In today’s dynamic business environment, organizations are under constant pressure to deliver products faster, reduce costs, and maintain flexibility. One strategic approach that companies increasingly rely on is outsourcing in supply chain management. By partnering with specialized vendors, businesses can delegate functions such as logistics, warehousing, procurement, or IT services, allowing them to focus on their core strengths while ensuring operational efficiency.

Recent studies show that about 60% of companies report that outsourcing provides them with the ability to scale operations up or down quickly in response to market demands. This built-in scalability has become one of the most valuable aspects of outsourcing in supply chain management, especially in industries where demand can fluctuate drastically. Whether it’s a retail company preparing for holiday surges or a manufacturer adjusting production to meet new contracts, outsourcing offers the flexibility to adapt without significant overhead.

Beyond scalability, outsourcing also provides access to expertise, advanced technology, and global networks that many businesses cannot build in-house. It can enhance efficiency, reduce costs, and improve customer satisfaction when managed effectively. However, companies must also balance these advantages with potential risks such as reduced control, vendor dependency, or compliance challenges. This makes having a robust strategy and the right tools essential for successful outsourcing.

This is where Deskera ERP can play a pivotal role. As an integrated platform, Deskera ERP offers complete visibility across outsourced operations, helping businesses track vendor performance, manage contracts, and forecast demand with accuracy. With built-in features for inventory management, procurement, and supply chain monitoring—plus the AI Assistant David—Deskera enables organizations to reduce risks and ensure smoother collaboration with partners. It provides the digital backbone businesses need to make outsourcing a driver of growth rather than a source of complexity.

What is Outsourcing in Supply Chain Management?

Outsourcing in supply chain management refers to the practice of delegating certain logistics, warehousing, transportation, order fulfillment, and other operational functions to external partners such as third-party logistics providers (3PLs), fulfillment centers, or business process outsourcers (BPOs). By doing so, companies can tap into the expertise, global networks, and advanced technologies of specialized providers while focusing on their core business activities.

The trend is rapidly growing. A 2025 report from the Council of Supply Chain Management Professionals (CSCMP) revealed that nearly 9 in 10 companies have increased their use of outsourced 3PL services. Among the most outsourced areas are transportation and warehousing, followed closely by inventory management, procurement, order fulfillment, returns management, customer service, and customs and trade compliance. This shift highlights how outsourcing has become a strategic tool to meet rising customer expectations and overcome the persistent disruptions affecting global supply chains.

Today’s businesses face mounting challenges such as tariff uncertainty, geopolitical risks, extreme weather events, and evolving consumer demands for fast, reliable delivery. In this environment, outsourcing is no longer just about cost reduction—it’s about achieving operational efficiency, building resilience, and gaining a competitive edge. Strategic relationships with 3PL providers and outsourcing partners help businesses scale quickly, manage risks, and deliver superior customer experiences.

At the same time, automation and digital integration are reshaping how outsourcing functions. Many organizations adopt automation technologies like inventory management software to handle functions internally that might otherwise be outsourced. More often, however, companies integrate their ERP systems with those of outsourcing partners to achieve real-time supply chain visibility, better asset management, and seamless collaboration. This combination of outsourcing and technology is redefining the modern supply chain, balancing efficiency with adaptability.

