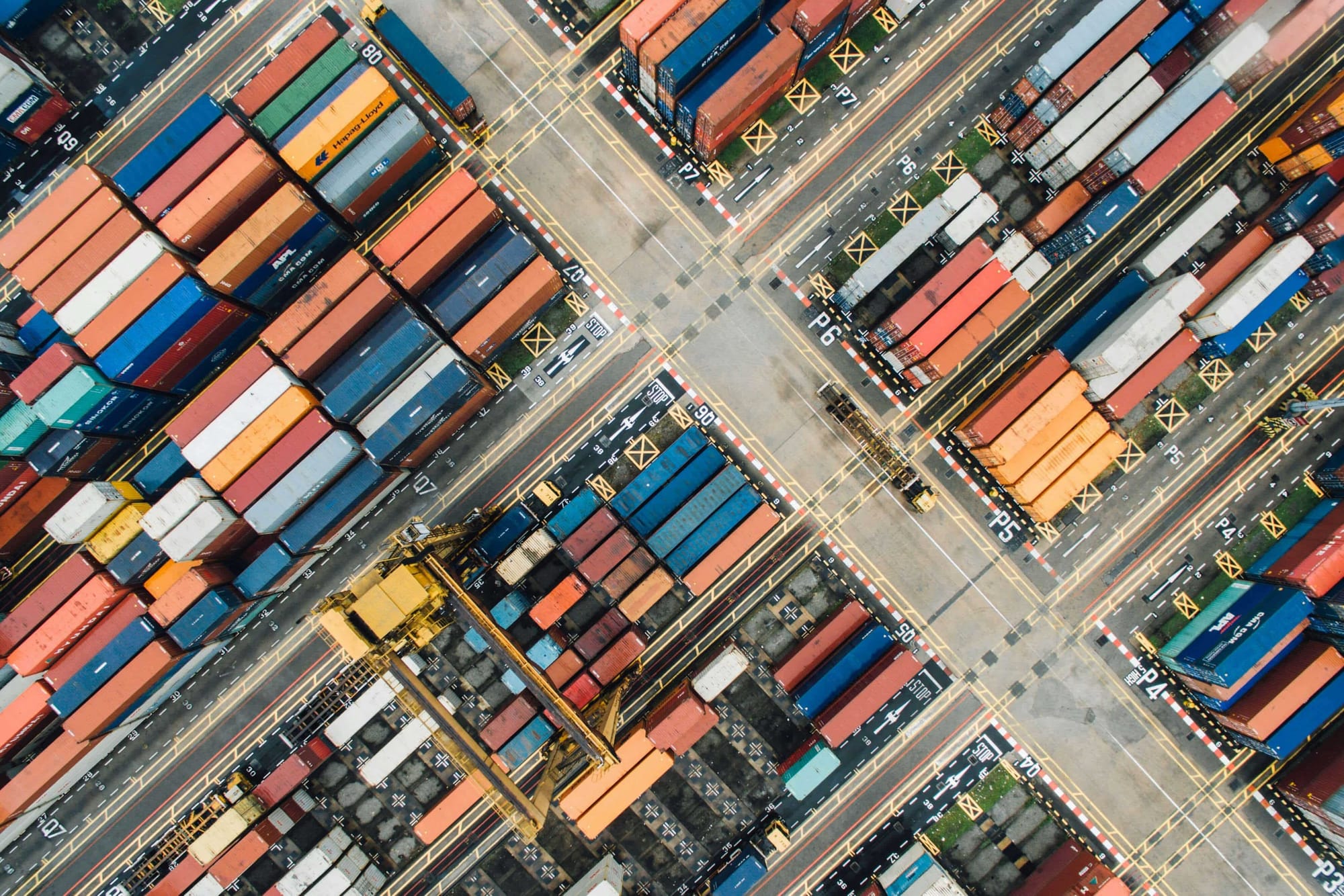

Have you ever wondered why some businesses can instantly update customers on their order status while others struggle to provide clear answers? The difference lies in order visibility — the ability to track and monitor every order’s journey from placement to delivery. In today’s fast-moving supply chains, visibility is not just a convenience; it’s a competitive necessity. When businesses can see exactly where an order stands, they can make faster decisions, minimize disruptions, and enhance customer trust.

