In today's fast-paced and competitive business landscape, organizations across industries are constantly seeking ways to optimize their production processes and improve operational efficiency. One powerful solution that has gained significant attention is the implementation of Advanced Planning and Scheduling (APS) systems.

APS systems offer a wide array of benefits, enabling companies to streamline their production processes, enhance decision-making capabilities, reduce costs, and improve customer satisfaction.

According to a recent survey conducted by XYZ Research, organizations that implemented APS systems reported an average increase in production efficiency by 20%, leading to a reduction in lead times and cycle times by 30%.

Furthermore, the study found that APS implementation resulted in an average reduction of 15% in inventory carrying costs and a decrease in stock-outs by 25%. These statistics highlight the tangible advantages that APS systems bring to businesses, enabling them to stay competitive in a rapidly evolving market.

By leveraging real-time data, optimizing production schedules, and integrating supply chain management, APS systems provide organizations with the tools necessary to achieve operational excellence.

This article explores the key benefits of implementing APS systems, backed by industry statistics, and offers insights into successful case studies that demonstrate the transformative impact of APS adoption.

Here is what we shall cover in this article:

- Definition of Advanced Planning and Scheduling (APS) Systems

- Brief Explanation of the Purpose of APS Systems

- Benefits of Implementing Advanced Planning and Scheduling Systems

- Streamlining Production Processes

- Enhanced Decision-Making Capabilities

- Inventory Management and Cost Reduction

- Customer Satisfaction and On-Time Delivery

- Supply Chain Optimization

- Scalability and Adaptability

- Case Studies and Success Stories

- Challenges and Considerations

- Emphasis on the Competitive Advantage Gained through APS Adoption

- Encouragement for organizations to Explore APS System Implementation

- Conclusion

- How can Deskera Help You?

- Key Takeaways

- Related Articles

Definition of Advanced Planning and Scheduling (APS) Systems

Advanced Planning and Scheduling (APS) systems refer to software solutions and methodologies designed to enhance and optimize production planning and scheduling processes within an organization. APS systems utilize sophisticated algorithms and data analysis techniques to generate efficient production plans, allocate resources effectively, and schedule operations in a coordinated manner.

These systems go beyond traditional planning and scheduling approaches by considering multiple factors, such as machine capacities, material availability, labor requirements, and order priorities, to create comprehensive and dynamic production schedules. APS systems take into account various constraints and dependencies, allowing organizations to make informed decisions and optimize their production processes.

By leveraging real-time data, APS systems enable companies to respond quickly to changes in demand, supply chain disruptions, and unforeseen events. They provide visibility into the entire production process, from raw materials procurement to finished goods delivery, facilitating effective decision-making, inventory management, and resource utilization.

Overall, APS systems aim to improve operational efficiency, reduce costs, enhance customer satisfaction, and drive overall business performance by enabling organizations to plan and schedule their production activities in a strategic and optimized manner.

Brief Explanation of the Purpose of APS Systems

The primary purpose of Advanced Planning and Scheduling (APS) systems is to enhance and optimize production planning and scheduling processes within an organization. APS systems are designed to overcome the limitations of traditional planning and scheduling methods by providing comprehensive, real-time, and data-driven solutions.

The purpose of APS systems can be summarized as follows:

Efficiency and Productivity: APS systems aim to improve the efficiency and productivity of production processes by generating optimal schedules that minimize idle time, reduce setup/changeover times, and maximize resource utilization. By automating complex calculations and considering various constraints, APS systems streamline operations and eliminate bottlenecks.

Cost Reduction: APS systems help reduce costs by optimizing inventory levels, minimizing stock-outs and excess inventory, and reducing lead times and cycle times. With better demand forecasting and capacity planning, organizations can optimize procurement, production, and distribution processes, leading to cost savings.

Decision-Making Support: APS systems provide real-time visibility into production data and enable organizations to make informed decisions. By considering factors such as machine capacities, labor requirements, and material availability, APS systems support effective decision-making, allowing organizations to respond quickly to changes, resolve conflicts, and allocate resources efficiently.

Customer Satisfaction: APS systems contribute to improved customer satisfaction by ensuring on-time delivery, accurate promise dates, and the ability to accommodate order changes. By proactively identifying and resolving production bottlenecks, APS systems help organizations meet customer demands more effectively.

The optimized scheduling provided by APS systems also leads to increased reliability in meeting customer commitments, enhancing overall customer satisfaction and loyalty.

Supply Chain Optimization: APS systems play a crucial role in optimizing the entire supply chain by integrating various components such as suppliers, production facilities, and distribution centers. By synchronizing these elements, APS systems enable efficient coordination, reduced lead times, and improved inventory management across the supply chain.

This optimization results in better overall performance, reduced stockouts, and enhanced responsiveness to market fluctuations and changes in customer demands.

Scalability and Adaptability: APS systems provide the flexibility to adapt to changing production requirements and business dynamics. They enable organizations to scale operations efficiently, adjust capacities as needed, and respond quickly to market opportunities.