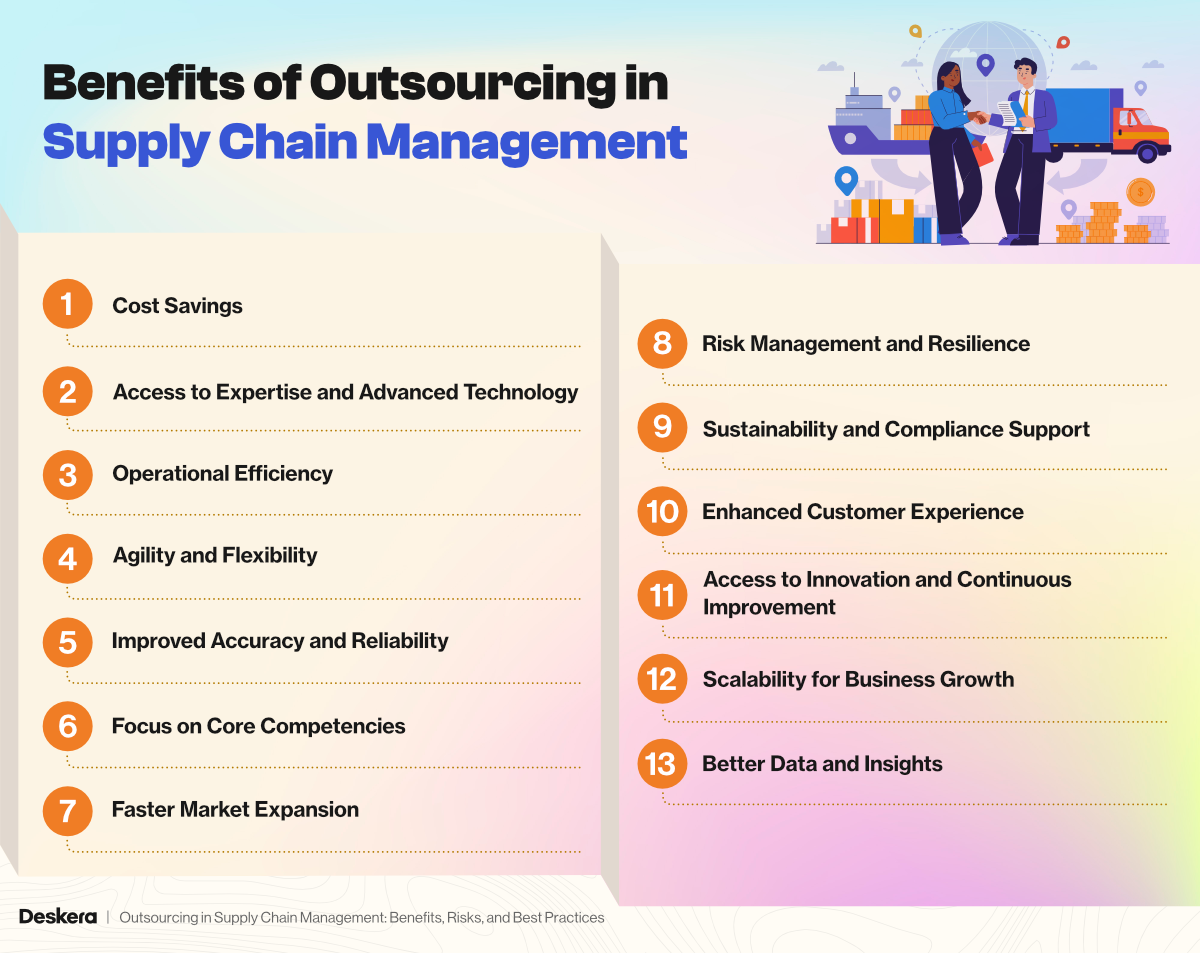

Benefits of Outsourcing in Supply Chain Management

Outsourcing has evolved from being a purely cost-saving tactic to a comprehensive strategy for enhancing efficiency, agility, and customer satisfaction. Partnering with third-party providers gives businesses access to specialized skills, advanced technologies, and flexible networks that would otherwise require heavy investments.

Below are the key benefits of outsourcing in supply chain management.

1. Cost Savings

Managing supply chains in-house often requires significant investment in infrastructure, labor, and technology. Outsourcing removes much of this burden by leveraging the scale and expertise of third-party providers. 3PLs consolidate shipments, optimize routes, and secure preferential rates with carriers—reducing per-unit logistics costs. Businesses also avoid fixed expenses like warehouse leasing, fleet ownership, and staffing, paying instead only for the space and services they actually use.

2. Access to Expertise and Advanced Technology

Outsourcing partners bring deep knowledge of logistics, customs compliance, warehousing, and distribution. They not only handle day-to-day tasks but also advise on strategy, such as entering new markets or optimizing sustainability practices. Many providers deploy cutting-edge tools, including AI-driven route optimization, supply chain control towers, and real-time inventory tracking, which would be expensive and complex for a single company to implement on its own.

3. Operational Efficiency

Delegating non-core activities such as inventory control, order fulfillment, and transportation allows companies to focus on innovation, marketing, and customer experience. Outsourcing providers often operate with highly automated systems and integrated platforms that streamline operations and reduce errors. This results in faster order processing, greater visibility across the supply chain, and smoother collaboration between business units and partners.