However, achieving complete order visibility is easier said than done. Many companies still rely on disconnected systems, manual tracking, and siloed data, which often lead to delays, miscommunication, and frustrated customers. Without a centralized system to connect departments — from procurement and inventory to logistics — maintaining transparency across the supply chain becomes nearly impossible. This lack of visibility not only affects operational efficiency but also erodes customer confidence in a brand’s reliability.

That’s where Enterprise Resource Planning (ERP) systems come into play. By integrating all business functions into a single platform, ERP systems provide real-time access to order information across departments. This integration allows managers to monitor progress, identify bottlenecks, and ensure smooth order fulfillment. With advanced reporting and automation, ERP solutions empower businesses to move away from guesswork and embrace data-driven decision-making.

Among the leading solutions, Deskera ERP stands out for its simplicity, scalability, and robust visibility tools. Designed for modern supply chains, Deskera ERP offers real-time dashboards, automated workflows, and seamless integration across sales, inventory, and logistics. It enables businesses to gain full transparency into their order lifecycle, reduce manual errors, and improve customer satisfaction. Whether you’re a growing business or an established enterprise, Deskera ERP provides the clarity and control needed to keep your supply chain running seamlessly.

What Is Order Visibility in Supply Chain Management?

Order visibility in supply chain management refers to a company’s ability to monitor and track the movement, location, and status of its orders throughout the entire supply chain — from procurement and inventory management to logistics and final delivery. It provides businesses with real-time insights into how orders are progressing at every stage, ensuring they can take proactive actions to prevent disruptions, minimize delays, and deliver on customer expectations.

At its core, order visibility is about transparency. It gives businesses and customers alike a clear view of where an order stands — whether it’s being processed, shipped, or delivered. With accurate, up-to-date information, companies can make informed decisions, manage inventory more effectively, and optimize their fulfillment processes. This visibility also plays a crucial role in enhancing customer experience, as timely and precise updates help build trust and reduce complaints caused by misinformation or missed deliveries.

Modern businesses achieve this level of clarity by integrating their supply chain operations with digital tools such as Order Management Systems (OMS) or ERP platforms. These systems centralize data from multiple sources into a single dashboard, allowing managers to track order status, shipping details, and inventory levels in real time. Such integration not only streamlines communication across departments but also enables automated workflows that improve operational accuracy and speed.

In essence, order visibility empowers companies to manage their supply chains more efficiently by turning fragmented data into actionable insights. When businesses can see and respond to what’s happening across their supply chain at any moment, they are better equipped to deliver consistent, reliable service — and that’s what sets them apart in a competitive market.

Key Components of Order Visibility

Order visibility is not a single function but an end-to-end approach that connects every stage of the supply chain — from sourcing raw materials to delivering the final product. To achieve true transparency and control, businesses must focus on four essential components that together form the foundation of effective order visibility.

1. Order Tracking

Real-time order tracking provides a clear view of where every order stands — from purchase to delivery. For operations teams, it means being able to detect issues such as shipment delays or routing errors before they escalate. For customers, it delivers the transparency they expect, allowing them to stay informed about the progress of their orders and improving overall satisfaction.

2. Supplier Performance

Suppliers play a critical role in determining how efficiently a business can fulfill customer demands. Monitoring supplier metrics such as lead times, reliability, defect rates, and responsiveness helps companies ensure quality and consistency. Strong visibility into supplier performance not only strengthens collaboration but also allows businesses to address potential issues proactively before they impact production or delivery timelines.

3. Manufacturing Status

Manufacturing visibility enables companies to track production progress in real time, identify capacity constraints, and anticipate potential bottlenecks. This allows teams to make quick adjustments to meet deadlines and provide accurate order updates to customers. When production data is transparent, planning becomes more precise, resource allocation improves, and promises to customers remain realistic and reliable.

4. Shipment and Logistics

Even the most efficiently produced products can lose value if they arrive late or damaged. Logistics visibility ensures that companies can monitor carrier performance, track in-transit orders, and evaluate delivery efficiency. By analyzing route performance and shipment accuracy, businesses can fine-tune their logistics operations — ensuring on-time deliveries, reducing transportation costs, and enhancing customer confidence.

Together, these components create a connected, data-driven supply chain ecosystem that allows businesses to track, manage, and optimize every step of the order journey with precision and transparency.

