What would happen if your largest supplier suddenly halted operations? Or if customer demand surged beyond your current production capacity? For manufacturers, uncertainty isn't just a risk—it's a constant. In today's volatile environment, traditional forecasting methods are no longer sufficient. Instead, forward-thinking manufacturers are embracing scenario analysis as a strategic tool to navigate disruption, build resilience, and drive smart growth.

The global manufacturing sector continues to expand despite ongoing challenges. In fact, value added in the manufacturing market is projected to reach US$2.28 trillion in 2025, with a compound annual growth rate (CAGR) of 1.27% expected between 2025 and 2029. This growth signals opportunity—but only for those who are ready. With fluctuating raw material prices, evolving regulations, and geopolitical uncertainties, manufacturers must plan not for one future, but for many possible futures.

Scenario analysis enables exactly that. By simulating various “what-if” situations—such as supply chain disruptions, price volatility, or demand shifts—manufacturers can proactively assess potential risks and outcomes. Whether you're a small-scale producer managing lean operations or a global enterprise overseeing complex supply chains, scenario analysis helps you make better, faster, and more informed decisions in a dynamic world.

Deskera Manufacturing ERP empowers businesses with real-time visibility and intelligent forecasting tools that make scenario planning simple and impactful. With integrated modules for production, inventory, procurement, and finance, manufacturers can run multiple scenarios using live data—driving smarter decisions at every level. From managing machine downtime to preparing for market expansion, Deskera helps you stay ahead of disruption and focused on growth.

What is Scenario Analysis?

Scenario analysis is a strategic technique used to evaluate a wide range of possible future events by considering their potential impact on business performance. Rather than trying to predict a single outcome, scenario analysis helps manufacturers explore multiple hypothetical situations—ranging from best-case to worst-case scenarios—so they can better understand how various factors might affect operations, finances, supply chains, and growth opportunities.

In the manufacturing context, scenario analysis could involve questions such as: What happens to profit margins if raw material costs increase by 20%? How would an economic slowdown in a key market affect our production targets? What if a competitor launches a similar product next quarter? By examining these possibilities, manufacturers gain clarity on how different external or internal changes could influence their business—and what responses may be required.

This technique plays a vital role in risk management and strategic planning. It highlights vulnerabilities in current strategies and equips leadership with actionable insights to design contingency plans before disruptions occur. Financially, it strengthens forecasting and budgeting by incorporating a range of outcomes, ultimately leading to more adaptive and resilient planning processes.

Beyond numbers, scenario analysis promotes a culture of agility and preparedness. It encourages cross-functional teams to challenge assumptions, think objectively, and collaboratively explore new ideas. This not only improves decision-making quality but also fosters innovation and organizational readiness—qualities essential for manufacturers aiming to thrive in a rapidly evolving global market.

How Scenario Analysis Works

Scenario analysis is a structured approach used by manufacturers to explore how different future conditions could impact their operations, financial health, and strategic goals.

It begins by identifying a specific event or change—such as a shift in demand, a regulatory development, or a new investment decision—and then outlines a set of potential scenarios that could emerge from that event.

Each scenario represents a possible future state. These typically include at least three core perspectives:

- Base-case scenario – the most likely outcome based on current trends and accepted assumptions

- Best-case scenario – the most favorable outcome where all major variables shift positively

- Worst-case scenario – the most challenging outcome where disruptions or setbacks significantly affect performance

For every scenario, key assumptions are made about variables relevant to the business, such as:

- Costs of raw materials and components

- Availability of labor and machinery

- Customer demand across markets

- Lead times and logistics reliability

- Capital costs and financing options

These assumptions are fed into operational or financial models to determine their impact on key performance indicators (KPIs) like:

- Revenue and gross margins

- Cash flow and profitability

- Production volumes and lead times

- Inventory turnover and utilization rates

Other important aspects of how scenario analysis works include:

- Assigning probabilities – Estimating how likely each scenario is to occur to guide decision-making

- Multiple scenario analysis – Expanding beyond the base/worst/best trio to include several nuanced scenarios for deeper insights

- Guiding strategic decisions – Using results to shape investments, budgeting, workforce planning, and contingency strategies

Though it requires thoughtful modeling and cross-functional collaboration, scenario analysis equips manufacturers with a realistic view of potential outcomes—so they can move forward with agility and confidence.

