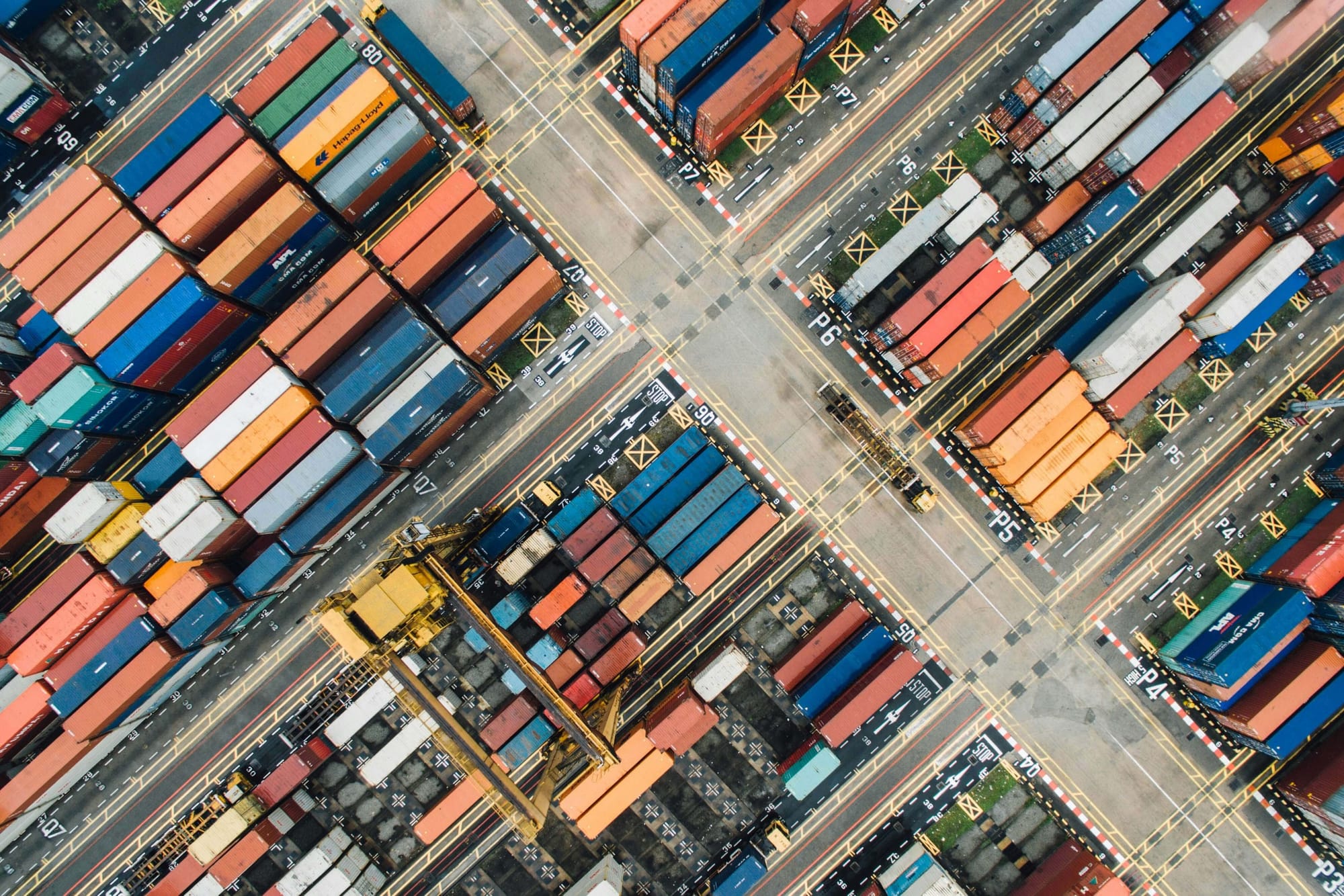

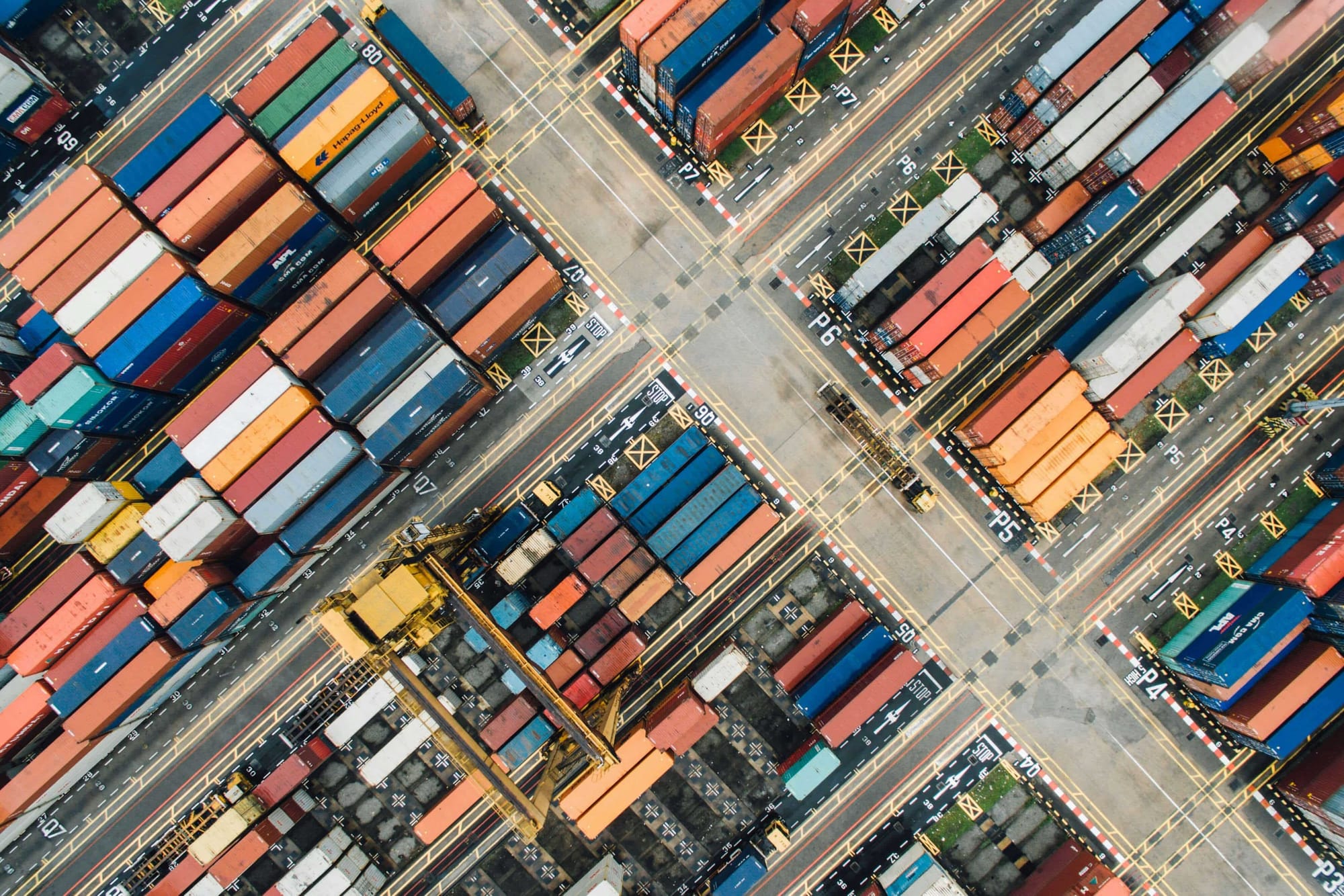

Why do so many manufacturers struggle to stay within their procurement budgets, even with tight cost controls and experienced purchasing teams? The answer lies in the complexity of modern manufacturing — where raw material costs fluctuate rapidly, supply chains face constant disruption, and even minor inefficiencies in procurement can lead to significant overspending. Managing procurement budgets efficiently isn’t just a financial task; it’s a strategic necessity that determines a manufacturer’s profitability and competitiveness.

