The art of inventory management has long been a cornerstone of operational success, but it's the science of demand forecasting that holds the key to unlocking efficiency and profitability. This article delves into the dynamic interplay between demand forecasting and inventory management, illuminating how accurate predictions can revolutionize business operations.

Did you know? According to a survey conducted by the Retail Industry Leaders Association, 70% of retailers consider inventory management their top priority, highlighting the pivotal role it plays in driving revenue and customer satisfaction.

Demand forecasting, the practice of predicting future customer demand based on historical data and market insights, has transcended from a mere projection tool to an integral part of strategic decision-making. With the advent of advanced analytics and artificial intelligence, businesses can now harness the power of big data to anticipate customer preferences, external influences, and even unforeseen events that shape demand patterns.

Stat Spotlight: Inaccurate demand forecasts can lead to overstocking, causing businesses in the United States alone to lose a staggering $634.1 billion annually, as estimated by the National Retail Federation.

In this exploration, we will uncover the diverse methodologies behind demand forecasting, ranging from traditional statistical models to cutting-edge machine learning algorithms.

By honing in on the art of timing and the science of quantity optimization, we will navigate the complexities of demand-supply equilibrium. Through collaborative forecasting, data-driven insights, and innovative technologies, businesses can navigate the turbulent waters of uncertain market dynamics with heightened accuracy.

Join us as we embark on a journey through the ever-evolving landscape of inventory management, where the right time and the right quantity converge to shape the future of business sustainability and success.

- Importance of Inventory Management

- Role of Demand Forecasting

- Understanding Demand Forecasting

- The Significance of Right Timing

- The Role of Quantity Optimization

- Strategies for Improving Inventory Management with Demand Forecasting

- Overcoming Challenges in Demand Forecasting

- Future Trends in Inventory Management and Demand Forecasting

- Emphasis on the Symbiotic Relationship between Demand Forecasting and Inventory Management

- Why should Businesses Prioritize Demand Forecasting for Improved Inventory Management?

- Conclusion

- Key Takeaways

- Related Articles

Importance of Inventory Management

Inventory management serves as the foundation upon which businesses build their supply chain strategies and customer service excellence. The ability to maintain the right balance between supply and demand can significantly impact a company's bottom line, customer satisfaction, and overall operational efficiency.

Efficient Resource Allocation: Inventory ties up a significant portion of a company's working capital. Effective inventory management ensures that resources are allocated optimally, preventing unnecessary tie-up of funds in excess stock while still meeting customer demands.

Customer Satisfaction: Timely and accurate order fulfillment directly affects customer satisfaction. Maintaining sufficient stock levels ensures that products are readily available, reducing the risk of stockouts and backorders that can tarnish a company's reputation.

Cost Control: Balancing the costs associated with holding inventory (holding costs, storage, obsolescence) against the cost of stockouts is a constant challenge. A well-managed inventory system minimizes these costs by aligning stock levels with anticipated demand.

Supply Chain Efficiency: Inventory management impacts not only a company's internal operations but also its entire supply chain. Accurate demand forecasting and inventory control lead to smoother production scheduling, better procurement decisions, and improved coordination with suppliers and distributors.

Revenue Optimization: Effective inventory management can influence a company's revenue stream. By ensuring that popular items are in stock and reducing excess inventory of slow-moving products, companies can maximize sales opportunities and reduce markdowns.

Risk Mitigation: External factors like market volatility, economic changes, and unexpected events can disrupt supply chains. A strategic approach to inventory management includes risk mitigation strategies to ensure a company's resilience against unforeseen disruptions.

Environmental Impact: Efficient inventory management also has environmental implications. Minimizing excess inventory helps reduce waste, conserves resources, and contributes to sustainable business practices.

Trivia: The beer game, a simulation game often used in business education, highlights the classic challenges of inventory management. It illustrates how small changes in demand forecasting and ordering decisions can lead to significant fluctuations in inventory levels along the supply chain.

In the following sections, we will delve deeper into the role of demand forecasting in achieving these inventory management goals, exploring the methods and strategies that businesses employ to optimize inventory levels and ensure a competitive edge in the market.

Role of Demand Forecasting

Demand forecasting stands as the compass guiding businesses through the intricate terrain of supply and demand dynamics. It is the process of estimating future customer demand for products and services, providing critical insights that enable companies to make informed decisions about production, procurement, inventory levels, and overall business strategy.

Strategic Decision-Making: Demand forecasting is the cornerstone of strategic planning. By anticipating customer preferences and market trends, businesses can align their resources and operations to meet future demand effectively.

Inventory Optimization: Accurate demand forecasting is the linchpin of inventory optimization. It empowers businesses to stock the right quantities of products, reducing the risk of stockouts that drive customers to competitors or overstocking that incurs unnecessary costs.

Production Planning: Manufacturers rely on demand forecasts to plan production schedules, allocate resources, and ensure that finished goods are available when customers are ready to purchase. This minimizes production bottlenecks and maximizes operational efficiency.

Supply Chain Efficiency: Demand forecasts enable businesses to collaborate more effectively with suppliers, distributors, and logistics partners. Timely and accurate information ensures smoother coordination throughout the supply chain.

Cost Management: By aligning production and procurement with accurate demand forecasts, companies can manage costs more effectively. This includes optimizing raw material purchases, reducing storage costs, and minimizing wastage due to excess inventory.

Marketing and Sales Strategies: Demand forecasts provide critical insights into market demand patterns, allowing marketing and sales teams to tailor their strategies to capitalize on trends and customer preferences.

Risk Mitigation: A robust demand forecasting process helps businesses anticipate and mitigate the impact of external factors such as seasonality, economic changes, and unexpected events, reducing the risk of disruptions.

Trivia: The famous "Coca-Cola Problem" of 1985, when Coca-Cola changed its formula and faced a backlash, is often cited as a lesson in the importance of accurate demand forecasting. The change was driven by an erroneous interpretation of consumer taste preferences.

In the subsequent sections of this article, we will explore the various methods of demand forecasting, delve into the strategies for improving accuracy, and highlight real-world examples of how demand forecasting has transformed businesses' approach to inventory management.

Understanding Demand Forecasting

At the heart of effective inventory management lies a crystal ball of sorts: demand forecasting. This section delves into the intricate art and science of demand forecasting, uncovering the methodologies and principles that enable businesses to peer into the future with greater clarity.

By understanding the nuances of demand forecasting, companies can navigate the ever-changing currents of market demand and tailor their inventory strategies accordingly. From traditional statistical approaches to cutting-edge machine learning algorithms, demand forecasting serves as the compass guiding businesses toward optimal decision-making in the realm of inventory management.

A. Definition and concept of demand forecasting

Demand forecasting is the systematic process of predicting future customer demand for products and services based on historical data, market trends, and relevant external factors. At its core, it aims to provide businesses with insights into the quantity and timing of customer demand, allowing them to align their operational activities and resources to meet anticipated market needs.