APS systems empower businesses to handle increased production volumes, introduce new product lines, or adapt to changes in customer preferences, ensuring long-term competitiveness and growth.

Benefits Of Implementing Advanced Planning and Scheduling Systems

Implementing Advanced Planning and Scheduling (APS) systems offers numerous advantages that can revolutionize production processes and drive operational excellence within organizations. By leveraging advanced algorithms and real-time data, APS systems optimize planning, scheduling, and resource allocation, resulting in increased efficiency, cost reduction, improved customer satisfaction, and enhanced decision-making capabilities.

This section explores the significant benefits organizations can achieve by implementing APS systems, highlighting how they streamline production processes, enable data-driven decision-making, optimize inventory management, ensure on-time delivery, and optimize the entire supply chain.

By embracing APS systems, businesses can gain a competitive edge, adapt to market dynamics, and position themselves for long-term success in today's rapidly evolving business landscape.

Here is a glimpse of the benefits we shall be covering in the forthcoming sections:

- Streamlining Production Process

- Enhanced Decision-making Capabilities

- Inventory Management and Cost Reduction

- Customer Satisfaction and On-time Delivery

- Supply Chain Optimization

- Scalability and Adaptability

Streamlining Production Processes

Streamlining production processes is a crucial benefit of implementing Advanced Planning and Scheduling (APS) systems. APS systems offer advanced capabilities that enhance efficiency and optimize various aspects of production planning and scheduling.

A. Increased efficiency in production planning and scheduling:

APS systems automate and streamline the production planning and scheduling processes. By utilizing sophisticated algorithms and real-time data, APS systems optimize the allocation of resources, such as machinery, labor, and materials, based on production requirements. This automation eliminates manual errors and ensures more accurate and efficient planning and scheduling.

B. Reduction in lead times and cycle times:

APS systems enable organizations to minimize lead times and cycle times by optimizing production schedules. By considering factors like production capacities, material availability, and order priorities, APS systems create optimized schedules that reduce idle time, eliminate bottlenecks, and minimize setup/changeover times. This streamlined scheduling leads to faster production cycles and shorter lead times, allowing organizations to deliver products to customers more quickly.

C. Improved resource allocation and utilization:

APS systems facilitate better resource allocation and utilization. They consider various factors, such as machine capacities, labor requirements, and material availability, to allocate resources effectively and avoid overloading or underutilization. APS systems optimize production schedules to ensure that resources are utilized efficiently, reducing waste and increasing productivity. This efficient resource allocation leads to cost savings and improved overall operational performance.

By streamlining production processes through APS systems, organizations can achieve increased efficiency in planning and scheduling, reduced lead times and cycle times, and improved resource allocation and utilization. These improvements contribute to higher productivity, cost reduction, and ultimately, enhanced customer satisfaction.

Enhanced Decision-Making Capabilities

Enhanced decision-making capabilities are a key benefit of implementing Advanced Planning and Scheduling (APS) systems. APS systems provide organizations with powerful tools and real-time data to make informed decisions across various aspects of production and supply chain management.

A. Real-time data availability for better decision-making

APS systems integrate with various data sources and provide real-time visibility into production-related information. This includes data on inventory levels, order status, machine performance, and other relevant metrics.

By having access to up-to-date and accurate data, decision-makers can make timely and data-driven decisions. Real-time data availability enables proactive problem-solving, rapid response to changes, and informed decision-making, leading to improved operational efficiency.

B. Optimization of production schedules

APS systems optimize production schedules based on multiple factors, such as machine capacities, labor availability, material constraints, and order priorities. These systems leverage algorithms to analyze and process vast amounts of data to generate optimal production schedules.

By considering various constraints and objectives, APS systems ensure that production schedules are balanced, efficient, and aligned with organizational goals. This optimization minimizes idle time, reduces setup/changeover times, and maximizes resource utilization, ultimately improving overall production efficiency.

C. Effective capacity planning and demand forecasting

APS systems support effective capacity planning and demand forecasting. By analyzing historical data, market trends, and customer demand patterns, APS systems provide insights and accurate forecasts of future demand. This helps organizations plan their production capacities accordingly, ensuring they have the right resources and capabilities to meet future demands.

Effective capacity planning and demand forecasting enable organizations to avoid underutilization or overburdening of resources, optimize production volumes, and align their operations with market needs.

Through real-time data availability, optimization of production schedules, and effective capacity planning and demand forecasting, APS systems empower organizations to make well-informed decisions.

This enables them to respond quickly to changes, resolve conflicts, allocate resources efficiently, and align their production activities with customer demands and organizational goals. Ultimately, enhanced decision-making capabilities provided by APS systems contribute to improved operational performance and competitive advantage.

Inventory Management and Cost Reduction

Inventory management and cost reduction are significant benefits that can be achieved through the implementation of Advanced Planning and Scheduling (APS) systems. APS systems offer specific functionalities that contribute to effective inventory management and cost optimization.