Procurement budgeting plays a crucial role in ensuring that every purchase — from raw materials to maintenance supplies — aligns with production demands and cost expectations. For manufacturers, even a small deviation in planned versus actual procurement costs can impact cash flow, production schedules, and overall business margins. A well-structured procurement budget provides visibility, control, and predictability, helping businesses maintain steady operations without compromising on quality or delivery timelines.

However, staying cost-competitive in today’s manufacturing environment requires more than traditional budgeting methods or spreadsheet tracking. Manufacturers must embrace data-driven decision-making, real-time cost monitoring, and automation to accurately plan, forecast, and manage their procurement spending. By integrating procurement with inventory, accounting, and production planning, businesses can identify inefficiencies early and make proactive cost-saving decisions.

This is where Deskera Manufacturing ERP makes a difference. Designed for modern manufacturers, Deskera ERP offers an all-in-one platform that connects procurement, inventory, production, and finance in real time. With automated purchase workflows, accurate cost tracking, and insightful analytics, manufacturers can eliminate manual errors, optimize supplier management, and ensure every procurement decision stays aligned with the budget. Ultimately, Deskera empowers manufacturers to control costs intelligently — helping them stay competitive in an ever-evolving market.

What Are Procurement Budgets?

A procurement budget is the financial blueprint that defines how much a business plans to spend on acquiring the goods and services necessary for its operations. In manufacturing, this typically includes raw materials, components, logistics, supplier fees, and other procurement-related costs. It serves as a roadmap for managing purchasing expenses, ensuring that every procurement decision aligns with the company’s financial goals and production requirements.

At its core, procurement budgeting involves the strategic planning, allocation, and control of financial resources used in purchasing activities. It allows businesses to forecast future needs, allocate funds efficiently, and maintain financial discipline across procurement functions. By setting clear spending limits and priorities, organizations can prevent budget leaks, minimize waste, and ensure smoother cash flow management.

A well-structured procurement budget not only tracks how much is being spent but also provides data-driven insights into where savings can be made. It helps procurement teams identify cost optimization opportunities, negotiate better terms with suppliers, and make informed purchasing decisions. For manufacturers dealing with fluctuating material prices and supply chain volatility, this visibility is crucial to maintaining cost efficiency and production continuity.

Ultimately, a procurement budget acts as both a financial control mechanism and a strategic tool. It fosters transparency, reduces the risk of overspending, and strengthens collaboration between procurement, finance, and operations teams. By aligning financial expenditure with business objectives, companies can achieve long-term sustainability, operational efficiency, and improved profitability.

Key Factors Affecting Procurement Budgets

A well-planned procurement budget must account for a variety of internal and external factors that influence costs, demand, and spending priorities. Understanding these factors helps manufacturers maintain financial control and avoid unexpected budget overruns.

Here are the key elements that affect procurement budgets:

1. Raw Material Costs and Market Volatility

Fluctuations in the prices of raw materials such as metals, chemicals, and components can significantly impact procurement budgets. Global supply-demand imbalances, inflation, and geopolitical events often cause price spikes that manufacturers must anticipate and plan for. Monitoring commodity trends and maintaining supplier flexibility can help mitigate these risks.

2. Supplier Pricing and Contract Terms

Procurement budgets are heavily influenced by supplier agreements and negotiated terms. Factors such as bulk discounts, payment schedules, delivery fees, and contract duration can either reduce or increase total procurement costs. Strong supplier relationships and strategic sourcing practices are essential to control expenses.

3. Demand Forecast Accuracy

Inaccurate demand forecasting can lead to either over-purchasing or stock shortages, both of which affect the procurement budget. Over-purchasing ties up capital in unused inventory, while shortages may lead to costly emergency orders. Integrating demand forecasting tools within ERP systems ensures procurement spending aligns with actual production needs.

4. Transportation and Logistics Costs

Freight charges, fuel prices, and shipping routes have a direct impact on procurement expenses. Manufacturers dealing with global suppliers face additional variables such as customs duties and import/export fees. Efficient logistics management and supplier location analysis can help minimize transportation-related budget fluctuations.

