In the intricate landscape of the food and beverage industry, where safety, quality, and compliance are paramount, the role of food and beverage ERP systems in navigating government regulations cannot be overstated. These specialized software solutions serve as indispensable tools for businesses seeking to uphold regulatory standards while efficiently managing their operations.

In this dynamic environment, where stringent government regulations govern every aspect of production, distribution, and labeling, food and beverage ERP systems emerge as vital assets, seamlessly integrating diverse functionalities to ensure compliance with regulatory mandates.

With the ever-evolving landscape of government regulations governing the food and beverage sector, businesses face the daunting task of staying abreast of the latest mandates and requirements.

Food and beverage ERP systems serve as the cornerstone of regulatory compliance in the industry, offering a cohesive platform to manage, monitor, and document adherence to government regulations.

By seamlessly integrating compliance management into core business processes, these systems enable businesses to uphold the highest standards of safety, quality, and transparency while navigating the intricate web of government regulations.

As the regulatory landscape continues to evolve, food and beverage ERP systems remain indispensable allies, empowering businesses to navigate the complexities of compliance with confidence and efficiency.

To help you better understand the role played by food and beverage ERP in navigating government regulations, the topics covered in this article are:

- What is the Food and Beverage Industry?

- Government Regulations in the Food and Beverage Industry

- Importance of Government Regulations in the Food and Beverage Industry

- What is Food and Beverage ERP?

- The Role of Food and Beverage ERP in Navigating Government Regulations

- How can Deskera Help in Navigating Government Regulations as a Food and Beverage ERP?

- Key Takeaways

- Related Articles

What is the Food and Beverage Industry?

The food and beverage industry encompasses businesses involved in the production, processing, distribution, and sale of food and drink products intended for human consumption.

This industry is vast and diverse, comprising a wide range of sectors, including agriculture, food processing, food manufacturing, packaging, distribution, retail, and food service.

Key components of the food and beverage industry include:

- Agriculture and Farming: This sector involves the cultivation of crops, raising livestock, and harvesting raw materials used in food production. Agriculture contributes to the supply chain by providing ingredients such as fruits, vegetables, grains, meats, and dairy products.

- Food Processing and Manufacturing: Food processing facilities transform raw agricultural materials into packaged food and beverage products. This sector includes activities such as milling, baking, canning, freezing, pasteurizing, and bottling, which enhance the safety, shelf life, and convenience of food products.

- Packaging and Labeling: Packaging companies produce containers, wrappers, bottles, and labels used to package and market food and beverage products. Packaging plays a crucial role in protecting products from contamination, maintaining freshness, and conveying information to consumers.

- Distribution and Logistics: Distribution companies transport food and beverage products from manufacturers to retailers, wholesalers, and food service establishments. Logistics operations involve warehouse management, inventory management, transportation, and supply chain optimization to ensure timely delivery and efficient distribution of products.

- Retail and Food Service: Retail outlets such as grocery stores, supermarkets, convenience stores, and specialty food shops sell food and beverage products directly to consumers. Food service establishments, including restaurants, cafes, bars, and catering businesses, offer prepared meals, beverages, and dining experiences to customers.

- Regulatory Compliance and Food Safety: Regulatory agencies oversee the food and beverage industry to ensure compliance with food safety standards, labeling requirements, quality assurance protocols, and industry regulations. These agencies conduct inspections, enforce regulations, and address food safety concerns to protect public health and consumer interests.

- Research and Development: Research institutions, laboratories, and food science organizations conduct research and development activities to innovate new food products, improve production processes, and address emerging trends and consumer preferences in the food and beverage industry.

Overall, the food and beverage industry is a vital sector of the global economy, providing essential goods and services to consumers worldwide. It encompasses a wide range of activities, from agricultural production to retail sales, and plays a significant role in shaping dietary habits, culinary culture, and economic development.

Government Regulations in the Food and Beverage Industry

Government regulations in the food and beverage industry are put in place to ensure the safety, quality, and integrity of food products, as well as to protect consumer health and well-being. These regulations cover various aspects of the production, processing, distribution, and sale of food and beverage products.

Some of the key areas regulated by government authorities include:

- Food Safety Standards: Government regulations establish food safety standards to prevent contamination, foodborne illnesses, and other hazards. These standards encompass guidelines for handling, storage, and preparation of food, as well as requirements for sanitation, hygiene, and pest control in food facilities.

- Labeling and Packaging Requirements: Regulations mandate accurate labeling of food and beverage products to provide consumers with essential information about ingredients, nutritional content, allergens, expiration dates, and country of origin. Labeling requirements also include guidelines for packaging materials and labeling claims such as organic, natural, or GMO-free.

- Quality Assurance and Testing: Government regulations establish requirements for quality assurance programs and product testing to ensure that food and beverage products meet specified standards for taste, texture, appearance, and nutritional value. These regulations may include sampling protocols, laboratory testing methods, and quality control measures to maintain product consistency and integrity.

- Ingredient Approval and Additive Usage: Regulations govern the approval and usage of ingredients, additives, and processing aids in food and beverage products. Authorities assess the safety, suitability, and regulatory status of ingredients before approving their use in food production. Additionally, regulations specify permissible levels of food additives and prohibit the use of certain harmful substances.

- Food Processing and Manufacturing Practices: Government regulations establish Good Manufacturing Practices (GMP) and Hazard Analysis and Critical Control Points (HACCP) guidelines to ensure the safety and quality of food processing and manufacturing operations. These regulations cover processes such as pasteurization, sterilization, refrigeration, and packaging to minimize the risk of contamination and ensure product safety.

- Allergen Control and Cross-Contamination Prevention: Regulations address allergen control measures to protect consumers with food allergies or sensitivities. Food facilities are required to implement procedures to prevent cross-contact between allergens and non-allergenic ingredients during production, packaging, and labeling processes.

- Supply Chain Management and Traceability: Regulations mandate traceability and record-keeping requirements to enable the identification and tracking of food and beverage products throughout the supply chain. This includes maintaining records of suppliers, production batches, distribution channels, and product shipments to facilitate recalls, investigations, and regulatory compliance.

- Food Import and Export Regulations: Governments impose regulations on the import and export of food and beverage products to ensure compliance with local standards and international trade agreements. These regulations include inspection procedures, documentation requirements, and import/export restrictions to safeguard public health and prevent the spread of diseases.