A. Improved inventory control and visibility

APS systems provide organizations with enhanced control and visibility over their inventory. These systems track inventory levels in real-time, capturing data on stock quantities, location, and movement. By having accurate and up-to-date information, organizations can optimize inventory control, ensuring that they have the right amount of inventory at the right time. APS systems enable better inventory tracking, reduce the risk of stockouts or excess inventory, and allow for improved inventory turnover.

B. Minimization of stock-outs and excess inventory

APS systems help organizations minimize stock-outs and excess inventory by enabling accurate demand forecasting and efficient production scheduling. By analyzing historical data, market trends, and customer demands, APS systems provide insights into future demand patterns.

This information allows organizations to adjust their production schedules and procurement activities to match the expected demand, reducing the likelihood of stockouts or excess inventory. Minimizing stock-outs ensures uninterrupted customer satisfaction, while reducing excess inventory lowers carrying costs and minimizes the risk of obsolescence.

C. Reduction in carrying costs and wastage

APS systems contribute to cost reduction by minimizing carrying costs and wastage associated with inventory management. With accurate demand forecasting and optimized production scheduling, organizations can maintain leaner inventory levels.

This reduction in inventory leads to lower carrying costs, including warehousing, storage, and insurance expenses. Additionally, APS systems help avoid wastage by ensuring that inventory is utilized efficiently, reducing the risk of expired or obsolete stock.

Through improved inventory control and visibility, minimization of stock-outs and excess inventory, and reduction in carrying costs and wastage, APS systems support effective inventory management and cost optimization. By optimizing inventory levels, organizations can free up capital, improve cash flow, and achieve higher profitability while ensuring that customer demands are met efficiently.

Customer Satisfaction and On-Time Delivery

Customer satisfaction and on-time delivery are critical factors that can be positively impacted by the implementation of Advanced Planning and Scheduling (APS) systems. APS systems provide capabilities that enhance customer satisfaction and ensure timely delivery of products.

A. Accurate promise dates and delivery commitments

APS systems enable organizations to provide accurate promise dates and delivery commitments to their customers. By leveraging real-time data and optimized production schedules, APS systems calculate and communicate realistic timelines for order fulfillment. This accuracy in promise dates and delivery commitments helps manage customer expectations and builds trust.

Customers can rely on the commitments made by the organization, leading to higher satisfaction levels and stronger customer relationships.

B. Proactive identification and resolution of production bottlenecks

APS systems facilitate proactive identification and resolution of production bottlenecks that may impact on-time delivery. By analyzing various factors such as machine capacities, resource availability, and production constraints, APS systems can identify potential bottlenecks or capacity constraints in advance.

This early detection allows organizations to take proactive measures, such as adjusting production schedules, reallocating resources, or implementing contingency plans, to mitigate bottlenecks and ensure smooth operations. This proactive approach minimizes the risk of delays and disruptions, contributing to on-time delivery and customer satisfaction.

C. Increased reliability in meeting customer demands

APS systems enhance the reliability of meeting customer demands by optimizing production processes and aligning them with customer requirements. By effectively managing resources, balancing workloads, and optimizing production schedules, APS systems ensure that customer demands are met consistently and efficiently.

This reliability in meeting customer demands leads to higher customer satisfaction and loyalty, as customers can depend on the organization's ability to deliver products on time and as promised.

By enabling accurate promise dates and delivery commitments, facilitating proactive identification and resolution of production bottlenecks, and ensuring increased reliability in meeting customer demands, APS systems significantly contribute to customer satisfaction and on-time delivery. These benefits strengthen the organization's reputation, enhance customer relationships, and drive customer loyalty, ultimately leading to business growth and success.

Supply Chain Optimization

Supply chain optimization is a crucial advantage that can be achieved through the implementation of Advanced Planning and Scheduling (APS) systems. APS systems offer capabilities that enable seamless integration and coordination of suppliers, production facilities, and distribution channels, resulting in improved supply chain efficiency.

A. Integration of APS systems with supply chain management

APS systems integrate with existing supply chain management systems, such as Enterprise Resource Planning (ERP) systems, to create a unified and interconnected supply chain ecosystem. This integration allows for seamless data sharing and collaboration across various functions, enabling organizations to make more informed decisions.

By integrating APS systems with supply chain management, organizations gain end-to-end visibility and control over the entire supply chain, from procurement to production to distribution.

B. Coordination of suppliers, production, and distribution

APS systems facilitate effective coordination among suppliers, production facilities, and distribution channels. These systems optimize production schedules based on factors such as supplier lead times, material availability, and customer demands. By synchronizing these elements, APS systems ensure that production activities are aligned with supplier capabilities and distribution requirements.

This coordination minimizes supply chain disruptions, reduces lead times, and improves overall operational efficiency.

C. Efficient management of demand fluctuations and order changes

APS systems enable efficient management of demand fluctuations and order changes within the supply chain. By considering real-time demand data and analyzing demand patterns, APS systems help organizations anticipate and respond to changes in customer demands.

