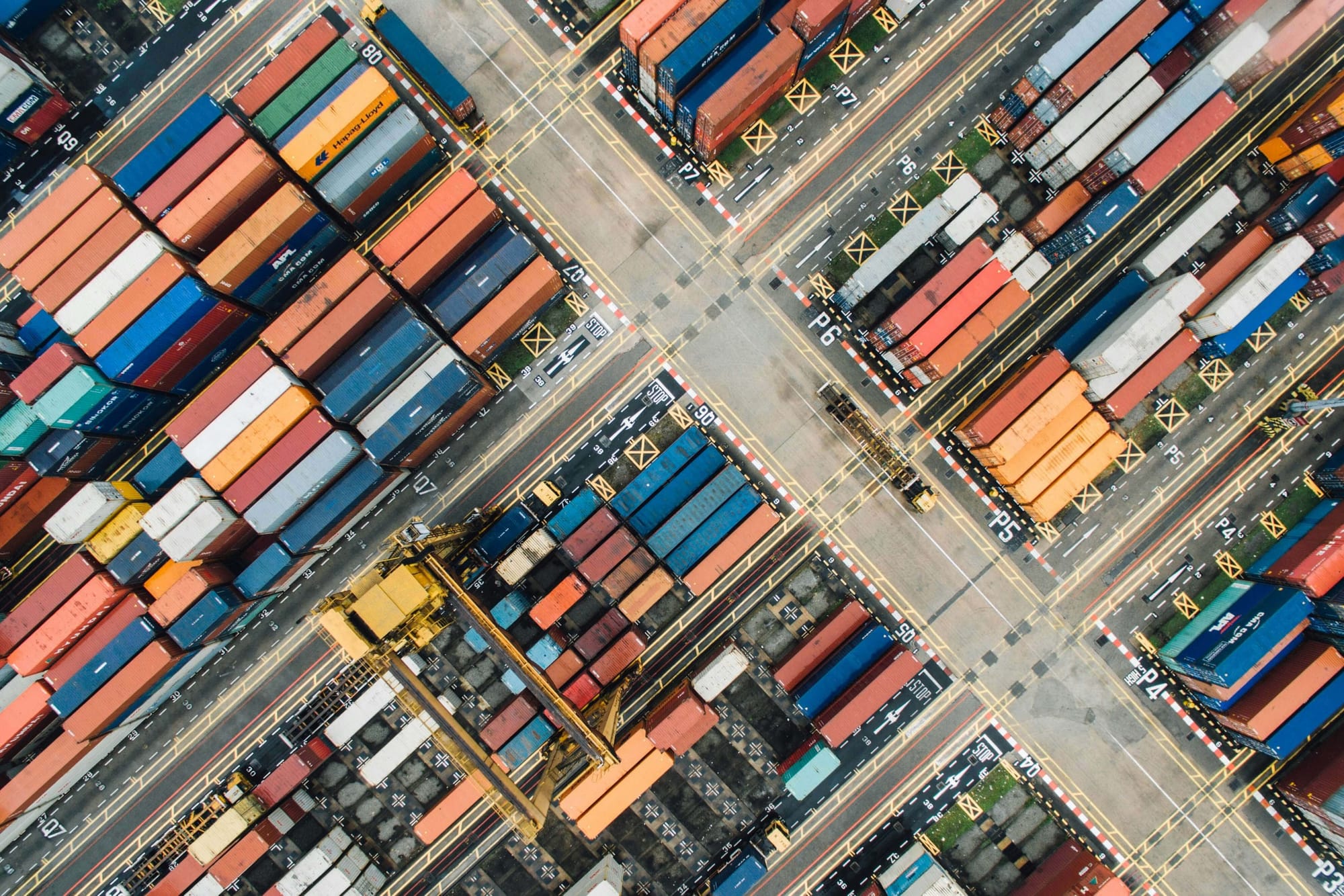

In today’s competitive business environment, supply chain planning has become the backbone of operational success. Companies that excel in this area consistently outperform their peers, with research showing that 79% of businesses with high-performing supply chains achieve greater revenue growth than their industry average. Effective planning not only ensures seamless product flow but also helps organizations respond swiftly to market fluctuations, customer expectations, and global disruptions.

High-performing supply chains don’t just deliver products—they drive revenue growth and operational excellence.

Optimized supply chains don’t just improve efficiency—they directly impact profitability. Studies indicate that businesses with well-structured supply chains operate at 15% lower costs compared to those that lack robust planning. By aligning demand forecasts, inventory levels, production schedules, and distribution networks, companies can cut down waste, minimize bottlenecks, and maximize margins.

