports, compliance risks, and wasted resources.

Moreover, manual accounting consumes significant time that could otherwise be invested in strategy and growth. Without automation, finance teams spend countless hours reconciling data, which slows down workflows and increases operational inefficiency.

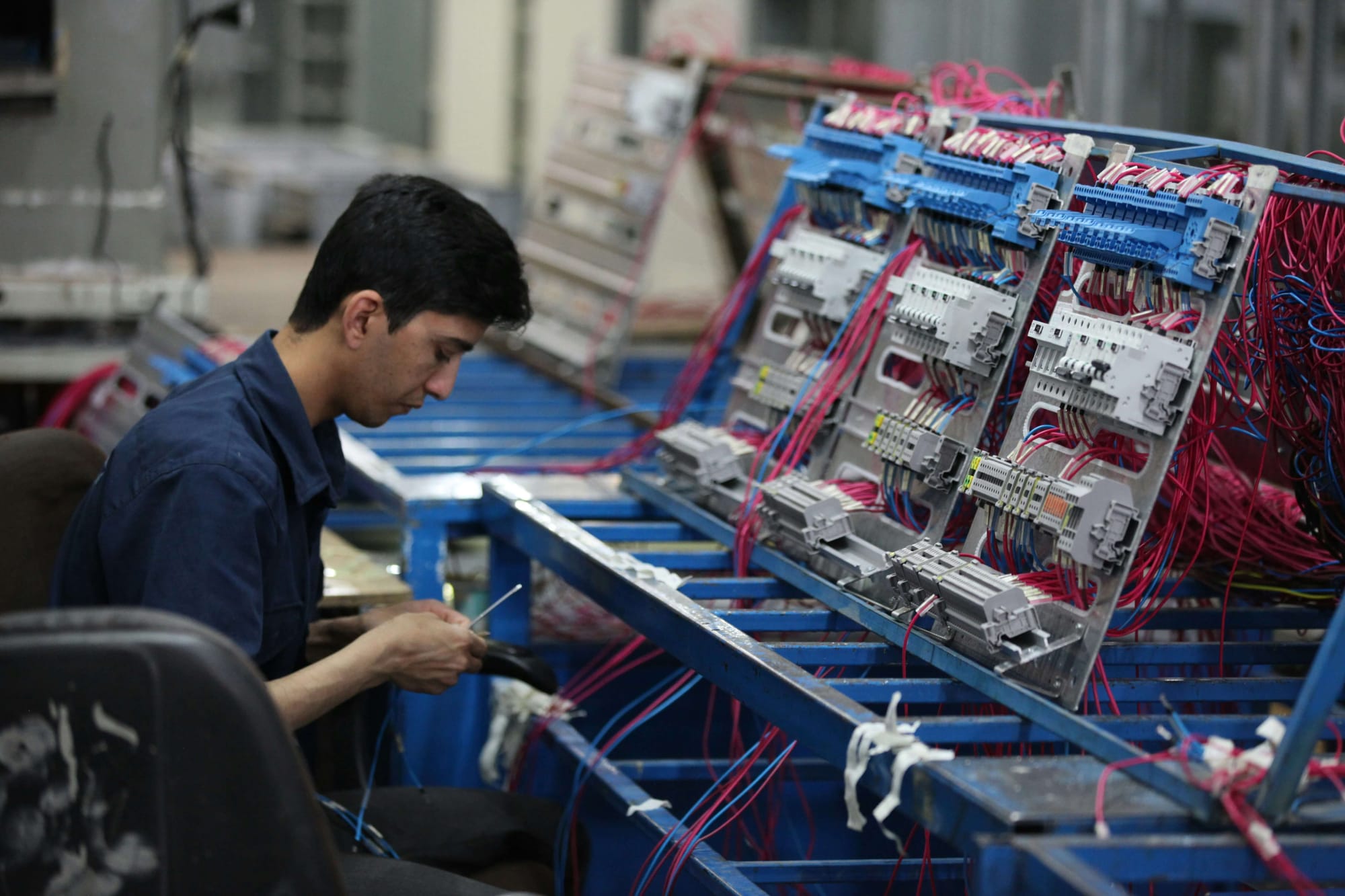

2. Difficulty in Tracking Costs Across Multiple Processes

Manufacturing involves numerous interdependent processes—procurement, production, labor, inventory, and distribution. Without accounting software, it becomes challenging to allocate and track costs across these functions.

Spreadsheets and manual records rarely provide the granular insights needed for accurate job costing or profitability analysis. This lack of visibility can result in overlooked inefficiencies, inaccurate pricing, and uncontrolled expenses. Consequently, businesses may face shrinking margins and struggle to make data-driven financial decisions.