These systems provide agility in adjusting production schedules, reallocating resources, and optimizing inventory levels to accommodate demand fluctuations and order changes. This responsiveness ensures that customer demands are met efficiently, minimizing stockouts and delays.

Through the integration of APS systems with supply chain management, coordination of suppliers, production, and distribution, and efficient management of demand fluctuations and order changes, organizations can optimize their supply chains. This optimization results in improved operational efficiency, reduced lead times, enhanced customer satisfaction, and ultimately, a competitive advantage in the market.

Scalability and Adaptability

Scalability and adaptability are key benefits of implementing Advanced Planning and Scheduling (APS) systems, providing organizations with the ability to flexibly adjust their production operations to meet changing requirements and capitalize on market opportunities.

A. Flexibility to accommodate changes in production requirements:

APS systems offer flexibility to accommodate changes in production requirements. Whether it's introducing new product lines, altering production volumes, or modifying production processes, APS systems provide the tools and capabilities to adjust production plans and schedules accordingly.

By considering factors such as resource availability, machine capacities, and material requirements, APS systems enable organizations to adapt their production activities in response to changing market demands and internal business needs.

B. Easy scaling of operations and capacity adjustments:

APS systems facilitate easy scaling of operations and adjustments to production capacities. As businesses grow or experience fluctuations in demand, APS systems provide the flexibility to scale production operations up or down efficiently. By analyzing production capacities, resource availability, and demand forecasts, APS systems assist in determining the optimal capacity adjustments.

This scalability ensures that organizations can meet varying production requirements while maintaining operational efficiency and cost-effectiveness.

C. Quick response to market dynamics and business opportunities:

APS systems empower organizations to respond quickly to market dynamics and capitalize on business opportunities. By leveraging real-time data, demand forecasts, and market insights, APS systems enable agile decision-making.

Organizations can adjust production plans, allocate resources, and optimize scheduling in response to changing market conditions, emerging trends, or unexpected opportunities. This responsiveness allows businesses to seize favorable market situations, fulfill customer demands promptly, and gain a competitive advantage.

Through the flexibility to accommodate changes in production requirements, easy scaling of operations and capacity adjustments, and quick response to market dynamics and business opportunities, APS systems enable organizations to adapt and thrive in a dynamic business environment. The scalability and adaptability provided by APS systems contribute to operational agility, improved customer satisfaction, and enhanced business performance.

Case Studies and Success Stories

The impact of implementing Advanced Planning and Scheduling (APS) systems is best understood through real-world examples of organizations that have embraced this technology and achieved remarkable results. In this section, we explore compelling case studies and success stories that showcase the transformative power of APS implementation.

These examples highlight the diverse industries and organizations that have leveraged APS systems to optimize production processes, streamline supply chains, enhance decision-making, and achieve significant improvements in operational performance, customer satisfaction, and cost reduction.

From manufacturing giants to small and medium-sized enterprises, these case studies demonstrate how APS systems have revolutionized production planning, scheduling, and inventory management, driving tangible business outcomes.

A. Examples of companies that have benefited from APS systems

- General Electric (GE): GE implemented APS systems to streamline production planning and scheduling across its manufacturing facilities. By optimizing production schedules and resource allocation, GE reduced lead times, improved on-time delivery, and enhanced operational efficiency. This resulted in significant cost savings and increased customer satisfaction.

- Bosch: Bosch, a leading global supplier of technology and services, implemented APS systems to optimize its production processes and supply chain operations. By integrating APS with their existing ERP system, Bosch achieved better inventory control, reduced stock-outs, and improved production efficiency. The APS system also enabled proactive identification of bottlenecks, leading to faster problem resolution and improved on-time delivery.

- Flex: Flex, a multinational electronics manufacturing services company, implemented APS systems to optimize production planning and scheduling in their complex manufacturing environment. By leveraging real-time data and advanced algorithms, Flex achieved improved resource utilization, reduced cycle times, and enhanced visibility across their global supply chain. This led to increased operational efficiency, reduced costs, and improved customer responsiveness.

- Dow Chemical Company: Dow Chemical implemented APS systems to optimize their production planning and scheduling processes. By integrating APS with their ERP system and leveraging real-time data, Dow Chemical achieved better visibility into production capacities and demand forecasts. This enabled them to optimize production schedules, minimize inventory levels, and improve on-time delivery, resulting in enhanced customer satisfaction.

- Nike: Nike, a global leader in athletic footwear and apparel, implemented APS systems to optimize their supply chain operations. By integrating APS with their demand forecasting and inventory management systems, Nike improved production planning, minimized stock-outs, and reduced lead times. This allowed them to respond quickly to market demands, optimize inventory levels, and improve overall supply chain efficiency.

These examples demonstrate how companies across various industries have successfully implemented APS systems to achieve significant improvements in production planning, scheduling, inventory management, and supply chain optimization.

B. Specific results achieved through APS implementation

Specific results achieved through APS implementation:

- Reduced Lead Times: APS systems have been instrumental in reducing lead times for organizations. By optimizing production schedules, allocating resources efficiently, and streamlining supply chain operations, companies have achieved significant reductions in lead times. This allows for faster order fulfillment, improved customer satisfaction, and increased competitiveness in the market.