Why Order Visibility Is Important

In today’s fast-paced and unpredictable supply chain environment, change is the only constant. From sudden demand surges and supply shortages to weather disruptions and transportation delays, businesses must be able to adapt quickly. Order visibility provides the real-time insights needed to respond to these fluctuations with agility and precision.

By knowing exactly where an order stands at every stage — from procurement to delivery — companies can plan capacity, manage inventory, and streamline logistics more effectively, minimizing costly surprises and customer dissatisfaction.

1. Increased Order Accuracy

Order visibility helps ensure that every customer receives exactly what they ordered — in the right quantity, at the right time, and in the right condition. Real-time tracking and data synchronization between departments reduce the chances of mismatched orders, missed deadlines, or incorrect shipments. This enhanced accuracy not only improves key performance indicators (KPIs) like fulfillment precision but also builds trust with customers who expect reliability and consistency.

2. Fewer Order Errors and Returns

Complex product configurations, dynamic pricing structures, and manual processes often lead to costly order errors. With greater visibility, businesses can identify inconsistencies early and prevent mistakes before they impact customers. This minimizes returns, reduces reverse logistics costs, and protects profit margins. Even high-performing organizations struggle to maintain near-perfect accuracy, but visibility tools help bridge that gap by reducing human and procedural errors.

3. Better Inventory Management

Strong order visibility goes hand in hand with effective inventory control. Real-time tracking helps businesses maintain accurate stock levels, avoiding both overstocking and stockouts. When companies have a clear picture of their inventory and open orders, they can forecast demand more accurately, manage warehouse space efficiently, and align production schedules with actual demand. This level of synchronization is key to maintaining a balanced and resilient supply chain.

4. Improved Transparency and Communication

Today’s customers expect transparency at every step of their purchase journey. Order visibility enables companies to provide accurate, real-time updates that reflect the true status of their orders. Internally, it keeps all teams — from sales and production to logistics — on the same page. With everyone accessing the same data, communication improves, decision-making becomes faster, and accountability increases across the organization.

5. Enhanced Customer Satisfaction and Loyalty

Few things frustrate customers more than delayed or inaccurate deliveries. Order visibility empowers businesses to meet fulfillment deadlines and quickly communicate any potential delays before they turn into problems. By keeping customers informed and confident in the process, businesses can strengthen relationships, encourage repeat purchases, and enhance overall brand reputation.

6. Faster and More Efficient Fulfillment

With complete visibility, orders move seamlessly from one stage to the next. Warehouse teams can prioritize urgent shipments, sales representatives can update customers instantly, and logistics managers can reroute deliveries when needed. This end-to-end alignment results in faster fulfillment times, fewer bottlenecks, and a smoother overall customer experience.

7. Proactive Risk Management

Order visibility enables businesses to identify disruptions early — such as delayed shipments, supplier issues, or transport bottlenecks — and take corrective actions before they escalate. With real-time insights, companies can reroute shipments, adjust production schedules, or reallocate inventory to minimize the impact on customers. This proactive approach reduces downtime and safeguards revenue even during unforeseen events.

8. Cost Optimization

Improved visibility directly translates to better cost control. When companies can monitor their order lifecycle, they can detect inefficiencies like redundant shipping routes, excess inventory, or inaccurate forecasting. This transparency allows for smarter resource allocation, lower operational expenses, and improved profit margins.

9. Stronger Collaboration Across the Supply Chain

Visibility creates a shared source of truth for all stakeholders — from suppliers and manufacturers to logistics providers and distributors. When everyone operates with the same real-time data, collaboration improves, misunderstandings decrease, and the entire supply chain becomes more synchronized and responsive.

10. Data-Driven Decision-Making

Comprehensive order visibility provides a wealth of data that can be analyzed to uncover trends, improve forecasting, and refine processes. Businesses can use these insights to make smarter strategic decisions — such as adjusting pricing, optimizing stock levels, or identifying underperforming carriers. This transforms order visibility from a monitoring tool into a growth enabler.

11. Regulatory Compliance and Traceability

In industries like pharmaceuticals, food, or electronics, regulatory compliance and traceability are critical. Order visibility ensures businesses can track every product’s journey through the supply chain — providing auditable records for quality assurance, recalls, or compliance reporting. This level of traceability also builds customer trust and brand integrity.