4. Agility and Flexibility

Global markets are increasingly volatile, with demand spikes, supply disruptions, and shifting customer expectations. Outsourcing provides businesses with the flexibility to scale their operations up or down quickly, without the need for major investments. 3PL providers can reallocate labor, adjust shipping routes, or tap into regional warehouse networks to ensure continuity and responsiveness. This agility is critical not only during seasonal peaks but also when businesses expand into new geographic markets.

5. Improved Accuracy and Reliability

Outsourcing enhances accuracy in order processing, inventory management, and shipping. Integration between a company’s systems and its outsourcing partners ensures that data is updated in real time, reducing errors and delays. Providers also maintain established relationships with logistics partners, allowing them to reroute shipments, resolve disruptions, and maintain high service levels even under pressure.

6. Focus on Core Competencies

Perhaps one of the most valuable benefits is the ability for businesses to redirect their resources toward what they do best. Instead of spending time and capital on logistics management, leaders can concentrate on product development, customer engagement, and long-term strategy. By entrusting supply chain complexity to experts, businesses position themselves for growth and competitive advantage.

7. Faster Market Expansion

Outsourcing enables companies to enter new regions without having to establish physical warehouses or logistics operations from scratch. 3PL providers already maintain networks of distribution centers and carrier partnerships worldwide, allowing businesses to serve international markets quickly while minimizing compliance risks.

8. Risk Management and Resilience

Outsourcing partners help mitigate risks related to supply chain disruptions such as natural disasters, trade restrictions, labor shortages, or political instability. Their diversified networks and contingency planning make it easier to reroute shipments or shift operations, ensuring supply chain continuity during unexpected events.

9. Sustainability and Compliance Support

Many outsourcing providers invest in green logistics solutions such as energy-efficient warehouses, route optimization for reduced emissions, and recyclable packaging. They also help businesses stay compliant with regional regulations, customs requirements, and industry standards—reducing the risk of fines or reputational damage.

10. Enhanced Customer Experience

A well-managed outsourcing arrangement directly improves customer satisfaction. Faster deliveries, accurate order fulfillment, and real-time shipment tracking create a smooth buying experience. Some providers even integrate customer support services, ensuring seamless communication between businesses and their customers.

11. Access to Innovation and Continuous Improvement

Top-tier outsourcing providers consistently invest in automation, robotics, AI, and analytics to stay competitive. By partnering with them, businesses automatically benefit from these innovations without bearing the full cost of development. This fosters a cycle of continuous improvement in supply chain operations.

12. Scalability for Business Growth

As businesses grow, their supply chain requirements often become more complex. Outsourcing partners provide scalable infrastructure, technology, and human resources that grow alongside the business. Whether it’s handling seasonal demand spikes or supporting rapid product line expansion, outsourcing ensures growth isn’t slowed down by operational bottlenecks.

13. Better Data and Insights

Advanced outsourcing partners offer powerful analytics dashboards and real-time reporting tools. These provide actionable insights on inventory levels, transportation efficiency, customer demand patterns, and cost-saving opportunities. Companies gain not just logistics support but also a data-driven foundation for better decision-making.

Risks and Challenges of Outsourcing in Supply Chain Management (and How to Overcome Them)

While outsourcing can streamline operations and reduce costs, it also introduces risks that businesses cannot ignore. Without careful planning and oversight, these challenges can impact efficiency, increase costs, or weaken customer trust. Below are the most common risks companies face when outsourcing supply chain management—along with practical solutions to address them.

1. Limited Control

One of the most common concerns with outsourcing is the reduced ability to directly manage day-to-day operations. Routing decisions, warehouse processes, or even customer service standards may be controlled by the outsourcing partner rather than the company itself. This lack of oversight can lead to inconsistencies in quality, slower responses to market changes, or brand dilution.

Solution: Create strong governance mechanisms by defining service-level agreements (SLAs), performance KPIs, and reporting requirements. Integrating ERP or supply chain visibility software helps ensure real-time oversight and accountability.

2. Potential for Disruption

Even the most reliable third-party providers are not immune to risks. System outages, staffing shortages, or disruptions caused by geopolitical conflicts and extreme weather can ripple across outsourced operations, leaving businesses vulnerable. If a 3PL partner experiences delays, it directly impacts customer satisfaction and revenue.

Solution: Reduce dependency on any single provider by maintaining multiple outsourcing partners for critical functions. Conduct periodic risk assessments, and develop contingency plans such as alternative carriers or backup warehouses.