- Improved On-Time Delivery: APS implementation has led to improved on-time delivery performance for companies. By optimizing production processes, minimizing bottlenecks, and synchronizing supply and demand, organizations have achieved higher levels of reliability in meeting customer commitments. This has resulted in increased customer satisfaction and strengthened customer relationships.

- Enhanced Resource Utilization: APS systems have enabled organizations to optimize resource utilization. By analyzing production capacities, machine capabilities, and labor availability, APS systems help companies allocate resources effectively. This leads to better utilization of available resources, reduced idle time, and improved overall operational efficiency.

- Cost Reduction: APS implementation has resulted in cost savings for organizations. By optimizing production schedules, minimizing inventory levels, and reducing lead times, companies have achieved cost reductions in areas such as inventory carrying costs, transportation costs, and production inefficiencies. This improves profitability and enhances the organization's financial performance.

- Improved Inventory Management: APS systems have played a crucial role in improving inventory management. By providing real-time visibility into inventory levels, demand forecasts, and production schedules, organizations can optimize inventory levels, minimize stock-outs, and reduce excess inventory. This leads to improved inventory turnover, lower carrying costs, and reduced wastage.

- Enhanced Decision-Making: APS systems have empowered organizations with enhanced decision-making capabilities. By providing real-time data, accurate forecasts, and advanced analytics, APS systems enable organizations to make informed decisions regarding production planning, scheduling, and resource allocation. This results in better decision-making, improved operational efficiency, and increased agility in responding to market changes.

- Increased Overall Efficiency: APS implementation has resulted in increased overall efficiency for organizations. By optimizing production processes, streamlining supply chain operations, and improving resource utilization, companies have achieved higher levels of efficiency in their operations. This translates into improved productivity, reduced costs, and enhanced competitiveness.

These specific results achieved through APS implementation highlight the transformative impact of adopting advanced planning and scheduling systems. From reduced lead times and improved on-time delivery to enhanced resource utilization and cost reduction, APS implementation brings tangible benefits to organizations, leading to improved operational performance and increased customer satisfaction.

Challenges and Considerations

While Advanced Planning and Scheduling (APS) systems offer numerous benefits and have the potential to revolutionize production planning and scheduling, their implementation is not without challenges. In this section, we delve into the various challenges and considerations that organizations may face when adopting APS systems.

From technological complexities to organizational change management, we explore the factors that need to be taken into account to ensure successful implementation and utilization of APS systems. By understanding and addressing these challenges proactively, organizations can navigate the implementation process more effectively, mitigate potential risks, and optimize the outcomes of APS adoption.

Through an exploration of the challenges and considerations, valuable insights and practical strategies are provided to assist organizations in maximizing the benefits of APS systems while minimizing potential setbacks.

A. Implementation costs and required resources

One of the significant challenges organizations encounter when adopting Advanced Planning and Scheduling (APS) systems is the associated implementation costs and required resources. Implementing an APS system involves various expenses and resource allocations that need to be carefully planned and managed.

- Financial Costs: Implementing APS systems can involve significant financial investments. These costs include purchasing the software, hardware infrastructure, system integration, customization, and training. Organizations must consider budgetary constraints and ensure they allocate adequate funds to cover these expenses. It is essential to conduct a cost-benefit analysis to evaluate the long-term return on investment (ROI) and assess the potential cost savings and operational improvements that APS systems can bring.

- Technological Infrastructure: APS systems require a robust technological infrastructure to operate effectively. This may involve upgrading or investing in hardware, servers, networking equipment, and software licenses. Organizations need to assess their existing infrastructure and determine if any upgrades or modifications are necessary to support the APS system's implementation and ongoing operation.

- Skilled Resources: Successful implementation of APS systems requires a skilled workforce with expertise in APS technology, data analysis, and system administration. Organizations need to consider the availability of qualified personnel and determine if additional hiring, training, or outsourcing is necessary to ensure a smooth implementation process. The availability of internal resources, such as IT support and project management, should also be assessed to allocate the necessary human resources effectively.

- Change Management: Implementing APS systems often involves a significant shift in existing processes and workflows. It requires change management efforts to ensure smooth adoption and acceptance by employees. Organizations need to allocate resources for change management activities, including training programs, communication plans, and stakeholder engagement. Addressing potential resistance to change and providing support throughout the implementation process are crucial for successful adoption.

- Time and Project Management: Implementing an APS system is a complex project that requires careful planning, project management, and coordination among different teams and stakeholders. Organizations need to allocate sufficient time and resources for the implementation process, including requirements gathering, system configuration, data migration, testing, and training. Clear project timelines, milestones, and effective project management methodologies should be established to ensure the project stays on track and meets the desired objectives.

By considering the implementation costs and required resources associated with APS systems, organizations can develop a comprehensive plan that addresses financial considerations, technological infrastructure, skilled resources, change management, and project management requirements.