Peering into the Future: Demand forecasting involves analyzing past sales patterns, customer behaviors, and market conditions to make informed estimates about future demand. It's a proactive approach that empowers businesses to make strategic decisions well in advance.

Quantitative and Qualitative Approaches: Demand forecasting employs both quantitative and qualitative methods. Quantitative methods rely on historical data, mathematical models, and statistical techniques to extrapolate trends. Qualitative methods, on the other hand, incorporate expert opinions, market research, and subjective insights to account for factors that may not be captured by data alone.

Short-Term and Long-Term Horizons: Demand forecasting covers various time horizons, ranging from short-term forecasts that aid in day-to-day operational decisions to long-term forecasts that guide strategic planning and investment.

Dynamic Nature of Forecasting: Demand forecasting recognizes that markets are dynamic and subject to change. External factors such as economic fluctuations, technological advancements, and shifts in consumer preferences constantly influence demand patterns.

Strategic Alignment: Accurate demand forecasting helps businesses align their production, procurement, and inventory management strategies with actual market needs. This optimization minimizes costs, reduces waste, and ensures timely availability of products.

B. Types of demand forecasting methods

Demand forecasting encompasses a variety of methods that fall into two broad categories: qualitative methods and quantitative methods. Each of these approaches offers unique insights into future customer demand, catering to different business contexts and levels of available data.

1. Qualitative Methods:

Qualitative methods rely on subjective inputs, expert opinions, and qualitative data to forecast future demand. These approaches are particularly useful when historical data is limited, or unreliable, or when new products are introduced. Qualitative methods are well-suited for scenarios where external factors significantly impact demand, and they provide a more holistic understanding of market dynamics.

- Market Research: Conduct surveys, interviews, focus groups, and customer feedback sessions to gather insights about customer preferences, buying behaviors, and emerging trends. This method helps identify potential shifts in demand due to changing consumer preferences.

- Expert Opinion: Consulting industry experts, market analysts, and professionals with domain knowledge to gain valuable insights and predictions about future market conditions. Expert opinions are valuable when historical data is scarce or when anticipating the impact of new technologies.

- Delphi Method: This involves soliciting input from a panel of experts anonymously. The experts' opinions are collected, summarized, and shared with the panel, who then revise their forecasts. This iterative process continues until a consensus is reached, offering a more refined prediction.

2. Quantitative Methods:

Quantitative methods rely on historical data and mathematical models to forecast future demand. These methods are particularly effective when a sufficient amount of reliable historical data is available. They provide a structured and objective way to predict demand patterns based on past performance.

- Time Series Analysis: Time series analysis involves analyzing historical data to identify patterns, trends, and seasonality in demand. Techniques such as moving averages, exponential smoothing, and ARIMA (AutoRegressive Integrated Moving Average) models are used to make predictions based on past data points.

- Causal Models: Causal models establish relationships between demand and external factors that influence it, such as economic indicators, population changes, or advertising expenditure. Regression analysis is a common technique within this category, aiming to quantify the impact of these variables on demand.

- Machine Learning: With the advent of machine learning, businesses can now leverage algorithms to identify complex patterns and relationships in vast datasets. Techniques like neural networks, decision trees, and random forests can uncover insights that may be missed by traditional methods.

C. Advantages of accurate demand forecasting

Accurate demand forecasting is a cornerstone of successful inventory management, offering a multitude of benefits that can positively impact a business's operations, financial health, and customer satisfaction.

By providing a clearer view of future demand patterns, accurate forecasting empowers businesses to make informed decisions that drive efficiency and competitiveness.

Optimized Inventory Levels: Accurate demand forecasts allow businesses to maintain optimal inventory levels. This eliminates the risk of overstocking, reducing carrying costs, and minimizing the chance of products becoming obsolete. Simultaneously, it prevents stockouts, ensuring products are available when customers want them.

Reduced Costs: Demand forecasting helps companies allocate resources more efficiently. By aligning production, procurement, and distribution with actual demand, businesses can avoid unnecessary expenditures associated with excess inventory and rush orders due to stockouts.

Improved Production Planning: Manufacturers can adjust production schedules and resource allocation based on accurate forecasts. This prevents overproduction and underproduction, optimizing resource utilization and minimizing wastage.

Enhanced Supply Chain Management: Accurate demand forecasting facilitates better coordination along the supply chain. Suppliers can adjust their production and delivery schedules based on anticipated demand, ensuring a steady flow of materials and products.

Efficient Marketing and Promotions: Businesses can tailor marketing campaigns and promotions based on forecasted demand patterns. This prevents the risk of overcommitting resources to promotions that exceed demand or underestimating the success of campaigns.

Enhanced Customer Satisfaction: Maintaining optimal inventory levels reduces the likelihood of stockouts, ensuring that customers can purchase desired products when they want them. This enhances customer loyalty and satisfaction.

Strategic Decision-Making: Accurate demand forecasts provide a foundation for strategic decision-making. Businesses can plan expansion, investments, and product launches based on a well-informed understanding of future demand.

Profitability: Effective inventory management resulting from accurate demand forecasting directly impacts a company's bottom line. It reduces costs, maximizes revenue opportunities, and contributes to improved profitability.

D. Challenges in demand forecasting

While demand forecasting offers numerous advantages, it's not without its challenges. Accurate prediction of future customer demand is a complex task influenced by various factors, both internal and external to the business. Addressing these challenges is crucial to achieving reliable and actionable forecasts.

1. Data Quality and Availability:

- Sparse or Incomplete Data: Inaccurate forecasts can result from limited historical data, especially for new products or emerging markets. Short timeframes of data collection can also hinder pattern recognition.

- Data Accuracy: Inconsistent or inaccurate data can lead to skewed forecasts. Errors in recording sales, returns, and other data points can compromise the reliability of the predictions.

- Lack of Granularity: Insufficient data granularity can mask underlying trends. Aggregated data might miss important nuances that impact demand at a more detailed level.

2. External Factors and Market Dynamics:

- Market Volatility: External factors such as economic changes, political events, and natural disasters can disrupt demand patterns. These factors are often difficult to predict and can render historical data less relevant.

- Seasonality and Trends: Accurate forecasting requires understanding seasonal fluctuations and identifying trends that affect demand. Failure to account for these can lead to inaccurate predictions and imbalanced inventory levels.

- Consumer Behavior: Rapid changes in consumer preferences and behaviors, influenced by cultural shifts and technological advancements, can make demand patterns unpredictable.

- Competition and Pricing: Actions taken by competitors, such as price changes or marketing campaigns, can significantly impact demand. Businesses must factor in these external influences.

- Globalization and Supply Chain Complexity: Businesses operating in a global marketplace face increased complexity due to diverse market conditions, regulations, and supply chain disruptions.

The Significance of Right Timing

This section delves into the art of timing in inventory management, showcasing how aligning supply with demand at the right moments can yield substantial benefits. From capturing seasonal trends to minimizing holding costs, understanding the significance of timing allows businesses to orchestrate their operations with finesse and precision.