3. Hidden and Unexpected Costs

What looks like a cost-saving opportunity on paper may come with hidden fees. Fuel surcharges, peak season fees, long-term storage costs, or administrative add-ons can quickly add up. Indirect costs, like the time spent managing the outsourcing relationship, can also erode the financial benefits.

Solution: Always demand transparent pricing models and clarify fees upfront. Regularly audit invoices, include cost-visibility clauses in contracts, and account for internal management costs when calculating the true ROI of outsourcing.

4. Choosing the Wrong Partner

A poor choice of outsourcing partner can result in misaligned priorities, weak technology capabilities, or inadequate service levels. This mismatch often leads to inefficiencies, customer complaints, and reputational risks. Once embedded, switching partners can be costly and disruptive.

Solution: Perform due diligence before committing. Evaluate providers for industry-specific expertise, scalability, compliance history, and cultural fit. Define expectations clearly in contracts and align on strategic goals before onboarding.

5. Communication Challenges

Effective collaboration relies on clear communication. Outsourcing relationships, however, often span multiple time zones, languages, and cultural differences. Miscommunication in order updates, shipment delays, or inventory levels can result in costly errors and unmet customer expectations.

Solution: Standardize communication protocols across both teams. Schedule regular meetings, share real-time dashboards, and align on KPIs. Using collaborative tools ensures seamless updates and minimizes misunderstandings.

6. Dependence on Providers

Relying heavily on a single outsourcing provider makes a business vulnerable to their operational, financial, or technological challenges. If the provider fails, the entire supply chain can grind to a halt, leaving the company with no immediate backup.

Solution: Retain in-house expertise for critical functions and consider splitting tasks between multiple providers. This creates flexibility and reduces reliance on a single point of failure.

7. Quality Control Issues

When third parties manage warehousing, handling, or shipping, businesses risk losing control over product quality and customer experience. Poor storage conditions, mishandling, or inaccurate fulfillment can damage a company’s reputation and result in higher returns.

Solution: Set clear quality benchmarks in contracts and conduct regular audits. Use ERP or inventory management integrations to track compliance in real time and flag issues early.

8. Technology Integration Issues

Seamless data sharing between a company and its outsourcing partner is critical. If the partner’s systems cannot integrate with existing ERP, CRM, or inventory platforms, it can lead to inaccurate data, delays, and inefficiencies.

Solution: Assess integration capabilities during the partner evaluation stage. Prioritize providers with API-ready platforms and test connections before scaling operations.

9. Compliance and Security Risks

Outsourcing partners operate under their own compliance frameworks, which may not always align with your region’s regulations or industry standards. Risks include customs violations, labor law breaches, or cybersecurity vulnerabilities that could compromise sensitive business data.

Solution: Partner only with providers that demonstrate proven compliance certifications and robust cybersecurity measures. Include detailed compliance and data-protection clauses in contracts, and monitor adherence continuously.

10. Long Onboarding and Transition Periods

Outsourcing is not a plug-and-play solution. Onboarding a partner involves system integrations, training, and process alignment, which can delay implementation. Poorly managed transitions risk creating short-term disruption and confusion.

Solution: Develop a structured onboarding plan with clear timelines, resource allocation, and milestone reviews. Conduct pilot projects before full-scale rollout to smooth the transition.

11. Cultural and Operational Misalignment

Outsourcing partnerships are more than transactional—they require alignment of values, processes, and service expectations. If the partner’s culture doesn’t fit with yours, collaboration can become strained, leading to inefficiencies or poor customer service.

Solution: Evaluate cultural fit during the selection process. Regular workshops, joint training sessions, and alignment reviews help ensure shared values and operational consistency.

12. Reduced Flexibility for Customization

Some outsourcing providers rely on standardized processes that may not align with your company’s unique needs. This can limit your ability to customize supply chain operations or offer differentiated customer experiences.

Solution: Negotiate flexibility upfront and select partners that allow process customization. Providers offering modular solutions tend to adapt better to evolving requirements.