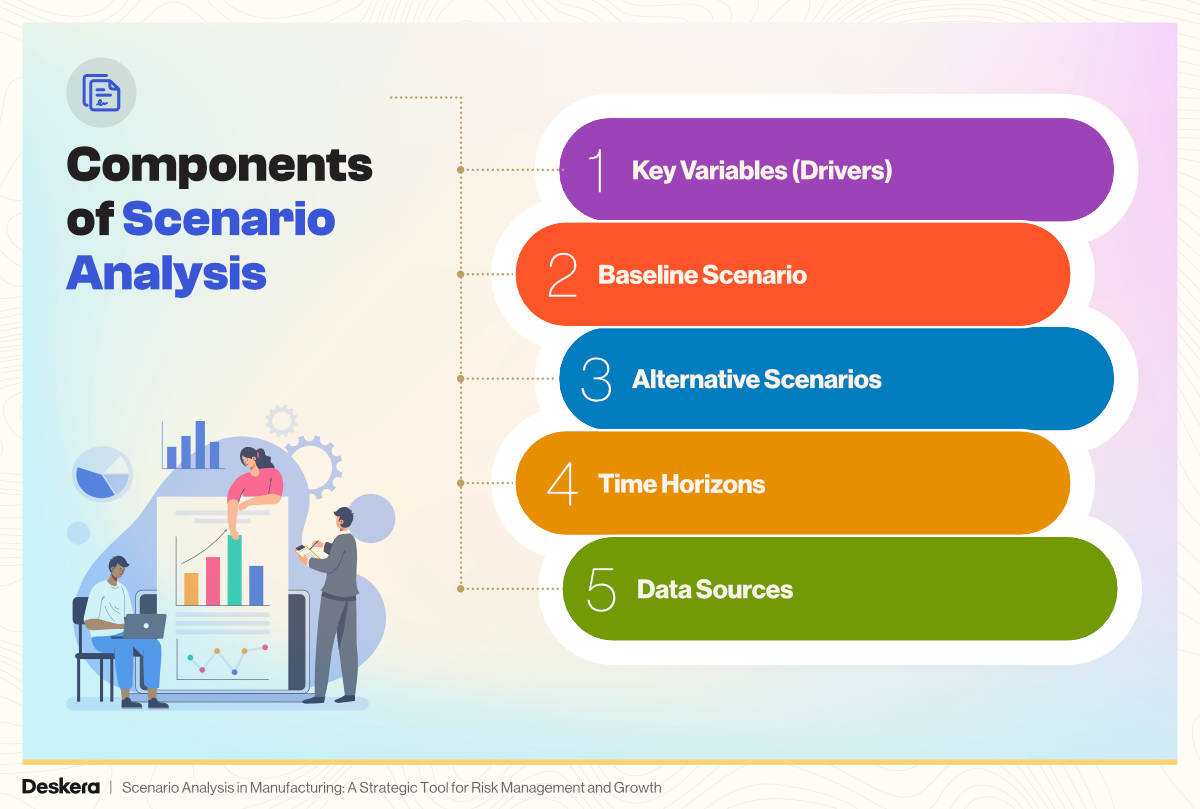

Components of Scenario Analysis

To generate meaningful, actionable insights, scenario analysis must be grounded in clearly defined components. These components ensure the analysis is structured, repeatable, and aligned with the business context.

In manufacturing, this clarity is essential to stress-test decisions against real-world uncertainties and build plans that are both flexible and robust.

Below are the core components of an effective scenario analysis:

1. Key Variables (Drivers)

These are the internal and external factors that have the greatest influence on outcomes. Identifying and adjusting these variables across different scenarios is what drives the analysis.

Common key variables in manufacturing include:

- Cost of raw materials

- Labor availability and cost

- Machine uptime and maintenance frequency

- Customer demand fluctuations

- Lead times and supply chain reliability

- Inventory levels and turnover rates

These inputs form the foundation for each scenario model and help pinpoint where the greatest risks and opportunities lie.

2. Baseline Scenario

Also called the base-case scenario, this sets the benchmark by assuming that current trends and business-as-usual conditions will continue. It reflects no major disruptions or changes to internal operations or market dynamics.

- Acts as a reference point for comparing more optimistic or pessimistic scenarios

- Helps validate whether current strategies are sufficient under expected conditions

3. Alternative Scenarios

These are variations around the baseline that explore different potential futures.

- Best-case scenario: Favorable shifts like increased demand, lower input costs, or production efficiencies

- Worst-case scenario: Challenges such as supply disruptions, labor shortages, or economic downturns

- Moderate scenario(s): Situations that lie between best and worst, reflecting mixed trends or partial impacts

Each scenario should be internally consistent and plausible based on the current context and available data.

4. Time Horizons

Time horizons define the length of time being analyzed. Different decisions require different time frames.

- Short-term: Weeks to months; ideal for inventory adjustments, staffing, and short-term cash flow planning

- Mid-term: 1–2 years; used for budgeting cycles, expansion plans, or product launches

- Long-term: 3+ years; best for capital investments, automation projects, or strategic transformation

Aligning the horizon with the decision-making window ensures relevance and practicality.

5. Data Sources

Reliable data is the foundation of accurate scenario analysis. Using diverse and trustworthy inputs ensures more realistic assumptions and credible outcomes.

Typical data sources include:

- Historical performance metrics

- ERP systems (like Deskera Manufacturing ERP) for real-time operational data

- Supplier and procurement data

- Market forecasts and economic indicators

- Customer behavior trends and industry benchmarks

By integrating these components, manufacturers can design scenarios that are not only strategically relevant but also grounded in measurable, data-driven insights. This structured approach makes it easier to evaluate decisions, test plans under pressure, and prepare proactively for a range of possible futures.