3. Lack of Integration Between Accounting and Production

One of the biggest hurdles manufacturers face without dedicated software is the disconnect between financial and production data. Separate systems or manual records create silos, making it difficult to align operational performance with financial outcomes.

For example, production delays or inventory shortages may not be reflected in accounting until much later. This lack of integration prevents managers from having a clear, real-time picture of their business, ultimately limiting agility and strategic responsiveness.

4. Delayed Financial Insights Leading to Poor Decision-Making

In a competitive manufacturing environment, timely access to financial insights is crucial. Relying on manual processes often means financial reports are delayed, outdated, or incomplete.

By the time data is compiled and analyzed, market conditions may have shifted, making the information less relevant. This lag in insights forces leaders to make decisions based on guesswork rather than reliable data, which can harm profitability, weaken competitiveness, and expose the company to unnecessary risks.

5. Compliance Risks and Audit Difficulties

Manufacturers must adhere to strict financial and regulatory standards, often across multiple jurisdictions. Without software to centralize and track transactions, compliance becomes a major challenge. Manual methods increase the risk of missing tax deadlines, misreporting, or failing audits due to incomplete documentation.

This not only exposes businesses to legal penalties but also damages credibility with stakeholders. Automated accounting systems simplify compliance by generating accurate records, ensuring transparency, and streamlining audits, which manual processes cannot achieve effectively.

How to Choose the Right Manufacturing Accounting Software

Selecting the right manufacturing accounting software is not a decision to be taken lightly. With numerous options available in both cloud-based and on-premise models, finding a solution that meets your company’s unique needs is critical. The right tool can streamline financial management, integrate seamlessly with production, and provide real-time visibility into your operations.

Below are key considerations to guide your decision-making process:

1. Consider Business Size and Complexity

The requirements of a small manufacturing unit are vastly different from those of a large enterprise with multiple plants. Smaller businesses may prioritize cost-effectiveness and ease of use, while larger organizations often require advanced modules such as job costing, multi-entity support, and regulatory compliance.

Assess your business model, workforce size, and production scope before choosing software. This ensures the solution aligns with your operational complexity and offers the right features without overloading you with unnecessary functions.

2. Cloud vs. On-Premise Solutions

One of the first choices you’ll face is between cloud-based and on-premise systems. Cloud solutions offer flexibility, remote access, and lower upfront costs, making them ideal for businesses seeking scalability and real-time collaboration.

On the other hand, on-premise systems provide greater control over data and customization but involve higher installation and maintenance costs. Evaluate your IT infrastructure, security needs, and budget to determine which model fits your organization’s strategic direction.

3. Scalability and Customization

Your software should grow as your business grows. A scalable solution ensures that as your production expands or diversifies, the system can handle increased transactions, new product lines, or additional plants. Look for platforms that offer add-on features, modular growth, and flexible licensing options.

Customization is equally important—manufacturers need dashboards, reports, and workflows tailored to their unique processes. The right mix of scalability and customization will future-proof your investment.

4. Integration with ERP, CRM, and Inventory Systems

Manufacturing accounting software should not operate in isolation. Seamless integration with ERP, CRM, and inventory systems eliminates data silos, reduces manual entry, and improves cross-departmental collaboration.

For example, integrating accounting with inventory allows automatic cost updates, while linking with ERP ensures unified reporting. This holistic approach provides end-to-end visibility into operations and finances, enabling smarter, data-driven decision-making across the organization.

5. User-Friendliness and Cost

Even the most feature-rich system is useless if it’s too complicated for your team to adopt. Prioritize software with intuitive interfaces, customizable dashboards, and straightforward workflows. Offering demos or trial runs can help assess usability before committing.

Alongside usability, consider the total cost of ownership—not just the license fee. Factor in training, implementation, support, and ongoing maintenance. Weigh these costs against the expected ROI to ensure long-term value.

Future Trends in Manufacturing Accounting Software

The manufacturing industry is evolving rapidly, and so is the software that supports its financial backbone. As technologies such as AI, automation, and cloud platforms reshape how businesses operate, manufacturing accounting software is becoming more intelligent, integrated, and future-ready. Companies that embrace these innovations will gain an edge in efficiency, cost control, and strategic decision-making.