12. Competitive Advantage in a Dynamic Market

In an era of increasing customer expectations and global supply chain complexity, companies with superior order visibility gain a competitive edge. They can respond faster to market changes, fulfill orders more efficiently, and offer the transparency today’s customers demand — all of which set them apart from competitors relying on outdated or manual systems.

In essence, order visibility is the backbone of an efficient, customer-centric supply chain. It provides businesses with the clarity needed to make informed decisions, minimize errors, and deliver exceptional service every time — turning transparency into a long-term competitive advantage.

Challenges of Poor Order Visibility

When businesses lack clear visibility into their orders, the consequences ripple across the entire supply chain — from internal operations to customer experience. Without real-time insights or a unified system to track orders, teams often make decisions based on incomplete or outdated information. This lack of coordination leads to inefficiencies, increased costs, and missed opportunities. Below are some of the most common and costly challenges caused by poor order visibility.

1. Miscommunication Between Departments

When departments like sales, procurement, logistics, and customer service operate in silos, miscommunication becomes inevitable. Without shared access to accurate order data, sales teams may promise unrealistic delivery timelines, fulfillment teams might miss critical updates, and customer service representatives could struggle to provide order status information. This disconnect erodes internal collaboration and impacts the overall customer experience.

2. Delayed Order Fulfillment

Without visibility into where an order stands at any given time, delays are almost guaranteed. Teams cannot proactively address bottlenecks or reroute shipments when disruptions occur. This lack of clarity slows down fulfillment cycles, causing late deliveries, customer dissatisfaction, and potential loss of repeat business. In today’s market, where customers expect speed and accuracy, delayed fulfillment can severely damage a brand’s reputation.

3. Inventory Imbalances

Poor order visibility often leads to poor inventory management. Businesses may experience frequent stockouts of high-demand items or excessive inventory of slow-moving products. Without a clear, real-time picture of stock levels and order flow, it’s nearly impossible to align supply with demand. This imbalance not only increases holding costs but also affects the company’s ability to fulfill customer expectations.

4. Increased Operational Costs

Lack of visibility leads to inefficiencies that directly impact the bottom line. Errors in order processing, redundant manual work, and emergency shipping costs to compensate for delays all add up. Businesses end up spending more to fix issues that could have been avoided with real-time insights and automation.

5. Poor Customer Experience

Customers expect accurate delivery dates and real-time tracking information. When businesses fail to provide timely updates or miss promised deadlines, customer trust quickly erodes. Repeated fulfillment errors or miscommunications can lead to complaints, negative reviews, and eventually lost loyalty — all because of insufficient visibility.

6. Difficulty in Identifying Bottlenecks

Without visibility, it becomes difficult to pinpoint where problems occur in the supply chain. Whether it’s a delay in production, a missed shipment, or a slow warehouse process, businesses can’t fix what they can’t see. The lack of real-time data makes process optimization nearly impossible and allows inefficiencies to persist.

7. Limited Forecasting and Planning Accuracy

Accurate forecasting depends on reliable data. When visibility is poor, businesses lack the insights needed to anticipate demand, plan capacity, or manage procurement effectively. This often leads to reactive decision-making — adjusting to issues after they arise rather than preventing them before they occur.

8. Higher Risk of Compliance and Traceability Issues

In industries where tracking and documentation are critical, poor order visibility can create compliance risks. Without detailed tracking data, companies struggle to provide traceability during audits, recalls, or quality checks. This not only leads to potential legal and financial penalties but also damages the brand’s credibility.

In short, poor order visibility undermines efficiency, accuracy, and customer trust. To overcome these challenges, businesses need integrated systems — such as ERP or order management solutions — that provide a single source of truth and enable real-time tracking across every stage of the supply chain.

Strategies for Improving Order Visibility

In a dynamic and unpredictable supply chain landscape, achieving full order visibility requires more than just tracking shipments — it demands strategic alignment, technological integration, and continuous collaboration.

Businesses must adapt to fluctuating market conditions, evolving customer expectations, and operational complexities. The following strategies can help companies strengthen their order visibility, enhance efficiency, and maintain customer satisfaction while keeping costs in control.

1. Define Clear Visibility Goals and KPIs

Before improving visibility, businesses must establish what success looks like. Setting key performance indicators (KPIs) for order visibility ensures measurable progress and accountability.