Overall, government regulations play a crucial role in safeguarding the integrity of the food and beverage industry, promoting consumer confidence, and protecting public health. Businesses operating in this sector must adhere to regulatory requirements to ensure compliance and mitigate risks associated with non-compliance.

Importance of Government Regulations in the Food and Beverage Industry

Government regulations play a vital role in the food and beverage industry due to their significance in ensuring public health, safety, and consumer confidence.

Here are several key reasons highlighting the importance of government regulations in this sector:

- Food Safety Assurance: Government regulations establish stringent standards and guidelines to ensure the safety of food and beverage products. These regulations cover various aspects of food production, processing, handling, and distribution to prevent contamination, foodborne illnesses, and outbreaks of foodborne diseases. By enforcing measures such as hygiene practices, sanitation standards, and microbial testing, regulations help safeguard public health and reduce the risk of foodborne hazards.

- Consumer Protection: Regulations in the food and beverage industry aim to protect consumers by providing accurate and transparent information about products. Labeling regulations mandate the disclosure of essential information such as ingredient lists, nutritional content, allergen warnings, and expiration dates, enabling consumers to make informed choices and avoid potential health risks. Additionally, regulations prohibit deceptive labeling practices and false advertising to prevent consumer deception and fraud.

- Quality Standards: Government regulations establish quality standards and requirements to ensure the integrity and consistency of food and beverage products. These standards encompass criteria such as taste, texture, appearance, freshness, and nutritional value, aiming to maintain product quality and meet consumer expectations. By setting minimum quality thresholds and enforcing compliance with industry standards, regulations help uphold product quality and integrity across the supply chain.

- Market Fairness and Competition: Regulations promote fair competition and market fairness in the food and beverage industry by preventing monopolistic practices, unfair trade practices, and anti-competitive behavior. Regulatory agencies monitor market activities, enforce antitrust laws, and investigate allegations of price-fixing, collusion, or unfair business practices to ensure a level playing field for businesses and protect consumer interests.

- Environmental Sustainability: Regulations address environmental concerns related to food production, packaging, and waste management to promote sustainability and environmental stewardship. These regulations may include requirements for sustainable sourcing practices, eco-friendly packaging materials, waste reduction strategies, and energy-efficient production methods. By promoting environmentally responsible practices, regulations help mitigate the environmental impact of the food and beverage industry and support long-term sustainability goals.

- Public Trust and Confidence: Government regulations play a crucial role in building and maintaining public trust and confidence in the food and beverage industry. By enforcing strict standards, monitoring compliance, and addressing safety concerns, regulations reassure consumers that food products are safe, reliable, and of high quality. Public trust in regulatory oversight fosters consumer confidence in the safety and integrity of the food supply, contributing to overall market stability and consumer satisfaction.

- Emergency Response and Crisis Management: Regulations provide a framework for emergency response and crisis management in the event of food safety incidents, outbreaks, or public health emergencies. Regulatory agencies collaborate with industry stakeholders to develop protocols for risk assessment, communication, and mitigation strategies during crises. By implementing coordinated response efforts and facilitating rapid interventions, regulations help minimize the impact of emergencies on public health and safety.

Overall, government regulations play a crucial role in ensuring the safety, quality, and integrity of the food and beverage industry while promoting consumer protection, market fairness, environmental sustainability, and public trust.

Compliance with regulatory requirements is essential for businesses to maintain operational integrity, protect public health, and sustain consumer confidence in the food products they produce and distribute.

What is Food and Beverage ERP?

A food and beverage ERP system is a specialized software solution designed to meet the unique needs and challenges of businesses operating in the food and beverage industry.

It integrates various functions and processes across the entire supply chain, from raw material procurement to distribution and sales, providing a comprehensive platform for managing key aspects of operations.

Food and beverage ERP systems offer features tailored to the specific requirements of the industry, including recipe management, batch tracking, inventory control, quality assurance, regulatory compliance, and traceability.

One of the primary functions of a food and beverage ERP system is to streamline and optimize production processes. These systems facilitate recipe and formulation management, allowing businesses to create, store, and manage recipes with precision.

With features for ingredient sourcing, costing, and supplier management, manufacturing ERP systems help businesses ensure consistency in product quality while managing costs effectively.

Additionally, food and beverage ERP systems enable batch tracking and traceability, allowing businesses to monitor the movement of raw materials and finished products throughout the supply chain, comply with regulatory requirements, and respond promptly to quality control issues or recalls.

Food and beverage ERP systems also play a crucial role in ensuring compliance with government regulations and industry standards. These systems incorporate features for regulatory compliance management, including labeling requirements, allergen tracking, and documentation of audit trails.

By automating compliance processes and providing real-time visibility into regulatory requirements, MRP software systems help businesses navigate complex regulatory landscapes and minimize the risk of non-compliance.

Overall, food and beverage ERP systems serve as central hubs for managing critical business functions, promoting operational efficiency, enhancing product quality, and ensuring compliance with industry regulations in the dynamic and competitive food and beverage market.

The Role of Food and Beverage ERP in Navigating Government Regulations

Food and beverage ERP systems are instrumental in helping businesses navigate the complex landscape of government regulations. Here's a detailed look at their role:

Traceability and Batch Tracking

Traceability and batch tracking are essential components of MRP software systems, playing a pivotal role in ensuring compliance with government regulations.

These functionalities enable businesses to trace the journey of products throughout the supply chain, from raw materials to the end consumer.

Let's delve deeper into how food and beverage ERP systems facilitate traceability and batch tracking in the context of navigating government regulations.

- Comprehensive Tracking Capabilities: Food and beverage ERP systems are equipped with robust tracking mechanisms that capture data at every stage of production, processing, and distribution. This includes recording information about the origin of raw materials, manufacturing processes, and final product destinations. By meticulously documenting these details, businesses can demonstrate compliance with regulatory requirements concerning product sourcing, handling, and distribution.

- Regulatory Reporting Requirements: Government regulations mandate strict reporting standards, particularly in the food and beverage industry, where consumer safety is paramount. Manufacturing ERP systems streamline compliance by automatically generating reports that align with regulatory guidelines. These reports provide authorities with comprehensive insights into product traceability, batch histories, and adherence to safety standards. By leveraging the capabilities of manufacturing software systems, businesses can efficiently meet reporting obligations and avoid penalties associated with non-compliance.