Technology is rapidly transforming this space, driving efficiency and resilience like never before. The adoption of artificial intelligence (AI) in supply chain planning has already shown promising results, enabling 5–10% reductions in transportation costs and up to a 20% boost in delivery reliability. Combined with real-time analytics, automation, and collaboration tools, businesses now have the power to build supply chains that are not only efficient but also agile and future-ready.

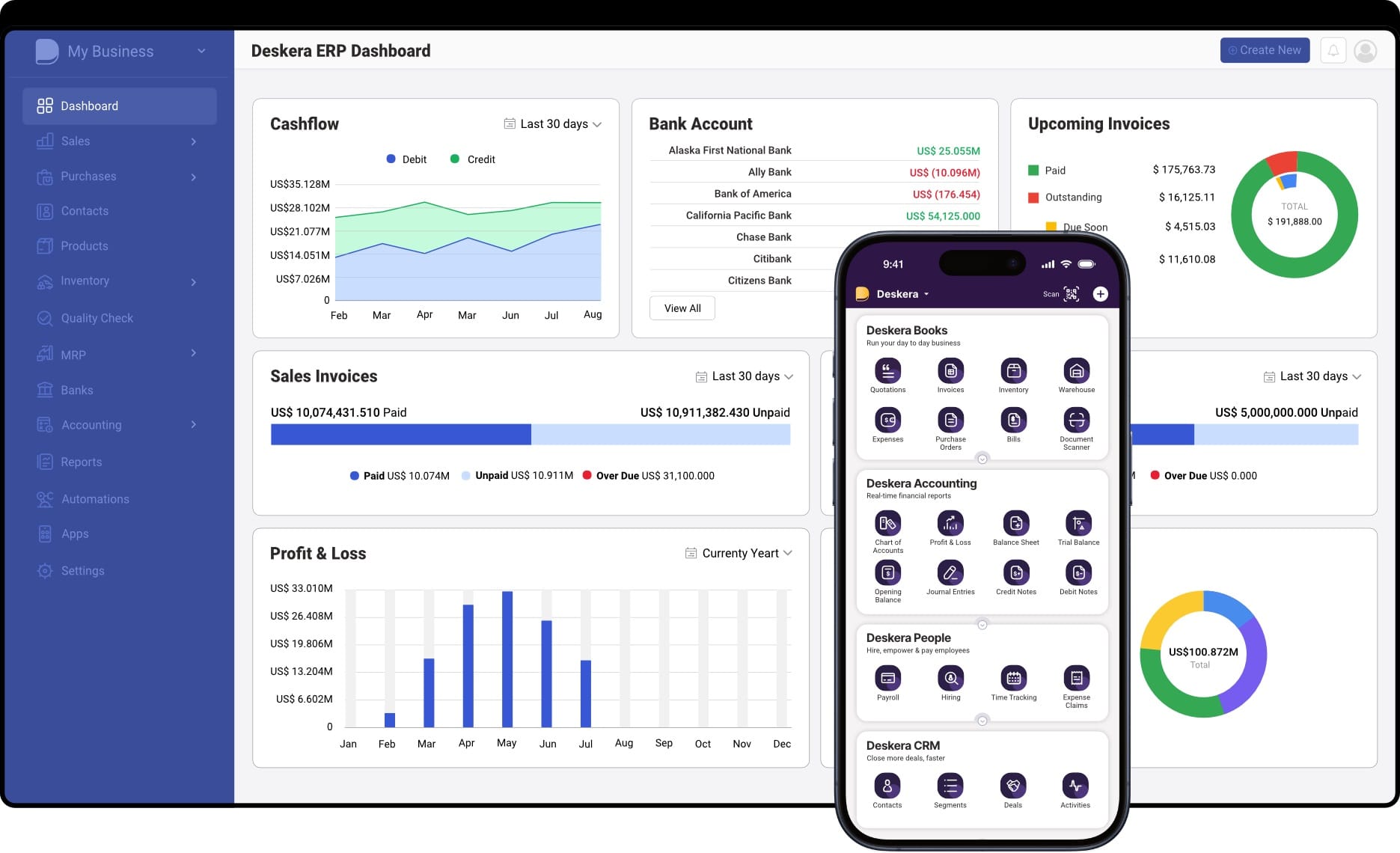

This is where solutions like Deskera ERP stand out. Deskera offers integrated tools for demand forecasting, MRP, inventory management, and procurement—all supported by its AI assistant, David. With real-time visibility, advanced reporting, and mobile accessibility, Deskera helps businesses of all sizes make smarter, faster, and more data-driven supply chain decisions. By leveraging such platforms, companies can transform their supply chain planning into a competitive advantage.

What is Supply Chain Planning?