A. Impact of timing on inventory management

Timing is the heartbeat of successful inventory management. The difference between having products readily available, when customers want them and experiencing stockouts, can determine a business's competitive edge. The impact of timing resonates across various aspects of inventory management, shaping everything from operational efficiency to customer satisfaction.

Meeting Customer Expectations: Timely product availability is the cornerstone of customer satisfaction. Businesses that can consistently provide products when customers are ready to purchase foster loyalty and positive brand perception.

Reduced Holding Costs: Holding costs, which include warehousing, storage, and maintenance expenses, can accumulate significantly if inventory sits idle for extended periods. Proper timing ensures that inventory turnover is optimized, reducing the financial burden of excess stock.

Minimized Stockouts: The costs of stockouts are multifaceted, ranging from lost sales and customer dissatisfaction to potential damage to brand reputation. Timely replenishment based on accurate timing mitigates these risks.

Efficient Production and Procurement: By aligning production and procurement with accurate timing, businesses can streamline their operations. This prevents overproduction, underproduction, and rush orders, ultimately leading to cost savings.

Seasonal and Trend Capitalization: Timing enables businesses to capitalize on seasonal trends and market fluctuations. Being prepared with the right products during peak demand periods maximizes sales opportunities.

Inventory Turnover and Cash Flow: Effective timing leads to higher inventory turnover, resulting in healthier cash flow. Funds that would otherwise be tied up in excess inventory become available for strategic investments.

B. Seasonal trends and their influence on timing

Seasonality is a recurring pattern of demand fluctuations that businesses encounter due to various factors, including weather, holidays, cultural events, and even economic cycles. Recognizing and effectively responding to seasonal trends is a critical aspect of mastering timing in inventory management.

Understanding Seasonal Fluctuations: Seasonal trends can significantly impact demand for certain products during specific times of the year. For example, winter clothing experiences heightened demand in colder months, while beach gear sees a surge in the summer.

Timing for Maximum Impact: Capitalizing on seasonal trends requires accurate timing in multiple areas. Procurement, production, marketing campaigns, and inventory restocking all need to be aligned to ensure products are available when customers are most likely to purchase them.

Anticipating Demand Peaks: By analyzing historical data and understanding historical demand patterns, businesses can predict when demand for specific products will peak. This allows them to plan and allocate resources effectively.

Avoiding Overstocking and Stockouts: The balance between overstocking and stockouts becomes more delicate during seasonal peaks. Businesses must time their inventory management strategies to prevent excess stock once the peak season subsides and to avoid stockouts during high-demand periods.

Enhancing Customer Satisfaction: Meeting customer demand during peak seasons enhances customer satisfaction and loyalty. On-time availability of products fosters positive experiences, strengthening brand reputation.

Optimizing Pricing Strategies: Timing plays a pivotal role in pricing strategies during seasonal peaks. Businesses can adjust pricing to capitalize on increased demand while remaining competitive in the market.

C. How accurate timing reduces holding costs

Accurate timing in inventory management has a direct impact on holding costs, which encompass expenses related to storing and maintaining inventory. By aligning inventory levels with anticipated demand through precise timing, businesses can significantly reduce these costs while maintaining optimal stock levels.

Optimized Inventory Turnover: Accurate timing prevents excess inventory buildup that often leads to longer holding periods. With products moving off the shelves more efficiently, the rate of inventory turnover increases, reducing the time items spend in storage.

Reduced Storage Expenses: Holding costs include expenses like storage space, utilities, insurance, and security. By minimizing excess inventory, businesses can decrease the physical space required for storage, leading to cost savings.

Preventing Obsolescence: Accurate timing helps prevent overstocking, which can result in products becoming obsolete before they are sold. Minimizing excess inventory reduces the risk of holding products that have lost their value.

Less Risk of Damage or Spoilage: Perishable or fragile items can deteriorate if held in storage for extended periods. Accurate timing ensures these items are sold before they reach their expiry date or become damaged.

Working Capital Optimization: By reducing holding costs, businesses free up working capital that can be reinvested in other strategic initiatives, contributing to business growth.

Reduced Carrying Costs: Carrying costs, which include expenses related to handling, insurance, and taxes, decrease as inventory levels are optimized based on accurate timing. This results in a more efficient allocation of resources.

The Role of Quantity Optimization

Quantity optimization emerges as a critical factor that shapes a business's ability to meet customer demand while managing costs. This section explores the multifaceted dimensions of quantity optimization, highlighting how accurate predictions of the right quantities can revolutionize businesses' inventory management practices.

From mitigating the risks of overstocking and understocking to optimizing costs and improving customer satisfaction, quantity optimization stands as a pivotal pillar in the inventory management landscape.

A. Balancing between excess and insufficient inventory

Walking the tightrope between excess and insufficient inventory is a challenge that businesses must navigate to achieve optimal inventory management. Striking this delicate balance ensures that products are available to meet customer demand while minimizing the costs associated with holding excess stock or facing stockouts.

Risk of Excess Inventory:

- Higher Holding Costs: Maintaining excess inventory ties up capital and incurs additional expenses in terms of storage, insurance, and potential obsolescence.

- Reduced Cash Flow: Excess inventory can strain working capital, limiting funds available for other critical business activities.

- Opportunity Cost: Capital invested in excess inventory could have been utilized for strategic investments or growth initiatives.

Risk of Insufficient Inventory:

- Stockouts and Customer Dissatisfaction: Inadequate inventory levels can lead to stockouts, disappointing customers and potentially driving them to competitors.

- Missed Sales Opportunities: Stockouts result in lost sales that might not be recoverable, impacting revenue and market share.

- Rush Orders: Faced with stockouts, businesses might resort to expedited shipping or production, incurring additional costs.

Quantity Optimization Strategies:

- Demand Forecasting: Accurate demand forecasting forms the foundation of quantity optimization. Predicting future demand patterns enables businesses to adjust inventory levels accordingly.

- Safety Stock: Maintaining a buffer of safety stock can mitigate the risks of stockouts due to demand variability or supply chain disruptions.

- Economic Order Quantity (EOQ): EOQ calculations help determine the optimal order quantity that minimizes the total cost of ordering and holding inventory.

- Lead Time Management: Accurately estimating lead times helps prevent stockouts by ensuring that products arrive in time to replenish inventory.

The term "stockout cost" refers to the financial impact of a stockout event, including lost sales, potential customer churn, and costs associated with expediting orders.

B. Effects of overstocking and understocking

The consequences of overstocking and understocking are two sides of the same coin in the realm of inventory management. Both scenarios carry distinct challenges and costs that businesses must grapple with to maintain operational efficiency and customer satisfaction.

Effects of Overstocking:

- Increased Holding Costs: Overstocking ties up working capital and increases expenses related to storage, insurance, and management of excess inventory.

- Risk of Obsolescence: Excess inventory is prone to becoming obsolete or outdated, resulting in potential write-offs and losses.