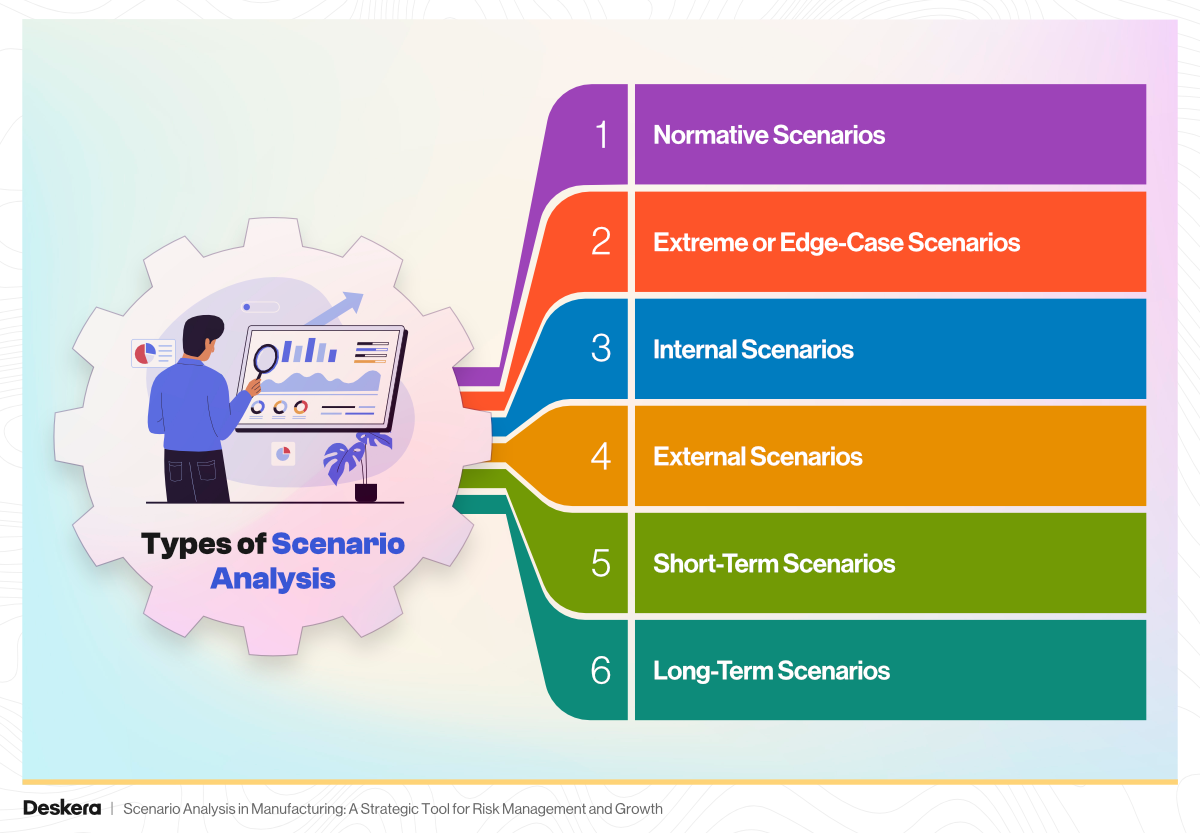

Types of Scenario Analysis

One of the greatest strengths of scenario analysis lies in its ability to break away from rigid or overly optimistic planning. By exploring a range of outcomes—each with its own assumptions and variables—manufacturers can avoid tunnel vision and prepare for both expected developments and surprising disruptions.

While the best-case, worst-case, and most-likely scenarios are common frameworks, there are several other types of scenario analyses that serve distinct strategic purposes.

1. Normative Scenarios

These scenarios are built around what is most likely to happen based on current trends, market conditions, and known variables.

In manufacturing, normative scenarios help align planning with realistic expectations—for example, projecting next year's output based on stable demand and steady input costs.

They're useful for resource allocation and operational planning where the goal is to match business plans with probable outcomes.

2. Extreme or Edge-Case Scenarios

Also known as “black swan” scenarios, these focus on highly unlikely but high-impact events. Think of sudden trade embargoes, catastrophic equipment failures, or global pandemics.

While these may never happen, evaluating them helps manufacturers stress-test their operations and build contingency plans. This improves organizational resilience by preparing for the unexpected.

3. Internal Scenarios

These examine situations that arise from within the business and are generally under management's control. Internal scenarios could explore the impact of expanding production capacity, launching a new product line, or switching to a just-in-time inventory model. Such scenarios help optimize operational efficiency and assess internal strategic choices.

4. External Scenarios

External scenarios explore factors outside the company’s control—such as shifting consumer preferences, changes in environmental regulations, new entrants in the market, or raw material price fluctuations. These help manufacturers prepare for changes in the competitive or macroeconomic landscape and guide market-facing strategies.

5. Short-Term Scenarios

Short-term scenarios typically look ahead 1 to 2 years and focus on tactical decisions, such as adjusting procurement based on seasonal demand or responding to a temporary labor shortage. They're especially valuable for day-to-day operations, budgeting, and immediate risk mitigation.