- Facilitating Product Recalls: In the event of a product recall, swift and accurate traceability is critical for identifying affected batches and minimizing the potential impact on consumers. Food and beverage ERP systems excel in this regard, enabling businesses to trace the precise origin of ingredients, track production batches, and identify distribution channels. By swiftly pinpointing the source of contamination or safety concerns, companies can execute targeted recalls, thereby demonstrating proactive compliance with government regulations and safeguarding public health.

- Enhanced Supply Chain Transparency: Transparency across the supply chain is paramount for ensuring compliance with government regulations. Manufacturing software systems offer unparalleled visibility into supply chain operations, allowing businesses to monitor and track the movement of ingredients and products in real time. This transparency not only facilitates regulatory compliance but also fosters trust among consumers, who increasingly demand insights into the origins and handling of the products they purchase.

- Integration with Regulatory Standards: Food and beverage ERP systems are designed to seamlessly integrate with regulatory standards and requirements. This integration ensures that traceability and batch-tracking functionalities align with the specific regulations governing the industry. By adhering to standardized protocols for data capture, documentation, and reporting, businesses can navigate government regulations with confidence, knowing that their manufacturing ERP system serves as a reliable ally in compliance efforts.

In summary, manufacturing ERP systems play a crucial role in facilitating traceability and batch tracking, thereby enabling businesses to navigate government regulations effectively.

By leveraging these capabilities, companies can uphold the highest standards of safety, transparency, and compliance, earning the trust of both regulatory authorities and consumers in the process.

Quality Management

Quality management is a cornerstone of regulatory compliance in the food and beverage industry, and food and beverage ERP systems play a pivotal role in ensuring adherence to government regulations.

Let's explore how these systems facilitate quality management and aid in navigating government regulations:

- Standardized Quality Assurance Processes: Food and beverage ERP systems streamline and standardize quality assurance processes, ensuring that products meet regulatory standards consistently. These systems enable businesses to define and enforce quality control measures across all stages of production, from ingredient sourcing to final packaging. By establishing standardized procedures for inspections, testing, and documentation, MRP software systems help companies demonstrate compliance with government regulations governing product quality and safety.

- Adherence to Regulatory Standards: Government regulations set stringent requirements for food and beverage manufacturers regarding product quality, hygiene, and safety. Manufacturing software systems are designed to align with these regulations, providing functionalities that support compliance efforts. These systems facilitate the implementation of Good Manufacturing Practices (GMP), Hazard Analysis and Critical Control Points (HACCP), and other regulatory frameworks, ensuring that products meet the highest quality standards mandated by authorities.

- Real-Time Quality Monitoring: Food and beverage ERP systems offer real-time monitoring capabilities that allow businesses to track quality metrics throughout the production process. By collecting data on key quality indicators such as temperature, pH levels, and microbial contamination, these systems enable proactive intervention to prevent quality deviations. Real-time alerts and notifications ensure that any issues affecting product quality are promptly addressed, minimizing the risk of non-compliance with government regulations.

- Documentation and Compliance Reporting: Documentation is a crucial aspect of quality management and regulatory compliance in the food and beverage industry. MRP software systems facilitate the generation, storage, and retrieval of quality-related documents, including inspection reports, test results, and compliance certificates. These systems automate the creation of compliance reports required by government authorities, ensuring that businesses can demonstrate adherence to regulatory standards with ease during audits or inspections.

- Supplier Quality Management: The quality of raw materials and ingredients directly impacts the final product's quality and compliance with government regulations. Food and beverage ERP systems include features for supplier quality management, enabling businesses to evaluate, monitor, and certify suppliers based on their adherence to quality standards. By maintaining comprehensive supplier records and conducting regular audits, companies can ensure a consistent supply of high-quality ingredients, thereby enhancing overall regulatory compliance.

- Continuous Improvement Initiatives: Continuous improvement is essential for maintaining compliance with evolving government regulations and industry standards. Manufacturing ERP systems support continuous improvement initiatives by providing tools for data analysis, performance tracking, and corrective action management. By identifying trends, root causes of quality issues, and opportunities for optimization, these systems empower businesses to proactively enhance their processes and products to meet regulatory requirements more effectively.

In conclusion, food and beverage ERP systems play a vital role in quality management and regulatory compliance efforts.

By providing robust tools for standardizing processes, monitoring quality in real-time, documenting compliance activities, managing supplier quality, and driving continuous improvement, these systems help businesses navigate government regulations with confidence and ensure the delivery of safe and high-quality products to consumers.

Compliance Documentation

Compliance documentation is a critical aspect of navigating government regulations in the food and beverage industry, and food and beverage ERP systems are instrumental in facilitating this process.

Let's delve deeper into how these systems aid in compliance documentation and help businesses meet regulatory requirements:

- Automated Documentation Generation: Food and Beverage ERP systems streamline the creation of compliance documentation by automating the generation of reports, certificates, and other necessary paperwork. These systems are equipped with templates and pre-configured formats that align with government regulations, ensuring consistency and accuracy in documentation. By eliminating manual data entry and paperwork, MRP software systems save time and reduce the risk of errors in compliance documentation.

- Centralized Data Repository: Food and beverage ERP systems serve as centralized repositories for compliance-related data, storing information such as ingredient lists, nutritional information, production records, and certification documents. This centralized approach ensures that all relevant documentation is readily accessible to authorized personnel, facilitating efficient retrieval and sharing of information during regulatory inspections or audits. By maintaining a comprehensive and organized database of compliance documentation, businesses can demonstrate adherence to government regulations with ease.

- Version Control and Audit Trails: Version control features in manufacturing software systems ensure the integrity and traceability of compliance documentation. These systems maintain detailed audit trails that track changes made to documents, recording the date, time, and user responsible for each modification. Audit trails provide transparency and accountability, allowing businesses to trace the evolution of compliance documentation and verify the accuracy of information presented to regulatory authorities.

- Integration with Regulatory Standards: Food and Beverage ERP systems are designed to integrate seamlessly with regulatory standards and requirements. These systems incorporate built-in compliance checks and validations, ensuring that documentation meets the specific criteria outlined by government regulations. By aligning with standardized protocols for labeling, packaging, and product information, manufacturing ERP systems help businesses avoid non-compliance issues and mitigate the risk of regulatory penalties.

