The production of food involves various stages, such as raw material procurement, processing, packaging and distribution. The process begins with the procurement of raw materials. These can be sourced from various sources, such as farms, fisheries, orchards and markets. The next step is processing, which involves the use of machines and equipment to transform the raw materials into a usable form. This includes cutting, grinding, mixing and blending.

This article covers the following:

- Types of Food Manufacturing

- Food Processing Equipment

- Food Safety & Regulations

- Quality Control & Testing

- Packaging & Labeling Requirements

- Supply Chain Management

- Automation & Robotics

- Food Manufacturing Trends

- Sustainability in Food Manufacturing

- Challenges & Opportunities of Food Manufacturing

Types of Food Manufacturing

Food manufacturing is the process of turning raw ingredients into food products. It is the process of combining, blending, and preserving ingredients into a final product, such as a cereal bar or a can of soup.

Food manufacturing is an important part of the food industry, providing a safe, quality-controlled means of producing food for consumers. Food manufacturing involves a variety of processes, from grinding raw ingredients into a powder to blending them together into a paste.

It also includes packaging and labeling the product, and in some cases, shipping it to the consumer. Food manufacturing is a complex process, requiring expertise in many areas.

Food manufacturing can be categorized into several different types, depending on the method used to create the final product. These types of food manufacturing include:

Baking:

This category involves the use of heat to cook ingredients, such as breads, cakes, cookies, and pies. Baking typically requires precise measurements and specific temperatures.

Blending:

Blending is a process used to combine ingredients into a homogeneous mixture. This can include dry ingredients, such as flour, sugar, and spices, as well as wet ingredients, such as milk and eggs.

Frying:

Frying is a cooking process that uses hot oil to cook food quickly. Foods that are commonly fried include french fries and chicken.

Freezing:

Freezing is a process used to preserve food for a longer period of time. This is often done with vegetables, fruits, and meats. Preserving: Preserving is a process used to extend the shelf life of food. This is typically done through canning, freezing, or drying.

Fermenting:

Fermenting is a process used to create alcoholic beverages, such as beer and wine. These are the most common types of food manufacturing. However, there are many other specialized processes used to manufacture food products, such as extrusion, dehydration, and aseptic packaging. All of these processes are used to create safe, nutritious, and high-quality food products for consumers.

Food Processing Equipment

Food processing equipment is a crucial component of the food manufacturing industry. It’s used to prepare, process, package, and ship food products, from raw ingredients to finished products.

The range of food processing equipment available is wide, from small-scale machines to large-scale production lines. Basic equipment includes mixers, blenders, grinders, and slicers, while more advanced machinery includes packaging systems, conveyor belts, food processors, and pasteurizers.

This machinery is used in the production of a range of food products, including dairy products, snacks, and bakery goods. It’s used to move, mix, cut, grind, and form food, as well as to package and store it. Food processing equipment is designed to be robust, reliable, and easy to use.

Manufacturers are constantly innovating with new technologies and designs to make the equipment more efficient and effective. For example, some food processing machines have built-in safety features, such as automatic shut-offs, to prevent contamination.

The food processing industry is highly regulated, and all equipment must meet strict safety and hygiene standards. To ensure these standards are met, manufacturers must ensure that their equipment is regularly serviced and maintained.

Food processing equipment is an essential part of the food manufacturing industry. It’s used to prepare, process, package, and ship food products, from raw ingredients to finished products. By investing in the right food processing equipment, manufacturers can ensure their products are of the highest quality and safe for consumption.

Food Safety & Regulations

Food safety regulations are an important part of food manufacturing. In recent years, there has been increased awareness of the risks associated with food production and the need to ensure that all food products are safe for consumption.

It is essential that companies in the food manufacturing industry adhere to food safety regulations to protect the public from potential health hazards. Food safety regulations are designed to ensure that food products are free from contamination, including bacteria, viruses, and toxins.

Regulations also require that food products are properly labeled, stored, and handled to prevent foodborne illnesses. In addition, food manufacturers must meet stringent standards for cleanliness and sanitation.

The Food and Drug Administration (FDA) is responsible for establishing the regulations that govern the food manufacturing industry. These regulations cover everything from the ingredients used in the production of food products to the packaging and labeling of those products.

In addition to the FDA regulations, food manufacturers must also comply with local and state regulations. Many states have their own set of food safety regulations that must be followed in order to obtain a license to manufacture food products. It is important for food manufacturers to be familiar with the regulations in their state in order to remain in compliance. Finally, food safety regulations require that food manufacturers regularly test their products for any potential contamination.

Regular testing is necessary to ensure that all food products meet the required safety standards. This testing is done by independent laboratories that are certified to evaluate the safety of food products.