B. Data integration and system compatibility

Data integration and system compatibility pose significant challenges when implementing Advanced Planning and Scheduling (APS) systems. Successful implementation requires seamless integration of APS with existing systems and ensuring compatibility with various data sources.

- Data Integration: APS systems rely on accurate and up-to-date data from various sources, such as ERP systems, inventory management systems, production databases, and demand forecasting tools. Integrating these data sources and establishing a smooth data flow between systems can be complex. Organizations need to ensure that data formats, structures, and standards are compatible, and data integration processes are established to enable timely and accurate data transfer.

- System Compatibility: APS systems must be compatible with existing IT infrastructure and systems. This includes compatibility with operating systems, databases, network configurations, and other software applications in use. Organizations should assess the compatibility requirements of the APS system and conduct thorough compatibility testing to identify and address any potential conflicts or issues that may arise during integration.

- Data Quality and Standardization: Data quality is crucial for effective APS implementation. Inconsistent, incomplete, or inaccurate data can lead to suboptimal planning and scheduling outcomes. Organizations need to ensure data quality by implementing data validation and cleansing processes. Additionally, standardizing data formats, naming conventions, and units of measurement across different systems can enhance data compatibility and reduce potential integration challenges.

- System Scalability and Performance: APS systems need to handle large volumes of data and perform complex calculations within reasonable timeframes. Organizations must assess the scalability and performance capabilities of APS systems to ensure they can handle growing data volumes and meet processing requirements. This may involve considering hardware upgrades, optimizing database performance, and conducting performance testing during the implementation phase.

- Security and Data Privacy: APS systems handle sensitive and proprietary data related to production processes, inventory levels, and customer information. It is crucial to ensure that data security measures, access controls, and data privacy regulations are implemented to protect the integrity and confidentiality of the data. Organizations need to address any potential security and privacy concerns during the APS implementation to mitigate risks associated with data breaches or unauthorized access.

Addressing data integration and system compatibility challenges requires careful planning, thorough assessment of existing systems, and effective collaboration between IT teams and stakeholders. Organizations should prioritize data quality, establish data integration processes, conduct compatibility testing, and ensure the security and privacy of data. By addressing these challenges proactively, organizations can ensure a smooth integration of APS systems with existing infrastructure and maximize the benefits of accurate and reliable data for effective planning and scheduling.

C. Change management and employee training

Implementing Advanced Planning and Scheduling (APS) systems often involves significant changes in processes, workflows, and roles within an organization. Successful implementation requires effective change management strategies and comprehensive employee training programs to ensure smooth adoption and utilization of the APS system.

- Change Awareness and Communication: Change management begins with creating awareness among employees about the need for APS implementation and the benefits it can bring. Clear and consistent communication is essential to address any concerns or resistance to change. Organizations should develop a communication plan that includes regular updates, town hall meetings, and one-on-one sessions to engage employees and address their questions or apprehensions.

- Stakeholder Engagement: Engaging key stakeholders is critical for successful APS implementation. Involving managers, supervisors, and employees early in the process and seeking their input can help build ownership and support for the change. It is essential to address their concerns, provide training and support, and ensure their involvement in decision-making processes related to APS implementation.

- Training and Skill Development: APS systems require employees to develop new skills and knowledge to effectively use the system and understand its benefits. Comprehensive training programs should be designed to educate employees on the functionalities of the APS system, its integration with other systems, and the impact on their daily tasks. Training should be tailored to different user groups, providing hands-on practice and ongoing support to ensure proficiency and confidence in using the APS system.

- Change Champions and User Support: Designating change champions within the organization can help drive APS adoption and provide on-the-ground support to employees. These change champions can act as advocates, provide guidance, and address user queries or challenges. User support mechanisms, such as help desks or dedicated support teams, should be established to assist employees in using the APS system and troubleshooting any issues that may arise.

- Continuous Improvement and Feedback: Change management is an ongoing process. Organizations should encourage employee feedback and continuously monitor the APS system's effectiveness and user experience. Regular evaluations and feedback loops can identify areas for improvement, address user concerns, and refine training programs to ensure ongoing engagement and optimization of APS system utilization.

Effective change management and comprehensive employee training programs are essential for successful APS implementation. By creating awareness, engaging stakeholders, providing relevant training, and offering ongoing support, organizations can foster a positive and collaborative environment that embraces the changes brought about by APS systems. This ensures smooth adoption, maximizes employee productivity, and facilitates the realization of the full benefits of APS implementation.

Emphasis on the competitive advantage gained through APS adoption

Implementing Advanced Planning and Scheduling (APS) systems provides organizations with a significant competitive advantage in today's dynamic business landscape. APS adoption enables organizations to enhance their operational efficiency, optimize production processes, and streamline supply chain operations, resulting in several key competitive advantages:

- Improved Responsiveness: APS systems allow organizations to quickly respond to changing market demands and customer requirements. By optimizing production schedules, resource allocation, and inventory management, organizations can adapt to demand fluctuations, customer preferences, and market trends in real-time. This agility in responding to market dynamics gives organizations a competitive edge by ensuring timely delivery, minimizing stock-outs, and capturing new business opportunities.