- Streamlined Reporting Processes: Reporting is a key aspect of compliance documentation, requiring businesses to submit periodic reports to regulatory authorities. Food and beverage ERP systems streamline the reporting process by aggregating data from various sources and generating comprehensive reports in the required format. These systems automate report generation tasks, reducing the administrative burden on staff and ensuring timely submission of compliance documentation to government agencies.

- Customizable Document Templates: Food and beverage ERP systems offer customizable document templates that can be tailored to meet specific regulatory requirements or industry standards. Businesses can configure these templates to include mandatory information such as allergen declarations, nutritional facts, and product certifications. By adapting document templates to reflect the latest regulatory changes or market trends, MRP software systems help businesses stay compliant and responsive to evolving government regulations.

In summary, food and beverage ERP systems play a crucial role in managing compliance documentation and navigating government regulations effectively.

By automating documentation generation, maintaining centralized data repositories, ensuring version control and audit trails, integrating with regulatory standards, streamlining reporting processes, and offering customizable document templates, these systems empower businesses to demonstrate adherence to regulatory requirements with confidence and precision.

Recipe and Formulation Management

Recipe and formulation management are integral components of food and beverage ERP systems, playing a crucial role in navigating government regulations in the industry.

Here's how these systems facilitate recipe and formulation management to ensure compliance:

- Standardized Formulation Processes: Food and beverage ERP systems standardize formulation processes by providing tools to create, store, and manage recipes according to government regulations. These systems ensure that formulations comply with regulatory requirements related to ingredient usage, proportions, and permissible additives. By enforcing standardized formulation processes, manufacturing ERP systems help businesses maintain consistency in product quality and meet regulatory standards consistently.

- Ingredient Compliance Checks: Food and beverage ERP systems incorporate ingredient compliance checks to verify the suitability of raw materials and additives used in formulations. These checks ensure that ingredients meet regulatory specifications regarding safety, quality, and permissible usage levels. By flagging non-compliant ingredients or formulations, MRP software systems enable businesses to make informed decisions and avoid potential regulatory violations.

- Allergen Management: Government regulations mandate clear labeling of allergens in food and beverage products to protect consumers with allergies. Food and beverage ERP systems assist in managing allergen information by tracking the presence of allergens in ingredients and formulations. These systems enable businesses to generate accurate allergen declarations for labeling purposes, ensuring compliance with regulatory requirements and safeguarding consumer health.

- Nutritional Analysis and Labeling: Food and beverage ERP systems include features for nutritional analysis and labeling, allowing businesses to calculate and display nutritional information accurately. Government regulations often stipulate specific labeling requirements for nutrients such as calories, fat, carbohydrates, and vitamins. Manufacturing ERP systems automate nutritional analysis based on formulation data, ensuring that product labels comply with regulatory standards and provide consumers with transparent information about nutritional content.

- Version Control and Change Management: Recipe and formulation management modules in food and beverage ERP systems include version control and change management functionalities to track revisions and updates to formulations. These features maintain a complete audit trail of formulation changes, recording the date, time, and user responsible for each modification. By ensuring traceability and accountability, manufacturing software systems help businesses demonstrate compliance with government regulations governing formulation management and document control.

- Regulatory Approval Workflows: Food and beverage ERP systems streamline regulatory approval workflows for new formulations or changes to existing recipes. These systems facilitate collaboration between cross-functional teams involved in formulation development, quality assurance, and regulatory compliance. By automating approval processes and documenting regulatory review activities, manufacturing ERP systems ensure that formulations undergo rigorous scrutiny before reaching the market, reducing the risk of non-compliance with government regulations.

- Global Regulatory Compliance: Food and beverage ERP systems support global regulatory compliance by accommodating regional variations in government regulations. These systems enable businesses to configure formulations and labeling requirements according to the regulatory standards of target markets. By facilitating compliance with diverse regulatory frameworks, MRP software systems help businesses expand their international presence while adhering to local laws and regulations.

In summary, food and beverage ERP systems play a crucial role in managing recipe and formulation data to ensure compliance with government regulations.

By standardizing formulation processes, conducting ingredient compliance checks, managing allergen information, facilitating nutritional analysis and labeling, implementing version control and change management, streamlining regulatory approval workflows, and supporting global regulatory compliance, these systems empower businesses to navigate complex regulatory requirements with confidence and precision.

Inventory Management

Inventory management is a critical aspect of navigating government regulations in the food and beverage industry, and food and beverage ERP systems play a pivotal role in ensuring compliance.

Here's how these systems facilitate inventory management to meet regulatory requirements:

- Accurate Tracking of Raw Materials and Ingredients: Food and beverage ERP systems enable businesses to accurately track the movement of raw materials and ingredients throughout the supply chain. These systems record key information such as batch numbers, expiration dates, and supplier details, ensuring full traceability. By maintaining precise records of inventory levels and ingredient usage, manufacturing ERP systems help businesses comply with government regulations governing inventory control and traceability.

- Compliance with Shelf-Life Regulations: Government regulations often impose strict requirements regarding the shelf life and expiration dates of food and beverage products. Food and beverage ERP systems include features to monitor shelf-life data and expiration dates for inventory items. These systems generate alerts and notifications when products approach their expiration dates, enabling businesses to take timely action such as rotation, disposal, or sale of expiring inventory to prevent non-compliance with regulatory standards.

- Temperature and Storage Compliance: Some food and beverage products require specific temperature-controlled storage conditions to maintain freshness and safety. Food and beverage ERP systems integrate with temperature monitoring devices and sensors to ensure compliance with storage regulations. These systems track temperature data in real time, alerting businesses to any deviations from prescribed storage conditions. By maintaining optimal storage conditions, MRP software systems help businesses uphold product quality and meet regulatory requirements.

- Inventory Documentation and Reporting: Food and beverage ERP systems automate the documentation and reporting of inventory-related data for regulatory compliance purposes. These systems generate comprehensive reports on inventory levels, transactions, and stock movements, providing visibility into inventory management practices. By maintaining accurate and up-to-date inventory records, manufacturing software systems help businesses demonstrate compliance with government regulations during audits or inspections.