These KPIs can include metrics such as on-time delivery rate, order accuracy, picking efficiency, and inventory turnover. For example, an online retailer may set targets for warehouse utilization, safety stock levels, and shipment timeliness to optimize order fulfillment. Defining these goals helps teams stay focused and continuously evaluate performance against tangible benchmarks.

2. Foster Collaboration Across Departments

Order visibility thrives when every division — from sales and procurement to logistics and customer service — operates from a shared data source. By integrating systems and facilitating the flow of real-time information, companies can ensure all teams are aligned on order status and inventory updates.

Cross-functional collaboration minimizes miscommunication, speeds up problem-solving, and ensures a unified approach to meeting customer commitments. Centralized dashboards or ERP systems play a key role in making this collaboration seamless.

3. Strengthen Supplier Relationships

Suppliers are integral to maintaining visibility and consistency in order fulfillment. Businesses should focus on building transparent and data-driven partnerships by monitoring key supplier KPIs such as lead times, defect rates, and delivery reliability.

Regular performance reviews, open communication, and collaborative planning help reduce risks of disruptions and build trust. A well-managed supplier relationship ensures that materials and components arrive on time, maintaining a smooth production and delivery flow.

4. Identify Automation Opportunities

Automation is one of the most effective ways to enhance visibility and reduce human error. By automating repetitive processes — such as order entry, data capture, inventory updates, and shipment notifications — companies can streamline workflows and maintain consistent accuracy.

According to research, nearly half of supply chain leaders consider automation crucial for improving operational efficiency. Automation also speeds up order processing and frees employees to focus on strategic decision-making rather than manual tracking.

5. Leverage AI and Predictive Analytics

Artificial Intelligence (AI) and predictive analytics have transformed order visibility by enabling smarter forecasting and proactive management. Businesses can use AI-powered insights to predict demand patterns, detect potential delays, and optimize warehouse operations.

Internet of Things (IoT) sensors, for instance, can monitor shipment conditions and inventory levels in real time. Predictive models can also anticipate disruptions, allowing companies to make informed decisions before issues impact delivery timelines.

6. Use Barcode Scanners and RFID Technology

Barcode and RFID (Radio Frequency Identification) technologies provide accurate, real-time tracking of goods as they move through the supply chain. By scanning products during receiving, storage, and dispatch, companies can maintain precise records of inventory movements.

RFID, in particular, enables automatic data capture without manual input, reducing errors and improving traceability. These technologies help businesses maintain better stock control and visibility across all stages of fulfillment.

7. Enable Real-Time Tracking Across the Supply Chain

Real-time tracking gives businesses a live view of order progress, helping teams address delays or discrepancies immediately. When order, inventory, and shipping data are synchronized, companies can ensure smoother operations and improved customer communication.

Real-time tracking reduces the risk of misplaced or delayed orders, enhances transparency, and enables customers to receive accurate delivery updates — building stronger trust and loyalty.

8. Implement Order Management Software (OMS)

A modern Order Management System (OMS) centralizes order information across all sales channels, providing complete visibility into the order lifecycle — from creation to fulfillment and returns.

OMS solutions automate workflows, consolidate data from multiple systems, and support omnichannel fulfillment. This integrated view enables businesses to optimize inventory allocation, reduce manual errors, and ensure consistent customer experiences regardless of where the order originates.

9. Integrate ERP Systems for End-to-End Visibility

While OMS focuses on orders, an ERP system provides holistic visibility across all supply chain functions — including procurement, production, warehousing, and distribution.

Integrating ERP with OMS or CRM tools ensures that all departments work from the same real-time data, improving coordination and reducing process redundancies. This comprehensive integration is key to achieving true end-to-end visibility and operational excellence.

10. Regularly Audit and Refine Visibility Processes

Continuous improvement is essential. Companies should conduct periodic audits to evaluate visibility gaps, assess technology performance, and gather stakeholder feedback. By refining workflows and adopting emerging technologies, businesses can stay agile and maintain high visibility standards even as their supply chains evolve.

Incorporating these strategies helps businesses move beyond reactive management to a proactive, data-driven approach. By embracing automation, integration, and collaboration, companies can transform their order visibility into a strategic advantage — ensuring greater efficiency, reliability, and customer satisfaction.

How ERP Systems Improve Order Visibility

In today’s fast-paced and customer-driven marketplace, maintaining real-time visibility into orders is no longer a luxury—it’s a necessity. Businesses need a single source of truth that allows every department to track, manage, and act on order data efficiently.