- Reduced Profit Margins: Clearance sales or markdowns might be necessary to clear excess inventory, impacting profit margins.

- Opportunity Costs: Capital invested in overstocked items could have been used for other productive investments.

Effects of Understocking:

- Stockouts and Lost Sales: Understocking leads to stockouts, which result in lost sales opportunities, customer dissatisfaction, and potential damage to brand reputation.

- Customer Churn: Repeated stockouts might drive customers to competitors who consistently provide the products they need.

- Expedited Costs: Faced with stockouts, businesses might resort to expedited shipping or production, incurring higher costs.

- Missed Revenue: Inability to meet demand can hinder revenue growth and hinder the achievement of sales targets.

Strategies to Mitigate Effects:

- Demand Forecasting: Accurate demand forecasting is key to avoiding both overstocking and understocking. It helps align inventory levels with anticipated demand.

- Safety Stock: Maintaining safety stock provides a buffer against sudden demand spikes or supply chain disruptions.

- Just-in-Time (JIT) Approach: JIT inventory management aims to minimize excess inventory by ordering and producing items only as needed.

- Continuous Monitoring: Regularly monitoring inventory levels and demand patterns enables timely adjustments to avoid stockouts or excess stock.

C. Cost implications of carrying excess inventory

Carrying excess inventory comes with a significant financial burden that extends beyond the mere accumulation of products on shelves. Understanding the various cost implications of excess inventory is essential for businesses to make informed decisions about their inventory management strategies.

Holding Costs:

- Storage Costs: Excess inventory occupies valuable space, leading to increased storage costs, including rent, utilities, and maintenance.

- Insurance Costs: Insuring excess inventory against damage or loss incurs additional expenses that impact profitability.

- Obsolescence Costs: Excess inventory is at a higher risk of becoming obsolete due to changes in customer preferences, technology advancements, or product updates.

Opportunity Costs:

- Capital Tie-Up: Capital invested in excess inventory is unavailable for other strategic investments that could drive growth or innovation.

- Working Capital Drain: Excess inventory can tie up working capital, affecting liquidity and financial flexibility.

Handling and Management Costs:

- Handling Expenses: The logistics and management of excess inventory entail extra costs, including transportation, handling, and tracking.

- Administrative Costs: Managing and tracking excess inventory requires additional administrative efforts, leading to higher labor and administrative costs.

Reduced Profitability:

- Markdowns and Discounts: To clear excess inventory, businesses often resort to offering discounts or markdowns, reducing profit margins.

- Opportunity for Sales Loss: While products remain unsold, potential revenue is lost, impacting overall profitability.

Storage Limitations and Space Constraints:

- Limited Space Utilization: Excess inventory can hinder the utilization of available space, limiting room for newer products or higher-demand items.

- Warehousing Investment: If storage capacity needs to be increased to accommodate excess inventory, businesses may need to invest in additional warehousing infrastructure.

D. Leveraging demand forecasting for optimal quantities

Demand forecasting serves as a powerful tool for businesses seeking to achieve optimal quantities of inventory. By accurately predicting future customer demand, businesses can fine-tune their inventory levels, reducing the risks of overstocking and understocking.

Leveraging demand forecasting effectively enables businesses to align their operations with actual market needs, enhancing profitability and customer satisfaction.

Demand-Driven Quantity Optimization:

- Accurate Demand Predictions: Demand forecasting provides insights into future demand patterns, helping businesses determine the right quantities of products to stock.

- Preventing Overstocking: Accurate forecasts guide businesses to order or produce only what is necessary, preventing excess inventory buildup.

- Mitigating Stockouts: By predicting demand accurately, businesses can ensure they have sufficient inventory to meet customer needs, minimizing stockouts.

Strategies for Leveraging Demand Forecasting:

- Collaborative Forecasting: Engaging key stakeholders, such as sales teams, marketing, and suppliers, in the demand forecasting process enhances accuracy by incorporating diverse perspectives.

- Data-Driven Insights: Advanced analytics and machine learning can analyze historical data and market trends to uncover patterns that drive more accurate predictions.

- Scenario Analysis: Running scenarios based on different demand assumptions helps businesses prepare for various outcomes and make more informed decisions.

- Continuous Improvement: Regularly updating and refining demand forecasting models based on actual performance and market changes enhances accuracy over time.

Case in Point: Retail Giant Z

Background: Retail Giant Z struggled with frequent stockouts and excess inventory, affecting their bottom line and customer satisfaction.

Solution: By implementing advanced demand forecasting models that integrated sales data, market trends, and external factors, Retail Giant Z achieved remarkable results.

Benefits:

- Optimized Inventory Levels: Retail Giant Z managed to maintain optimal inventory levels, reducing holding costs and stockouts.

- Enhanced Customer Satisfaction: Accurate inventory quantities led to improved customer satisfaction due to product availability.

- Increased Profitability: By aligning inventory with actual demand, Retail Giant Z minimized markdowns and boosted profit margins.

Strategies for Improving Inventory Management with Demand Forecasting

This section delves into a comprehensive array of strategies that empower businesses to enhance their inventory management practices through the lens of demand forecasting.

By dissecting methods for refining accuracy, optimizing timing, and achieving quantity optimization, businesses can harness the power of predictive insights to elevate their operational efficiency, customer satisfaction, and bottom-line performance. From advanced analytics to collaborative supply chain initiatives, these strategies provide a roadmap for businesses aiming to unlock the full potential of demand forecasting in their pursuit of inventory excellence.

A. Data-driven demand forecasting

Data-driven demand forecasting is a cornerstone strategy for improving inventory management. By harnessing historical sales data and utilizing statistical models, businesses can extract valuable insights to predict future customer demand more accurately.

1. Historical Sales Data Analysis:

Historical sales data serves as a treasure trove of information that reveals past demand patterns and trends. Analyzing this data helps businesses identify seasonality, cyclic trends, and other recurring patterns that influence demand. Key elements include:

- Seasonal Patterns: Identifying recurring peaks and troughs in sales that correspond to specific seasons, holidays, or events.

- Cyclic Patterns: Recognizing longer-term fluctuations that extend beyond a year, often influenced by economic cycles.

- Trend Analysis: Identifying upward or downward trends in sales that reflect changes in customer preferences, market dynamics, or external factors.

- Outlier Detection: Identifying exceptional events that might have affected sales, such as promotions, product launches, or external disruptions.

2. Statistical Models (e.g., Moving Averages, Exponential Smoothing):

Statistical models are powerful tools for generating forecasts based on historical data. These models apply mathematical techniques to capture patterns and predict future demand. Some common techniques include:

- Moving Averages: This method calculates the average of a set number of past data points. Moving averages smooth out short-term fluctuations and help identify underlying trends.

- Exponential Smoothing: Exponential smoothing assigns different weights to historical data points, giving more weight to recent data. This technique adapts quickly to changes in demand patterns.