- Allergen and Ingredient Labeling Compliance: Inventory management in food and beverage ERP systems extends to the tracking of allergens and ingredients used in product formulations. These systems ensure that inventory items are properly labeled with allergen information and ingredient lists, as required by government regulations. By accurately documenting the presence of allergens and ingredients in inventory items, manufacturing ERP systems help businesses meet labeling compliance standards and protect consumer health.

- Regulatory Reporting and Audit Preparedness: Food and beverage ERP systems streamline regulatory reporting processes by consolidating inventory data and generating compliance reports. These reports include information on inventory levels, stock movements, and inventory valuation, which are essential for regulatory compliance. By facilitating the preparation of regulatory reports and maintaining detailed audit trails, MRP software systems help businesses demonstrate compliance with government regulations and ensure readiness for regulatory audits.

- Integration with Compliance Standards: Food and Beverage ERP systems are designed to integrate seamlessly with compliance standards and regulatory requirements. These systems incorporate built-in checks and validations to ensure that inventory management practices align with government regulations. By adhering to standardized protocols for inventory control and documentation, manufacturing software systems help businesses avoid non-compliance issues and mitigate the risk of regulatory penalties.

In summary, food and beverage ERP systems play a vital role in inventory management to ensure compliance with government regulations.

By enabling accurate tracking of inventory, compliance with shelf-life and storage regulations, documentation and reporting of inventory data, allergen and ingredient labeling compliance, regulatory reporting, audit preparedness, and integration with compliance standards, these systems empower businesses to navigate regulatory requirements with efficiency and confidence.

Supply Chain Visibility

Supply chain visibility is crucial for navigating government regulations in the food and beverage industry, and food and beverage ERP systems play a significant role in facilitating this visibility.

Here's how these systems contribute to supply chain visibility and help businesses meet regulatory requirements:

- End-to-end Traceability: Food and beverage ERP systems provide end-to-end traceability across the supply chain, enabling businesses to track the movement of raw materials, ingredients, and finished products. These systems capture data at each stage of the supply chain, from procurement to distribution, ensuring full visibility into product origins, handling, and transportation. By maintaining comprehensive traceability records, manufacturing ERP systems help businesses comply with government regulations governing product traceability and recall management.

- Real-Time Monitoring and Alerts: Food and beverage ERP systems offer real-time monitoring capabilities that allow businesses to track the status and location of inventory items throughout the supply chain. These systems integrate with sensors, IoT devices, and other technologies to capture data on factors such as temperature, humidity, and transportation conditions. By analyzing real-time data and generating alerts for deviations from prescribed parameters, MRP software systems enable businesses to proactively address issues and ensure compliance with regulatory standards for product safety and quality.

- Batch Tracking and Identification: Food and beverage ERP systems facilitate batch tracking and identification, allowing businesses to trace specific batches of products back to their source. These systems assign unique identifiers to each batch and capture data on production processes, ingredients used, and quality control measures implemented. By maintaining accurate batch records and documentation, manufacturing software systems help businesses comply with government regulations requiring batch traceability for product recalls, quality control, and regulatory reporting purposes.

- Supplier and Vendor Management: Food and beverage ERP systems include features for managing supplier and vendor relationships, providing visibility into supplier performance, reliability, and compliance with regulatory requirements. These systems maintain supplier records, certifications, and compliance documents, enabling businesses to assess and verify supplier compliance with government regulations. By conducting regular audits and assessments of suppliers, manufacturing ERP systems help businesses ensure the integrity and safety of raw materials and ingredients sourced from external partners.

- Risk Management and Mitigation: Food and beverage ERP systems support risk management and mitigation strategies by identifying potential risks and vulnerabilities within the supply chain. These systems analyze data on supplier reliability, transportation routes, and inventory levels to assess the likelihood of supply chain disruptions or compliance issues. By identifying high-risk areas and implementing proactive measures such as alternate sourcing or safety stock management, MRP software systems help businesses mitigate risks and maintain continuity of operations while complying with government regulations.

- Regulatory Compliance Reporting: Food and beverage ERP systems streamline regulatory compliance reporting by consolidating supply chain data and generating compliance reports in the required format. These reports include information on supply chain activities, inventory levels, transportation logistics, and supplier compliance status. By automating the generation and submission of compliance reports to government authorities, manufacturing software systems help businesses demonstrate adherence to regulatory requirements and ensure transparency in supply chain operations.

In summary, food and beverage ERP systems play a vital role in enhancing supply chain visibility and ensuring compliance with government regulations.

By providing end-to-end traceability, real-time monitoring and alerts, batch tracking and identification, supplier and vendor management, risk management and mitigation, and regulatory compliance reporting, these systems empower businesses to navigate complex regulatory requirements with efficiency, accuracy, and transparency.

Regulatory Reporting

Regulatory reporting is a critical aspect of navigating government regulations in the food and beverage industry, and food and beverage ERP systems play a crucial role in streamlining this process.

Here's how these systems contribute to regulatory reporting and help businesses meet compliance requirements:

- Automated Report Generation: Food and beverage ERP systems automate the generation of regulatory reports required by government authorities. These systems consolidate data from various sources, including production, inventory, quality control, and supply chain management modules, to create comprehensive reports. By eliminating manual data entry and processing, manufacturing ERP systems save time and reduce the risk of errors in regulatory reporting.

- Standardized Reporting Formats: Government regulations often specify standardized formats for regulatory reports, such as product safety reports, quality assurance records, and compliance certificates. MRP software systems include pre-configured templates and reporting formats that align with regulatory requirements. These templates ensure consistency and accuracy in reporting, making it easier for businesses to comply with government regulations and submit reports in the required format.

- Integration with Regulatory Databases: Food and beverage ERP systems integrate with regulatory databases and information systems to facilitate regulatory reporting. These integrations enable businesses to access up-to-date regulatory information, including reporting requirements, deadlines, and submission procedures. By leveraging data from regulatory databases, manufacturing software systems ensure that regulatory reports are accurate, relevant, and compliant with current regulations.

- Real-Time Data Capture and Analysis: Food and beverage ERP systems capture real-time data on production, inventory, quality, and compliance activities, providing businesses with timely insights for regulatory reporting. These systems analyze data trends, identify compliance issues, and generate alerts for potential deviations from regulatory requirements. By monitoring key performance indicators and compliance metrics in real-time, manufacturing ERP systems enable businesses to proactively address regulatory concerns and ensure accurate reporting.