5. Currency Exchange Rates

For manufacturers sourcing internationally, foreign exchange rate variations can alter the actual cost of goods purchased. Even small changes in currency rates can lead to substantial differences in procurement spending. Using hedging strategies or sourcing locally when possible helps stabilize budgets.

6. Internal Procurement Processes and Efficiency

Manual workflows, delayed approvals, and lack of process automation often lead to overspending or missed savings opportunities. Automated procurement systems—like those in Deskera ERP—streamline approvals, track spending in real time, and reduce the risk of budget deviations through better visibility and control.

7. Regulatory and Compliance Requirements

Changes in trade regulations, tariffs, or environmental standards can affect supplier costs and, in turn, procurement budgets. Manufacturers must regularly review compliance-related expenses and ensure their procurement policies align with evolving government requirements.

8. Supplier Reliability and Performance

Supplier delays, poor quality materials, or inconsistent fulfillment can lead to unplanned purchases and higher costs. Evaluating supplier performance regularly helps manufacturers maintain predictable procurement spending and prevent emergency budget allocations.

By monitoring these key factors and adopting integrated procurement management tools, manufacturers can build resilient budgets that adapt to market shifts, control costs effectively, and support long-term operational efficiency.

How to Outsmart Common Procurement Budgeting Pitfalls

Even with a solid procurement budget in place, manufacturers often face obstacles that derail spending discipline and cost efficiency. From data silos to fluctuating raw material prices, these challenges can quickly lead to overspending and supply disruptions. Here’s how to recognize and overcome the most common pitfalls in procurement budgeting.

1. Lack of Integration Across Departments

A major pitfall is the absence of integration between procurement, finance, production planning, and inventory management. When these teams work in isolation, purchasing decisions may not align with production schedules or cash flow priorities.

How to outsmart it: Adopt an integrated ERP system that synchronizes procurement with production and financial data. This allows seamless communication between departments, ensuring every purchase order supports production targets and fits within the approved budget.

2. Inaccurate or Incomplete Data

Procurement budgets are only as reliable as the data behind them. Inaccurate cost histories, outdated supplier records, or incomplete inventory data can result in over-ordering or budget overruns.

How to outsmart it: Maintain real-time, centralized data on material costs, supplier performance, and stock levels. Conduct regular data audits, and use analytics-driven tools (like Deskera Manufacturing ERP) to generate precise forecasts and automate variance tracking.

3. Market Volatility and Price Fluctuations

Commodity price shifts, exchange rate fluctuations, or sudden supplier shortages can inflate procurement costs unexpectedly. This is especially critical for manufacturers dependent on raw materials like steel, aluminum, or plastics.

How to outsmart it: Build contingency buffers into your procurement budget and diversify your supplier base. Negotiate long-term contracts or implement vendor-managed inventory (VMI) for high-volume materials to stabilize costs during volatile periods.

4. Weak Compliance and Risk Management

Ignoring procurement compliance or supplier risk controls can result in legal exposure, quality issues, and financial loss. Manufacturers working with multiple global suppliers are particularly vulnerable to contract breaches and regulatory lapses.

How to outsmart it: Establish robust compliance frameworks that align supplier contracts with internal and external regulations. Regularly assess supplier reliability and maintain a risk register to track potential disruptions or financial vulnerabilities.

5. Limited Technology and Visibility

Without digital visibility, procurement teams struggle to monitor real-time spending or detect budget deviations. Manual processes also make it difficult to manage multi-supplier operations or consolidate data across production units.

How to outsmart it: Leverage cloud-based procurement tools and ERPs that integrate purchasing, budgeting, and analytics. Platforms like Deskera Manufacturing ERP provide real-time dashboards, automated purchase order tracking, and alerts for overspending — empowering manufacturers to act before issues escalate.

6. Ignoring Continuous Improvement

Many manufacturers treat procurement budgeting as a one-time annual process rather than a continuous optimization cycle. This limits responsiveness to changing market dynamics and operational demands.