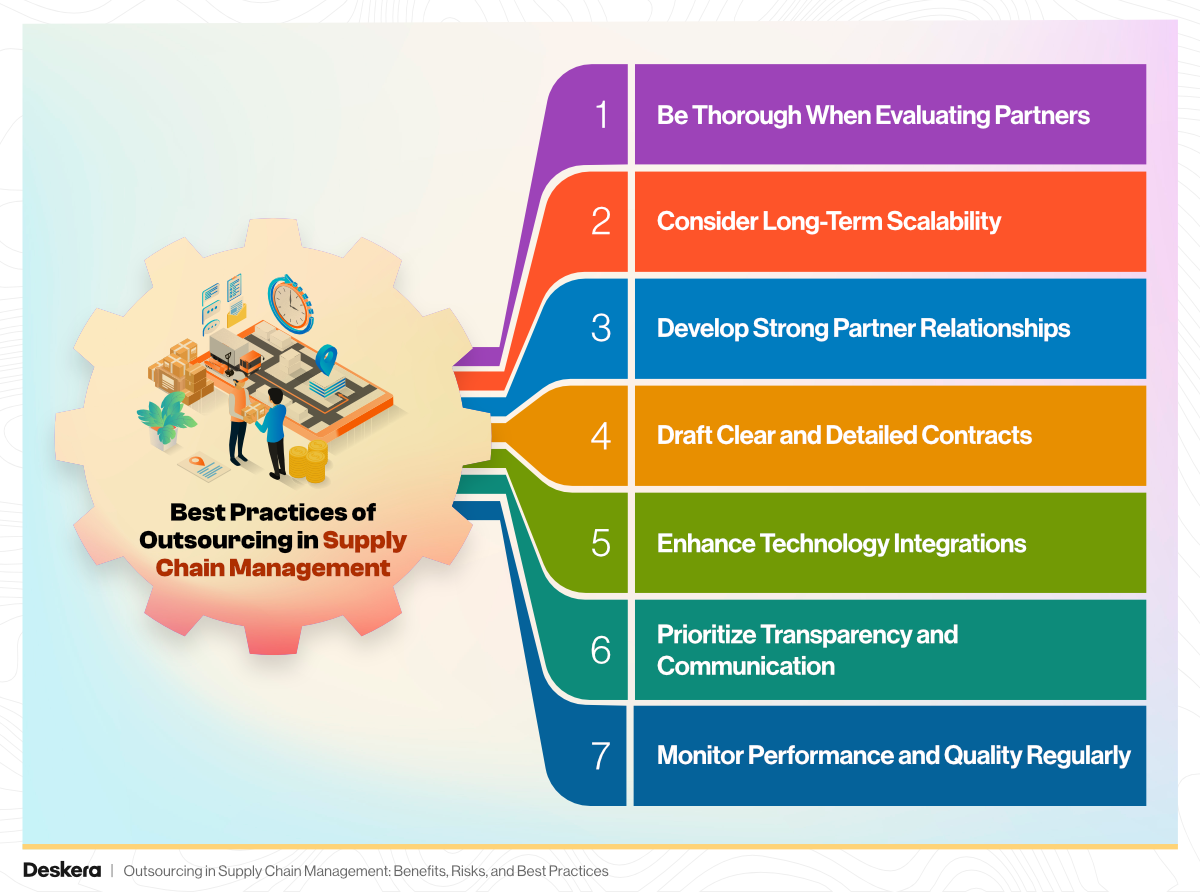

Best Practices of Outsourcing in Supply Chain Management

Outsourcing in supply chain management can unlock enormous value—reducing costs, improving efficiency, and driving scalability. However, realizing these benefits requires a careful and strategic approach. Without the right practices, companies risk service disruptions, hidden costs, or misaligned objectives. Below are some key best practices to follow when building a successful outsourcing strategy.

1. Be Thorough When Evaluating Partners

Selecting the right outsourcing partner sets the foundation for success. A hasty choice can expose your business to risks like operational inefficiencies or regulatory issues.

When evaluating potential partners, look beyond pricing. Assess their operational capabilities, industry experience, financial health, and compliance with regulations. Ensure that their technology platforms can integrate seamlessly with your existing systems, reducing the chances of disruption.

Request references, conduct site visits, and analyze client success stories to gauge their credibility. Additionally, consider the cultural fit—your outsourcing partner should align with your business values and customer service standards.

2. Consider Long-Term Scalability

Outsourcing is not just about solving today’s challenges—it’s about preparing for the future. The best providers can adapt to your evolving needs, whether that means handling seasonal demand spikes or supporting global expansion.

Evaluate how flexible and scalable a partner’s services are. Do they have the infrastructure and resources to manage growth? Are they innovating with new technologies like AI and automation? Long-term alignment ensures that your outsourcing relationship evolves alongside your business goals, rather than holding you back.