6. Long-Term Scenarios

Long-term scenarios span 5 to 10 years or more and focus on transformative developments like technological disruption, automation trends, or demographic shifts in workforce or customer base.

These help manufacturers think big—preparing for structural changes in the industry and guiding capital investments, product innovation, and strategic partnerships.

Incorporating a balanced mix of these scenario types is essential. For instance, when planning a product launch, a manufacturer might use short-term internal scenarios to evaluate the initial production ramp-up, while relying on long-term external scenarios to project market adoption, competitive responses, and future profitability. The ultimate goal isn’t to predict the future with precision—but to be prepared for a wide range of outcomes with clarity and confidence.

Scenario Analysis vs. Sensitivity Analysis

While both scenario analysis and sensitivity analysis are essential tools for evaluating business risks and outcomes, they serve distinct purposes and offer different insights—especially in manufacturing environments where even small shifts in variables can have major operational impacts.

1. Purpose and Focus

- Scenario Analysis evaluates multiple possible future situations by considering a combination of variables changing together. It answers: “What happens if these specific events or conditions occur together?”

- Sensitivity Analysis examines how the outcome changes when one variable changes at a time, keeping all others constant. It answers: “How sensitive is our outcome to a change in this single factor?”

2. Scope of Change

- Scenario Analysis: Broad and multi-dimensional. Useful for simulating realistic, complex future scenarios (e.g., a combination of increased raw material costs, lower customer demand, and delayed supplier shipments).

- Sensitivity Analysis: Narrow and focused. Ideal for identifying which single input (e.g., labor cost or lead time) has the biggest impact on output.

3. Use Cases in Manufacturing

4. Output and Insight

- Scenario Analysis: Provides a range of outcomes and supports strategic decision-making under uncertainty.

- Sensitivity Analysis: Highlights key risk drivers and helps prioritize variables that need tighter control or monitoring.

5. Complexity

- Scenario Analysis: More complex due to multiple variables and interdependencies.

- Sensitivity Analysis: Simpler, quicker, and often used as a preliminary analysis tool.

In summary, use scenario analysis when you're planning for the bigger picture with interconnected variables and future states. Use sensitivity analysis when you want to drill down into which single factors matter most to your outcomes.

Both are powerful when used together—scenario analysis gives you direction, while sensitivity analysis shows you where to focus.

Scenario Analysis vs. Scenario Modeling

While the terms scenario analysis and scenario modeling are often used interchangeably, they refer to different—though related—steps in strategic planning and decision-making.

Understanding the distinction is key for manufacturers looking to improve forecasting, risk management, and operational planning.

1. Definition and Focus

- Scenario Analysis is the evaluation process. It involves identifying potential future situations and assessing their impact on the business. It’s focused on understanding what could happen and why.

- Scenario Modeling is the technical process of building mathematical or data-driven models to simulate those scenarios. It focuses on quantifying and visualizing outcomes using tools like spreadsheets, simulations, or ERP systems.

2. Purpose

- Scenario Analysis: To explore strategic possibilities and prepare for a range of business outcomes.

- Scenario Modeling: To calculate the numeric impact of different scenarios based on variable changes and assumptions.

3. Use in Manufacturing

4. Output

- Scenario Analysis: Narrative and qualitative insights (e.g., best-case, worst-case, moderate-case).

- Scenario Modeling: Quantitative, measurable outcomes (e.g., % change in throughput, ROI projections, inventory cost variations).

5. Relationship Between the Two

Think of scenario analysis as the strategic thinking phase and scenario modeling as the execution phase:

Scenario analysis frames the “what if”; scenario modeling delivers the “then what happens.”

In summary, scenario analysis helps manufacturers think through strategic possibilities, while scenario modeling turns those ideas into actionable numbers. Together, they form a powerful decision-making framework that blends judgment, data, and foresight.

Steps to Perform Scenario Analysis in Manufacturing

A structured approach to scenario analysis helps manufacturers plan for a range of future outcomes—both risks and opportunities. Below are six essential steps, each followed by a contextual example from a real-world manufacturing scenario.

1. Identify Key Uncertainties

Start by pinpointing what uncertainties could impact your business. These could be internal or external and may include:

- Economic conditions

- Internal risks (e.g., equipment failure, talent shortages)

- Supply chain dependencies

- Regulatory changes

- Market competition

Example: A mid-sized furniture manufacturer exploring expansion into Southeast Asia identifies key uncertainties such as:

- Fluctuating costs of wood and foam

- Availability of skilled labor in the region

- Import/export regulations

- Currency exchange fluctuations

- Market demand in urban areas

2. Define Baseline Scenario

Develop a baseline scenario that represents the current state or a “business-as-usual” trajectory based on known variables and current trends. This scenario serves as the foundation for comparison.