Food safety regulations are in place to protect the public from potential health hazards. It is important for food manufacturers to understand and adhere to these regulations in order to remain compliant and maintain a safe and healthy environment for their customers.

Quality Control & Testing

Quality control and testing plays an important role in the food manufacturing industry. It is critical to ensure that the food products being produced are safe, wholesome, and of the highest quality.

Quality control and testing processes are used to ensure the safety of the food products from the moment they enter the manufacturing facility, until the final product is packaged and ready for the consumer.

The quality control and testing process begins with the raw materials that are used to make the food products. The raw materials must be checked for quality, safety, and purity.

Raw materials must meet certain standards set forth by regulatory bodies and industry standards. If the raw materials fail to meet these standards, then they must be discarded or sent for reprocessing.

Once the raw materials have passed quality control, they are sent to the manufacturing process. Here, the ingredients are blended, cooked, and processed according to the recipe and the manufacturer’s specifications.

At this stage, quality control teams monitor the manufacturing process to ensure that the product meets all of the necessary standards. The teams also regularly take samples of the product to analyze for safety and quality.

The next step in the quality control and testing process is the packaging. Here, the product is carefully inspected and tested to ensure that it is safe and meets all of the necessary quality standards.

The packaging also must meet certain standards in terms of safety and freshness. The final step in the quality control and testing process is the delivery. All of the food products must be checked for quality and safety before they are shipped out to the consumer.

This is done to ensure that the food products are safe and of the highest quality when they reach the consumer. Quality control and testing is an important part of the food manufacturing process.

It ensures that the food products are safe, wholesome, and of the highest quality. Quality control and testing processes must be followed in order to guarantee that the food products are safe for consumption.

Packaging & Labeling Requirements

Packaging and labeling is an essential component of food manufacturing, as it helps to ensure the safety of consumers and the quality of the product. Proper packaging and labeling of food products help to protect the product from contamination, as well as to provide information to the consumer.

When packaging food, manufacturers must consider packaging materials, production costs, and shelf-life. They must also consider the intended use of the product, such as whether it will be stored in a refrigerator or a pantry.

Additionally, food must be packaged in a way that minimizes waste, and that is environmentally friendly. Labeling requirements are designed to ensure that consumers have the necessary information to make an informed purchasing decision.

Labels must include information such as the name of the product, ingredients, nutrition facts, and use-by dates. Labels must also include the manufacturer’s contact information, as well as any potential allergen warnings.

In the United States, the Food and Drug Administration (FDA) regulates the packaging and labeling of food products. The FDA requires that all food labels be accurate and truthful, and that labels do not make any false or misleading claims.

Additionally, labels must include all required information, as well as information on any potential allergens contained in the product. Manufacturers must also ensure that their packaging and labeling meets the regulations of the country in which the food is sold.

For example, in the European Union, all food packaging must include a nutrition label and information on allergens must be clearly highlighted. Packaging and labeling is a critical component of food manufacturing, as it helps to ensure the safety of consumers and the quality of the product.

By following the required regulations and guidelines, manufacturers can help to ensure that their food products are safe and that consumers have all the necessary information to make an informed purchasing decision.

Supply Chain Management

Supply chain management (SCM) is a critical component of food manufacturing as it involves the planning, coordination, and control of materials, information, and finances as they move in a process from supplier to manufacturer to wholesaler to retailer to consumer.

SCM ensures that the right products and services are delivered to the right place at the right time with the right cost. The supply chain in food manufacturing is complex and critically important. It begins with the sourcing of raw materials, such as ingredients, packaging, and equipment.

The supply chain then moves through manufacturing, packaging, transportation, storage, and distribution. The food manufacturing supply chain must be managed carefully in order to ensure that the products meet safety standards, are of high quality, and are delivered on time.

To accomplish this, manufacturers must consider a number of factors, such as supplier selection and management, cost control, inventory management, logistics, and customer service.

Supplier selection and management are key to a successful supply chain. Manufacturers must carefully evaluate potential suppliers and select those who can provide the quality and quantity of materials needed.

They must also have a clear understanding of their suppliers’ capabilities and capacities so that they can anticipate potential risks. Cost control is also an important aspect of supply chain management.

Manufacturers must find ways to reduce cost while still maintaining quality. This could involve negotiating with suppliers for better prices, improving processes and systems, and reducing inventory.

Inventory management is another important aspect of the supply chain. Manufacturers must ensure that their inventory levels are balanced so that they have the right amount of materials to meet customer demand.

This could involve using inventory management software to track inventory levels and set reorder points. Logistics is another important part of the supply chain.

Manufacturers must ensure that their products are delivered on time and in good condition. This could involve using a third-party logistics provider, such as a freight forwarder, to manage the transportation and storage of goods.