3. Develop Strong Partner Relationships

Outsourcing should be seen as a strategic partnership, not a transactional arrangement. Strong relationships foster collaboration, innovation, and shared responsibility for results.

Work closely with your providers on cost optimization strategies, such as route planning or automation projects. Co-develop contingency plans to mitigate risks during disruptions.

Maintain transparency by sharing critical data and forecasts so that your partner can plan effectively. Regular meetings, joint planning sessions, and performance reviews will strengthen trust and help both parties align on short- and long-term goals.

4. Draft Clear and Detailed Contracts

Contracts are the backbone of any outsourcing relationship. A vague or incomplete agreement can lead to hidden costs, misaligned expectations, or disputes.

Ensure your contract outlines service-level agreements (SLAs), pricing structures, communication protocols, and responsibilities of each party. Include clauses covering data security, confidentiality, dispute resolution, and performance reviews.

For example, SLAs should specify delivery timelines, problem-resolution thresholds, and performance-based incentives. Periodic reviews and renegotiation clauses also provide flexibility to adapt to changing market conditions.

5. Enhance Technology Integrations

Technology is the glue that binds modern supply chain outsourcing. Without strong digital integration, visibility gaps and inefficiencies are inevitable.

Leverage real-time data platforms, cloud-based systems, and IoT-enabled tracking to create a seamless flow of information between your company and your outsourcing partner.

AI-driven tools can further enhance forecasting, automate repetitive tasks, and improve decision-making. For example, AI can optimize carrier selection, predict delivery times, and adjust routing in real time. Aligning technology systems not only reduces errors but also improves collaboration and customer satisfaction.

6. Prioritize Transparency and Communication

Clear communication and transparency build trust and minimize misunderstandings. Both you and your outsourcing partner should have visibility into supply chain processes, KPIs, and potential risks.

Establish open reporting channels, define performance metrics upfront, and schedule regular check-ins. Use dashboards and shared platforms for real-time visibility into shipments, inventory, and fulfillment. Transparency ensures you remain in control of your supply chain, even when key functions are outsourced.

7. Monitor Performance and Quality Regularly

Outsourcing is not a “set it and forget it” arrangement. Continuous monitoring is essential to maintain standards and identify improvement opportunities.

Conduct periodic audits, evaluate SLA compliance, and collect customer feedback to measure service quality. Early detection of issues—such as delivery delays or inventory discrepancies—allows corrective action before they escalate. This proactive approach helps ensure that outsourcing relationships remain productive and aligned with your business needs.

Following these best practices—rigorous partner evaluation, scalability planning, strong relationships, clear contracts, technology integration, transparency, and ongoing monitoring—ensures that outsourcing in supply chain management delivers sustainable value and mitigates risks.

Role of Technology in Outsourcing Supply Chain Management

Technology has become the backbone of modern supply chain outsourcing. Without it, businesses and their outsourcing partners would struggle to achieve visibility, coordination, and efficiency across complex global networks. From real-time tracking to AI-driven insights, technology enables companies to maintain control while leveraging third-party expertise.

1. Enhancing Visibility and Transparency

One of the most significant contributions of technology in outsourcing is end-to-end supply chain visibility. Cloud-based dashboards, IoT sensors, and GPS tracking allow companies and their 3PL/4PL partners to monitor shipments, inventory levels, and delivery timelines in real time. This transparency reduces blind spots, empowers proactive decision-making, and builds trust between partners.

2. Driving Data-Driven Decision Making

Advanced analytics, powered by big data and AI, transform raw supply chain data into actionable insights. Companies can forecast demand, identify bottlenecks, and optimize routes or warehouse layouts. Outsourcing partners equipped with predictive analytics can prevent stockouts, manage seasonal demand fluctuations, and ensure more accurate order fulfillment.

3. Streamlining Inventory and Order Management

Digital tools enable outsourcing providers to automate critical functions such as inventory tracking, order processing, and fulfillment. Technologies like RFID, barcode scanning, and warehouse management systems (WMS) reduce manual errors while ensuring real-time synchronization with a company’s ERP or e-commerce platforms. This integration guarantees smoother order fulfillment and faster response to customer demands.

4. Improving Collaboration Between Stakeholders

Technology facilitates seamless collaboration across multiple supply chain stakeholders. Cloud-based communication platforms, shared data portals, and integrated systems ensure that all parties—manufacturers, logistics providers, and retailers—are aligned. Automated alerts and shared dashboards improve responsiveness and minimize delays in problem resolution.

