Why do some businesses consistently outperform their competitors while others struggle with inefficiencies and rising costs? The answer often lies in how well their supply chains are integrated. In today’s fast-moving global economy, a disconnected or fragmented supply chain can lead to delays, higher expenses, and lost opportunities. On the other hand, enterprises with integrated supply chains report 20% higher profitability and 25% greater productivity, proving that seamless coordination is not just a competitive edge but a growth necessity.

Supply chain integration brings together all the moving parts—procurement, production, logistics, sales, and customer service—into one unified ecosystem. Instead of working in silos, teams, partners, and technologies collaborate in real time, ensuring better decision-making and faster responses to market shifts. For modern enterprises, this integration is no longer optional; it’s the backbone of resilience, agility, and long-term sustainability.

However, achieving effective supply chain integration isn’t without its challenges. From dealing with outdated legacy systems and data silos to managing global disruptions, enterprises must adopt both the right strategies and the right technologies. This is where digital transformation and advanced ERP solutions play a critical role, ensuring smooth communication, process standardization, and operational visibility across the entire value chain.

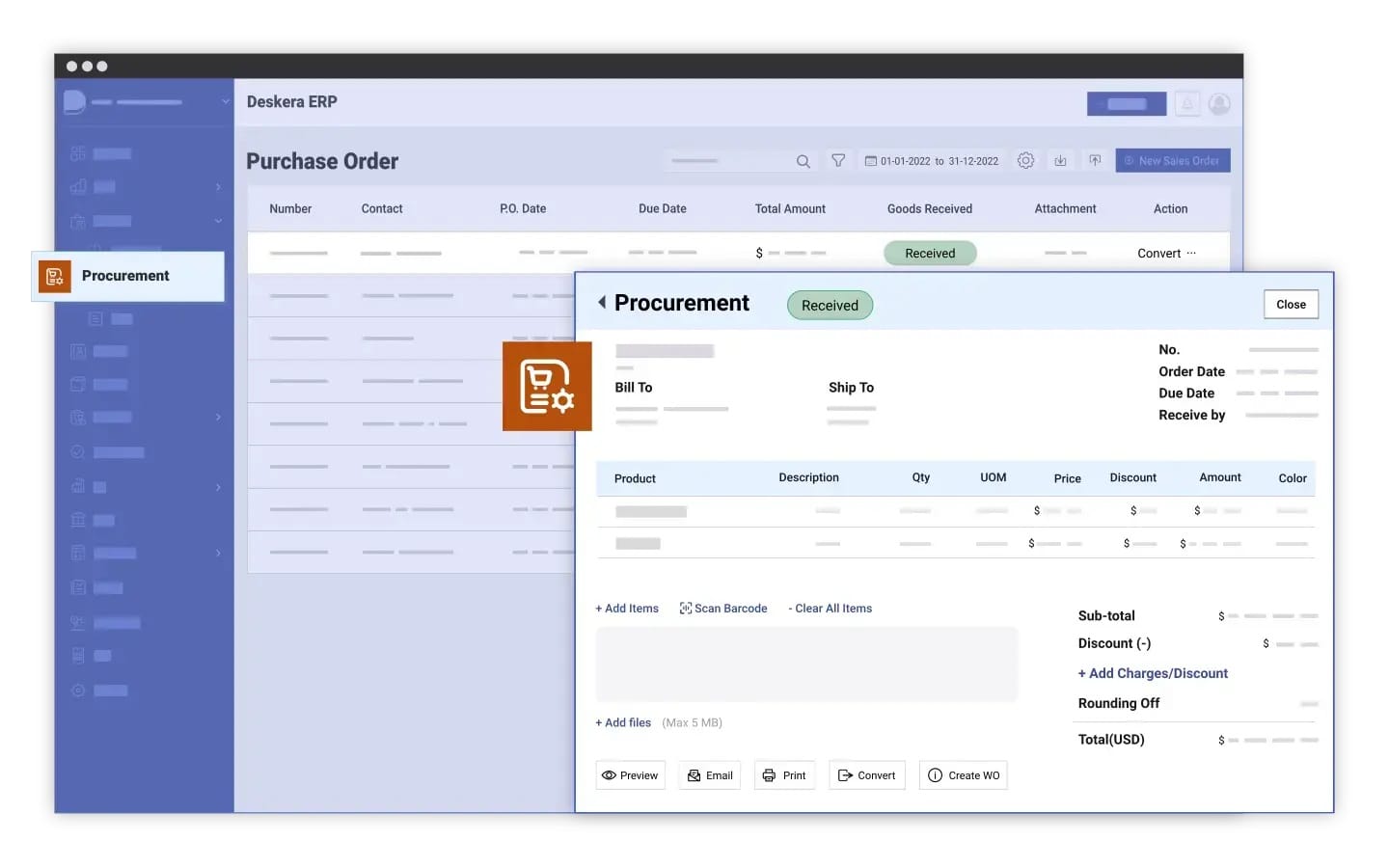

Platforms like Deskera ERP make this transformation possible by providing a cloud-based, all-in-one solution for businesses. With features such as automated inventory tracking, AI-powered demand forecasting, advanced reporting, and real-time collaboration, Deskera helps enterprises break down silos and achieve true supply chain visibility. Designed with scalability and mobility in mind, it empowers decision-makers to monitor operations anytime, anywhere—driving efficiency and profitability in the modern supply chain.

What is Supply Chain Integration?

Supply chain integration is the process of unifying all the functions, stakeholders, and activities within the supply chain into one seamless system. Instead of operating in silos—where procurement, production, logistics, and distribution function separately—an integrated supply chain promotes real-time communication, collaboration, and coordination. The goal is to create a connected network that improves efficiency, reduces costs, and enhances customer satisfaction.

At its core, supply chain integration enhances visibility and information flow across the entire value chain. This means every stakeholder—from suppliers providing raw materials to distributors and retailers delivering finished products—works with shared data and synchronized processes.

For example, when manufacturers can see accurate demand forecasts and inventory levels, they avoid overproduction or stockouts, leading to better resource utilization and lower operational costs. In fact, enterprises that achieve supply chain integration often report significant improvements in performance, including higher productivity and profitability.