When most people think of supply chain planning, they immediately picture inventory and logistics—but the scope is far broader. For physical products and manufacturing, planning begins with sourcing raw materials from suppliers and extends all the way to the moment a product reaches a customer’s doorstep or store shelf. It even goes beyond, encompassing returns, recycling, and reverse logistics. At its core, supply chain planning is influenced by consumer behavior at every stage—shopping habits, reviews, and shifting demand patterns.

In simple terms, supply chain planning is the process of coordinating and optimizing the flow of goods, services, and information from suppliers to customers. It focuses on anticipating demand and aligning it with supply, ensuring that operations run smoothly while meeting market needs. The ultimate objective is to balance supply and demand in a way that maximizes revenue opportunities, minimizes waste, and maintains high customer satisfaction.

Effective supply chain planning is a forward-looking process. As Gartner defines it, it involves coordinating assets to optimize delivery while providing what-if scenario analysis to help businesses manage uncertainty. It begins with demand planning, where sales, marketing, and production teams forecast requirements using historical data and market insights. This projection then informs production, inventory management, procurement, and logistics decisions. With this approach, organizations can maintain optimal inventory levels, reduce carrying costs, and avoid shortages.

More than just a tactical activity, supply chain planning is a strategic enabler of business growth. By standardizing processes, leveraging advanced forecasting techniques, and incorporating real-time data, businesses can reduce costs, improve delivery reliability, and respond effectively to disruptions. Done well, it transforms supply chains into resilient, customer-focused ecosystems that not only react to demand but anticipate and shape it.

Supply chain planning is the art of aligning supply with demand to keep businesses agile, efficient, and customer-focused.

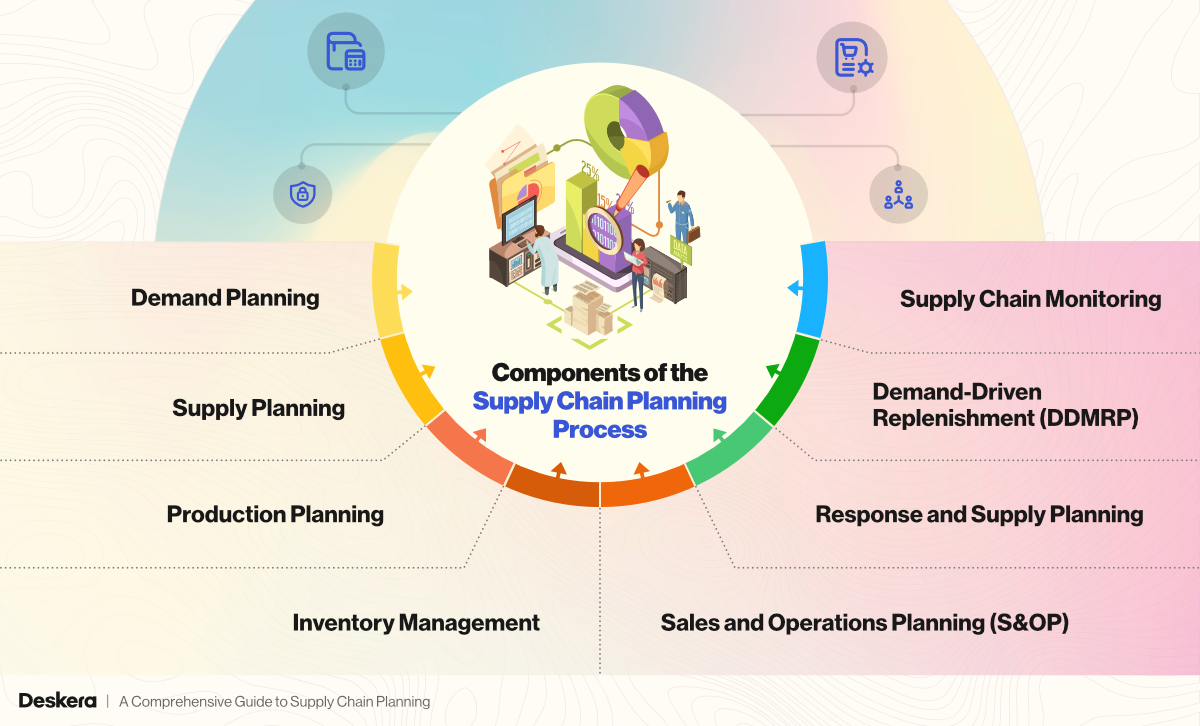

Components of the Supply Chain Planning Process

A robust supply chain succeeds when demand, supply, production, inventory, and operations work together seamlessly.