How to outsmart it: Adopt a continuous improvement mindset — conduct quarterly reviews of procurement spend vs. production outcomes. Use the findings to fine-tune cost models, renegotiate contracts, and identify automation opportunities for the next cycle.

Importance of Procurement Budgeting

Procurement budgeting plays a far greater role than simply controlling costs — it acts as a strategic tool that drives efficiency, stability, and competitiveness within manufacturing operations.

By aligning purchasing activities with financial goals, manufacturers can ensure optimal resource utilization, minimize waste, and build stronger supplier relationships.

Here’s why procurement budgeting is essential for modern manufacturing businesses.

1. Enables More Accurate Predictions

The procurement team is uniquely positioned to forecast realistic costs and identify potential challenges early in the budgeting cycle. They understand supplier dynamics, lead times, and market fluctuations better than any other department.

By involving procurement experts in budget planning, manufacturers can anticipate material shortages, negotiate better pricing terms, and avoid underestimating key expenses.

This proactive collaboration helps prevent costly surprises during production and allows businesses to make data-driven spending decisions that enhance profitability.

2. Offers a Detailed View of Past Spending

Procurement budgeting provides visibility into historical spending patterns, enabling manufacturers to learn from previous inefficiencies. By comparing actual spending to projected budgets, businesses can assess how accurately past budgets were planned and identify areas that need improvement.

For example, if the cost of raw materials exceeded expectations in the previous year, procurement can analyze supplier performance and explore alternative sourcing strategies. Advanced analytics tools can further highlight cost-saving opportunities and track spend-to-value ratios across departments and product lines.

3. Helps Manage Market Volatility

Manufacturing supply chains are particularly vulnerable to price fluctuations, currency shifts, and raw material shortages. Procurement budgeting helps organizations plan ahead by incorporating contingency allowances for volatile market conditions.

With procurement’s insights, manufacturers can forecast how changes in commodity prices, transportation costs, or regulatory tariffs may affect their margins. This foresight allows them to secure long-term supplier contracts, diversify sourcing regions, and build resilience against unexpected cost escalations.

4. Strengthens Information Flow and Collaboration

An effective procurement budget fosters transparency and alignment across departments such as finance, production, and logistics. When procurement knows what materials will be required and when, it can strategically schedule purchases, maintain optimal inventory levels, and prevent production delays.

Better communication also allows procurement to coordinate with suppliers early, ensuring favorable contract terms and timely delivery schedules. This collaborative flow of information minimizes operational friction and improves end-to-end supply chain performance.

5. Promotes Strategic Resource Allocation

A well-defined procurement budget ensures that resources are allocated to high-priority production areas, avoiding overinvestment in non-critical categories. It supports long-term planning by balancing immediate needs with growth-oriented initiatives such as capacity expansion or sustainability programs.

By linking procurement goals directly to corporate objectives, manufacturers can transform purchasing from a transactional function into a strategic enabler of business growth.

6. Reduces Financial and Operational Risk

Procurement budgeting introduces greater financial control by setting clear spending thresholds and tracking expenses in real time. This not only minimizes the risk of overspending but also ensures compliance with internal policies and external regulations.

Moreover, accurate budgeting helps mitigate operational risks such as supplier insolvency or sudden demand fluctuations — both of which can disrupt production if not properly anticipated.

7. Enhances Forecasting Through Technology

Modern procurement tools and Manufacturing ERP systems, like Deskera Manufacturing ERP, simplify the budgeting process with automated spend analysis, supplier performance tracking, and cost forecasting.

These systems consolidate real-time data across departments, giving manufacturers full visibility into expenses and helping them adjust budgets dynamically based on changing production needs or market conditions.

Procurement Budgeting: A Step-by-Step Process

For manufacturers, procurement budgeting is a strategic exercise that ties purchasing to production plans, cost control, and supplier performance. The process below covers everything from identifying needs and estimating costs to approval, real-time tracking, and continuous improvement — with practical manufacturer-focused actions at each step.