There are typically two levels of integration: horizontal integration, which connects all internal departments within an organization, and vertical integration, which extends collaboration to external partners such as suppliers, logistics providers, and customers.

Real-world examples include Walmart and Procter & Gamble’s integrated information systems that ensure products are always available on shelves, or Dell’s close collaboration with software partners like Microsoft to deliver just-in-time, customized products. These strategies not only optimize operations but also strengthen long-term relationships across the supply chain.

Ultimately, supply chain integration is about building a system based on mutual goals, open communication, and technology-driven transparency. By connecting people, processes, and platforms, businesses can better navigate external challenges such as labor shortages, transportation delays, or geopolitical disruptions. With an integrated supply chain, organizations are equipped to respond to real-time changes, make data-driven decisions, and deliver consistent value to customers—turning the supply chain into a strategic driver of growth.

Key Components of Supply Chain Integration

Supply chain integration is not a one-size-fits-all approach—it looks different depending on the industry, business size, and complexity of operations. However, there are a few core components that consistently define successful integration efforts. These elements work together to create transparency, improve collaboration, and drive efficiency across the supply chain.

Centralized Communication

Clear and consistent communication is the backbone of an integrated supply chain. When stakeholders—from internal teams to external vendors—exchange information through a single platform or standardized format, everyone has clarity on expectations, timelines, and responsibilities. This reduces miscommunication, minimizes delays, and ensures the entire network stays aligned even during disruptions.

Integrated Technology

Technology acts as the enabler of integration. A centralized supply chain management (SCM) or ERP system that connects seamlessly with vendor and logistics tools ensures every department has access to real-time, accurate data. This integration allows for immediate updates on inventory, production schedules, and shipments, helping companies avoid errors, reduce waste, and respond quickly to market changes.

Coordination Between Key Players

An integrated supply chain requires close coordination between all participants, including suppliers, manufacturers, distributors, and logistics providers. When each stakeholder understands their role and has visibility into others’ processes, it becomes easier to prevent bottlenecks and delays. Strong coordination builds resilience and enables all partners to deliver on time and at the right cost.