Supply chain planning is not a single step—it’s an integrated process that combines multiple elements working in harmony. Each component plays a vital role in balancing supply with demand, improving efficiency, and building resilience across the value chain.

Below are the key components:

1. Demand Planning

Demand planning is the foundation of supply chain planning. It involves using historical sales data, market trends, consumer behavior, and real-time insights to forecast demand accurately. By leveraging AI and predictive analytics, businesses can anticipate demand fluctuations, reduce excess stock, and ensure that inventory aligns with customer needs. Accurate demand planning not only minimizes costs but also helps maximize revenue opportunities.

2. Supply Planning

Once demand has been forecasted, businesses must develop a supply plan to meet it. Supply planning involves sourcing raw materials, components, and other inputs required for production. The objective is to ensure supply availability while optimizing procurement costs and lead times. A well-structured supply plan prevents disruptions, aligns with demand requirements, and enhances supplier coordination.

3. Production Planning

Production planning focuses on how resources—people, machines, materials, and time—are allocated to meet demand efficiently. The goal is to avoid overproduction, reduce waste, and ensure product availability at the right time. Effective production planning also supports lean manufacturing practices by streamlining workflows, maintaining optimal inventory levels, and increasing cross-functional visibility across operations.

4. Inventory Management

Inventory management ensures that businesses maintain the right balance of stock—enough to meet demand without tying up excess capital. Using advanced analytics and cloud-based solutions, organizations gain a unified view of inventory across the supply chain. This visibility allows them to respond to demand variability, simplify distribution networks, and avoid costly stockouts or surpluses.

5. Sales and Operations Planning (S&OP)

S&OP is a collaborative process that brings together sales, marketing, operations, and finance teams to create a unified business plan. Conducted regularly, S&OP helps synchronize supply capabilities with demand requirements, both in the short and long term. When done effectively, it aligns company-wide objectives, improves decision-making, and ensures that all teams work toward shared goals.

6. Response and Supply Planning

Response planning focuses on how organizations react to unexpected disruptions—such as sudden demand spikes, raw material shortages, or logistical delays. By integrating AI and machine learning, businesses can build supply chains that are adaptive, resilient, and capable of executing what-if scenarios to minimize risks.

7. Demand-Driven Replenishment (DDMRP)

Traditional replenishment often relies on past demand data, which can be limiting in volatile markets. Demand-driven material requirements planning (DDMRP) takes forecasting further by using predictive models and real-time demand signals. This helps businesses stay agile, adapt quickly to changes, and maintain product quality without carrying excessive inventory.

8. Supply Chain Monitoring

At the heart of modern supply chain planning lies continuous monitoring through a control tower dashboard. These systems provide end-to-end visibility into every stage of the supply chain—from suppliers to final delivery. With real-time insights, AI-driven analytics, and collaborative information sharing, supply chain monitoring enables better decision-making, reduces risks, and ensures seamless operations.

Importance of Effective Supply Chain Planning

Supply chain planning isn’t just a behind-the-scenes process—it’s a strategic driver of business growth and customer satisfaction. In today’s globalized and competitive market, organizations that manage their supply chains effectively are more resilient, cost-efficient, and agile. Here’s why effective supply chain planning matters:

1. Improves Forecasting Accuracy

A well-executed supply chain plan helps businesses predict demand more accurately. By using historical data, market insights, and real-time analytics, organizations can better anticipate customer needs and reduce the risks of overproduction or stockouts. This ensures that products are available when customers need them, without tying up excess capital in inventory.

2. Reduces Costs and Waste

Effective planning optimizes resource allocation across procurement, production, and logistics. Companies with streamlined supply chains operate at lower costs by reducing excess inventory, avoiding last-minute shipping expenses, and minimizing waste. This not only enhances profitability but also supports leaner, more sustainable operations.

3. Enhances Customer Satisfaction

Today’s customers expect faster deliveries and reliable service. Supply chain planning ensures that businesses meet these expectations by aligning production and distribution with demand. With efficient planning, companies can deliver the right product, at the right place, and at the right time—resulting in higher customer loyalty and retention.

Effective planning turns complexity into opportunity—reducing costs, improving service, and driving growth.

4. Builds Resilience Against Disruptions

Unexpected events such as pandemics, natural disasters, or supplier shortages can significantly disrupt operations. Effective planning allows businesses to prepare for these uncertainties with what-if scenarios, contingency strategies, and agile response mechanisms. This resilience helps companies bounce back quickly and maintain business continuity.

5. Supports Sustainability Goals

Supply chain planning also plays a critical role in sustainability initiatives. By reducing waste, optimizing transportation routes, and lowering energy usage, businesses not only cut costs but also minimize their environmental footprint. This makes supply chains both economically and environmentally sustainable, which is increasingly valued by customers and stakeholders.