- Incorporates existing business conditions

- Reflects no major changes or disruptions

- Based on internal forecasts and historical performance

Example: The furniture company defines its baseline scenario as:

- Steady 5% annual growth in existing markets

- Stable raw material prices

- Normal port and shipping timelines

- No change in current workforce levels

3. Build Alternative Scenarios

Create multiple alternative scenarios, typically including:

- Best-case scenario: Optimistic but plausible

- Worst-case scenario: Pessimistic, stress-testing your resilience

- Moderate/middle-ground scenario: A realistic projection between best and worst

Example: The company outlines:

- Best-case: Southeast Asia market surges, material costs drop by 10%, and lead times improve

- Worst-case: Tariffs are imposed, raw material prices rise 25%, demand slumps

- Moderate-case: Demand grows slightly (3%), lead times extend, labor remains stable

4. Quantify Impact

Use tools and data models to assess the financial, operational, and strategic implications of each scenario. Consider:

- Revenue changes

- Operating margin shifts

- Impact on inventory levels

- Production or delivery disruptions

Example: Using Deskera Manufacturing ERP, the company:

- Models the effect of raw material price changes on unit cost

- Analyzes delivery lead times and how they affect cash flow

- Estimates profit margin variations from 5% (worst case) to 18% (best case)

5. Develop Action Plans

Based on scenario outcomes, develop strategic or tactical responses:

- Contingency plans for supply chain disruption

- Budget adjustments

- Resource allocation strategies

- Pricing or product mix changes

Example:

- Best-case: Scale up output by adding weekend shifts and reallocating marketing budget to demand-heavy regions

- Worst-case: Diversify suppliers, reduce marketing spend, delay hiring plans

- Moderate-case: Maintain lean inventory, cautiously expand sales outreach

6. Monitor & Update

Scenario analysis is an ongoing process. Regularly review:

- Industry developments

- Internal KPIs and performance data

- Updated market forecasts

- Regulatory or geopolitical changes

Example: The company sets up a quarterly scenario review cycle. Using Deskera Manufacturing ERP, it tracks:

- Freight and input cost trends

- Factory capacity utilization

- Market response in Southeast Asia

Based on the latest data, it adjusts its action plan and assumptions accordingly.

By following these steps with discipline and agility, manufacturers can future-proof their strategies and respond with confidence to a rapidly evolving business environment.

Applications of Scenario Analysis by Manufacturing Scale

Scenario analysis is a versatile tool that adapts to the scale and complexity of operations. Whether it’s a small local workshop or a multinational manufacturer, scenario analysis can help anticipate risks, explore opportunities, and align strategies accordingly.

Below are specific applications tailored to different business sizes:

A. Small Manufacturers: Navigating Short-Term Volatility

Small manufacturers often operate with tighter margins and limited buffers, making them more vulnerable to sudden disruptions. Scenario analysis helps them:

- Prepare for seasonal demand spikes

- Mitigate supplier delays or cost fluctuations

- Optimize inventory and workforce planning

- Respond quickly to market shifts

Example: A small garment manufacturing unit anticipates festive season surges in orders. Using scenario analysis, they create:

- A baseline where demand increases moderately

- A best-case scenario with a 40% demand spike

- A worst-case where fabric supply is delayed

Based on these, they plan inventory purchases, adjust production timelines, and coordinate with backup suppliers.

B. Medium Manufacturers: Balancing Growth and Risk

Mid-sized manufacturers face complex challenges related to scale. Scenario analysis supports them in:

- Managing cash flow amid raw material price volatility

- Adjusting workforce capacity and shifts

- Streamlining production across multiple facilities

- Balancing stock levels without overcommitting resources

Example: A regional chemical manufacturer expects fluctuations in raw material prices due to geopolitical tensions. They conduct scenario analysis to:

- Forecast cost implications under varying price increases

- Assess profitability under different customer demand levels

- Create staffing plans that align with high and low production volumes

This helps them protect margins and avoid stockouts or excess production.

C. Large Manufacturers: Strategic Long-Term Planning

For large manufacturers with multi-location operations, scenario analysis is a strategic tool for:

- Long-term capacity and investment planning

- Mapping global risks (geopolitical, regulatory, climate-related)

- Modeling transitions to new technologies or markets

- Evaluating multi-billion-dollar capital expenditures

Example: A global automotive company is preparing for the industry’s shift toward electric vehicles (EVs). It models several scenarios, such as:

- A base case where EV demand grows steadily

- A worst-case with regulatory delays or battery material shortages

- A best-case where subsidies accelerate EV adoption globally

These scenarios guide R&D allocation, factory upgrades, and supplier diversification strategies.

In short, scenario analysis scales to match business size—offering focused tactical planning for small manufacturers, operational agility for mid-sized firms, and strategic foresight for large enterprises.