Collaborative Planning and Forecasting

Forecasting and demand planning become far more accurate when all stakeholders contribute their insights. Sharing data on sales, inventory, and production capacity helps align supply with demand and reduces costly mismatches.

Many companies now use advanced analytics and machine learning tools to support collaborative planning. This approach has been proven by leaders like Walmart and Procter & Gamble, who leverage shared forecasting to maintain efficiency and meet customer needs.

Information Sharing and Visibility

Transparency across the supply chain is crucial for quick decision-making. Stakeholders should have access to relevant information such as order status, inventory levels, and shipment tracking.

Centralized platforms like ERP and SCM software make this possible, providing a single source of truth for all participants. Enhanced visibility improves accountability and allows companies to anticipate and resolve issues before they escalate.

Process Synchronization and Optimization

Finally, integration requires aligning and optimizing processes from procurement and production to distribution and delivery. Standardizing workflows, identifying bottlenecks, and implementing best practices like Lean Manufacturing or Six Sigma help improve efficiency and reduce lead times. This continuous improvement mindset ensures that the supply chain evolves in response to both internal and external changes.

Key Benefits of Supply Chain Integration

An integrated supply chain does much more than connect systems—it transforms how businesses operate, make decisions, and deliver value to customers.

While integration requires effort and investment, the benefits far outweigh the challenges. From cost savings to agility, businesses that adopt supply chain integration gain a competitive edge in today’s dynamic markets.

Here are the key benefits that make integration indispensable.

Improved Visibility and Transparency

End-to-end visibility enables businesses to monitor every stage of the supply chain, from raw material sourcing to last-mile delivery. Real-time tracking of inventory, production status, and shipments reduces blind spots and makes it easier to anticipate bottlenecks. Studies show that only 6% of businesses achieve full supply chain visibility, highlighting a significant opportunity for companies that integrate effectively.

Faster Decision-Making with Real-Time Data

Integrated systems provide instant access to critical data across departments and partners. This enables managers to make informed decisions quickly—whether adjusting procurement, reallocating inventory, or responding to demand shifts.

Real-time data sharing also prevents delays caused by siloed information and ensures every stakeholder operates with the same facts.

Reduced Costs and Waste

Integration eliminates redundancies and inefficiencies across procurement, inventory management, and logistics. Lean practices such as just-in-time (JIT) delivery become easier to implement, lowering inventory holding costs while reducing waste. According to case studies, collaborative inventory planning can reduce inventory costs by 10–15% while improving inventory turns by up to 10%.

Enhanced Supplier and Customer Relationships

A connected supply chain fosters stronger collaboration with both suppliers and customers. Suppliers benefit from transparent performance tracking, joint problem-solving, and vendor-managed inventory (VMI) programs. Customers, meanwhile, enjoy accurate delivery promises, real-time updates on their orders, and improved product availability—all of which build trust and loyalty.

Greater Agility and Responsiveness to Market Shifts

Market volatility, changing customer demands, and supply disruptions require agility. Integrated supply chains enable companies to reconfigure production, logistics, and sourcing strategies swiftly. IDC predicts that by 2024, 50% of companies will adopt balanced multi-shoring strategies to reduce risks—a move made possible through deeper integration and agility.

Amplified Efficiency and Productivity

Streamlined workflows and real-time collaboration eliminate delays and duplication of effort. Teams can optimize resources, align schedules, and boost throughput, resulting in higher productivity across operations. For example, businesses adopting vendor-managed inventory often see double-digit improvements in order fulfillment rates.

Smarter Spending and Accurate Financial Tracking

By reducing inefficiencies and eliminating unnecessary transactions, integration lowers operating costs and improves financial visibility. Real-time data on procurement, inventory, and logistics helps finance teams track spending, identify inefficiencies, and manage risks proactively. With inflation and rising costs, accurate financial tracking is a crucial advantage.

Better Risk Management

Visibility across the supply chain allows businesses to anticipate risks such as supplier delays, inventory shortages, or geopolitical disruptions. Integrated systems provide early warnings and data-driven insights, enabling companies to take corrective action before small issues escalate. This strengthens resilience and helps ensure continuity even in turbulent markets.