This is where Enterprise Resource Planning (ERP) systems come into play. By unifying data across procurement, inventory, production, and logistics, ERP systems empower companies to gain a holistic view of their order lifecycle from initiation to delivery.

Here’s how ERP systems significantly enhance order visibility across the supply chain:

1. Centralized Data Management

ERP systems consolidate data from multiple sources—such as sales, inventory, and logistics—into one unified platform. This centralization ensures that every stakeholder, from procurement to customer service, has access to accurate and up-to-date information. As a result, businesses can avoid miscommunication, reduce duplication of effort, and respond quickly to changes in order status or customer demands.

2. Real-Time Order Tracking

Modern ERP systems enable real-time order monitoring, providing updates at every stage of the process—from order creation and fulfillment to shipment and delivery. This visibility allows businesses to detect potential bottlenecks early, resolve issues proactively, and deliver accurate updates to customers. It not only enhances transparency but also builds trust by aligning expectations with performance.

3. Seamless Integration with Supply Chain Partners

ERP systems often integrate directly with supplier and logistics platforms, enabling a transparent flow of information across the entire supply chain.

This integration ensures that all stakeholders—suppliers, manufacturers, and distributors—work from the same data set, improving coordination and minimizing disruptions.

For example, suppliers can update inventory or shipment details in real time, helping businesses adjust production or delivery schedules accordingly.

4. Improved Inventory and Demand Forecasting

Accurate order visibility depends heavily on knowing what inventory is available and where. ERP systems use predictive analytics and historical sales data to anticipate demand trends and align stock levels accordingly. This helps businesses prevent overstocking or stockouts, ensuring they can meet customer demand without unnecessary delays or excess costs.

5. Enhanced Customer Communication

With ERP-driven visibility, customer service teams can provide precise, real-time updates about order status, shipment tracking, and delivery timelines. Instead of relying on manual updates or separate systems, they can access integrated dashboards that give them a complete view of the customer journey. This not only improves response times but also strengthens customer satisfaction and loyalty.

6. Data-Driven Decision-Making

ERP systems transform order management into a data-rich process by offering detailed reports and analytics. Businesses can analyze performance metrics—like fulfillment accuracy, delivery times, and supplier reliability—to identify inefficiencies and optimize workflows.

This continuous improvement cycle ensures that organizations make proactive, data-backed decisions that enhance both visibility and efficiency.

Benefits of Improved Order Visibility with ERP Systems

When businesses achieve full order visibility through ERP systems, they move beyond simply tracking orders—they transform how their entire supply chain operates.

The integration of order, inventory, production, and logistics data in a single system allows companies to predict challenges, make informed decisions, and deliver consistent performance. The benefits extend far beyond process efficiency, influencing profitability, scalability, and customer loyalty.

Here are the key business benefits of enhanced order visibility powered by ERP systems:

1. End-to-End Process Integration

ERP systems connect every touchpoint—from procurement and manufacturing to fulfillment and returns—into one seamless workflow. This interconnectedness eliminates information silos, allowing every department to access the same real-time order data. As a result, coordination improves, delays are minimized, and operations become smoother and more predictable.

2. Proactive Problem Solving

With real-time visibility, businesses can detect disruptions before they escalate. For instance, if a supplier shipment is delayed or a production bottleneck emerges, ERP alerts teams instantly. This proactive approach helps companies resolve issues before they affect customers, reducing downtime and improving operational resilience.

3. Data-Driven Efficiency

Improved visibility provides a clear view of order cycles, resource utilization, and fulfillment rates. ERP analytics transform this information into actionable insights, helping businesses optimize resource allocation, reduce redundant tasks, and improve overall workflow efficiency. This leads to better cost control and higher productivity.

4. Strengthened Financial Performance

By minimizing order errors, optimizing inventory, and reducing manual rework, businesses can significantly lower their operational costs. Faster order processing and accurate invoicing also improve cash flow and shorten the order-to-cash cycle, directly contributing to higher profitability.

5. Greater Supply Chain Agility

Market conditions and customer demands can change overnight. ERP-enabled visibility gives organizations the agility to adapt quickly—whether by reallocating inventory, rerouting shipments, or adjusting production schedules. This flexibility helps companies stay competitive even in volatile environments.