5. Leveraging Automation and Robotics

Outsourcing partners are increasingly investing in warehouse automation technologies like autonomous mobile robots (AMRs), robotic picking systems, and automated sorting machines. These innovations accelerate order processing, minimize labor dependency, and reduce operational costs while delivering consistent accuracy.

6. Enabling Scalability Through Cloud Solutions

Cloud-based platforms are vital for scaling outsourced operations. Whether a company expands into new markets or faces seasonal surges, cloud technology allows outsourcing providers to scale capacity quickly without heavy infrastructure investments. This flexibility aligns perfectly with outsourcing’s goal of providing adaptable supply chain solutions.

7. Strengthening Risk Management

Global supply chains face risks ranging from natural disasters to cyberattacks. Technology helps mitigate these risks by providing predictive alerts, AI-driven contingency planning, and cybersecurity safeguards. For instance, blockchain can secure transaction records, ensuring data integrity and reducing fraud risks across outsourced networks.

Technology transforms outsourcing in supply chain management from a transactional service into a strategic partnership. By enabling visibility, automation, scalability, and risk management, it ensures that companies can outsource with confidence while maintaining agility and control.

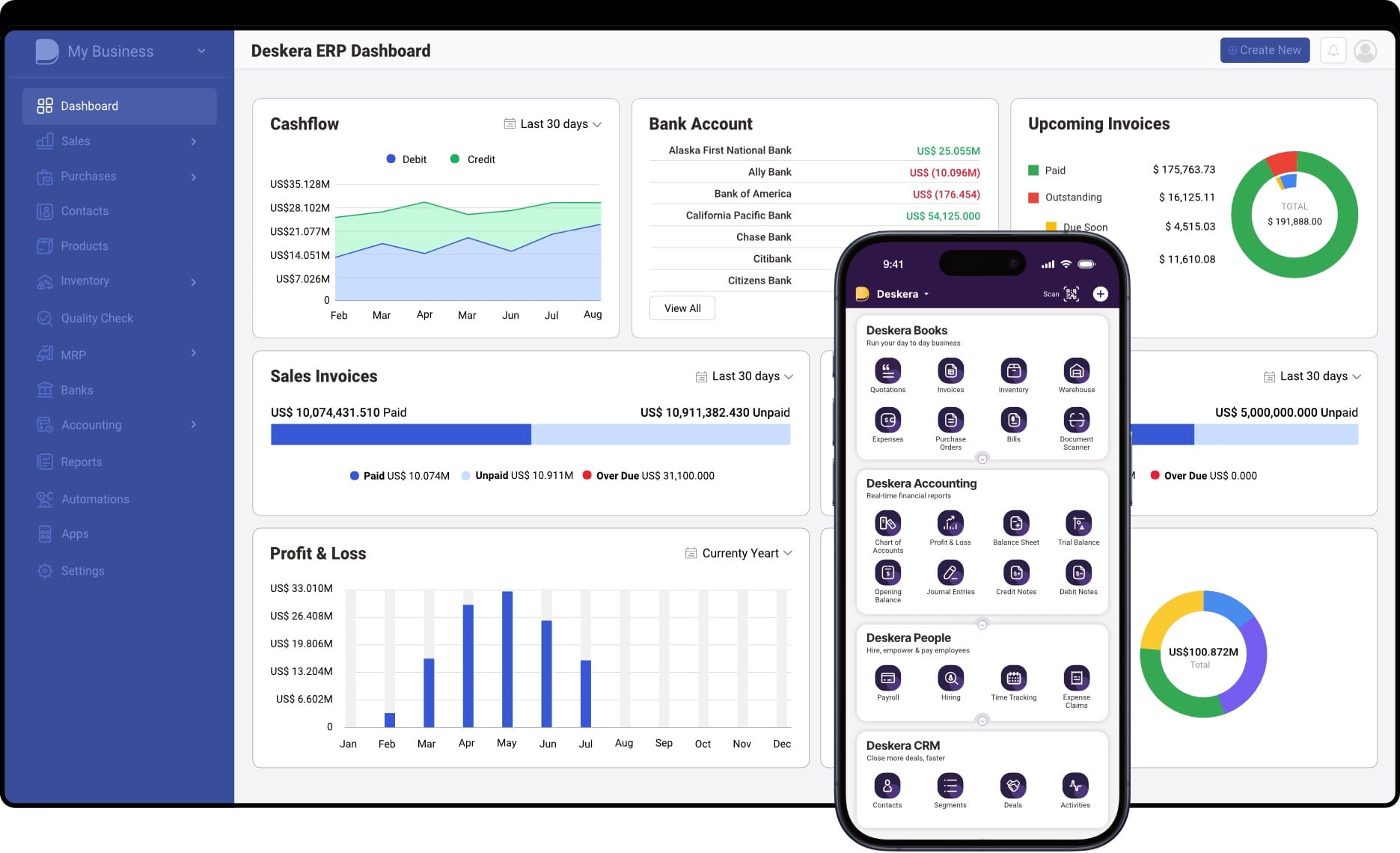

How Can Deskera ERP Help with Outsourcing Supply Chain Management?

Outsourcing supply chain management can bring immense value, but it also introduces challenges such as limited visibility, fragmented communication, and risks around quality or cost control. This is where Deskera ERP can play a transformative role by acting as the central nervous system that connects your business with outsourcing partners.

1. End-to-End Visibility

Deskera ERP provides real-time dashboards that allow you to monitor outsourced operations—whether warehousing, logistics, or procurement. This visibility ensures that even if you rely on third-party providers, you can still track inventory levels, order statuses, and delivery performance without blind spots.

2. Seamless Integration with Outsourcing Partners

Outsourced operations often involve multiple stakeholders, each using their own systems. Deskera ERP’s cloud-based platform can integrate with partner systems, ensuring smooth data sharing. This prevents delays, reduces duplication of effort, and keeps your internal teams aligned with your 3PL/4PL providers.

3. AI-Powered Forecasting and Planning

Managing outsourced supply chains requires precise forecasting to avoid overstocking or stockouts. Deskera ERP’s AI assistant, David, helps forecast demand, automate procurement, and suggest optimized production schedules. This ensures that outsourced partners work with accurate, data-driven instructions, minimizing inefficiencies.