- Audit Trail Documentation: Food and beverage ERP systems maintain detailed audit trails that document every step of the regulatory reporting process. These audit trails record the date, time, and user responsible for each report submission, modification, or approval. By maintaining a comprehensive record of regulatory reporting activities, MRP software systems provide transparency and accountability, facilitating compliance with government regulations and regulatory audits.

- Customizable Reporting Parameters: Food and beverage ERP systems offer customizable reporting parameters that allow businesses to tailor reports to specific regulatory requirements or industry standards. These systems enable users to select relevant data fields, filters, and criteria for regulatory reporting purposes. By customizing reporting parameters, businesses can ensure that regulatory reports contain the necessary information to demonstrate compliance with government regulations and address specific regulatory concerns.

In summary, food and beverage ERP systems play a vital role in regulatory reporting, enabling businesses to comply with government regulations efficiently and accurately.

By automating report generation, standardizing reporting formats, integrating with regulatory databases, capturing real-time data, documenting audit trails, and offering customizable reporting parameters, these systems empower businesses to navigate regulatory requirements with confidence and ease.

Audit Trail

Audit trails are a fundamental feature of food and beverage ERP systems that play a crucial role in ensuring compliance with government regulations.

Here's how audit trails contribute to navigating government regulations in the food and beverage industry:

- Comprehensive Documentation of Activities: Food and beverage ERP systems maintain comprehensive audit trails that document every activity and transaction within the system. These audit trails capture details such as user actions, timestamps, and the nature of changes made to data or configurations. By recording a detailed history of system interactions, manufacturing ERP audit trails provide transparency and accountability, facilitating compliance with government regulations that require documentation of operational activities.

- Traceability of Changes: Audit trails in food and beverage ERP systems enable businesses to trace changes made to critical data elements, such as product formulations, inventory levels, and compliance documentation. Each change is logged with information about who made the change, when it was made, and the specific nature of the modification. This traceability helps businesses demonstrate compliance with government regulations governing data integrity, accuracy, and transparency.

- Regulatory Audit Preparation: Government regulations often mandate periodic audits of food and beverage businesses to ensure compliance with regulatory requirements. Audit trails in MRP software systems serve as valuable resources during regulatory audits, providing auditors with a detailed record of system activities and data modifications. By presenting comprehensive audit trail documentation, businesses can demonstrate adherence to regulatory standards and facilitate the audit process.

- Proof of Compliance: Audit trails serve as evidence of compliance with government regulations, providing documented proof of adherence to regulatory requirements. Businesses can use audit trail data to demonstrate that appropriate controls are in place to prevent unauthorized access, mitigate risks, and maintain data integrity. By presenting audit trail records as part of compliance documentation, businesses can verify their commitment to regulatory compliance and regulatory authorities' trust.

- Identification of Compliance Issues: Food and beverage ERP audit trails help businesses identify potential compliance issues or deviations from regulatory requirements. By analyzing audit trail data, businesses can detect anomalies, unauthorized activities, or unusual patterns of system usage that may indicate non-compliance. Prompt identification of compliance issues enables businesses to take corrective action, address root causes, and prevent regulatory violations before they escalate.

- Continuous Improvement Initiatives: Audit trails support continuous improvement initiatives by providing insights into system usage, performance, and compliance-related activities. Businesses can analyze audit trail data to identify opportunities for optimization, enhance internal controls, and strengthen compliance processes. By leveraging audit trail information to drive continuous improvement, businesses can proactively address regulatory requirements and adapt to evolving government regulations.

In summary, audit trails in manufacturing software systems are invaluable tools for navigating government regulations in the food and beverage industry.

By maintaining comprehensive documentation of activities, facilitating traceability of changes, preparing for regulatory audits, providing proof of compliance, identifying compliance issues, and supporting continuous improvement initiatives, food and beverage ERP audit trails help businesses demonstrate adherence to regulatory requirements and ensure transparency, accountability, and integrity in their operations.

Automatic Updates for Regulatory Changes

Automatic updates for regulatory changes are a critical feature of food and beverage ERP systems, ensuring businesses stay compliant with evolving government regulations.

Here's how this functionality contributes to navigating government regulations in the food and beverage industry:

- Real-Time Compliance Monitoring: Food and beverage ERP systems are equipped with features that monitor regulatory changes in real time. These systems continuously scan regulatory databases and government websites for updates, alerts, and announcements related to food and beverage regulations. By staying abreast of regulatory changes as they occur, manufacturing ERP systems enable businesses to proactively adapt their processes and practices to remain compliant.

- Timely Notification of Updates: Food and beverage ERP systems automatically notify relevant stakeholders within the organization about regulatory changes that may impact operations. These notifications include details such as the nature of the regulatory update, its implications for the business, and any actions required to ensure compliance. By providing timely notifications, manufacturing software systems empower businesses to stay informed and take proactive measures to address regulatory changes promptly.

- Impact Assessment and Analysis: Upon receiving updates on regulatory changes, food and beverage ERP systems facilitate impact assessment and analysis to evaluate the potential effects on business operations. These systems analyze the impact of regulatory changes on processes, products, supply chains, and compliance requirements. By conducting thorough assessments, MRP software systems help businesses understand the implications of regulatory updates and develop strategies to mitigate risks and maintain compliance.

- Automated Compliance Updates: Food and beverage ERP systems automate the process of implementing compliance updates in response to regulatory changes. These systems update relevant modules, templates, and configurations to align with the latest regulatory requirements. By automatically applying compliance updates, manufacturing ERP systems ensure that businesses adhere to current regulations without manual intervention, reducing the risk of non-compliance and associated penalties.

- Documentation of Regulatory Changes: Food and beverage ERP systems maintain documentation of regulatory changes and updates for audit and compliance purposes. These systems record details such as the date, source, and nature of regulatory updates, as well as the actions taken by the organization to address them. By documenting regulatory changes, manufacturing software systems provide a transparent record of compliance efforts, demonstrating diligence and adherence to regulatory requirements during audits or inspections.