6. Superior Customer Retention

ERP systems empower customer service teams with accurate, real-time order information. With fewer delays and greater transparency, customers gain confidence in the brand’s reliability. This trust translates into stronger customer retention, positive reviews, and higher lifetime value.

7. Continuous Improvement and Scalability

ERP-driven visibility provides a foundation for long-term growth. With measurable KPIs and performance dashboards, businesses can continually refine their processes, identify improvement areas, and scale operations efficiently—without sacrificing quality or control.

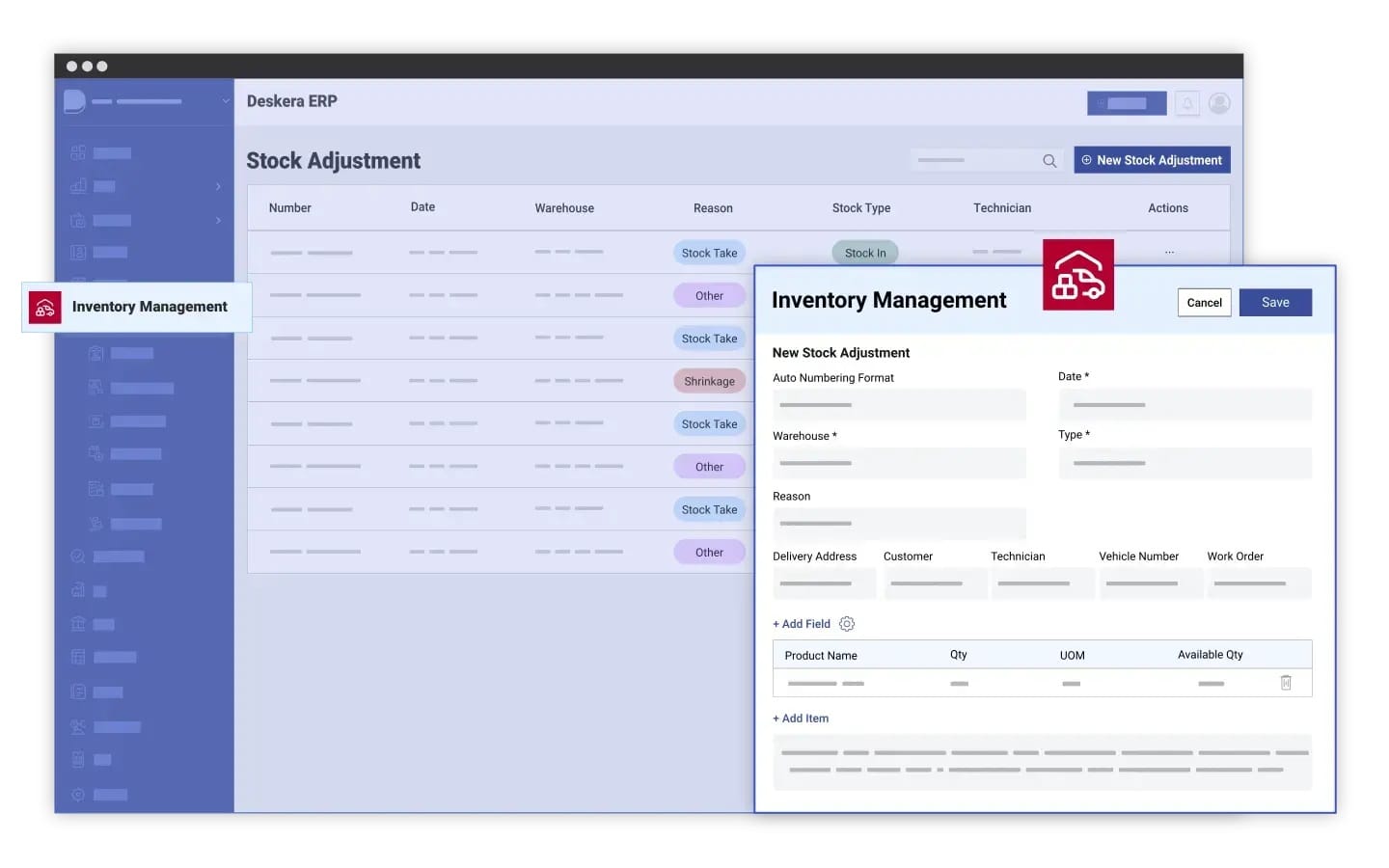

How Deskera ERP Helps Improve Order Visibility

Order visibility is only as good as the systems supporting it. That’s where Deskera ERP makes a difference. Designed to unify finance, inventory, production, and fulfillment processes, Deskera ERP enables businesses to see the complete order lifecycle in one place — from purchase to delivery. Its built-in automation, reporting, and collaboration tools simplify operations while ensuring teams always have the most accurate, real-time information.