6. Improves Collaboration Across Teams

Effective planning breaks down silos between departments such as sales, marketing, production, and finance. Tools like Sales and Operations Planning (S&OP) ensure all teams work toward common goals. This cross-functional alignment improves transparency, accountability, and decision-making across the organization.

7. Enables Better Use of Technology

With AI, IoT, and advanced ERP systems, companies can collect and analyze massive amounts of supply chain data. Effective planning provides a framework for using these technologies to drive automation, improve visibility, and create smarter, faster decision-making.

8. Increases Market Responsiveness

Consumer demand patterns are constantly shifting. Businesses with strong supply chain planning can respond quickly to changing market trends, seasonal spikes, or even viral product demand. This agility creates a competitive advantage in industries where speed to market matters.

9. Strengthens Supplier and Partner Relationships

A well-planned supply chain fosters stronger collaboration with suppliers, logistics providers, and distributors. Clear visibility into demand and supply needs allows for better contract negotiations, more reliable deliveries, and long-term partnerships that benefit both sides.

10. Drives Long-Term Business Growth

Ultimately, effective supply chain planning directly contributes to business scalability. Companies that master planning can expand into new markets, introduce new products, and handle increased demand with minimal disruption. This positions supply chain planning as a foundation for sustainable growth.

Challenges in Supply Chain Planning

The biggest challenge isn’t planning itself—it’s preparing for the unexpected.

While supply chain planning offers immense benefits, it is far from straightforward. Globalization, shifting consumer expectations, and rapid technological change have made the process more complex than ever. Businesses must overcome several challenges to ensure their supply chains remain efficient, resilient, and profitable.

1. Demand Volatility and Uncertainty

Customer preferences and buying patterns are increasingly unpredictable. Seasonal spikes, sudden product trends, or global disruptions can throw demand forecasts off balance. Without accurate forecasting, businesses risk either stockouts that frustrate customers or excess inventory that ties up working capital.

2. Rising Logistics and Transportation Costs

Fuel price fluctuations, driver shortages, and port delays make logistics planning highly challenging. With transportation representing a significant portion of supply chain costs, even small inefficiencies can impact profitability.

3. Global Supply Disruptions

Events such as pandemics, geopolitical tensions, and natural disasters highlight the fragility of global supply chains. Over-reliance on a single supplier or region can cause major bottlenecks when disruptions occur.

4. Data Silos and Lack of Visibility

Many organizations still operate with fragmented systems where data is spread across departments. This lack of integration makes it difficult to gain a real-time, end-to-end view of the supply chain, hindering quick and informed decision-making.

5. Balancing Efficiency and Resilience

Businesses often struggle to find the right balance between cost efficiency and supply chain resilience. Lean supply chains lower costs but can be more vulnerable to disruptions, while resilient supply chains may require extra inventory and backup suppliers that increase costs.

6. Sustainability Pressures

Consumers and regulators are demanding greener supply chains. However, reducing emissions, ensuring ethical sourcing, and implementing circular practices can be costly and complex, especially for businesses with extensive global networks.

7. Rapid Technological Change

While technology enables smarter supply chains, many companies find it difficult to keep up with innovations such as AI, IoT, and blockchain. High implementation costs and change management challenges often delay digital transformation.

8. Supplier Reliability and Coordination

Suppliers form the backbone of the supply chain, but issues such as delays, quality problems, or poor communication can disrupt the entire process. Maintaining strong, collaborative supplier relationships is a persistent challenge.

9. Labor Shortages and Skills Gaps

From truck drivers to warehouse staff to supply chain analysts, labor shortages are affecting multiple areas. Additionally, the shift toward data-driven supply chain planning requires new skill sets that many businesses struggle to acquire.

10. Regulatory and Compliance Complexity

International trade regulations, tariffs, and compliance standards vary widely across markets. Staying compliant while ensuring smooth operations requires constant vigilance and adaptability.

Role of Technology in Supply Chain Planning

Technology transforms supply chains from reactive systems into proactive, data-driven engines.

Technology has become the backbone of modern supply chain planning. With increasing complexity, global competition, and ever-changing customer expectations, businesses can no longer rely solely on manual processes or intuition. Advanced tools and technologies help organizations forecast demand accurately, optimize operations, and respond quickly to disruptions.

1. Demand Forecasting with AI and Machine Learning

Artificial intelligence (AI) and machine learning (ML) allow businesses to predict customer demand with unprecedented accuracy. These technologies analyze historical sales data, market trends, real-time consumer behavior, and external factors to generate precise forecasts. By anticipating fluctuations in demand, companies can minimize stockouts, reduce excess inventory, and increase overall profitability.