Faster Time-to-Market

With integrated planning and collaboration, businesses can shorten product lifecycles and accelerate launches. Cross-functional teams working in real-time on design, production, and logistics ensure that products reach customers faster. Research shows that concurrent engineering approaches supported by integration can reduce product development time by up to 50%.

Improved Customer Experience

Customers today expect transparency, speed, and reliability. An integrated supply chain delivers on these expectations by ensuring timely fulfillment, providing real-time updates, and enabling personalized services. With 83% of businesses prioritizing customer experience in their digital supply chain strategies, integration is now central to building long-term customer loyalty.

Common Supply Chain Integration Challenges

While the benefits of supply chain integration are undeniable, the path to achieving it is often riddled with obstacles. Businesses need to tackle not only technical issues but also organizational, financial, and cultural barriers.

Understanding these challenges is the first step toward building a strategy that avoids costly mistakes and sets the foundation for long-term success.

Complexity in Coordination and Management

Modern supply chains are vast networks involving procurement, production, logistics, and customer fulfillment. Coordinating all these moving parts—often across different regions and partners—can be overwhelming.

Outdated processes, siloed operations, and incompatible tools only add to the complexity, making it difficult to maintain consistency and efficiency. Conducting supply chain audits and gradually modernizing processes can help simplify this complexity.

Resistance to Change

One of the biggest barriers to integration lies within the organization itself. Employees and even leadership teams may be reluctant to abandon legacy systems and familiar workflows.

This resistance often stems from fear of disruption, skill gaps, or lack of trust in new technology. Successful integration requires strong change management, proper training, and clear communication of the long-term benefits.

High Costs and Resource Demands

Integration requires significant investment in technology, infrastructure, and training. Smaller businesses, in particular, may find it challenging to allocate resources without straining budgets.

Beyond the upfront financial burden, hidden costs—such as retraining employees or reconfiguring partner systems—can quickly accumulate. A phased approach, implemented in budgeted stages, often minimizes financial strain while ensuring smoother adoption.

System Incompatibility and Technical Barriers

Supply chain partners frequently use different technologies and data standards, creating serious integration hurdles. Achieving true interoperability may require middleware, APIs, or costly customization.

Without standardized systems, businesses face delays, duplication of effort, and limited data sharing. Choosing flexible ERP and SCM platforms that integrate easily with partner tools is key to overcoming this challenge.

Dependency on Partners

Integration thrives on collaboration, but it also creates higher interdependencies. If a key supplier or logistics partner faces disruption, the ripple effects can slow down the entire network.

This dependency also makes it harder to switch vendors or reconfigure the supply chain quickly. Building resilience through diversified sourcing and transparent partner agreements can help reduce this risk.

Data Security and Privacy Risks

With more data flowing across multiple partners, the potential attack surface for cybercriminals expands. A breach at any point in the chain can expose sensitive information and compromise operations.

Moreover, regulations such as GDPR and CCPA add compliance pressure. Companies need robust cybersecurity protocols, data governance frameworks, and regular audits to mitigate these risks.

Poor Communication and Collaboration

Siloed operations and a lack of standardized communication often undermine integration efforts. When departments or partners don’t share timely and accurate information, delays, duplication, and errors occur.

Trust issues between stakeholders can further discourage collaboration. Establishing transparent communication channels and incentivizing shared goals can help bridge these gaps.

Scalability and Flexibility Issues

Once systems and processes are deeply integrated, scaling them to include new markets, partners, or products can become difficult. Over-integration can also create rigidity, making it harder to pivot in response to sudden market shifts. Companies need to strike a balance—integrating enough to gain efficiency but maintaining enough flexibility to stay agile.

Best Practices for Effective Supply Chain Integration

Achieving successful supply chain integration requires more than just connecting systems—it demands a strategic approach, cultural alignment, and the right technology. Companies that invest in robust integration practices can reduce costs, boost collaboration, and improve efficiency across the board.

Below are key best practices to guide your integration journey.

Standardize Processes Across the Supply Chain

A common barrier to supply chain integration is inconsistency in processes across teams, departments, or partners. Standardizing workflows, communication protocols, and reporting formats helps eliminate silos and reduces errors.