Finally, customer service is an important part of supply chain management. Manufacturers must ensure that their customers are satisfied with their products and services.

This could involve using customer feedback to improve processes and systems and providing timely customer service. The supply chain in food manufacturing is complex and must be managed carefully in order to ensure that products are delivered on time and meet safety and quality standards.

By carefully evaluating and selecting suppliers, controlling costs, managing inventory, utilizing logistics, and providing excellent customer service, manufacturers can ensure that their supply chain is efficient and effective.

Automation & Robotics

Automation and robotics have become an integral part of the food manufacturing process. Automation and robotics can help improve the production process, increase efficiency and reduce costs.

Automation and robotics can be used for a variety of tasks in the food manufacturing process, from packaging to sorting, labeling and even cooking. Robots have been used in food manufacturing for many years, but recently advancements in robotic technology have enabled more precise and efficient automation processes.

Robots are now able to operate in a much more accurate and efficient manner, reducing the possibility of human error. This allows food manufacturers to produce higher quality products with a shorter lead time.

Robots can be used in a variety of ways in the food manufacturing process. For example, robots can be used to assemble food products such as sandwiches, salads and other ready-to-eat meals.

They can also be used for sorting, labeling and packaging. In addition, robots can be used for tasks such as cleaning, sterilizing and sanitizing equipment and areas. Robotics can also be used to improve the efficiency of food manufacturing processes.

Automated systems can monitor and control production processes, ensuring that the desired output is produced in the most efficient manner possible. This can help to reduce waste and improve the quality of the product.

Automation and robotics can also be used to reduce labor costs. Automated systems can be used to reduce the amount of manual labor required in the production process. This allows food manufacturers to produce more with fewer employees, which can help to reduce overhead costs.

Automation and robotics are an important part of the food manufacturing process and are becoming increasingly important as technology advances. Automated systems can help to reduce costs, improve efficiency and quality, and reduce human error. By utilizing the latest technologies, food manufacturers can continue to produce high-quality products in an efficient manner.

Food Manufacturing Trends

Food manufacturing is a rapidly changing industry. New technologies, regulations, and consumer trends are all influencing the industry, and it's important to stay up to date on the latest developments. In this blog post, we'll look at some of the top trends currently impacting food manufacturing.

Automation

Automation has been a major trend in food manufacturing for a few years now. Automation can help increase efficiency, reduce costs, and improve product quality. Automated systems are becoming increasingly sophisticated and can now complete complex tasks such as sorting, labeling, and packaging.

Alternative proteins

Plant-based proteins are becoming increasingly popular with consumers, and food manufacturers are responding. Plant-based proteins such as peas, beans, and lentils are being used to replace animal proteins in a variety of food products.

Clean labels

Consumers are increasingly looking for food products with clean labels, meaning labels that are free of artificial ingredients and preservatives. This has led to a boom in organic and natural food products. Food manufacturers are responding by reformulating their products to meet these demands.

Traceability

Traceability is becoming increasingly important in food manufacturing due to the need to ensure food safety. Traceability helps manufacturers track food products from the farm to the store, and can help identify the source of food-borne illnesses quickly.

Eco-friendly packaging

Consumers are becoming aware of the environmental impact of packaging, and are looking for food products that come in eco-friendly packaging. Manufacturers are responding by transitioning to more sustainable packaging options such as bioplastics, compostable containers, and recyclable materials.

These are just a few of the trends currently impacting the food manufacturing industry. By staying up to date with these trends, manufacturers can ensure their products are up to date with consumer demands and remain competitive in the marketplace.

Sustainability in Food Manufacturing

When it comes to food manufacturing, sustainability is becoming increasingly important. As consumers become more aware of their environmental impact, they are demanding food that is produced in a way that is mindful of the planet.

Food manufacturers must be proactive in reducing their environmental impact and this means implementing sustainable practices in their production processes. One of the most important aspects of sustainability in food manufacturing is the use of renewable resources.

This means that manufacturers should use as few non-renewable resources as possible and instead focus on sustainable sources of energy such as solar, wind, or hydroelectricity.

Additionally, manufacturers should reduce their water usage by implementing water-saving technologies such as low-flow toilets and water recycling systems. By reducing the amount of water and energy used, food manufacturers can reduce their environmental footprint.

Another important aspect of sustainability in food manufacturing is reducing waste. This can be done by using efficient production methods that minimize waste and by using recyclable packaging materials.

Additionally, manufacturers should strive to reduce the amount of packaging they use by using lightweight materials and using packaging that is reusable or compostable. By reducing packaging, manufacturers can reduce their environmental impact while still ensuring the safety of their products.

Finally, food manufacturers should strive to reduce their emissions of greenhouse gases. This can be done by switching to cleaner forms of energy and investing in more efficient production processes.