- Time Series Decomposition: This technique breaks down a time series into its underlying components—seasonal, trend, and residual—allowing businesses to better understand the contributing factors.

Benefits:

- Accurate Predictions: Data-driven demand forecasting provides more accurate predictions by incorporating historical sales data and statistical trends.

- Proactive Planning: Understanding historical patterns allows businesses to anticipate demand shifts and make informed decisions.

- Strategic Resource Allocation: Data-driven forecasts guide businesses in allocating resources effectively, from production and procurement to staffing and marketing.

B. Incorporating external factors

Incorporating external factors into demand forecasting adds a layer of sophistication by considering influences beyond historical sales data. Businesses can enhance the accuracy of their forecasts by accounting for market trends, economic indicators, and seasonality adjustments.

1. Market Trends and Economic Indicators:

Market trends, influenced by broader economic conditions, consumer sentiment, and industry developments, can significantly impact demand. Integrating these trends into forecasting involves:

- Economic Indicators: Tracking economic indicators such as GDP, unemployment rates, and inflation can provide insights into consumer purchasing power and overall market health.

- Consumer Behavior Analysis: Analyzing shifts in consumer behavior due to changing preferences, technological advancements, or cultural changes helps predict demand adjustments.

- Competitor Analysis: Monitoring competitors' actions, such as pricing strategies or product launches, helps anticipate their potential impact on demand.

2. Seasonal Adjustments and Promotions:

Seasonality and promotions play a critical role in demand fluctuations. Incorporating these factors into forecasting improves accuracy during peak demand periods:

- Seasonal Adjustments: Adjusting forecasts to account for predictable seasonal variations ensures inventory is available when demand is expected to spike.

- Promotion Impact: Evaluating the impact of promotions, discounts, or marketing campaigns on demand helps forecast increased sales during these periods.

Benefits:

- Holistic Predictions: By including external factors, businesses gain a more comprehensive view of demand drivers beyond historical data.

- Adaptive Strategies: Incorporating market trends and external factors enables businesses to adjust inventory and operations proactively.

- Strategic Decision-Making: Businesses can align strategies with economic conditions, industry trends, and consumer behavior to optimize inventory levels.

C. Collaborative forecasting

Collaborative forecasting involves fostering partnerships and information exchange among various stakeholders within the supply chain to generate more accurate and reliable demand forecasts. By integrating the insights and perspectives of suppliers, distributors, and other partners, businesses can enhance their forecasting accuracy and optimize their inventory management strategies.

1. Integration with Suppliers and Distributors:

Collaborative forecasting breaks down the traditional silos between businesses and their partners by fostering open communication and data sharing. Integration with suppliers and distributors includes:

- Shared Information: Sharing historical sales data, inventory levels, and upcoming promotions with suppliers and distributors allows them to align their operations more effectively.

- Joint Demand Planning: Businesses collaborate with suppliers to jointly plan for future demand, enabling them to adjust production schedules and stock levels accordingly.

- Real-time Data Exchange: Utilizing technology to facilitate real-time data exchange ensures that all partners have access to the most up-to-date information for better decision-making.

2. Demand Sharing and Information Exchange:

Demand sharing involves sharing forecasted demand data with partners, allowing them to adjust their production and distribution plans. Information exchange focuses on open communication channels for rapid response to changes:

- Reduced Bullwhip Effect: Collaborative forecasting reduces the "bullwhip effect," where small fluctuations in demand amplify as they move up the supply chain.

- Improved Responsiveness: By sharing demand forecasts, partners can adjust their operations to meet actual customer demand, leading to improved responsiveness.

- Optimized Inventory Levels: Accurate forecasts shared across the supply chain enable partners to optimize their inventory levels, preventing overstocking or stockouts.

Benefits:

- Enhanced Accuracy: Collaborative forecasting leverages diverse insights from partners, leading to more accurate demand predictions.

- Aligned Operations: By aligning production, distribution, and inventory levels across the supply chain, businesses can achieve better operational efficiency.

- Reduced Lead Times: Faster response times to changes in demand lead to reduced lead times and improved customer satisfaction.

D. Technology and automation

Leveraging technology and automation is pivotal in harnessing the full potential of demand forecasting for improved inventory management. Innovative tools, such as inventory management software, artificial intelligence (AI), and machine learning applications, provide businesses with advanced capabilities to enhance accuracy, efficiency, and adaptability in their forecasting processes.

1. Inventory Management Software:

Inventory management software streamlines and centralizes the demand forecasting process, offering tools for data analysis, scenario modeling, and collaboration. Key features include:

- Data Integration: These systems integrate with various data sources, including sales data, historical records, and market trends.

- Advanced Analytics: Inventory management software employs advanced statistical techniques to analyze data and generate forecasts.

- Scenario Modeling: Businesses can simulate different scenarios to understand the potential impact of changes in demand or market conditions.

- Collaboration: Many software solutions facilitate collaboration among teams and partners, enabling shared forecasting insights.

- Real-time Monitoring: Real-time monitoring of inventory levels and sales data allows for agile adjustments based on changing conditions.

2. AI and Machine Learning Applications:

AI and machine learning bring predictive capabilities to demand forecasting, improving accuracy and adaptability. These technologies are employed in various ways:

- Pattern Recognition: Machine learning algorithms identify patterns in historical data that are difficult for humans to discern.

- Time Series Analysis: AI models excel in time series forecasting, capturing intricate demand patterns over time.

- Demand Classification: AI can classify products based on demand characteristics, aiding in customized forecasting strategies.

- Anomaly Detection: AI can identify anomalies or unusual trends in data, allowing for early response to unexpected changes.

- Continuous Learning: Machine learning models continuously adapt and learn from new data, improving accuracy over time.

Benefits:

- Enhanced Accuracy: Technology-driven solutions offer more accurate and reliable demand forecasts.

- Efficiency Gains: Automation reduces manual effort, allowing teams to focus on analyzing insights rather than data entry.

- Adaptability: AI and machine learning models adapt to changing demand patterns and market dynamics.

- Real-time Insights: Technology provides real-time insights, enabling rapid adjustments to demand changes.

Overcoming Challenges in Demand Forecasting

This section delves into the multifaceted landscape of challenges that businesses encounter while striving to predict future customer demand. From grappling with the intricacies of data quality and availability to deciphering the complex dance of external factors and market dynamics, the journey to achieving reliable forecasts is marked by hurdles that require strategic solutions.

By understanding, dissecting, and ultimately conquering these challenges, businesses can fortify their demand forecasting practices, transforming uncertainty into opportunity and unleashing the power of predictive insights to steer their inventory management endeavors. Embarking on this voyage equips businesses to tackle the unpredictabilities of the market head-on, forging a path to more efficient, profitable, and customer-centric inventory management strategies.

A. Data quality improvement

Ensuring the accuracy and reliability of data is a foundational step in overcoming challenges in demand forecasting. Data quality improvement involves refining the process of data collection, cleansing, and analysis to enhance the integrity of information used for predicting future customer demand.