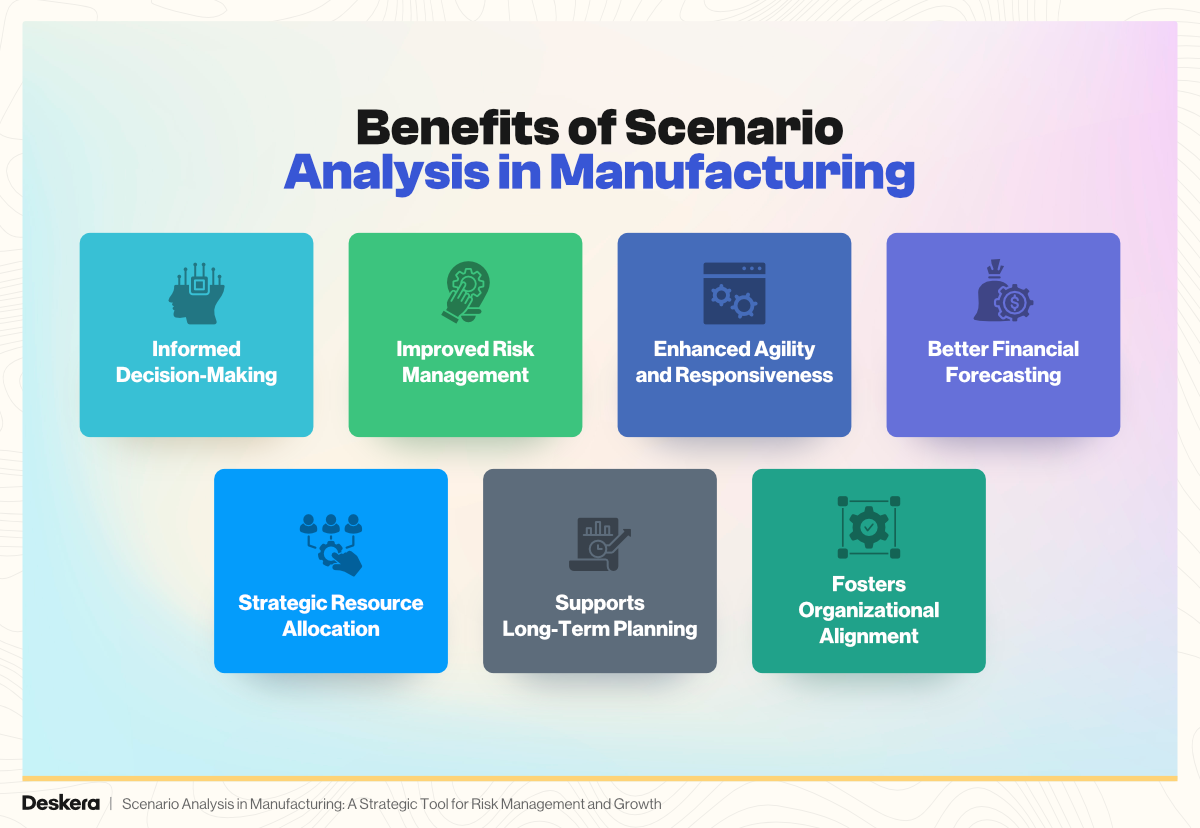

Benefits of Scenario Analysis in Manufacturing

Scenario analysis offers manufacturers a structured and forward-thinking approach to managing uncertainty. By evaluating multiple potential futures, manufacturers can better prepare for volatility, enhance strategic planning, and make smarter operational decisions. Here are the key benefits:

1. Informed Decision-Making

- Helps manufacturers assess the impact of different events before they occur.

- Encourages data-driven choices rather than relying on gut instinct.

- Supports investment decisions, production planning, and pricing strategies with clear rationale.

2. Improved Risk Management

- Identifies vulnerabilities in current operations or supply chains.

- Highlights exposure to external risks such as raw material shortages, policy changes, or market shifts.

- Enables the creation of contingency plans tailored to each risk scenario.

3. Enhanced Agility and Responsiveness

- Equips teams with predefined action plans, reducing reaction time during disruptions.

- Fosters a proactive rather than reactive mindset across departments.

- Allows quick reallocation of resources when conditions change unexpectedly.

4. Better Financial Forecasting

- Models the financial impact of varying inputs (e.g., labor costs, demand levels, exchange rates).

- Enables more realistic budgeting and forecasting with a range of potential outcomes.

- Helps protect margins by modeling profitability under stress scenarios.

5. Strategic Resource Allocation

- Guides capacity planning, equipment investment, and workforce management.

- Ensures optimal use of limited resources in best-, worst-, and moderate-case situations.

- Reduces the risk of overproduction or underutilization of assets.

6. Supports Long-Term Planning

- Aligns operational and financial planning with long-term goals.

- Helps manufacturers prepare for structural industry changes such as sustainability regulations, automation trends, or technological shifts.

- Builds confidence in board-level strategic discussions.

7. Fosters Organizational Alignment

- Encourages collaboration across departments like finance, operations, supply chain, and HR.

- Builds a shared understanding of potential risks and opportunities.

- Promotes a culture of strategic foresight and continuous improvement.

Scenario analysis isn’t just about anticipating problems—it’s about empowering manufacturers to seize opportunities and make confident, future-ready decisions. Whether you're a small unit or a multinational, this technique can transform your approach to growth, risk, and operational resilience.