- Integration with Compliance Resources: Food and beverage ERP systems integrate with external compliance resources, such as regulatory databases, industry publications, and legal sources. These integrations provide access to a wealth of regulatory information, including updates, interpretations, and guidance documents. By leveraging external compliance resources, MRP software systems enhance their ability to track and respond to regulatory changes effectively, ensuring continuous compliance with government regulations.

In summary, automatic updates for regulatory changes are essential features of food and beverage ERP systems that help businesses navigate government regulations with agility and confidence.

By enabling real-time compliance monitoring, timely notification of updates, impact assessment and analysis, automated compliance updates, documentation of regulatory changes, and integration with compliance resources, manufacturing ERP systems empower businesses to stay compliant with evolving regulatory requirements and maintain a competitive edge in the marketplace.

Recall Management

Recall management is a critical aspect of navigating government regulations in the food and beverage industry, and food and beverage ERP systems play a crucial role in facilitating this process.

Here's how these systems contribute to recall management and help businesses meet regulatory requirements:

- End-to-end Traceability: Food and beverage ERP systems provide end-to-end traceability of products throughout the supply chain, enabling businesses to quickly identify and trace the source of contaminated or unsafe products. These systems capture detailed data on ingredients, production processes, and distribution channels, facilitating rapid recall management in compliance with government regulations.

- Batch Tracking and Identification: Food and beverage ERP systems enable businesses to track and identify specific batches of products affected by a recall. By assigning unique identifiers to each batch and maintaining accurate batch records, manufacturing ERP systems streamline the recall process and ensure precise identification of affected products. This level of batch tracking and identification is essential for complying with government regulations governing recall management.

- Real-Time Notification and Alerts: Food and beverage ERP systems offer real-time notification and alert functionalities that notify stakeholders about potential recall incidents as soon as they occur. These systems monitor key indicators such as quality control parameters, customer complaints, and regulatory alerts to trigger immediate action in response to safety concerns or compliance issues. By providing timely notifications, manufacturing software systems facilitate prompt recall management in accordance with government regulations.

- Automated Recall Procedures: Food and beverage ERP systems automate recall procedures to expedite the process of removing unsafe products from the market and mitigating potential risks to consumers. These systems enable businesses to initiate recall actions, notify relevant parties, and coordinate recall activities seamlessly. By automating recall procedures, MRP software systems help businesses comply with government regulations requiring swift and effective recall management in response to safety incidents or regulatory non-compliance.

- Communication and Coordination: Food and beverage ERP systems facilitate communication and coordination among internal teams, external partners, and regulatory authorities during the recall process. These systems provide centralized platforms for sharing information, coordinating response efforts, and documenting recall activities. By fostering collaboration and transparency, manufacturing ERP systems ensure efficient recall management and compliance with government regulations governing communication and coordination in recall situations.

- Documentation and Reporting: Food and beverage ERP systems maintain detailed documentation of recall activities, including communication logs, action plans, and audit trails. These systems generate comprehensive reports on recall incidents, response efforts, and outcomes for regulatory reporting purposes. By documenting recall activities and outcomes, MRP software systems help businesses demonstrate compliance with government regulations and provide evidence of effective recall management practices.

In summary, food and beverage ERP systems play a vital role in recall management, enabling businesses to comply with government regulations and protect consumer safety.

By providing end-to-end traceability, batch tracking and identification, real-time notification and alerts, automated recall procedures, communication and coordination tools, and documentation and reporting capabilities, manufacturing software systems empower businesses to navigate recall situations with efficiency, accuracy, and compliance.

How can Deskera Help in Navigating Government Regulations as a Food and Beverage ERP?

Deskera, as a food and beverage ERP solution, can play a significant role in helping businesses navigate government regulations in several ways:

- Regulatory Compliance Monitoring: Deskera ERP can monitor and track changes in government regulations relevant to the food and beverage industry. By providing real-time updates and alerts on regulatory changes, Deskera ensures that businesses stay informed about new mandates and requirements, allowing them to adapt their processes accordingly to maintain compliance.

- Automated Compliance Management: Deskera ERP automates compliance management processes by integrating regulatory requirements directly into its ERP platform. Businesses can configure the system to enforce compliance with labeling standards, food safety regulations, traceability requirements, and other regulatory mandates. Automated workflows streamline compliance tasks, reducing the risk of errors and ensuring consistency in regulatory adherence.

- Documentation and Audit Trail Management: Deskera ERP maintains comprehensive documentation and audit trails to support regulatory compliance efforts. Businesses can easily access and retrieve records of regulatory activities, including compliance assessments, inspections, and corrective actions. This documentation facilitates regulatory audits and demonstrates due diligence in adhering to government regulations.

- Traceability and Batch Tracking: Deskera ERP offers robust traceability and batch tracking capabilities, enabling businesses to trace the movement of products throughout the supply chain. With Deskera, businesses can quickly identify and recall products affected by safety issues or regulatory non-compliance, ensuring swift and effective responses to regulatory concerns.