1. Identify Present and Future Requirements

Assess production plans, bills of materials (BOMs), engineering change notices, and anticipated new product launches to list required raw materials, components, and services. Include lead times, minimum order quantities (MOQs), critical spares, and seasonal demand shifts so procurement schedules match production timelines.

2. Research the Market / Supplier Landscape

Conduct market exploration to understand pricing trends, alternative suppliers, lead-time risks, and capacity constraints. For global buys, factor in tariffs, import rules, and regional logistics options. Use supplier scorecards to shortlist partners who meet quality, cost, and delivery requirements.

3. Analyze Historical Spend Data

Review past purchase orders, cost-per-unit trends, emergency buys, and supplier performance. Reconcile procurement spend against production output to spot waste, over-ordering, or material yield issues. Historical variance analysis helps set realistic baselines for the new budget.

4. Forecast Costs and Demand

Combine production forecasts, sales orders, and historical consumption to estimate material quantities. Layer in market forecasts (commodity indexes, FX expectations, inflation) to predict raw material price movements. Build best/worst case scenarios to quantify budget exposure.

5. Estimate Direct, Indirect & Contingency Costs

Break estimates into direct costs (raw materials, parts), indirect costs (transport, import duties, warehousing, utilities), and contingency (percentage for price spikes or unexpected demand). For manufacturers, include cost-per-unit and landed cost calculations to capture full procurement impact.

6. Prioritize Expenditures

Categorize spend by strategic importance: critical production inputs (high priority), secondary materials (medium), and non-critical indirects (low). Use ABC/XYZ or criticality matrices to decide where budget flexibility is permitted and where strict controls are required.

7. Engage Stakeholders & Secure Buy-in

Involve production planners, engineering, quality, finance, and senior management early. Align procurement priorities with cash flow, production targets, and project timelines. Early stakeholder engagement shortens approval cycles and reduces last-minute emergency purchases.

8. Create the Procurement Plan & Draft the Budget

Document expected purchases, timing, preferred suppliers, payment terms, and delivery schedules. Map the plan to production milestones and cash flow forecasts. Include negotiation strategies, volume discount plans, and planned contract terms for strategic suppliers.

9. Report the Budget for Approval

Compile a clear budget report with expected costs, justifications, variance analysis versus prior periods, and scenario outcomes. Present ROI and risk mitigations to finance and leadership for sign-off. Make approval conditional on mapped KPIs and contingency thresholds.