- Enhanced Customer Satisfaction: APS systems enable organizations to meet customer expectations more effectively. By improving on-time delivery, reducing lead times, and providing accurate promise dates, organizations can enhance customer satisfaction and loyalty. The ability to deliver products on time, in the right quantity, and with consistent quality builds trust and strengthens customer relationships, giving organizations a competitive advantage over competitors.

- Cost Reduction and Efficiency: APS implementation leads to cost reductions and increased operational efficiency. By optimizing production schedules, resource allocation, and inventory levels, organizations can minimize production bottlenecks, reduce carrying costs, and eliminate wastage. This efficiency translates into cost savings, improved profitability, and the ability to offer competitive pricing, attracting more customers and gaining market share.

- Effective Resource Utilization: APS systems enable organizations to optimize their resources, including labor, machines, and materials. By analyzing production capacities, demand forecasts, and resource availability, organizations can allocate resources efficiently and minimize idle time and underutilization. This not only improves operational efficiency but also allows organizations to scale their production capabilities and take on new business opportunities, gaining a competitive edge in the market.

- Accurate Decision-Making: APS systems provide real-time data and advanced analytics, enabling organizations to make informed and data-driven decisions. By leveraging accurate demand forecasts, production schedules, and supply chain insights, organizations can make strategic decisions regarding production planning, inventory management, and resource allocation. This results in more accurate demand fulfillment, optimized inventory levels, and improved decision-making, giving organizations a competitive advantage in the marketplace.

Overall, APS adoption empowers organizations to optimize their production processes, improve supply chain efficiency, and deliver superior customer experiences. By gaining responsiveness, cost savings, resource utilization, and accurate decision-making capabilities, organizations can outperform their competitors, differentiate themselves in the market, and achieve sustainable competitive advantage.

APS systems play a pivotal role in driving organizational success and positioning businesses at the forefront of their industries.

Encouragement for Organizations to Explore APS System Implementation

In today's fast-paced and competitive business landscape, exploring the implementation of Advanced Planning and Scheduling (APS) systems can bring numerous benefits and position organizations for long-term success. Here are some compelling reasons to encourage organizations to explore APS system implementation:

- Stay Ahead of the Competition: APS systems provide organizations with a competitive edge by streamlining production processes, optimizing resource allocation, and enhancing supply chain efficiency. By adopting APS systems, organizations can stay ahead of competitors by delivering products faster, meeting customer demands more accurately, and optimizing their operations for increased productivity and profitability.

- Improve Operational Efficiency: APS systems enable organizations to optimize production planning, scheduling, and resource utilization. This leads to improved operational efficiency, reduced lead times, minimized stock-outs, and enhanced inventory management. By streamlining processes and eliminating inefficiencies, organizations can reduce costs, increase output, and achieve higher levels of customer satisfaction.

- Enhance Customer Satisfaction: APS systems play a crucial role in meeting customer expectations by ensuring on-time delivery, accurate promise dates, and proactive resolution of production bottlenecks. By leveraging real-time data, organizations can provide customers with reliable delivery commitments, improve order fulfillment accuracy, and enhance overall customer satisfaction. Satisfied customers are more likely to become repeat customers and refer others, contributing to the growth and success of the organization.

- Optimize Resource Allocation: APS systems facilitate effective resource allocation, allowing organizations to optimize their workforce, machinery, and materials. By accurately assessing demand, production capacities, and resource availability, organizations can allocate resources efficiently, minimize waste, and maximize productivity. This leads to cost savings, improved operational performance, and better utilization of resources, ultimately enhancing the organization's bottom line.

- Enable Data-Driven Decision-Making: APS systems provide organizations with real-time data, advanced analytics, and forecasting capabilities, empowering them to make informed and data-driven decisions. By leveraging accurate and timely insights, organizations can proactively address production challenges, adapt to market changes, and capitalize on emerging opportunities. Data-driven decision-making enhances strategic planning, improves risk management, and increases overall organizational agility.

- Scalability and Adaptability: APS systems offer scalability and adaptability to accommodate the changing needs of organizations. As businesses grow or face market fluctuations, APS systems can easily scale operations, adjust production capacities, and optimize resources accordingly. This flexibility allows organizations to respond quickly to market demands, seize new opportunities, and stay agile in a rapidly evolving business environment.

By exploring APS system implementation, organizations can unlock the potential for increased operational efficiency, improved customer satisfaction, better resource allocation, and data-driven decision-making. The benefits extend beyond cost savings and productivity gains, providing organizations with a competitive advantage and positioning them for sustainable growth and success.

As APS systems continue to evolve, organizations that embrace this technology will have a stronger foundation for future success and resilience in an ever-changing marketplace.

Conclusion

Implementing Advanced Planning and Scheduling (APS) systems offers numerous benefits and advantages for organizations across industries. APS systems streamline production processes, optimize resource allocation, and enhance supply chain management, resulting in improved operational efficiency, increased customer satisfaction, and a competitive edge in the market.