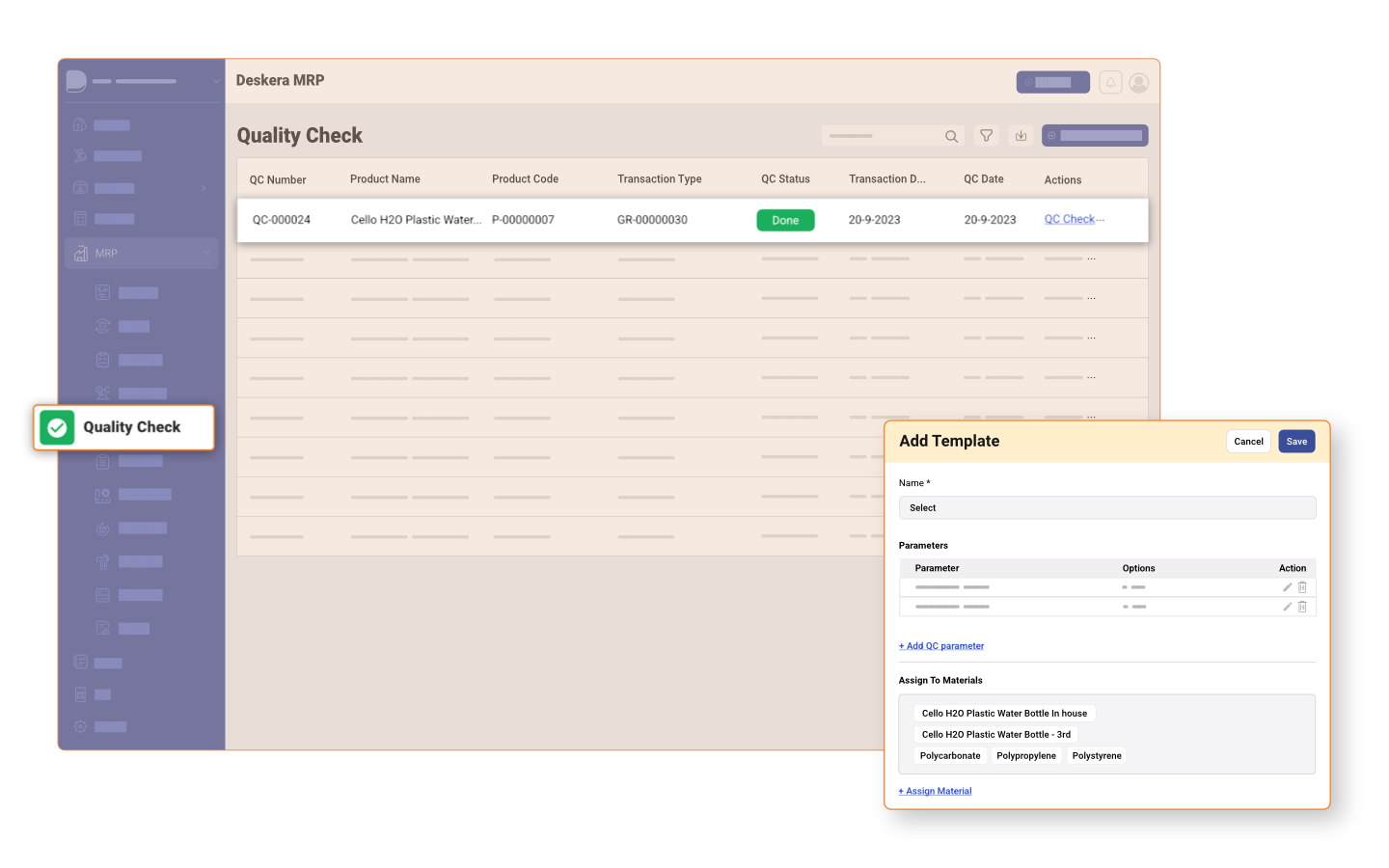

- Quality Control and Assurance: Deskera ERP includes features for quality control and assurance to ensure that products meet regulatory standards for safety, quality, and integrity. Businesses can implement quality control checks, inspections, and testing protocols within the ERP system to verify compliance with government regulations and industry standards.

- Supplier and Vendor Management: Deskera ERP helps businesses manage relationships with suppliers and vendors to ensure compliance with regulatory requirements. The ERP system maintains records of supplier certifications, compliance documents, and audit results, allowing businesses to assess supplier compliance and mitigate risks associated with non-compliant partners.

Key Takeaways

In today's highly regulated food and beverage industry, the role of Food and Beverage ERP systems in navigating government regulations cannot be overstated. These sophisticated software solutions serve as indispensable tools for businesses seeking to uphold compliance with evolving regulatory mandates.

The role of food and beverage ERP in navigating government regulations is as follows:

Traceability and Batch Tracking:

- Manufacturing ERP systems in the F&B industry enable robust traceability by tracking raw materials through production and distribution.

- Batch tracking features help in identifying and isolating specific batches in case of product recalls or regulatory audits.

Quality Management:

- MRP software systems help in implementing and maintaining quality control measures, ensuring that products meet regulatory standards and specifications.

- Quality assurance modules help track and document quality tests, inspections, and certifications, which are often required by regulatory bodies.

Compliance Documentation:

- Food and beverage ERP systems assist in creating and maintaining documentation required for compliance, such as ingredient lists, nutritional information, and allergen declarations.

- Automatic generation of compliance reports helps streamline the reporting process and ensures accuracy.

Recipe and Formulation Management:

- Manufacturing ERP systems help manage recipes and formulations, ensuring that ingredients and proportions comply with regulatory standards.

- Changes in formulations can be tracked and documented for regulatory approval and audit purposes.

Inventory Management:

- Accurate inventory management is crucial for compliance, especially in terms of tracking raw materials, finished goods, and packaging materials.

- MRP software systems help maintain real-time visibility into inventory levels, facilitating compliance with regulations related to stock levels, shelf life, and storage conditions.

Supply Chain Visibility:

- Food and beverage ERP systems provide end-to-end visibility into the supply chain, allowing businesses to monitor and ensure compliance at every stage.

- This visibility helps in identifying potential issues in the supply chain that may impact compliance and enables proactive measures.

Regulatory Reporting:

- Manufacturing ERP systems automate the generation of regulatory reports, reducing the risk of errors and ensuring timely submission to regulatory authorities.

- Reports can cover various aspects such as product safety, labeling, and production processes.

Audit Trail:

- MRP software systems maintain comprehensive audit trails, documenting every transaction and change made within the system.

- These audit trails serve as a valuable tool during regulatory audits, providing a transparent record of activities and changes.

Automatic Updates for Regulatory Changes:

- Manufacturing software systems often integrate with regulatory databases, ensuring that businesses are informed about and can adapt to changes in regulations seamlessly.

Recall Management:

- In the event of a product recall, manufacturing ERP systems help streamline the process by quickly identifying affected batches, notifying stakeholders, and ensuring prompt action to minimize the impact on consumers and meet regulatory requirements.

In summary, food and beverage ERP systems play a pivotal role in managing and ensuring compliance with government regulations by providing robust tools for tracking, documenting, and managing various aspects of the production and supply chain processes.

As the regulatory environment continues to evolve, leveraging the capabilities of MRP software systems will remain essential for ensuring compliance, mitigating risks, and maintaining consumer trust in the food and beverage industry.

Overall, Deskera serves as a comprehensive solution for navigating government regulations in the food and beverage industry. By offering regulatory compliance monitoring, automated compliance management, documentation and audit trail management, traceability and batch tracking, quality control and assurance, and supplier and vendor management capabilities, Deskera empowers businesses to navigate regulatory complexities with confidence and efficiency.

Related Articles