10. Implement Real-Time Tracking & Controls

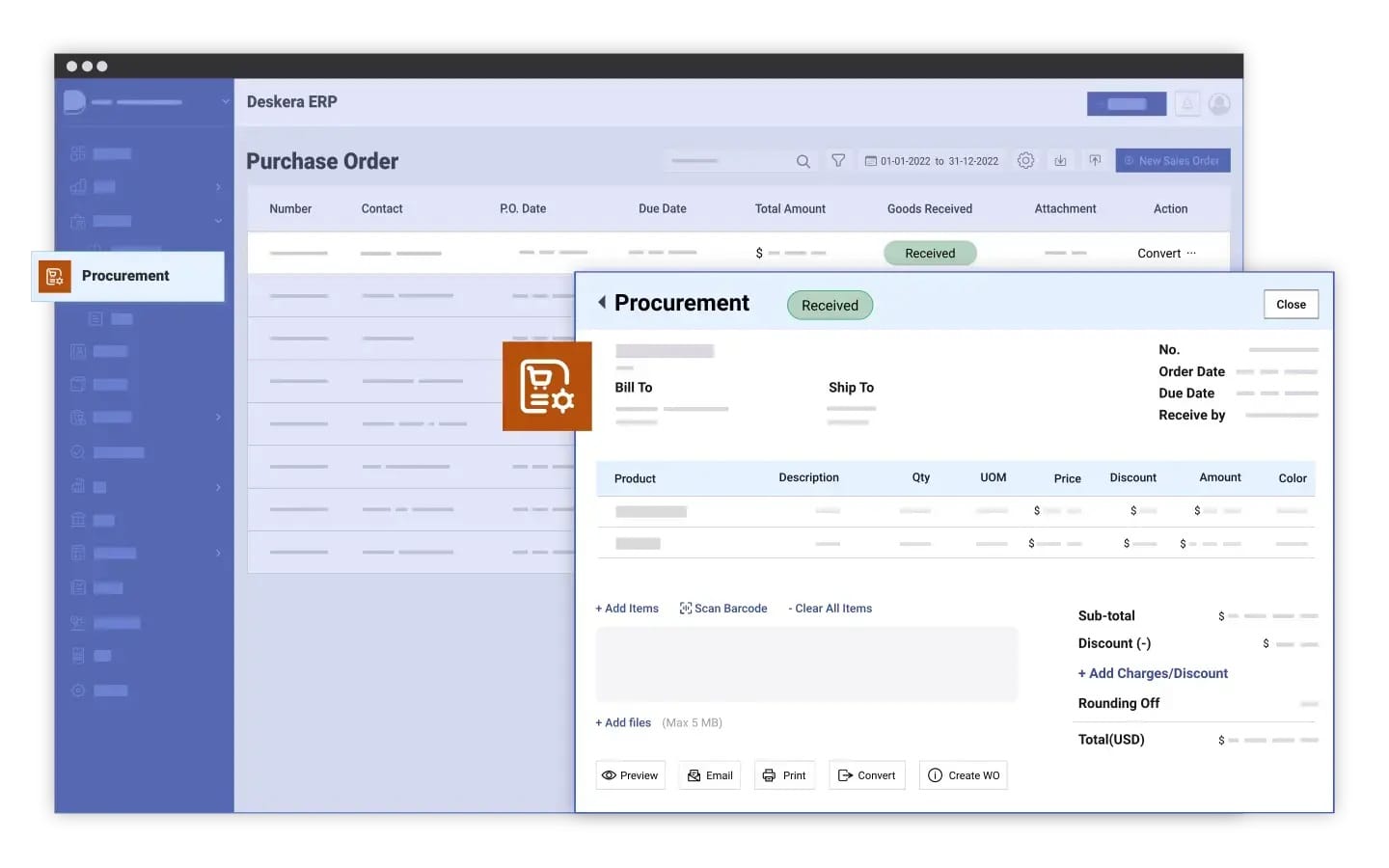

Deploy procurement/ERP tools (e.g., Deskera Manufacturing ERP) to integrate purchase requisitions, POs, inventory, and finance. Enable real-time spend tracking, approval workflows, budget holds at requisition, and guided buying to ensure purchases follow approved suppliers and price lists.

11. Monitor KPIs and Operational Performance

Track procurement KPIs: purchase price variance (PPV), supplier lead time adherence, cost per unit, PO cycle time, emergency purchase frequency, and on-time delivery. Link these KPIs to production KPIs (downtime, yield) to see procurement’s operational impact.

12. Review, Reforecast & Adjust Regularly

Run periodic reviews (monthly/quarterly) to compare actual spend vs budget, update forecasts with fresh market data, and reallocate funds as priorities change. Trigger reforecasting when commodity prices move beyond predefined thresholds or when production plans change.

13. Optimize & Continuous Improvement

Use spend analytics to identify consolidation opportunities, renegotiate contracts, adopt vendor-managed inventory (VMI) for critical SKUs, or switch to local suppliers where appropriate. Apply lessons from variance and supplier performance reviews to reduce cost-per-unit over time.

14. Close the Loop: Audit, Report, and Institutionalize

Document outcomes vs targets, perform variance and root-cause analysis, and publish learnings. Institutionalize successful contract terms, guided-buy catalogs, and procurement playbooks so future budgets start from an improved baseline.

How Deskera Manufacturing ERP Helps Manufacturers Optimize Procurement Budgets

Procurement budgeting in manufacturing is complex — it involves coordinating raw material costs, supplier contracts, production schedules, and logistics expenses. Manual tracking or disconnected systems often result in cost overruns and inefficiencies. Deskera Manufacturing ERP streamlines this entire process by providing end-to-end visibility, real-time analytics, and automation tools that help manufacturers make smarter budgeting decisions and control spend effectively.