Developing detailed “as-is” and “to-be” process blueprints allows stakeholders to see the inefficiencies in current practices and visualize the future state of an integrated supply chain. Standardization ensures smoother collaboration and faster issue resolution, while also enabling scalability as the network grows.

Invest in the Right Technology

Technology is the backbone of supply chain integration. Implementing solutions such as ERP, supply chain planning tools, warehouse management systems (WMS), and transportation management systems (TMS) creates a unified platform for data sharing.

Emerging technologies like AI, IoT, blockchain, and advanced analytics can further enhance real-time visibility, predictive insights, and automation. Choosing the right mix of tools helps bridge compatibility gaps and ensures end-to-end connectivity across the supply chain.

Foster Collaboration with Suppliers and Partners

Integration is impossible without strong collaboration. Open communication channels, real-time data sharing, and joint problem-solving are essential for building trust.

Internally, foster a culture of transparency and teamwork to break down silos. Externally, strengthen supplier and partner relationships by sharing forecasts, demand signals, and inventory levels.

These efforts reduce the risk of misalignment, improve response times, and make the supply chain more resilient against disruptions.

Overcome Resistance to Change

Resistance from employees and stakeholders is one of the biggest hurdles to integration. Teams may hesitate to adopt new systems or processes because they’re comfortable with legacy approaches.

To address this, invest in change management strategies: provide training, explain how integration will simplify their work, and emphasize the personal benefits of the new systems. Gaining buy-in ensures smoother adoption and reduces delays in implementation.

Build a Data-Driven Culture with Analytics and KPIs

Integrated supply chains thrive on data. Real-time visibility into inventory, orders, and logistics helps organizations make smarter decisions and reduce inefficiencies.

Establish clear KPIs such as order fulfillment rates, lead times, and on-time delivery performance to measure success. By adopting a data-first mindset, companies can predict demand more accurately, optimize inventory levels, and improve customer satisfaction. Analytics also provide a feedback loop that supports continuous improvement.

Seek End-to-End Visibility and Real-Time Data

Integration isn’t complete without full visibility into every stage of the supply chain. Real-time tracking of raw materials, inventory, and shipments enables proactive decision-making and quick response to disruptions.

For example, monitoring stock levels in real time can prevent stockouts and inform sourcing strategies. Visibility also strengthens collaboration, as all stakeholders—from suppliers to logistics providers—have access to the same reliable data.

Incorporate Omnichannel Fulfillment

Customers expect seamless experiences across every channel. Supply chain integration must extend to fulfillment operations so that whether a customer buys online, in-store, or through a distributor, they receive the same speed and accuracy.

Achieving this consistency often requires advanced fulfillment technology or third-party logistics support. A well-integrated omnichannel strategy ensures businesses can scale efficiently while meeting rising customer expectations.

Prioritize Cybersecurity and Data Protection

As integration deepens, supply chains become increasingly digital and interconnected. This creates a larger attack surface for cyber threats. Protecting sensitive data, ensuring compliance with regulations like GDPR, and implementing secure protocols for data exchange are non-negotiable.

Invest in cybersecurity training for staff, adopt encryption technologies, and establish strong governance frameworks to safeguard against breaches that could compromise both operations and trust.

Continuously Evaluate and Improve

Supply chain integration is not a one-time project—it’s an ongoing journey. Regularly review KPIs, gather feedback from internal teams and external partners, and refine integration strategies based on performance outcomes. Adopting agile methodologies allows for incremental improvements, ensuring your supply chain remains adaptable in the face of evolving technologies and market conditions.

By following these best practices—standardizing processes, investing in the right tools, fostering collaboration, embracing data, and prioritizing security—businesses can transform their supply chains into engines of efficiency, agility, and growth.

The Role of Technology in Supply Chain Integration

Technology has become the backbone of modern supply chain integration, enabling businesses to seamlessly connect processes, improve decision-making, and achieve end-to-end visibility. By integrating the right digital tools, companies can streamline operations, optimize resources, and foster real-time collaboration across suppliers, partners, and customers.

Effective supply chain integration allows entities to share data intelligently, make informed decisions faster, and respond dynamically to market changes.

Cloud-Based ERP Systems for Real-Time Collaboration

Enterprise Resource Planning (ERP) systems provide a holistic view of business operations, helping companies respond quickly to market fluctuations. Cloud-based ERP platforms unify processes across procurement, production, finance, and logistics, making collaboration seamless and efficient.

Key benefits of ERP integration include:

- Improved management of demand and procurement needs

- Faster documentation processing and approvals

- Enhanced visibility into operations for smarter decision-making

Deskera ERP, for instance, centralizes supply chain processes on a single cloud platform. It integrates procurement, inventory, order management, and financials, helping businesses achieve real-time visibility and faster collaboration across teams.

AI and Machine Learning for Demand Forecasting

Artificial intelligence and machine learning are transforming supply chain planning by enabling predictive analytics. These technologies analyze historical data, market signals, and real-time trends to forecast demand with higher accuracy.

With AI-enabled systems, businesses can:

- Automate order fulfillment and route optimization

- Predict customer preferences and inventory needs

- Make proactive adjustments to avoid stockouts or overstocking

This leads to a leaner, more responsive supply chain that adapts quickly to changing conditions.

IoT for Inventory and Logistics Tracking

The Internet of Things (IoT) connects devices and sensors across the supply chain to collect and transmit real-time data. From smart warehouses to connected delivery fleets, IoT creates transparency at every stage.

IoT enables businesses to:

- Track shipments and monitor conditions (e.g., temperature-sensitive goods)

- Detect errors and delays early

- Automate inventory replenishment with real-time stock levels

IoT-driven insights make supply chains more agile, accurate, and customer-focused.

Blockchain for Secure, Transparent Transactions

Blockchain technology introduces a secure and decentralized ledger, ensuring trust and transparency in transactions. It prevents counterfeiting, streamlines compliance, and provides a verifiable trail of goods as they move through the supply chain.

Blockchain’s impact includes:

- Transparent and tamper-proof record-keeping

- Faster dispute resolution with clear audit trails

- Strengthened trust among suppliers, logistics providers, and customers

This is particularly valuable for industries where traceability and authenticity are critical, such as pharmaceuticals or food supply chains.

Integrating Supporting Systems for a Unified Supply Chain

Beyond ERP, AI, IoT, and blockchain, effective supply chain integration also involves connecting other essential systems:

- Warehouse Management Systems (WMS): Increase inventory accuracy, match supply with demand, and optimize stock levels.

- Financial Systems: Provide tighter cost control, accurate budget forecasts, and visibility into expenses.

- Customer Relationship Management (CRM): Align supply chain with customer needs, supporting accurate projections and improved satisfaction.

- Business Intelligence (BI): Enable smarter decisions through predictive analytics and real-time reporting.

- Transportation Management Systems (TMS): Streamline logistics, cut costs, and improve delivery performance.

When these systems work together, businesses create a connected ecosystem that drives agility, efficiency, and profitability.

Does Your Business Require Supply Chain Integration?

Not every business realizes the importance of supply chain integration until inefficiencies start affecting performance. The truth is, in today’s competitive environment, integration is no longer optional—it’s essential for growth, agility, and customer satisfaction.

But how do you know if your business truly needs it? Let’s look at some key indicators.

Struggling with Inventory Imbalances

If your business frequently faces stockouts or excess inventory, it’s a clear sign of disconnected processes. Without integrated systems, sales, procurement, and warehouse teams may work in silos, leading to mismatched supply and demand. Integration ensures real-time visibility across all inventory levels, reducing both shortages and wastage.

Experiencing Delays in Order Fulfillment

Long lead times, late deliveries, and inconsistent order fulfillment often stem from poor communication between suppliers, manufacturers, and distributors. An integrated supply chain enables seamless information flow, allowing businesses to respond faster and meet customer expectations consistently.

Lack of Visibility Across Operations

One of the biggest challenges companies face is the inability to track processes from end to end. If you can’t easily monitor where materials are, how production is progressing, or when deliveries will reach customers, it indicates the need for integration. Supply chain visibility improves decision-making and builds trust with partners and clients.

Rising Operational Costs

Disconnected systems and manual processes usually result in higher costs—whether through inefficiencies, duplication of efforts, or emergency purchases. By adopting an integrated approach, businesses can streamline workflows, automate repetitive tasks, and better negotiate with suppliers based on accurate data.

Difficulty Scaling the Business

When companies try to expand without an integrated supply chain, bottlenecks become more frequent. Managing multiple suppliers, larger inventories, or new markets is almost impossible without centralized data and standardized processes. Integration provides the flexibility and agility needed to scale operations smoothly.

Steps to Implement Supply Chain Integration in Your Business

Implementing supply chain integration requires a structured approach, as it involves aligning people, processes, and technology across multiple touchpoints.

Businesses that follow a systematic plan are more likely to see tangible results such as improved efficiency, reduced costs, and stronger collaboration with partners.

Below are the essential steps you can take to successfully integrate your supply chain.

Assess Current Supply Chain Gaps

Before diving into integration, start by evaluating your existing supply chain processes. Identify inefficiencies such as communication delays, inventory mismatches, or lack of visibility between departments. This analysis will highlight where integration can add the most value.

For instance, if suppliers and warehouses don’t share real-time data, it could lead to stockouts or overstocking. A thorough audit ensures you have a clear roadmap for improvement.

Define Goals and KPIs

Integration is not a one-size-fits-all approach, so it’s crucial to define what success looks like for your business. Set clear objectives such as reducing lead times, lowering costs, or improving customer satisfaction.

Along with goals, establish measurable KPIs like order fulfillment rates, inventory turnover, or supplier performance metrics. These benchmarks will help track progress and ensure your integration strategy stays aligned with business objectives.

Select the Right Technology/ERP Solution

Technology is the backbone of supply chain integration. Choosing the right ERP or supply chain management software can streamline operations and create real-time visibility across departments and external partners.

For example, solutions like Deskera ERP provide features such as automated purchase orders, demand forecasting, and integrated financials. By consolidating data into a single platform, businesses eliminate silos and enable faster, more informed decision-making.

Train Teams and Promote Cross-Functional Collaboration

Even the best technology won’t drive results without people behind it. Training employees to use new systems and promoting collaboration across procurement, sales, finance, and logistics teams is essential.

Encourage a culture of shared accountability where departments work toward common goals rather than focusing solely on their individual tasks. This cultural shift ensures integration becomes part of everyday operations, not just a temporary initiative.

Monitor Progress and Optimize Continuously

Supply chain integration is not a one-time project but an ongoing process. Regularly monitor your KPIs to identify areas that need improvement.

Leverage analytics and feedback loops to fine-tune workflows, enhance supplier relationships, and adopt new technologies as they emerge.

Continuous optimization allows businesses to stay agile and competitive, especially in an environment where customer expectations and market conditions change rapidly.

Future Trends in Supply Chain Integration

As global supply chains become more complex, integration is evolving beyond simply connecting processes. Businesses are adopting advanced technologies and strategies to create intelligent, resilient, and customer-centric supply chains. Here are the key trends shaping the future of supply chain integration.

Increased Use of Artificial Intelligence and Machine Learning

AI and ML are transforming supply chain integration by enabling predictive analytics, demand forecasting, and automated decision-making.

Businesses can anticipate disruptions, optimize routes, and adjust production plans in real-time. This reduces uncertainty and increases responsiveness across the supply chain.

Blockchain for Transparency and Trust

Blockchain technology is emerging as a powerful tool for supply chain integration, ensuring secure and transparent data sharing. By recording transactions on a decentralized ledger, businesses can trace materials, verify authenticity, and strengthen supplier relationships. This is especially valuable in industries where compliance and traceability are critical.

Greater Adoption of IoT and Real-Time Tracking

The Internet of Things (IoT) allows businesses to integrate physical assets with digital systems. Real-time tracking of shipments, monitoring warehouse conditions, and automated inventory updates help companies maintain accuracy and reduce losses. IoT ensures every stakeholder has access to up-to-date, actionable insights.