4. Cost Control and Transparency

Outsourcing can introduce hidden costs, but Deskera ERP helps you track all expenses in one place—from logistics fees to procurement charges. Automated financial reporting and expense tracking make it easier to identify unexpected charges and keep outsourcing costs under control.

5. Streamlined Communication and Collaboration

Miscommunication is a common outsourcing risk. Deskera ERP offers centralized communication channels, shared data access, and automated alerts. This fosters better collaboration between your business and outsourcing partners, ensuring accountability and faster problem resolution.

6. Scalability and Flexibility

Outsourcing is often used to scale operations quickly. Deskera ERP supports this by offering cloud-based scalability. Whether you expand into new markets, outsource new functions, or experience seasonal demand spikes, Deskera ERP adapts without requiring heavy IT investments.

7. Enhanced Compliance and Risk Management

Global outsourcing introduces compliance challenges. Deskera ERP helps maintain records for audits, ensures documentation for regulatory requirements, and secures sensitive data. Its advanced reporting capabilities also support risk assessments and proactive contingency planning.

Deskera ERP empowers businesses to fully leverage outsourcing in supply chain management while reducing associated risks. With its AI-driven insights, real-time visibility, cost tracking, and seamless partner integration, Deskera ensures that outsourcing becomes a strategic advantage rather than an operational challenge.

Key Takeaways

- Businesses can outsource functions like procurement, warehousing, logistics, order fulfillment, and customer service to streamline operations and focus on core competencies.

- Benefits of Outsourcing in Supply Chain Management: Outsourcing reduces operational costs, improves efficiency, enhances scalability, and provides access to specialized expertise and advanced technologies.

- Risks and Challenges of Outsourcing Supply Chain Management: Risks such as limited control, hidden costs, quality issues, and dependency on third parties can disrupt operations—but proactive planning and oversight can mitigate them.

- Best Practices for Successful Outsourcing: Thorough partner evaluations, strong relationship management, detailed contracts, and robust technology integrations are essential to achieve outsourcing success.

- Role of Technology in Outsourcing Supply Chain Management: Digital tools like cloud platforms, IoT, AI, and real-time tracking systems enable transparency, collaboration, and smarter decision-making with outsourcing partners.

- How Deskera ERP Helps with Outsourcing Supply Chain Management: Deskera ERP provides end-to-end visibility, seamless integration, AI-powered forecasting, and cost control to turn outsourcing into a competitive advantage.

Related Articles