Challenges and Limitations of Scenario Analysis in Manufacturing

While scenario analysis is a valuable strategic tool, it comes with its own set of challenges—especially in complex manufacturing environments. Understanding these limitations can help manufacturers apply the method more effectively and avoid common pitfalls.

1. High Dependence on Assumptions

- The accuracy of scenario outcomes heavily relies on the quality of underlying assumptions.

- Over-optimistic or unrealistic assumptions can lead to misleading projections.

- Biases from decision-makers can skew results toward preferred scenarios.

2. Data Limitations

- Reliable historical data may be unavailable, especially for small manufacturers or new product lines.

- External market data, supplier performance stats, or macroeconomic inputs may be outdated or incomplete.

- Inadequate data quality can weaken the credibility of scenario outcomes.

3. Complexity in Modeling

- Building accurate and dynamic models requires financial, operational, and statistical expertise.

- In larger manufacturers, the interdependencies between variables can make scenario modeling time-consuming and technically demanding.

- Tools like spreadsheets may be insufficient to handle complex multi-variable analyses.

4. Resource-Intensive Process

- Scenario development, validation, and refinement can consume significant time and effort.

- May require cross-functional collaboration and frequent updates, adding strain to teams already focused on day-to-day operations.

- Smaller manufacturers may lack the bandwidth or skilled personnel to carry out deep scenario planning.

5. Difficulty in Assigning Probabilities

- Estimating the likelihood of each scenario can be challenging, especially for low-probability, high-impact events.

- Without probability weighting, companies may struggle to prioritize action plans or allocate resources effectively.

6. Risk of Oversimplification or Overcomplication

- Too few scenarios may oversimplify reality, missing important possibilities.

- Too many scenarios can overwhelm stakeholders and dilute focus, making it difficult to take clear actions.

7. Limited Predictive Power

- Scenario analysis is not a forecasting tool—it does not predict the future but explores possibilities.

- Unexpected disruptions (e.g., pandemics, geopolitical crises) may fall completely outside the range of considered scenarios.

8. Requires Regular Updates

- Static scenarios quickly become obsolete in dynamic markets.

- Continuous monitoring and updating are essential but often neglected after initial implementation.

Scenario analysis is most effective when paired with robust data, realistic assumptions, and a disciplined process. Acknowledging its limitations helps manufacturers avoid missteps and extract meaningful strategic value from the exercise.