Additionally, manufacturers should look for ways to reduce their carbon footprint by investing in renewable energy sources and investing in carbon capture and storage technologies.

By implementing sustainable practices in their production processes, food manufacturers can ensure that their products are produced in a way that is mindful of the environment. By reducing their environmental footprint, food manufacturers can show consumers that they are committed to protecting the planet while still producing high-quality food products.

Challenges & Opportunities of Food Manufacturing

Food manufacturing is the process of transforming raw ingredients into food products that can be bought in grocery stores and supermarkets. The food industry has seen tremendous growth in recent years, as consumers become more health-conscious and demand healthier food options.

However, with this growth comes a number of challenges and opportunities for food manufacturers. One of the biggest challenges facing food manufacturers is food safety. In recent years, there have been a number of high-profile food safety scandals, which have raised public awareness of food safety issues.

As such, food manufacturers must ensure that their products are safe for consumers, and that they are compliant with relevant regulations. This means having stringent processes in place for quality control, sanitation and ingredient verification.

Another challenge for food manufacturers is the ever-changing consumer landscape. With the rise of health-conscious and ethical eating, consumers are now demanding more from the food they buy.

Manufacturers must be able to adapt to these changes, and provide products that meet the needs and expectations of their customers. This can include introducing new products, reformulating existing products or using alternative ingredients.

At the same time, food manufacturers have also been presented with numerous opportunities. One of these is the rise of online grocery shopping, which has given food manufacturers access to a wider consumer base.

Additionally, manufacturers are now able to use technology to streamline their production processes, reduce waste and improve efficiency. This has enabled them to produce higher-quality products at a lower cost.

In conclusion, food manufacturing presents both challenges and opportunities. As a food manufacturer, it is important to be aware of these challenges and opportunities, and to develop strategies to address them.

By doing so, you can ensure that your products meet the needs and expectations of your customers, while also improving the efficiency and profitability of your operations.

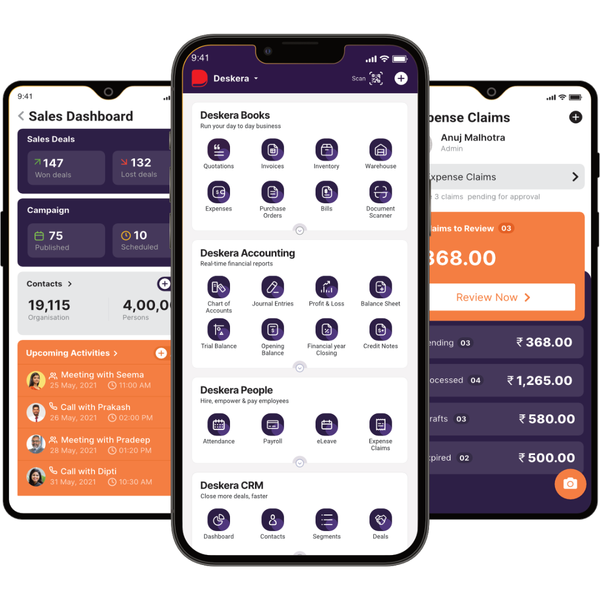

How Can Deskera Assist You?

As a manufacturer, you must keep track of your inventory stock. The condition of your inventory has a direct impact on production planning. It also has a direct impact on people and machinery use and capacity utilization.

Deskera MRP is the one tool that lets you do all of the above. With Deskera, you can:

- Control production schedules

- Compile a Bill of Materials

- Produce thorough reports

- Make your dashboard

Deskera ERP is a complete solution that allows you to manage suppliers and track supply chain activity in real-time. It also allows you to streamline a range of other company functions.

Deskera Books allows you to manage your accounts and finances better. It helps maintain good accounting standards by automating billing, invoicing, and payment processing tasks.

Deskera CRM is a powerful tool that organizes your sales and helps you close deals rapidly. It enables you to perform crucial tasks like lead generation via email and gives you a comprehensive view of your sales funnel.

Deskera People is a straightforward application for centralizing your human resource management activities. Not only does the technology expedite payroll processing, but it also helps you to handle all other operations such as overtime, benefits, bonuses, training programs, and much more.

Key Takeaways:

- The leather manufacturing industry is highly competitive, with many players vying for a share of the market.

- Another trend that is likely to shape the future of the leather industry is the growing demand for personalized and customized products.

- Emerging markets such as China, India, and Brazil are becoming major players in the leather industry.

- Some of the main environmental concerns associated with leather production include the use of hazardous chemicals, high water usage, air and water pollution, and deforestation.

- The future of the leather manufacturing industry is likely to be shaped by a range of factors, including changing consumer preferences, technological advancements, and environmental concerns.

Related Articles: