Have you ever wondered why some businesses always seem to have the right products in stock while others struggle with shortages or excess inventory? The secret often lies in accurate demand forecasting. In today’s fast-paced markets, supply chains need more than just guesswork — they need proven strategies to anticipate customer needs and respond with agility.

Demand forecasting in supply chain management is not just about predicting sales; it’s about aligning production, inventory, and distribution with real-world demand. When done effectively, it helps businesses cut costs, minimize waste, and enhance customer satisfaction. On the other hand, poor forecasting can lead to missed sales opportunities, rising operational costs, and damaged customer relationships.

That’s why companies are increasingly looking for ways to refine their forecasting accuracy and efficiency. From leveraging historical data and advanced analytics to fostering collaboration across departments, the right approach can transform forecasting from a challenge into a strategic advantage. This blog will explore 10 proven strategies to improve demand forecasting in supply chain, helping businesses boost resilience and profitability.

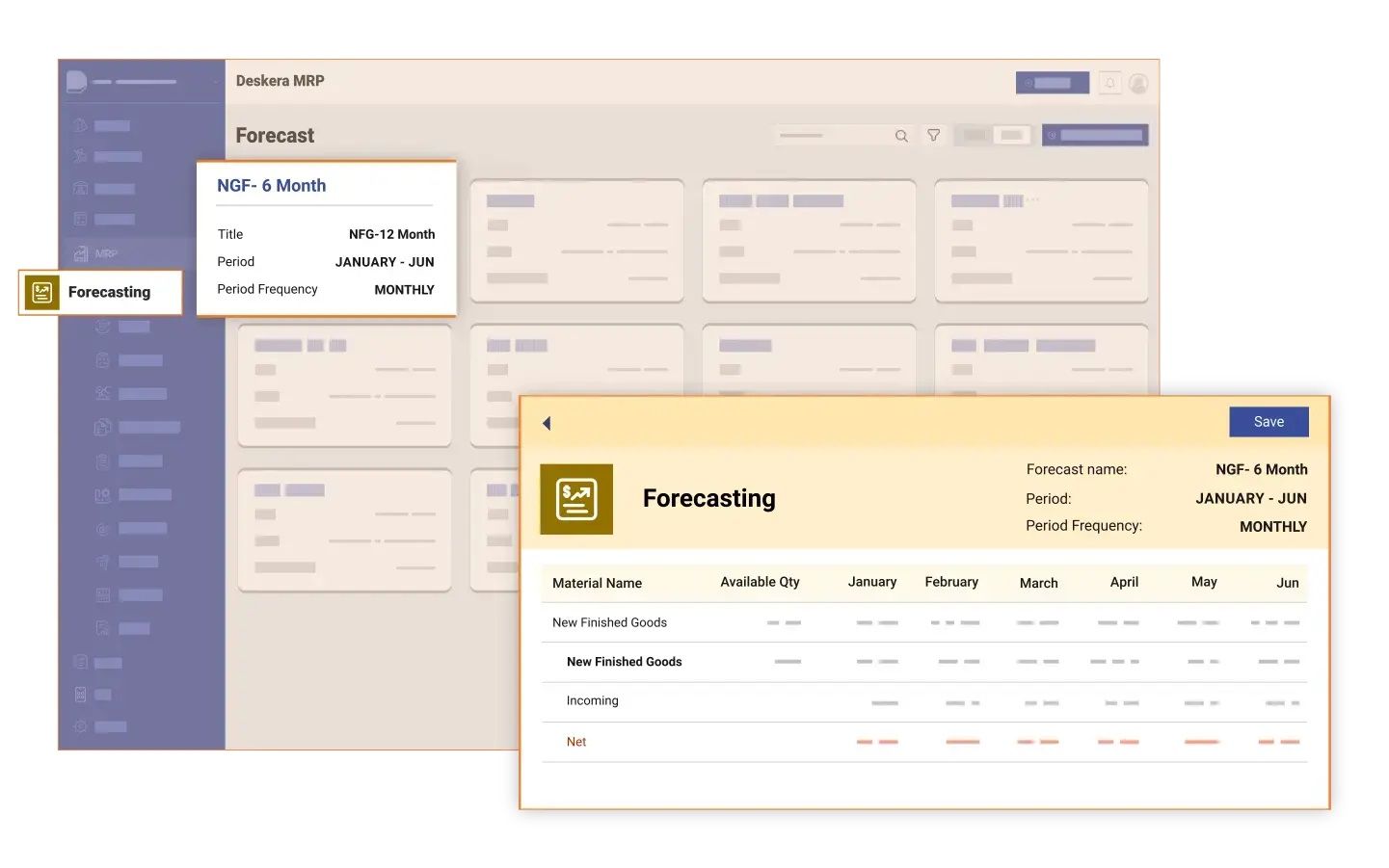

One powerful enabler of accurate forecasting is technology. Deskera MRP simplifies demand forecasting with built-in tools for demand planning, inventory optimization, and production scheduling. With features like AI-powered insights, real-time reporting, and seamless integration across departments, Deskera helps businesses make smarter decisions and achieve greater efficiency in their supply chain operations.

Why Demand Forecasting Matters in Supply Chain

Demand forecasting is at the heart of efficient supply chain management. It enables businesses to anticipate customer needs, optimize inventory levels, and align operations with market realities. Without accurate forecasting, companies risk stockouts, excess inventory, or missed sales opportunities. Here’s why demand forecasting plays such a crucial role:

1. Optimizes Inventory Management

Accurate demand forecasting helps businesses strike the right balance between supply and demand. By predicting customer needs, companies can reduce the chances of overstocking or understocking. This leads to lower holding costs, fewer lost sales, and better utilization of warehouse space.

2. Enhances Customer Satisfaction

When businesses can meet customer demand without delays, it builds trust and loyalty. Forecasting ensures the right products are available at the right time, leading to smoother order fulfillment and improved customer experience.

3. Improves Cost Efficiency

Better forecasting translates into smarter procurement and production planning. Companies can avoid unnecessary expenses such as expedited shipping, last-minute supplier orders, or excessive storage fees. The result is a leaner, more cost-effective supply chain.

4. Strengthens Decision-Making

Demand forecasting provides valuable insights into sales patterns, market trends, and seasonal fluctuations. These insights empower managers to make data-driven decisions, plan promotions, and allocate resources more effectively across the supply chain.

5. Increases Supply Chain Resilience

Uncertainty is a constant in supply chain operations. With accurate forecasts, businesses can anticipate disruptions, adjust quickly to demand fluctuations, and maintain smoother operations even during volatile market conditions.

6. Facilitates Better Supplier Relationships

Forecasting gives suppliers visibility into future demand, enabling them to align their own production schedules. This collaboration helps secure raw materials on time, reduces lead time issues, and builds stronger supplier partnerships.

7. Supports New Product Planning

Accurate forecasting is essential when launching new products. By analyzing historical data of similar items or leveraging market insights, businesses can better estimate demand for new SKUs and avoid costly overproduction or shortages.

8. Enables Strategic Growth

Demand forecasting helps businesses identify growth opportunities. For example, if data shows rising demand in a particular region or product category, companies can strategically expand into those markets with confidence.

9. Improves Workforce and Resource Planning

In addition to inventory, accurate demand forecasts ensure the right labor, equipment, and logistics capacity are in place. This prevents bottlenecks during peak seasons and improves overall operational efficiency.

10. Drives Sustainability in Supply Chain

By aligning production with actual demand, businesses can reduce waste, energy consumption, and excess transportation needs. This not only lowers costs but also supports sustainable supply chain practices — a growing priority for modern organizations.

10 Proven Strategies to Improve Demand Forecasting in Supply Chain

Accurate demand forecasting is critical for supply chain efficiency, cost control, and customer satisfaction. In today’s competitive market, businesses cannot rely on guesswork to manage inventory, production, or procurement.

Implementing effective strategies ensures that supply meets demand, reduces waste, and improves operational performance.

The following 10 proven strategies will help businesses enhance their forecasting accuracy, optimize inventory, and build a more resilient and responsive supply chain.

1. Use Historical Sales Data Effectively

Historical sales data provides a foundation for accurate demand forecasting. By analyzing past sales trends, seasonality, and product performance, businesses can identify patterns that indicate future demand. This approach helps in making informed decisions about inventory levels, procurement schedules, and production planning.

However, relying solely on historical data can be risky if market conditions shift, so it should be complemented with other data sources. Advanced ERP tools, like Deskera, can automatically gather and analyze historical sales data to generate actionable forecasts, saving time and improving accuracy.

2. Incorporate Market Trends and External Factors

Demand is influenced by more than internal sales data — market trends, economic shifts, competitor activity, and even weather can affect customer behavior. Incorporating these external factors ensures forecasts reflect real-world conditions.

For example, a surge in online shopping trends during festive seasons should influence stock planning. Businesses can combine historical data with predictive analytics to account for such trends.

Using platforms like Deskera MRP, companies can integrate external market insights with internal data, enabling more responsive and proactive supply chain planning.

3. Segment Products and Customers

Not all products and customers behave the same way, so segmentation is crucial. High-volume or fast-moving products may need more precise forecasting methods than slow-moving items. Similarly, key customers may require tailored forecasts to ensure consistent fulfillment.

Techniques like ABC analysis or customer profiling allow businesses to allocate resources effectively. By segmenting, companies can focus efforts where accuracy matters most, reduce wastage, and improve service levels.

Deskera MRP enables automated segmentation and tracking, making it easier to apply differentiated forecasting strategies across products and customer groups.

4. Leverage Advanced Forecasting Tools and Software

Modern forecasting software transforms raw data into actionable insights. Tools like AI, machine learning, and ERP systems analyze complex patterns quickly and provide predictions with higher accuracy. These platforms can detect trends humans might overlook and continuously refine forecasts as new data arrives.

Deskera MRP, for example, integrates inventory, production, and sales data to deliver real-time forecasting, reducing manual errors and enabling faster, data-driven decisions. Leveraging such tools ensures businesses stay ahead of demand fluctuations and maintain optimal supply chain efficiency.

5. Collaborate Across Departments

Effective demand forecasting requires input from multiple departments — sales, marketing, finance, and supply chain. Sales teams provide insights into promotions and customer behavior, marketing shares upcoming campaigns, and supply chain teams understand operational constraints. This cross-functional collaboration ensures forecasts are realistic and actionable.

When teams align, businesses can avoid stockouts, optimize inventory, and respond quickly to market changes. Deskera MRP supports collaborative forecasting by centralizing data and enabling multiple stakeholders to view, adjust, and approve forecasts in real time, ensuring everyone stays on the same page.

6. Integrate Supplier and Partner Insights

Suppliers and partners play a critical role in meeting customer demand. Sharing forecasted demand with suppliers helps them plan production and inventory, reducing lead time delays. Vendor-managed inventory (VMI) agreements and regular supplier communication further improve accuracy.

Businesses that incorporate supplier data into forecasting can better anticipate shortages, mitigate risks, and strengthen supply chain relationships. Deskera MRP enables seamless integration with supplier systems, providing a shared view of forecasts, orders, and inventory, which enhances coordination and ensures timely product availability.

7. Apply Multiple Forecasting Methods

No single forecasting method works in all situations. Quantitative techniques like time series analysis or regression provide numerical precision, while qualitative methods such as expert judgment or market research capture insights that data alone may miss. Combining multiple methods creates a hybrid approach that balances accuracy and adaptability.

Businesses can use historical data, predictive analytics, and expert input simultaneously for better results. Deskera MRP allows users to apply different forecasting models, compare outputs, and select the most reliable approach for each product or scenario, improving overall supply chain performance.

8. Continuously Monitor and Adjust Forecasts

Markets are dynamic, and demand can fluctuate unexpectedly. Continuous monitoring of forecast accuracy using metrics like MAPE (Mean Absolute Percentage Error) and tracking deviations allows businesses to adjust predictions in real time.

Regular updates ensure that production schedules, inventory levels, and procurement plans remain aligned with actual demand. Deskera MRP provides dashboards and alerts to track forecast accuracy, enabling timely adjustments. This iterative process not only improves accuracy over time but also builds a resilient and responsive supply chain that can adapt to market changes seamlessly.

9. Factor in New Product Introductions

Forecasting demand for new products is challenging due to the lack of historical data. Companies can use analogous forecasting by comparing new SKUs with similar existing products or conduct small test launches to gather early data.

Incorporating market research, consumer surveys, and competitor analysis helps create initial forecasts. Deskera MRP supports this process by integrating pre-launch data, early sales trends, and market intelligence into forecasting models, helping businesses minimize risks, avoid overproduction, and prepare inventory for new product launches more confidently.

10. Invest in Employee Training and Forecasting Culture

Even the best tools cannot replace skilled employees who understand data interpretation and forecasting principles. Investing in training ensures staff can analyze trends, validate assumptions, and respond to deviations effectively.

Cultivating a data-driven culture encourages collaboration, accountability, and proactive decision-making across the supply chain. Deskera MRP complements this by providing intuitive dashboards, automated reports, and visualizations that help employees at all levels make informed decisions. Together, skilled teams and advanced tools create a robust forecasting system that drives accuracy, efficiency, and overall business success.

Navigating Common Challenges in Demand Forecasting in Supply Chain

Even the most sophisticated supply chains struggle with demand forecasting. Market volatility, changing customer preferences, and operational complexities make predicting demand a moving target.

Understanding the specific challenges and adopting forward-thinking solutions is essential for building a supply chain that is both agile and resilient.

1. Data Quality and Silos

Challenge: Forecasting accuracy is only as good as the data behind it. Many organizations suffer from fragmented, outdated, or inconsistent data across departments, leading to skewed projections.

Solution: Centralize data collection and standardize reporting processes. Tools like Deskera MRP consolidate sales, inventory, and production data in real time, breaking down silos and ensuring forecasts are based on reliable, unified information.

2. Navigating Demand Volatility

Challenge: Sudden market shifts—like seasonal surges, promotional spikes, or unexpected global events—can disrupt traditional forecasting models.

Solution: Incorporate predictive analytics and scenario planning to model multiple demand possibilities. Deskera MRP’s AI-powered insights help detect early signals of demand changes, allowing supply chains to pivot quickly and maintain optimal stock levels.

3. Cross-Functional Misalignment

Challenge: Sales, marketing, and supply chain teams often work in isolation, resulting in forecasts that are disconnected from market realities.

Solution: Foster cross-department collaboration by sharing data and involving all teams in forecasting discussions. Deskera MRP enables real-time collaboration, so each department can contribute insights, validate assumptions, and align operational plans.

4. Forecasting for New Products

Challenge: New SKUs come with uncertainty because historical data doesn’t exist, making traditional forecasting approaches ineffective.

Solution: Use analogous forecasting, test launches, and market research to create a baseline forecast. Deskera MRP integrates early sales trends and predictive models to guide inventory and production decisions, reducing the risk of overstocking or understocking new products.

5. Overdependence on Manual Processes

Challenge: Manual forecasting is time-intensive, prone to errors, and reactive rather than proactive.

Solution: Automate forecasts with modern ERP tools. Deskera MRP streamlines calculations, tracks multiple variables in real time, and provides actionable dashboards, allowing teams to focus on insights and strategy rather than data entry.

6. Supply Chain Disruptions and Uncertainty

Challenge: Delays from suppliers, logistics bottlenecks, or external crises like natural disasters can invalidate forecasts quickly.

Solution: Build adaptive forecasting models and maintain strategic safety stock. Integrating supplier and partner data in Deskera MRP enables proactive adjustments, ensuring resilience even during disruptions.

7. Lack of Performance Measurement

Challenge: Without measuring forecast accuracy, organizations cannot learn from mistakes or improve processes.

Solution: Track metrics such as MAPE (Mean Absolute Percentage Error) and bias. Deskera MRP dashboards provide real-time visibility into forecast performance, enabling continuous refinement and smarter decision-making.

Demand forecasting is no longer just a numbers game—it’s a strategic capability. Businesses that combine quality data, predictive tools, cross-functional collaboration, and continuous monitoring can turn forecasting challenges into competitive advantages, building a supply chain that is agile, efficient, and ready for the unexpected.

How Deskera MRP Helps with Demand Forecasting in Supply Chain

Accurate demand forecasting is critical for optimizing inventory, production, and procurement, but it can be complex without the right tools. Deskera MRP simplifies and enhances forecasting by combining real-time data, advanced analytics, and automation in a single platform. Here’s how it supports businesses in improving their supply chain performance:

1. Centralized Data Management

Deskera MRP consolidates data from sales, inventory, procurement, and production into one centralized platform. This eliminates silos and ensures that forecasts are based on accurate, up-to-date information. With all departments working from a single source of truth, businesses can generate reliable demand projections and align their operations more effectively.

2. AI-Powered Forecasting

The platform uses AI and machine learning to analyze historical sales, market trends, and external factors. This allows Deskera MRP to generate predictive forecasts with high accuracy. By identifying patterns and anomalies that humans might miss, it helps businesses anticipate changes in demand and make proactive decisions.

3. Scenario Planning and “What-If” Analysis

Deskera MRP allows businesses to create multiple demand scenarios, accounting for variables like promotions, seasonal trends, or supply chain disruptions. By testing different “what-if” situations, companies can prepare for uncertainties, adjust production schedules, and maintain optimal inventory levels.

4. Real-Time Tracking and Automated Alerts

With Deskera MRP, businesses can monitor demand and inventory in real time. Automated alerts notify teams of deviations from forecasts, low stock levels, or sudden demand spikes. This ensures timely actions, reduces stockouts, and prevents overstocking, improving operational efficiency and customer satisfaction.

5. Enhanced Collaboration Across Teams

The platform enables cross-functional collaboration by allowing sales, marketing, procurement, and supply chain teams to contribute to forecasts in real time. Deskera MRP ensures everyone has access to the same data, fostering better alignment and more accurate, actionable forecasting.

By leveraging Deskera MRP, businesses can transform demand forecasting from a reactive task into a strategic advantage. It not only improves forecast accuracy but also enhances agility, reduces costs, and strengthens overall supply chain performance.

Key Takeaways

- Accurate demand forecasting is essential for supply chain efficiency, cost control, and customer satisfaction. Businesses that implement effective forecasting strategies gain a competitive edge and reduce operational risks.

- Forecasting aligns supply with demand, optimizes inventory, reduces costs, improves customer satisfaction, and enables data-driven decision-making.

- Strategy 1: Use Historical Sales Data Effectively: Historical data provides the foundation for forecasting patterns and trends, helping businesses make informed decisions about production, procurement, and inventory planning.

- Strategy 2: Incorporate Market Trends and External Factors: Considering external influences like seasonality, economic shifts, and market trends ensures forecasts reflect real-world conditions and remain actionable.

- Strategy 3: Segment Products and Customers: Segmentation allows businesses to prioritize high-volume products and key customers, applying tailored forecasting methods to improve accuracy and efficiency.

- Strategy 4: Leverage Advanced Forecasting Tools and Software: Using AI, machine learning, and ERP systems like Deskera MRP enhances forecast precision, reduces manual errors, and enables proactive supply chain decisions.

- Strategy 5: Collaborate Across Departments: Cross-functional collaboration ensures sales, marketing, and supply chain teams align, creating more realistic and actionable forecasts.

- Strategy 6: Integrate Supplier and Partner Insights: Sharing forecasts with suppliers and partners improves coordination, reduces lead time risks, and strengthens supply chain relationships.

- Strategy 7: Apply Multiple Forecasting Methods: Combining quantitative and qualitative approaches balances precision and insight, resulting in more reliable and adaptable forecasts.

- Strategy 8: Continuously Monitor and Adjust Forecasts: Ongoing monitoring using key metrics allows businesses to refine forecasts, quickly respond to demand changes, and maintain supply chain agility.

- Strategy 9: Factor in New Product Introductions: Using analogous forecasting, test launches, and market research helps businesses plan inventory and production for new SKUs while minimizing risk.

- Strategy 10: Invest in Employee Training and Forecasting Culture: Skilled staff and a data-driven culture enable teams to interpret forecasts effectively, leverage tools like Deskera MRP, and make proactive supply chain decisions.

- Accurate forecasting requires clean data, cross-functional collaboration, adaptable models, and automated tools to mitigate volatility, disruptions, and uncertainty.

- Advanced technologies, including ERP systems, AI, predictive analytics, and real-time automation, transform forecasting from a reactive process into a strategic capability.

- Deskera MRP centralizes data, applies AI-driven predictive models, enables scenario planning, automates monitoring, and fosters collaboration, improving forecast accuracy, operational efficiency, and supply chain resilience.

Related Articles