Cloud-Based ERP Solutions for Unified Operations

Cloud-based ERP platforms are at the core of future supply chain integration. They unify procurement, inventory, production, and logistics into a single system accessible anytime, anywhere. Scalable and cost-effective, they provide businesses with the flexibility to grow without compromising efficiency.

Focus on Sustainability and Green Supply Chains

Sustainability is becoming a strategic priority in supply chain management. Integration will increasingly involve aligning processes with eco-friendly goals such as reducing carbon emissions, optimizing energy use, and promoting circular supply chains. Businesses that integrate sustainability gain both competitive and reputational advantages.

Rise of Collaborative Supply Chain Networks

The future of integration lies in collaboration, not just connection. Businesses are moving toward shared platforms where suppliers, manufacturers, and distributors work together with real-time data. This promotes agility, reduces risks, and strengthens long-term partnerships.

How Can Deskera ERP Help with Supply Chain Integration

For modern enterprises, achieving seamless supply chain integration requires more than just connecting systems—it demands a unified platform that ensures visibility, collaboration, and automation across all operations. Deskera ERP provides exactly that, helping businesses streamline processes from procurement to delivery.

Centralized Data for Better Visibility

Deskera ERP consolidates data from procurement, inventory, production, and distribution into a single platform. This real-time visibility ensures that decision-makers have access to accurate information, reducing errors and improving responsiveness across the supply chain.

Automated Procurement and Supplier Management

With built-in automation, Deskera ERP simplifies procurement workflows and supplier collaboration. Businesses can automate purchase orders, track supplier performance, and ensure timely replenishment, minimizing stockouts and delays.

AI-Powered Demand Forecasting

Deskera ERP uses AI-driven insights to forecast demand more accurately. By analyzing historical data and market trends, businesses can align production schedules with actual customer needs, reducing waste and optimizing inventory.

MRP and Production Planning

Manufacturers can integrate Material Requirements Planning (MRP) directly into their supply chain processes. Deskera ERP ensures raw materials, labor, and equipment are allocated effectively, aligning in-house production with external supply chain operations.

Real-Time Monitoring with Mobile Accessibility

Deskera ERP’s mobile-first approach enables managers to track supply chain activities from anywhere. Whether monitoring stock levels or approving purchase orders, mobile accessibility ensures agility and faster decision-making.

AI Assistant “David” for Quick Insights

Deskera’s AI assistant, David, simplifies reporting and analysis by delivering instant insights. From tracking supplier lead times to monitoring order fulfillment rates, David helps executives make informed decisions without waiting for manual reports.

Scalability for Business Growth

As businesses expand, Deskera ERP scales seamlessly, supporting additional suppliers, customers, and warehouses. This ensures that supply chain integration grows with the business without disrupting operations.

Key Takeaways

- Supply chain integration is about unifying processes, data, and partners across the supply chain to improve collaboration and efficiency.

- Key Components of Supply Chain Integration: Core components include real-time data sharing, collaboration, process standardization, and technology-driven visibility across the network.

- Key Benefits of Supply Chain Integration: Businesses with integrated supply chains enjoy higher profitability, productivity, cost savings, and stronger customer satisfaction.

- Challenges in Supply Chain Integration: Common hurdles include siloed data, lack of collaboration, resistance to change, and technology adoption barriers.

- Best Practices for Supply Chain Integration: To succeed, businesses should prioritize clear goals, collaboration, continuous training, and adopting scalable ERP solutions.

- Role of Technology in Supply Chain Integration: Modern tools like ERP, AI, IoT, and blockchain enable seamless communication, predictive insights, and smarter decision-making.

- Steps to Implement Supply Chain Integration in Your Business: Integration requires assessing gaps, setting KPIs, adopting ERP, training teams, and continuous optimization.

- Does Your Business Require Supply Chain Integration?: Companies struggling with inefficiencies, limited visibility, or high costs should strongly consider integration.

- Future Trends in Supply Chain Integration: The future points to AI-driven forecasting, blockchain-enabled transparency, and highly resilient, automated networks.

- How Can Deskera ERP Help with Supply Chain Integration: Deskera ERP simplifies integration through centralized data, automation, AI forecasting, and mobile accessibility.

Related Articles