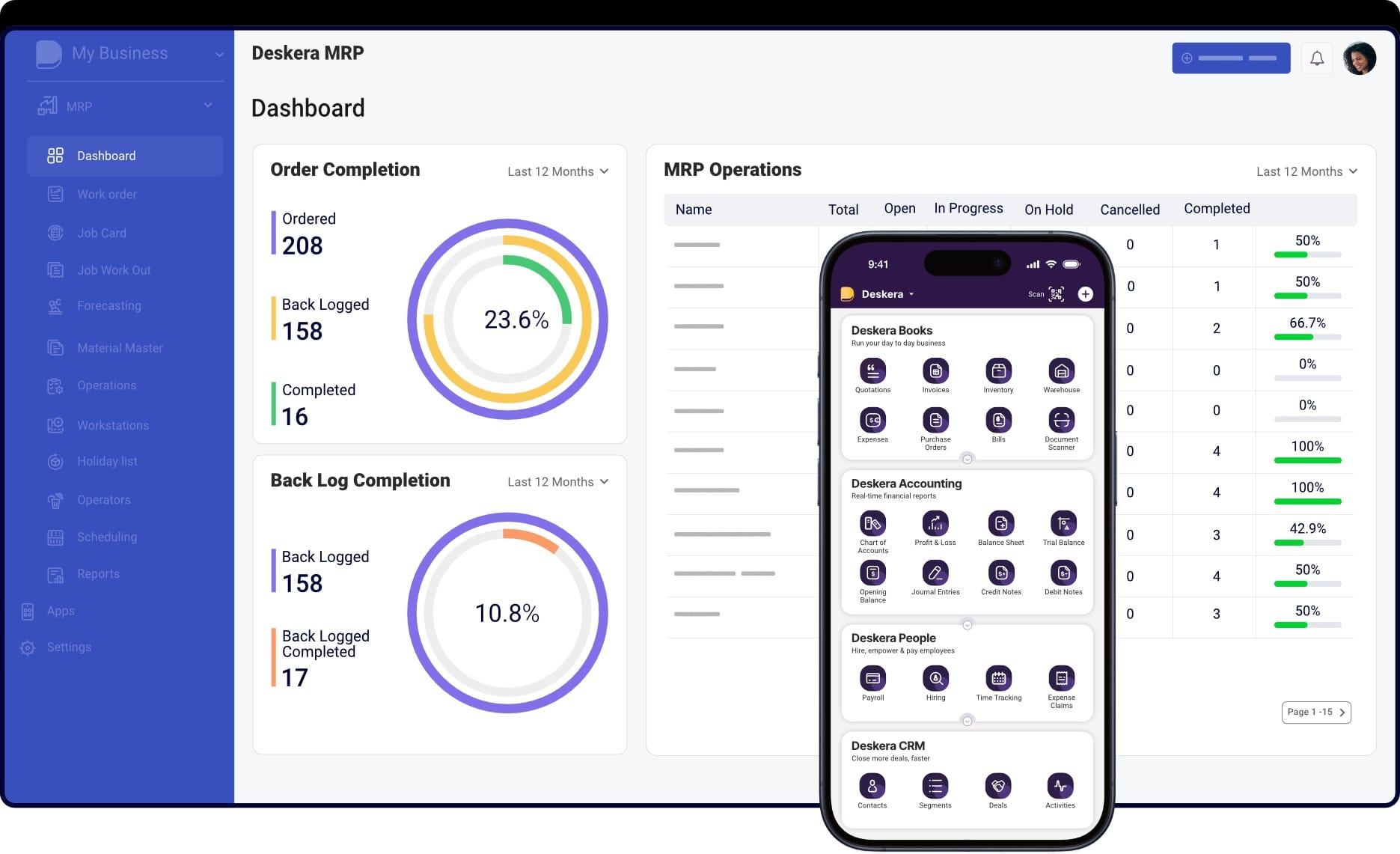

How Deskera Manufacturing ERP Supports Scenario Analysis

Scenario analysis becomes significantly more effective when it's backed by real-time data, integrated tools, and intelligent automation. Deskera Manufacturing ERP empowers manufacturers of all sizes to carry out scenario analysis seamlessly by combining operational, financial, and inventory data within a single unified platform. Here's how:

Real-Time Data

- Deskera provides live access to operational metrics—like inventory levels, production rates, and procurement cycles.

- Manufacturers can simulate scenarios based on current conditions, not outdated spreadsheets.

- Reduces the lag between decision-making and action by enabling real-time responsiveness.

Forecasting Tools

- Built-in demand forecasting helps businesses anticipate customer needs under different market conditions.

- Estimate raw material and labor costs across best-case, base-case, and worst-case scenarios.

- Streamline resource planning by testing how workforce, machine uptime, or order volumes would shift under various assumptions.

Integrated Modules

- Deskera connects all core manufacturing functions—finance, inventory, production, sales, and procurement—under one ERP system.

- This integration eliminates data silos, allowing scenario analysis to reflect the full impact across departments.

- Enables seamless coordination between planning, execution, and resource allocation.

Mobile-First & AI-Powered

- Access scenario results, reports, and forecasts anytime, anywhere through Deskera’s mobile-first platform.

- Get decision support from David, Deskera’s AI assistant, who can surface insights, trends, and alerts to inform scenario planning.

- Enhances speed and accuracy in response to changing conditions on the shop floor or in the supply chain.

Custom Reporting & Dashboards

- Create visual dashboards to track KPIs under each simulated scenario—like profit margins, lead times, or stockouts.

- Use custom reports to compare outcomes across multiple scenarios and evaluate which path aligns with business goals.

- Empower decision-makers with data-driven insights tailored to their function—finance, operations, or strategy.

By integrating real-time visibility, intelligent forecasting, and flexible reporting, Deskera Manufacturing ERP transforms scenario analysis from a theoretical exercise into a practical, high-impact decision-making tool.

Whether you're a small manufacturer preparing for seasonal demand or a large enterprise planning capital investments, Deskera helps you prepare for every "what if."

Key Takeaways

- Scenario analysis is a strategic planning tool that enables manufacturers to prepare for various possible future outcomes by evaluating the potential impact of both risks and opportunities on operations, finances, and growth.

- Scenario analysis works by identifying key variables, developing a range of scenarios (best, worst, and base case), and modeling their impact on business performance to support more resilient decision-making.

- Effective scenario analysis includes key drivers (like cost and demand), a baseline and alternative scenarios, varied time horizons, and trusted data sources such as ERP systems and market forecasts.

- Manufacturers can explore different types of scenarios—normative, extreme, internal, external, short-term, and long-term—to better prepare for uncertainty and stress-test their strategic assumptions.

- While scenario analysis evaluates multiple possible futures with varied variables, sensitivity analysis tests how changes in a single input affect an outcome—making them complementary tools in risk management.

- Scenario analysis focuses on the strategic implications of different futures, whereas scenario modeling dives deeper into quantifying those implications through detailed simulation and data modeling.

- A structured approach includes identifying uncertainties, defining baseline and alternative scenarios, quantifying impacts, creating action plans, and continuously monitoring and updating your assumptions.

- Scenario analysis is flexible—small manufacturers use it for seasonal planning, medium manufacturers for managing risk and cash flow, and large manufacturers for long-term investments and global strategy.

- It enhances risk preparedness, supports informed investment decisions, improves budgeting accuracy, and fosters agility by helping manufacturers proactively adapt to future challenges.

- Despite its value, scenario analysis can be limited by data quality, resource intensity, bias in assumptions, and the inherent uncertainty of future events.

- Deskera Manufacturing ERP empowers scenario analysis through real-time data, integrated forecasting tools, AI assistance, mobile accessibility, and customizable dashboards—enabling faster, more informed decisions across manufacturing operations.

Related Articles