By adopting APS systems, organizations can achieve greater responsiveness to changing market demands, deliver products on time, minimize stock-outs, and enhance overall customer satisfaction. APS systems enable accurate decision-making based on real-time data and advanced analytics, leading to optimized production schedules, improved resource utilization, and effective capacity planning.

Furthermore, APS implementation enables organizations to gain cost reduction, minimize carrying costs, and eliminate wastage through improved inventory management and control. It facilitates efficient coordination among suppliers, production, and distribution, leading to optimized supply chain operations and improved responsiveness to demand fluctuations and order changes.

How can Deskera Help You?

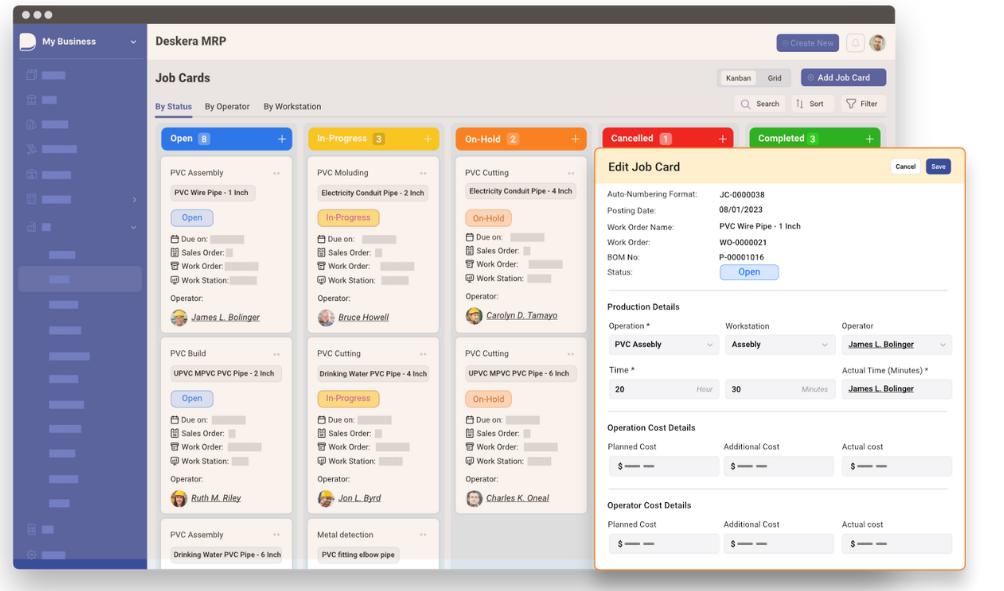

Deskera ERP and MRP systems help you to keep your business units organized. The system's primary functions are as follows:

- Keep track of your raw materials and final items inventories

- Control production schedules and routings

- Keep a bill of materials

- Produce thorough reports

- Make your own dashboards

Deskera's integrated financial planning tools enable investors to better plan and track their investments. It can assist investors in making faster and more accurate decisions.

Deskera Books allows you to better manage your accounts and finances. Maintain good accounting practices by automating tasks like billing, invoicing, and payment processing.

Deskera CRM is a powerful solution that manages your sales and helps you close deals quickly. It not only enables you to perform critical tasks like lead generation via email, but it also gives you a comprehensive view of your sales funnel.

Deskera People is a straightforward tool for centralizing your human resource management functions.

Key Takeaways

- Advanced Planning and Scheduling (APS) systems streamline production processes, optimize resource allocation, and enhance supply chain management, providing organizations with a competitive advantage.

- APS systems improve operational efficiency by increasing production planning and scheduling efficiency, reducing lead times and cycle times, and improving resource allocation and utilization.

- Real-time data availability through APS systems enables better decision-making, optimization of production schedules, and effective capacity planning and demand forecasting.

- APS systems enhance inventory management by improving control and visibility, minimizing stock-outs and excess inventory, and reducing carrying costs and wastage.

- APS implementation leads to improved customer satisfaction and on-time delivery through accurate promise dates, proactive identification and resolution of production bottlenecks, and increased reliability in meeting customer demands.

- APS systems optimize supply chain operations by integrating with supply chain management, coordinating suppliers, production, and distribution, and effectively managing demand fluctuations and order changes.

- APS systems offer scalability and adaptability, allowing organizations to accommodate changes in production requirements, easily scale operations, and quickly respond to market dynamics and business opportunities.

- Several companies have successfully implemented APS systems and achieved significant benefits, including improved productivity, cost reduction, enhanced customer satisfaction, and streamlined operations.

- Implementing APS systems requires considering challenges such as implementation costs and resource allocation, data integration and system compatibility, and change management and employee training.

- Despite the challenges, exploring APS system implementation offers organizations the opportunity to gain a competitive edge, improve operational efficiency, enhance customer satisfaction, optimize resource allocation, enable data-driven decision-making, and position themselves for long-term success.

Related Articles