With Deskera ERP, businesses can track orders seamlessly, improve communication between departments, and make data-backed decisions that enhance customer satisfaction and supply chain reliability. Here’s how it helps:

1. Centralized Order Management

Deskera ERP consolidates all order-related data — sales, inventory, shipping, and returns — into a unified dashboard. This eliminates the need to switch between systems or rely on manual updates, ensuring that every team member has access to the same accurate order information. This centralization minimizes miscommunication and enhances coordination between sales, warehouse, and logistics teams.

2. Real-Time Tracking and Inventory Synchronization

The platform provides real-time visibility into stock levels, order progress, and fulfillment status. As soon as an order is placed, inventory levels automatically update, helping prevent stockouts and overstocking. Deskera’s live tracking also gives businesses a transparent view of the supply chain, ensuring that any disruptions can be identified and resolved promptly.

3. Automated Workflows and Notifications

Deskera ERP automates routine order management tasks — from order confirmation and invoicing to shipment tracking and customer updates. Its automated alerts notify teams of potential issues such as delayed shipments or low inventory thresholds, allowing for proactive intervention before problems escalate.

4. Integrated Supplier and Customer Management

With built-in supplier and customer modules, Deskera ERP strengthens relationships on both ends of the supply chain. Businesses can monitor supplier performance, track delivery schedules, and maintain accurate communication logs. On the customer side, automated order updates and transparency build trust and improve post-purchase satisfaction.

5. Data Analytics and Performance Insights

Deskera’s advanced reporting and analytics tools convert order and inventory data into meaningful insights. Businesses can track KPIs such as fulfillment time, order accuracy, and delivery performance. This data-driven approach enables continuous process improvement and helps management make smarter, faster decisions that optimize profitability.

6. Seamless Integration with Other Systems

Deskera ERP easily integrates with external systems such as CRM platforms, eCommerce stores, and third-party logistics (3PL) providers. This interconnected ecosystem ensures that all sales channels and operational systems work together to maintain real-time visibility and smooth data flow across the entire supply chain.

7. Scalable Solution for Growing Businesses

Whether you’re managing 100 orders a month or 10,000, Deskera ERP scales effortlessly with your business. Its cloud-based architecture ensures flexibility, allowing growing enterprises to expand their visibility capabilities as operations evolve — without heavy infrastructure costs or disruptions.

In short, Deskera ERP turns fragmented processes into a synchronized, transparent system. By empowering businesses with complete, real-time visibility across every stage of the order lifecycle, it helps improve efficiency, strengthen collaboration, and elevate customer satisfaction — all while keeping costs in check.

Key Takeaways

- Order visibility enables businesses to monitor the entire journey of an order—from procurement to delivery—ensuring transparency, accuracy, and timely decision-making across the supply chain.

- The four key components—order tracking, supplier performance, manufacturing status, and logistics—work together to provide end-to-end visibility that strengthens efficiency and customer satisfaction.

- Visibility enhances order accuracy, improves inventory management, reduces errors, and builds trust with customers, ultimately leading to faster fulfillment and higher satisfaction levels.

- Lack of visibility can cause miscommunication, delayed fulfillment, and inventory mismatches, resulting in operational inefficiencies, higher costs, and dissatisfied customers.

- Businesses can strengthen visibility by defining KPIs, fostering collaboration, automating workflows, leveraging AI and predictive analytics, and adopting real-time tracking technologies.

- ERP systems integrate data from multiple functions—inventory, sales, manufacturing, and logistics—into one unified platform, enabling seamless tracking, automation, and real-time updates across the supply chain.

- ERP-driven visibility delivers measurable gains, including proactive issue resolution, process efficiency, cost savings, supply chain agility, and stronger customer loyalty.

- Deskera ERP enhances order visibility by centralizing data, automating workflows, and offering real-time tracking, analytics, and integration—empowering businesses to achieve complete control and transparency throughout the order lifecycle.

Related Articles