2. ERP and MRP Systems

Enterprise Resource Planning (ERP) and Material Requirements Planning (MRP) systems integrate all supply chain functions—from procurement to production to distribution—into a single platform. These systems enable real-time visibility, streamline workflows, and facilitate data-driven decision-making. Tools like Deskera ERP offer built-in forecasting, inventory management, and AI-powered insights to simplify supply chain planning and execution.

3. Real-Time Supply Chain Monitoring

Modern supply chains use IoT devices, sensors, and cloud-based dashboards to monitor operations in real time. This visibility allows companies to track shipments, monitor inventory levels, and detect disruptions before they escalate. AI-powered control towers can even suggest corrective actions, ensuring smooth operations across the entire supply chain.

4. Automation of Processes

Automation technologies, such as robotics in warehouses, automated procurement, and AI-driven logistics, reduce manual intervention and human error. By streamlining repetitive tasks, businesses can improve efficiency, speed up order fulfillment, and focus on strategic planning rather than operational firefighting.

5. Predictive and Prescriptive Analytics

Beyond forecasting, predictive analytics identify potential risks, such as supplier delays or capacity shortages, while prescriptive analytics recommends optimal actions. These technologies help companies make proactive decisions, mitigate risks, and improve responsiveness in dynamic markets.

6. Collaboration and Integration Tools

Cloud-based platforms allow seamless collaboration between internal teams, suppliers, and logistics partners. Integrated data sharing and communication ensure all stakeholders have access to the same real-time information, improving coordination, reducing errors, and enhancing overall supply chain efficiency.

7. Sustainability and Green Supply Chain Technologies

Technology also helps organizations meet sustainability goals. Route optimization, energy-efficient logistics, and waste reduction tools allow companies to reduce their carbon footprint while maintaining operational efficiency.

By leveraging these technologies, businesses can transform their supply chain from a reactive, cost-heavy function into a proactive, efficient, and resilient competitive advantage.

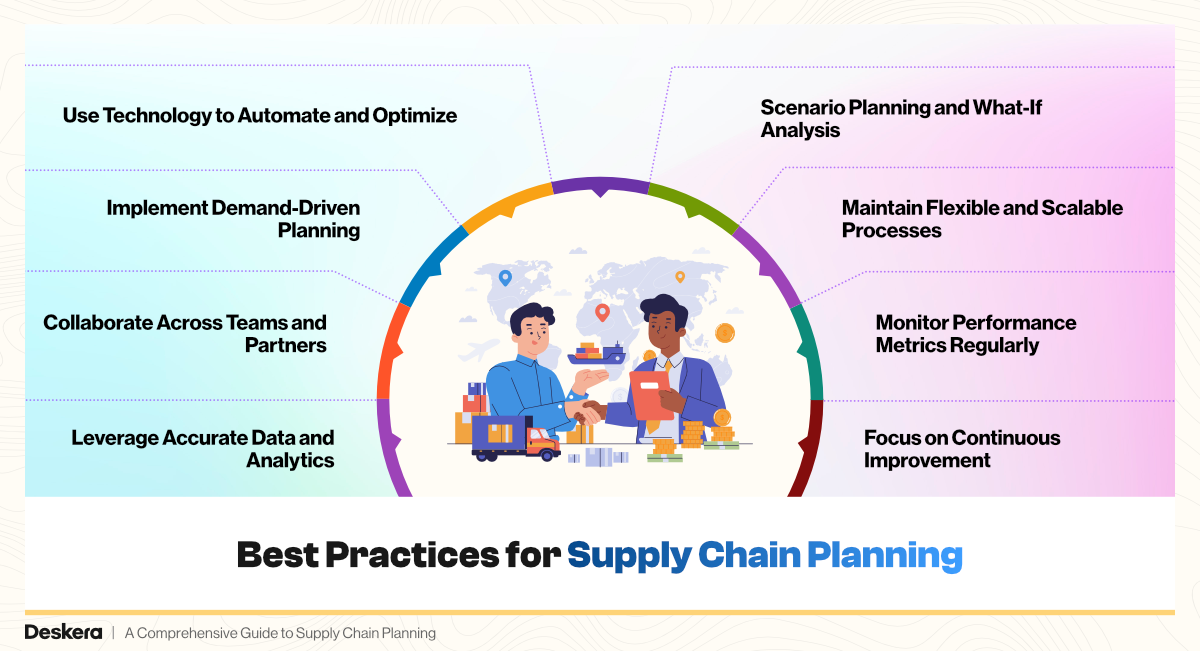

Best Practices for Supply Chain Planning

Collaboration, data-driven insights, and continuous improvement are the pillars of supply chain excellence.