1. Data Collection and Cleansing:

Data collection involves gathering relevant information from various sources, such as sales transactions, customer interactions, and market data. However, data can be prone to errors, inconsistencies, and inaccuracies. Data cleansing involves:

- Eliminating Errors: Identifying and rectifying data entry errors, such as typos, missing values, and duplication, to ensure the data is accurate and complete.

- Standardizing Formats: Standardizing data formats, units, and naming conventions ensures consistency and ease of analysis.

- Addressing Outliers: Identifying and handling outliers or extreme data points that can skew forecasts and compromise accuracy.

2. Historical Data Analysis and Validation:

Historical data serves as the foundation for demand forecasting. Proper analysis and validation of historical data are essential to ensure its accuracy and relevance. This process involves:

- Identifying Patterns: Analyzing historical sales data helps identify trends, seasonality, and cyclic patterns that influence demand fluctuations.

- Cross-Validation: Validating historical data by comparing actual sales against predicted forecasts ensures the accuracy of forecasting models.

- Model Performance Evaluation: Assessing the performance of forecasting models using historical data helps select the most suitable approach for accurate predictions.

Benefits:

- Accurate Forecasts: Improved data quality leads to more accurate demand forecasts, enhancing inventory management decisions.

- Reduced Errors: Data cleansing mitigates errors that can lead to flawed predictions and suboptimal inventory levels.

- Enhanced Analysis: High-quality historical data provides a reliable basis for analyzing trends and patterns.

- Confident Decision-Making: Validated historical data instills confidence in forecasting models and informs strategic decisions.

B. Dealing with uncertain external factors

External factors, ranging from economic fluctuations and geopolitical events to unexpected market trends, introduce an element of unpredictability into demand forecasting. Dealing with these uncertainties requires strategies that enhance the adaptability of forecasting models and provide businesses with tools to manage risks effectively.

1. Sensitivity Analysis:

Sensitivity analysis involves assessing the impact of variations in external factors on demand forecasts. By simulating different scenarios and observing how changes in variables affect predictions, businesses can identify potential vulnerabilities and opportunities. This includes:

- Parameter Adjustments: Changing input parameters, such as economic indicators or consumer behavior assumptions, to analyze their influence on forecast outcomes.

- Best- and Worst-Case Scenarios: Exploring extreme scenarios helps assess the range of possible outcomes under varying conditions.

2. Scenario Planning and Risk Assessment:

Scenario planning entails creating multiple forecasts based on different possible future scenarios. This approach helps businesses anticipate and prepare for a range of outcomes, reducing the impact of uncertainties. This includes:

- Risk Assessment: Identifying and assessing potential risks associated with external factors, such as supply chain disruptions or economic downturns.

- Contingency Plans: Developing contingency plans to respond to different scenarios, enabling businesses to pivot quickly in response to changing conditions.

- Mitigation Strategies: Outlining strategies to mitigate risks and capitalize on opportunities identified in different scenarios.

Benefits:

- Resilience to Uncertainty: Sensitivity analysis and scenario planning prepare businesses to navigate uncertain external factors more effectively.

- Risk Management: By identifying potential risks and developing mitigation strategies, businesses can minimize negative impacts on forecasts.

- Adaptive Strategies: Businesses armed with scenario forecasts can adapt quickly to changing conditions and make informed decisions.

- Enhanced Preparedness: Sensitivity analysis and scenario planning enhance preparedness for a wide range of future outcomes.

Future Trends in Inventory Management and Demand Forecasting

As businesses continue to navigate the ever-evolving landscape of supply chains, customer preferences, and technological advancements, the future of inventory management and demand forecasting is poised to undergo transformative shifts. This section delves into the exciting prospects and emerging trends that are set to reshape the way businesses anticipate, manage, and optimize their inventory levels.

From the integration of cutting-edge technologies like artificial intelligence and the Internet of Things (IoT) to the emphasis on sustainability and ethical practices, the future of inventory management holds the promise of enhanced efficiency, agility, and customer-centricity.

By exploring these trends, businesses can position themselves at the forefront of innovation, ready to embrace the challenges and opportunities that lie ahead, and ultimately elevate their inventory management and demand forecasting practices to new heights of excellence.

A. Advanced analytics and AI-driven forecasting

The convergence of advanced analytics and artificial intelligence (AI) is set to revolutionize inventory management and demand forecasting, unlocking unprecedented levels of accuracy, adaptability, and strategic insight. This trend leverages the power of data and intelligent algorithms to enhance forecasting capabilities and optimize inventory decisions.

AI-Powered Demand Forecasting:

- Predictive Models: AI algorithms analyze vast amounts of data, uncovering intricate patterns and relationships that human analysis might miss.

- Real-Time Insights: AI-driven forecasts adapt quickly to changing conditions, providing real-time insights into evolving demand patterns.

- Machine Learning: Machine learning models continuously learn from new data, refining their predictions and improving accuracy over time.

Advanced Analytics for Inventory Optimization:

- Dynamic Demand Modeling: Advanced analytics models factor in various demand influencers, such as weather, social trends, and economic indicators.

- Optimal Replenishment Strategies: Analytics tools identify the best times to reorder products to maintain optimal inventory levels.

- Prescriptive Analytics: Beyond predictions, prescriptive analytics offer actionable recommendations for inventory strategies.

Benefits:

- Hyper-Precision: AI-driven forecasting delivers unparalleled accuracy by processing complex data patterns.

- Agility: Real-time insights enable rapid adjustments to demand changes, reducing stockouts and excess inventory.

- Data-Driven Decisions: Advanced analytics provide data-driven guidance for inventory optimization.

- Strategic Advantage: Businesses adopting AI and advanced analytics gain a competitive edge through optimized inventory management.

Future Outlook:

The integration of AI and advanced analytics is poised to become a staple in demand forecasting and inventory management. As technology advances and AI algorithms continue to evolve, businesses will be able to predict demand shifts with exceptional precision and navigate supply chain complexities with unparalleled agility.

B. Real-time demand sensing

Real-time demand sensing is a futuristic trend that empowers businesses to capture and respond to demand signals as they unfold, enabling proactive and agile inventory management. This trend leverages technology and data to sense shifts in customer demand in near real-time, revolutionizing the way businesses optimize their inventory levels.

Technology-Driven Sensing:

- IoT Integration: Internet of Things (IoT) devices embedded in products, shelves, and transportation enable continuous data collection on inventory movement.

- Connected Supply Chain: IoT-enabled supply chain networks provide real-time visibility into inventory levels, allowing for rapid response to changes.

- Data Fusion: Combining IoT data with other sources, such as sales data and external factors, enhances demand sensing accuracy.

Benefits of Real-Time Demand Sensing:

- Agility: Real-time demand sensing allows businesses to adjust inventory levels swiftly in response to sudden demand shifts.

- Reduced Stockouts: By capturing real-time demand signals, businesses can avoid stockouts and ensure products are available when needed.