1. Real-Time Visibility into Procurement Spend

Deskera ERP centralizes all procurement data — from purchase requisitions to supplier invoices — giving manufacturers a single, unified view of all expenses. This transparency allows procurement and finance teams to monitor spending in real time, track cost deviations, and make quick adjustments to stay within budget. By eliminating data silos, businesses can spot cost leakages early and prevent unnecessary expenditures.

2. Data-Driven Budget Forecasting

With Deskera’s advanced analytics and reporting tools, manufacturers can analyze historical purchasing data, market trends, and supplier performance to forecast future spend accurately. The system automatically identifies seasonal patterns or cost variations across materials, helping companies plan for demand fluctuations and allocate budgets strategically. This predictive capability ensures that financial plans are based on solid data — not assumptions.

3. Seamless Integration Between Procurement and Finance

One of the biggest reasons budgets fail is the lack of alignment between procurement and finance teams. Deskera ERP bridges this gap by integrating procurement workflows with financial accounting and inventory management. As a result, every purchase order, goods receipt, and supplier payment is automatically reflected in the financial ledger, ensuring accurate, up-to-date budget tracking without manual reconciliation.

4. Smarter Supplier Management and Negotiation

Deskera’s supplier management module provides detailed insights into vendor pricing, lead times, and performance history. Manufacturers can use this data to negotiate better rates, identify reliable suppliers, and reduce dependency on high-cost vendors. By maintaining transparent supplier scorecards, procurement teams can strengthen partnerships and optimize sourcing strategies that support long-term cost control.

5. Automated Budget Monitoring and Alerts

The ERP system continuously monitors procurement activities and compares them against allocated budgets. If spending approaches the limit or deviates from planned thresholds, Deskera triggers automated alerts to help managers take corrective actions before overspending occurs. This proactive approach ensures that financial discipline is maintained throughout the procurement cycle.

6. Improved Production Planning and Inventory Control

Deskera Manufacturing ERP connects procurement budgets with real-time inventory levels and production schedules. The system ensures that raw materials are purchased just in time — reducing carrying costs and minimizing excess stock. This integration between procurement and production not only helps in staying within budget but also supports lean manufacturing practices that enhance overall efficiency.

7. Enhanced Reporting and Audit Readiness

With centralized data and configurable reports, Deskera simplifies financial reporting and ensures audit-ready transparency. Procurement teams can generate detailed insights into category-wise spending, supplier costs, and budget utilization — making it easier to evaluate performance and refine future strategies.

In essence, Deskera Manufacturing ERP transforms procurement budgeting from a reactive, manual process into a strategic, data-driven discipline. By uniting procurement, finance, and production on one intelligent platform, manufacturers can improve cost control, forecast with accuracy, and build more resilient, cost-efficient operations.

Key Takeaways

- Procurement budgets define how manufacturers allocate, plan, and control financial resources for purchasing goods and services. A clear budgeting strategy helps prevent overspending and ensures that procurement aligns with business goals.

- Procurement budgets are influenced by supplier pricing, raw material volatility, logistics costs, market demand, and internal collaboration. Understanding these factors helps manufacturers maintain financial control even in fluctuating market conditions.

- Procurement budgeting promotes accurate forecasting, better risk management, and efficient resource allocation. It empowers manufacturers to make informed spending decisions, strengthen supplier relationships, and sustain long-term financial stability.

- Avoiding issues such as data inaccuracies, poor integration, and market volatility requires robust data management, cross-departmental alignment, and the use of advanced technology to maintain budget accuracy and compliance.

- A structured budgeting process — from identifying needs and analyzing historical data to engaging stakeholders and reviewing performance — transforms procurement into a strategic business function that supports operational efficiency and growth.

- Deskera ERP enables real-time spend tracking, data-driven forecasting, and seamless integration between procurement, finance, and production. This empowers manufacturers to optimize budgets, enhance supplier management, and improve cost competitiveness.

Related Articles