Effective supply chain planning requires more than just advanced tools—it demands strategic processes, collaboration, and continuous improvement. Implementing best practices helps organizations optimize resources, reduce costs, and improve responsiveness across the supply chain. Here are some proven strategies:

1. Leverage Accurate Data and Analytics

Decisions in supply chain planning should be driven by reliable data. By analyzing historical sales, market trends, inventory levels, and customer behavior, businesses can create more precise forecasts and actionable insights. Advanced analytics also help identify inefficiencies, bottlenecks, and opportunities for cost savings.

2. Collaborate Across Teams and Partners

Supply chain planning works best when departments—sales, marketing, production, procurement, and finance—are aligned. Regular Sales and Operations Planning (S&OP) meetings and integrated communication platforms ensure everyone is working toward the same goals. Collaboration with suppliers and logistics partners also improves transparency and responsiveness.

3. Implement Demand-Driven Planning

Instead of relying solely on historical data, adopt demand-driven planning approaches that respond to real-time market signals. Techniques such as Demand-Driven Material Requirements Planning (DDMRP) help businesses remain agile, adapt to fluctuations, and reduce the risks of overstocking or stockouts.

4. Use Technology to Automate and Optimize

Leverage ERP, MRP, and AI-powered tools to streamline workflows, improve forecasting, and monitor operations in real time. Automation reduces manual errors, enhances efficiency, and frees teams to focus on strategic decision-making. Tools like Deskera ERP integrate demand forecasting, inventory management, and production planning into a single platform for smarter supply chain management.

5. Scenario Planning and What-If Analysis

Prepare for uncertainties by running scenario-based simulations. What-if analysis allows businesses to explore the impact of disruptions, capacity changes, or demand spikes, helping them develop contingency plans and respond proactively to unforeseen events.

6. Maintain Flexible and Scalable Processes

Supply chains must be adaptable to changing market conditions. Building flexibility into procurement, production, and distribution processes ensures organizations can scale operations up or down without sacrificing efficiency or service quality.

7. Monitor Performance Metrics Regularly

Track key performance indicators (KPIs) such as order fulfillment rate, inventory turnover, delivery reliability, and production efficiency. Regular monitoring helps identify gaps, measure improvements, and guide continuous optimization across the supply chain.

8. Focus on Continuous Improvement

Supply chain planning is not static. Regularly reviewing processes, adopting new technologies, and learning from past performance ensures the supply chain evolves alongside market demands, improving resilience and competitiveness over time.

Future Trends in Supply Chain Planning

The supply chain landscape is evolving rapidly, driven by technology, changing consumer expectations, and global disruptions. Businesses that stay ahead of emerging trends can gain a competitive advantage, increase efficiency, and build resilience. Here are the key trends shaping the future of supply chain planning:

1. AI-Driven Autonomous Supply Chains

Artificial intelligence and machine learning are enabling supply chains that can operate autonomously. AI can predict demand, optimize inventory, and make real-time decisions without constant human intervention. Autonomous systems help businesses reduce errors, improve efficiency, and respond instantly to disruptions.

2. Blockchain for Transparency and Security

Blockchain technology is transforming supply chains by providing secure, immutable records of every transaction and movement. This increases transparency, enhances trust between partners, and simplifies compliance with regulatory requirements. Consumers also benefit from the ability to track the provenance of products.

3. Sustainability-Driven Supply Chains

Environmental responsibility is becoming a central focus. Companies are investing in green logistics, energy-efficient operations, and circular supply chains that reduce waste and carbon emissions. Supply chain planning is increasingly integrating sustainability metrics alongside traditional KPIs.

4. Increased Use of Digital Twins

Digital twins—virtual replicas of physical supply chains—allow businesses to simulate operations, test scenarios, and identify inefficiencies before implementing changes in the real world. This predictive capability reduces risks, improves planning accuracy, and enhances agility.

5. Cloud-Based and Collaborative Platforms

Cloud technology enables real-time collaboration across geographies, connecting suppliers, manufacturers, distributors, and retailers on a single platform. These systems enhance visibility, streamline communication, and allow companies to respond faster to market changes.

6. Advanced Predictive Analytics

Predictive and prescriptive analytics will play an even bigger role in anticipating demand, mitigating risks, and optimizing production schedules. By combining internal data with external market signals, businesses can make more proactive and informed decisions.

7. Integration of IoT and Real-Time Monitoring

The Internet of Things (IoT) allows sensors and connected devices to provide real-time visibility into inventory, shipments, and equipment performance. This enables predictive maintenance, dynamic routing, and faster issue resolution, making supply chains more responsive and resilient.