- Optimized Production: Manufacturers can adjust production schedules in real time to align with actual demand, minimizing overproduction.

- Enhanced Customer Service: Meeting customer demand promptly enhances customer satisfaction and loyalty.

Supply Chain Resilience:

Real-time demand sensing contributes to supply chain resilience by improving visibility and responsiveness. Businesses can better predict disruptions, optimize inventory distribution, and prevent bottlenecks in the supply chain.

Future Outlook:

As technology continues to advance and IoT adoption becomes more widespread, real-time demand sensing is poised to become a standard practice in inventory management. Businesses that integrate this trend into their strategies will gain a competitive edge in delivering products to customers at the right time and in the right quantity.

C. Integration with supply chain management

The future of inventory management lies in seamless integration with supply chain management, creating a holistic approach that optimizes the entire journey of products from production to consumption. This trend emphasizes collaboration, visibility, and efficiency across the supply chain, leading to improved demand forecasting and inventory management.

Collaborative Supply Chain Networks:

- Demand Orchestration: Collaboration among suppliers, manufacturers, distributors, and retailers allows for synchronized responses to demand fluctuations.

- Data Sharing: Real-time sharing of inventory, sales, and production data enables partners to align strategies and make informed decisions.

- Joint Planning: Businesses collaborate with partners on demand planning, production scheduling, and inventory replenishment.

Benefits of Integration:

- End-to-End Visibility: Integrated supply chain networks provide real-time visibility into inventory levels and movement across the entire chain.

- Optimized Inventory Levels: Collaboration enables optimal inventory levels at different stages, minimizing excess and stockouts.

- Efficient Logistics: Coordinated efforts enhance logistics efficiency, reducing lead times and ensuring products reach customers faster.

- Risk Mitigation: Collaborative supply chains can respond more effectively to disruptions, ensuring resilience against uncertainties.

Technological Enablers:

Integration is facilitated by emerging technologies such as blockchain and cloud-based platforms, which offer secure and transparent data sharing among supply chain partners.

Future Outlook:

The integration of inventory management with supply chain management is a trend poised for rapid growth. Businesses that embrace this trend will be better equipped to navigate market dynamics, enhance demand forecasting accuracy, and achieve optimal inventory levels.

D. Sustainable and eco-friendly inventory practices

The future of inventory management is intrinsically linked to sustainability and eco-conscious practices. As environmental concerns gain prominence, businesses are recognizing the significance of responsible inventory management that minimizes waste, conserves resources, and aligns with ethical values.

Green Supply Chain Strategies:

- Circular Economy: Embracing the principles of a circular economy involves designing products for longevity, repairability, and recyclability.

- Reverse Logistics: Implementing efficient systems for product returns, recycling, and refurbishment minimizes waste and reduces the environmental impact of excess inventory.

- Sustainable Sourcing: Choosing suppliers and materials that adhere to eco-friendly practices contributes to the overall sustainability of the supply chain.

Benefits of Sustainable Practices:

- Reduced Environmental Footprint: Eco-friendly inventory practices contribute to lower resource consumption, waste generation, and carbon emissions.

- Enhanced Brand Reputation: Ethical and sustainable practices resonate with conscious consumers, enhancing brand reputation and loyalty.

- Cost Savings: Sustainable practices often lead to operational efficiency, reduced waste disposal costs, and optimized resource utilization.

Technology for Sustainability:

Incorporating technologies like RFID, IoT, and blockchain can enhance traceability and transparency in supply chains, enabling better tracking of eco-friendly practices.

Global Initiatives and Regulations:

Increasing regulations and initiatives focus on sustainability, influencing businesses to adopt responsible inventory management practices.

Future Outlook:

As environmental awareness continues to grow, businesses will be driven to integrate sustainable practices into their inventory management strategies. The future will witness a shift towards circular supply chains and responsible consumption, where inventory practices contribute positively to both business success and the planet's health.

Emphasis on the Symbiotic Relationship between Demand Forecasting and Inventory Management

Demand forecasting serves as the compass, guiding inventory management decisions with predictive insights. Inventory management, in turn, transforms these predictions into tangible actions, ensuring products are available at the right time and in the right quantity. This interdependence is the bedrock upon which businesses can thrive in the dynamic marketplace.

Strategic Alignment:

Demand forecasting acts as the foundation upon which inventory management strategies are built. Accurate predictions empower businesses to make informed decisions about procurement, production, and distribution. This strategic alignment ensures that inventory levels are fine-tuned to meet customer demand, minimizing stockouts and excess inventory.

Agility and Responsiveness:

The synergy between demand forecasting and inventory management enhances agility and responsiveness. Businesses armed with accurate forecasts can nimbly adjust inventory levels, quickly adapting to changes in customer preferences, market trends, and external factors. This flexibility empowers businesses to seize opportunities and mitigate risks effectively.

Efficiency and Cost Savings:

Efficiency is the hallmark of the demand forecasting-inventory management relationship. When inventory is aligned with predicted demand, businesses optimize resource allocation, reduce holding costs, and prevent overstocking. This efficiency translates into cost savings, improved profitability, and a leaner supply chain.

Customer-Centricity:

At the heart of this symbiosis lies customer-centricity. By understanding and predicting customer demand accurately, businesses enhance customer satisfaction and loyalty. Availability of products when and where customers need them fosters positive experiences and long-term relationships.

Continuous Improvement:

The symbiotic relationship between demand forecasting and inventory management thrives on continuous improvement. As businesses analyze historical data, integrate technology, collaborate with partners, and embrace sustainability, the relationship evolves to meet the ever-changing demands of the market.

In essence, demand forecasting and inventory management are two halves of a whole, each complementing and enhancing the other. This relationship encapsulates the essence of supply chain optimization, enabling businesses to navigate challenges, seize opportunities, and ultimately achieve excellence in meeting customer needs.

As businesses continue to evolve and innovate, the synergy between these critical elements remains a constant beacon guiding them toward success in the intricate tapestry of modern commerce.

Why should Businesses Prioritize Demand Forecasting for Improved Inventory Management?

In the dynamic landscape of modern business, where customer expectations are soaring and market shifts are constant, the importance of demand forecasting cannot be overstated. As businesses strive for operational excellence, embracing accurate demand forecasting is not just a strategy—it's a necessity.

The call to action is clear: prioritize demand forecasting to revolutionize your inventory management practices and stay ahead in a competitive market.

Harness the Power of Predictive Insights:

By leveraging historical data, advanced analytics, and AI-driven models, you can tap into the power of predictive insights. Understand customer preferences, anticipate demand fluctuations, and make informed decisions that resonate with the ebb and flow of the market.

Empower Agility and Responsiveness:

Demand forecasting isn't just about numbers; it's about empowerment. Equip your business with the ability to pivot swiftly in response to changing customer behavior, emerging trends, and unexpected disruptions. When your inventory management is attuned to demand, you're positioned to seize opportunities and address challenges with confidence.