Here are the key trends shaping the future of manufacturing accounting software:

1. AI and Machine Learning for Predictive Insights

Artificial intelligence and machine learning are revolutionizing accounting by enabling predictive financial modeling. Instead of just recording past transactions, advanced systems will forecast production costs, cash flows, and profitability based on historical data and real-time inputs. This trend will help manufacturers anticipate demand fluctuations, optimize budgets, and make smarter investment decisions.

2. Greater Integration with ERP and Supply Chain Platforms

Future accounting solutions will focus heavily on seamless integration with ERP, CRM, and supply chain systems. This will eliminate data silos, ensuring that financial insights are directly connected to production, inventory, and procurement data. The result is faster decision-making and more accurate cost tracking across every stage of manufacturing.

3. Cloud-First and Mobile Accessibility

With remote work and global operations becoming the norm, cloud-based accounting software will dominate. These platforms will allow financial teams and managers to access real-time data anytime, anywhere, using mobile devices. This shift ensures agility, scalability, and enhanced collaboration across geographically dispersed teams.

4. Automated Compliance and Regulatory Reporting

As compliance requirements grow more complex, accounting software will incorporate automation for tax filings, auditing, and regulatory reporting. This reduces manual effort while ensuring accuracy and adherence to global standards. Automated compliance will help manufacturers save time and minimize the risk of penalties.

5. Advanced Analytics and Visualization Tools

Future platforms will prioritize data-driven decision-making through advanced analytics and customizable dashboards. Interactive charts, KPIs, and scenario modeling will empower managers to track financial health in real time, identify bottlenecks, and test the impact of strategic decisions before implementation.

6. Sustainability and ESG Reporting Features

With growing focus on sustainability, upcoming accounting systems will include tools to track environmental, social, and governance (ESG) metrics. Manufacturers will be able to measure carbon footprints, resource usage, and waste costs alongside financial data, ensuring transparency for stakeholders and compliance with sustainability standards.

How Can Deskera Manufacturing ERP Help You?

Managing manufacturing accounting is not just about recording numbers—it’s about connecting financial data with production, inventory, and supply chain operations. Deskera Manufacturing ERP simplifies this by offering an integrated, cloud-based platform designed to help manufacturers overcome accounting challenges and streamline operations.

Here’s how Deskera can support your business:

- Seamless Integration – Connects accounting, inventory, procurement, and production modules to eliminate data silos and improve cost tracking accuracy.

- Real-Time Financial Insights – Automated dashboards and analytics provide timely, accurate data to support faster and better decision-making.

- Budgeting and Forecasting – Helps manufacturers plan resources, monitor expenses, and adapt to market fluctuations with predictive accuracy.

- Cloud Accessibility – Enables secure anytime, anywhere access via web and mobile, ensuring collaboration across teams and locations.

- AI-Powered Assistant (David) – Speeds up financial reporting, demand forecasting, and production planning with intelligent recommendations.

- Compliance and Reporting Templates – Offers pre-built tax, audit, and financial reports to streamline compliance processes.

- Sustainability Tracking – Monitors resource use and waste management, aligning financial decisions with sustainable manufacturing practices.

- Automated Journal Entries – Reduces manual bookkeeping errors with auto-generated entries for sales, purchases, and production transactions.

- Multi-Currency and Multi-Entity Support – Simplifies global operations by managing different currencies and subsidiaries in a unified system.

- Advanced Costing Features – Tracks job costing, BOM (Bill of Materials), and production costs for accurate margin analysis.

- Inventory Valuation – Supports methods like FIFO, LIFO, and weighted average for precise inventory accounting.

- Scalability – Adapts to growing business needs with modular add-ons, ensuring the system evolves as your operations expand.

- Automated Workflows – Minimizes delays and bottlenecks by automating routine approvals and transaction flows.

- Mobile Accessibility – Manage accounting, invoices, and reports on the go with Deskera’s mobile-friendly interface.

By combining automation, intelligence, and integration, Deskera Manufacturing ERP ensures that manufacturers maintain financial accuracy while staying agile, scalable, and competitive.

Key Takeaways

- Manufacturing accounting software bridges finance with operations, giving businesses better control over costs, resources, and profitability.

- Essential features like cost tracking, inventory management, financial reporting, and automation ensure accuracy and efficiency across departments.

- Businesses gain from reduced manual errors, real-time data visibility, improved compliance, cost control, and scalability for future growth.

- Relying on manual processes leads to errors, inefficiency, delayed insights, and a lack of integration between accounting and production.

- AI, automation, predictive analytics, blockchain, and cloud-based solutions are shaping the next generation of manufacturing finance.

- Deskera integrates accounting with MRP, inventory, compliance, and reporting—offering automation, real-time insights, and scalability in one platform.

Related Articles