8. Agile and Resilient Network Design

Future supply chains will prioritize flexibility over rigid efficiency. Companies are moving toward multi-supplier strategies, regional distribution centers, and modular network designs to quickly adapt to disruptions or changing demand patterns.

9. Hyper-Personalization and Customer-Centric Planning

With consumer expectations rising, supply chains will increasingly be designed around personalized experiences. From customized products to faster delivery options, planning processes will need to integrate granular customer insights to meet individual preferences.

The future of supply chains is smart, transparent, and customer-centric—powered by AI, IoT, and sustainability.

How Deskera Can Help with Supply Chain Planning

In today’s complex business environment, managing a supply chain efficiently requires more than intuition—it demands intelligent tools that provide real-time insights, predictive analytics, and end-to-end visibility. Deskera ERP offers an integrated platform designed to streamline every aspect of supply chain planning, helping businesses stay agile, reduce costs, and improve service levels.

1. Demand Forecasting and Planning

Deskera’s AI-powered forecasting tools analyze historical sales, market trends, and real-time data to generate accurate demand predictions. By anticipating demand fluctuations, businesses can optimize inventory levels, reduce stockouts, and prevent excess inventory, ensuring resources are aligned with market needs.

2. Inventory and Procurement Management

With Deskera, companies gain a unified view of inventory across all locations. The platform helps manage stock levels efficiently, automate reorder points, and coordinate procurement with supplier lead times. This ensures the right materials are available at the right time, minimizing carrying costs and production delays.

3. Production Planning and MRP

Deskera’s Material Requirements Planning (MRP) module streamlines production scheduling by aligning resources, materials, and workforce with anticipated demand. It helps optimize manufacturing capacity, reduce waste, and ensure products are ready for delivery on time.

4. Sales and Operations Planning (S&OP)

The platform supports cross-functional collaboration by integrating sales, operations, and finance data. Deskera’s S&OP capabilities enable teams to align objectives, share forecasts, and make informed decisions that improve overall supply chain efficiency.

5. Real-Time Analytics and Reporting

Deskera offers advanced reporting and analytics tools, providing visibility into KPIs such as inventory turnover, order fulfillment rates, and production efficiency. Real-time dashboards empower managers to make proactive decisions, identify bottlenecks, and respond quickly to disruptions.

6. AI-Powered Insights with David

Deskera’s AI assistant, David, provides actionable insights, highlights anomalies, and suggests optimization strategies across the supply chain. From predicting demand spikes to identifying cost-saving opportunities, David helps businesses make smarter, faster, and data-driven decisions.

7. Mobile Accessibility and Cloud-Based Operations

Deskera’s cloud-based platform ensures supply chain data is accessible anytime, anywhere. Mobile access allows managers to monitor operations, approve orders, and respond to issues in real time, keeping the supply chain agile and responsive.

By integrating these capabilities, Deskera ERP transforms supply chain planning from a reactive, manual process into a proactive, strategic advantage, helping businesses improve efficiency, reduce costs, and enhance customer satisfaction.

With AI-powered insights and integrated operations, Deskera turns supply chain planning into a strategic advantage.

Key Takeaways

- Effective supply chain planning is essential for revenue growth, cost reduction, and operational efficiency, with high-performing supply chains delivering significant competitive advantages.

- Supply chain planning is the forward-looking process of aligning supply with demand, coordinating resources, and optimizing the flow of goods, services, and information across the value chain.

- A robust supply chain relies on integrated processes like demand planning, supply planning, production planning, inventory management, S&OP, DDMRP, and real-time monitoring to ensure efficiency and responsiveness.

- Well-executed planning improves forecasting accuracy, reduces costs, enhances customer satisfaction, builds resilience against disruptions, and supports sustainability initiatives.

- Businesses face challenges such as demand volatility, supply disruptions, rising logistics costs, data silos, and balancing efficiency with resilience, all of which require proactive strategies and technology adoption.

- Advanced technologies—AI, machine learning, ERP/MRP systems, IoT, predictive analytics, and automation—enable real-time visibility, data-driven decision-making, and agile, resilient supply chains.

- Adopting best practices such as data-driven planning, cross-functional collaboration, demand-driven replenishment, automation, scenario planning, and continuous improvement ensures efficiency, flexibility, and scalability.

- Future supply chains will be AI-driven, transparent with blockchain, sustainable, digitally connected through cloud and IoT, agile, and highly customer-centric, enabling faster adaptation to market changes.

- Deskera ERP provides AI-powered demand forecasting, integrated inventory and production management, S&OP collaboration, real-time analytics, and mobile accessibility, helping businesses transform supply chain planning into a strategic advantage.

Related Articles