Enhance Customer Experience:

Customer satisfaction is the heart of sustainable success. Accurate demand forecasting ensures that your shelves are stocked with the products your customers desire, when they desire them. This enhances their experience, builds loyalty, and sets the stage for lasting relationships.

Unlock Operational Efficiency:

Wasted resources, excess inventory, and stockouts are the enemies of efficiency. Demand forecasting enables you to optimize your inventory levels, reduce holding costs, and streamline your supply chain. This efficiency translates into cost savings and improved bottom-line performance.

Lead with Innovation and Adaptation:

In a world where change is constant, the ability to innovate and adapt is paramount. Demand forecasting empowers you to be a trailblazer, harnessing technological advancements, collaborating with partners, and embracing sustainable practices that shape the future of inventory management.

Elevate Your Competitive Edge:

The businesses that thrive are those that can anticipate the future and respond effectively. Accurate demand forecasting gives you the edge to stay ahead of your competitors, providing the agility and foresight needed to outperform and outshine.

The journey to inventory excellence begins with a commitment to demand forecasting. Embrace the trends, leverage the tools, and align your strategies to navigate the complexities of modern commerce. By prioritizing demand forecasting, you're not just managing inventory—you're shaping the future of your business.

Take the first step. Embrace demand forecasting. Transform your inventory management. Secure your place at the forefront of success in the ever-evolving world of business. Your future starts now.

Conclusion

In the dynamic landscape of modern business, inventory management and demand forecasting stand as pivotal pillars that determine the success, resilience, and competitiveness of enterprises. Through the journey of this exploration, we've traversed the realms of accurate demand forecasting, optimal timing, quantity optimization, and the array of challenges that accompany these endeavors. We've witnessed the integration of technology, collaboration, and sustainability as the driving forces behind the evolution of inventory management practices.

From harnessing the power of data-driven insights to leveraging the capabilities of AI and machine learning, businesses are poised to transcend traditional limitations and achieve unparalleled accuracy in predicting customer demand. The integration of real-time demand sensing and collaborative supply chain networks enables businesses to respond with agility, efficiency, and precision to the ever-changing market dynamics.

Moreover, as sustainability takes center stage, responsible inventory practices are shaping the future landscape. Businesses that embrace eco-friendly and circular supply chain strategies not only secure their own success but also contribute to a more sustainable planet.

As we conclude this journey through the intricacies of inventory management and demand forecasting, one overarching theme emerges: the future belongs to the innovative, the adaptable, and the visionary. Businesses that boldly embrace emerging trends, seize technological advancements, and align with ethical principles are best positioned to flourish in the intricate tapestry of the global market.

By navigating the challenges, leveraging the opportunities, and embracing the principles of accuracy, sustainability, and collaboration, businesses can transform inventory management from a logistical task into a strategic advantage. As the landscape continues to evolve, one certainty remains: the potential for excellence in inventory management is boundless for those willing to harness it.

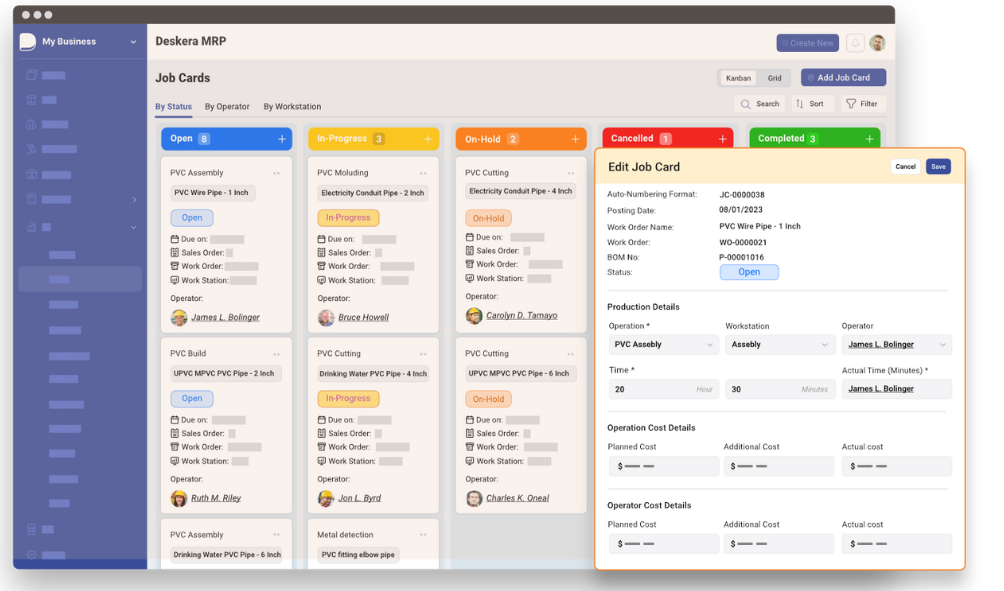

How can Deskera Help You?

Deskera ERP and MRP systems help you to keep your business units organized. The system's key features of demand forecasting with Deskera include as follows:

- Establish Demand Forecasting Process

- Automate Data Collection

- Monitor Market Trends

- Analyze Historical Data

- Estimate Future Demand

- Adjust Production Levels

- Manage Supply Chain and much more!

Deskera's integrated financial planning tools enable investors to better plan and track their investments. It can assist investors in making faster and more accurate decisions.

Deskera CRM is a powerful solution that manages your sales and helps you close deals quickly. It not only enables you to perform critical tasks like lead generation via email, but it also gives you a comprehensive view of your sales funnel.

Deskera Books allows you to better manage your accounts and finances. Maintain good accounting practices by automating tasks like billing, invoicing, and payment processing.

Deskera People is a straightforward tool for centralizing your human resource management functions.

Key Takeaways

- Strategic Foundation: Demand forecasting serves as the strategic foundation for inventory management, guiding decisions with predictive insights.

- Accurate Predictions: Historical data analysis, statistical models, and AI-driven algorithms enable businesses to make accurate demand predictions.

- Real-Time Agility: Real-time demand sensing and IoT integration empower businesses to respond rapidly to changing market dynamics.

- Collaborative Networks: Integration with supply chain partners facilitates data sharing, joint planning, and efficient response to demand shifts.

- Holistic Approach: Successful demand forecasting requires integrating external factors, market trends, and economic indicators.

- Sustainability Matters: Embracing sustainable and eco-friendly practices minimizes waste and enhances brand reputation.

- Data Quality is Key: Data collection, cleansing, and validation are critical to ensuring accurate demand forecasts.

- Strategic Timing: Accurate timing reduces holding costs, prevents overstocking, and aligns production with actual demand.

- Optimal Quantities: Balancing between overstocking and understocking prevents excess inventory costs and stockouts.

- Innovation and Adaptation: Businesses that embrace technology, collaborate, and prioritize sustainability are poised for success in the evolving landscape.

Related Articles