Leather manufacturing is an intricate process that necessitates meticulous attention to detail, quality control, and regulatory compliance. Compliance requirements in the leather manufacturing industry are intended to ensure that manufacturers prioritize sustainability, protect worker health and safety, and reduce the environmental impact of their operations.

The U.S. Environmental Protection Agency (EPA) has established national emission standards for hazardous air pollutants for the leather manufacturing industry. (Source: EPA)

With growing awareness of the environmental and social consequences of industrial processes, pressure is mounting on leather manufacturers to demonstrate their commitment to responsible manufacturing practices. Failure to meet these requirements can have serious effects, including legal penalties and reputational harm.

In this article, we will look at the compliance requirements that leather manufacturers must meet, as well as why compliance and sustainability are so substantial in the leather manufacturing industry.

We will also talk about the challenges that manufacturers face in meeting these requirements and offer practical advice on how to stay in compliance.

- Importance of Compliance Requirements in Leather Manufacturing

- Environmental Compliance for Leather Manufacturing

- Worker Safety and Health Compliance for Leather Manufacturing

- Chemical Management Compliance for Leather Manufacturing

- Compliance and Reporting Regulations for Leather Manufacturers

- What can Manufacturers do to Prioritize Compliance and Sustainability?

- How can MRP and ERP Systems Assist in Making Leather Production More Compliant?

- How can Deskera Help You?

- Key Takeaways

- Related Articles

Importance of Compliance Requirements in Leather Manufacturing

Compliance requirements play a crucial role in the leather manufacturing industry. They help ensure that leather manufacturers prioritize sustainability, protect the health and safety of workers, and minimize the impact of their operations on the environment. Compliance requirements are put in place by regulatory agencies to help ensure that manufacturers are operating in a responsible manner, following best practices, and adhering to legal standards.

In addition to protecting the environment and worker safety, compliance requirements also help maintain the reputation of leather manufacturers. Consumers are becoming increasingly aware of the social and environmental impacts of their purchasing decisions and are more likely to choose products from companies that prioritize sustainability and ethical practices.

By complying with regulations and demonstrating a commitment to responsible manufacturing, leather manufacturers can strengthen their brand and appeal to conscious consumers.

Finally, compliance requirements are essential for protecting the long-term viability of the leather manufacturing industry. By prioritizing sustainability and responsible manufacturing practices, leather manufacturers can help ensure that their operations are sustainable and that they are meeting the needs of present and future generations.

In this way, compliance requirements are crucial for the continued growth and success of the leather manufacturing industry.

Environmental Compliance for Leather Manufacturing

Environmental compliance is a critical aspect of the leather manufacturing industry. Leather production can have significant environmental impacts, particularly in terms of water and air pollution, waste generation, and greenhouse gas emissions. To mitigate these impacts, regulatory agencies have put in place a range of environmental compliance requirements that leather manufacturers must follow.

These requirements typically include limits on the discharge of pollutants into the air and water, restrictions on the use of hazardous materials, and conditions for the proper management and disposal of waste. Leather manufacturers must also ensure that their operations are energy-efficient and that they are reducing their carbon footprint wherever possible.

Complying with environmental regulations is a legal requirement and a social responsibility. By minimizing the environmental impacts of their operations, leather manufacturers can help protect the health and well-being of their workers, their communities, and the natural environment.

In addition, environmental compliance can also help companies to reduce their costs, increase their efficiency, and improve their reputation, particularly in the eyes of consumers who are increasingly concerned about the environmental impact of their purchases.

Overall, environmental compliance is essential for the long-term sustainability of the leather manufacturing industry and for the protection of the planet's natural resources.

Key Requirements for Air Quality, Water Quality, and Waste Management

There are several critical requirements that leather manufacturers must follow in order to comply with environmental regulations related to air quality, water quality, and waste management. These requirements include:

Air Quality:

Air quality is an important aspect of environmental compliance for leather manufacturers. Leather manufacturing processes can produce air pollutants such as volatile organic compounds (VOCs), particulate matter, and other hazardous air pollutants (HAPs).

These pollutants can have negative impacts on the environment and public health, including respiratory problems, skin irritation, and eye irritation. To ensure compliance with environmental regulations, leather manufacturers must meet specific requirements related to air quality.

The key requirements for air quality include:

- Emission limits: Regulatory agencies set specific emission limits for air pollutants that leather manufacturers must not exceed. These limits are based on the type of pollutant, the size of the facility, and the specific requirements of the regulatory agency.

- Monitoring: Leather manufacturers must install and maintain air monitoring equipment to measure the amount of pollutants emitted from their operations. This equipment must be calibrated regularly and maintained to ensure that it is accurate and reliable.

- Recordkeeping and reporting: Leather manufacturers must keep detailed records of their emissions, monitoring results, and compliance activities. These records must be made available to regulatory agencies upon request and must be kept for a specified period of time.

- Pollution control equipment: To minimize emissions, leather manufacturers must install and maintain air pollution control equipment such as dust collectors, scrubbers, and filters. This equipment must be designed, installed, and operated according to regulatory standards.

- Employee training: Leather manufacturers must provide training to their employees on air quality regulations, pollution prevention techniques, and the proper use and maintenance of pollution control equipment.

It is essential for leather manufacturers to prioritize air quality compliance to ensure that their operations are sustainable, responsible, and in line with environmental regulations.

Water Quality:

Water quality is another critical aspect of environmental compliance for leather manufacturers. Leather manufacturing processes require large amounts of water for various techniques such as soaking, washing, and finishing.

As a result, these operations can produce wastewater that may contain pollutants such as chemicals, metals, and organic compounds that can harm the environment and public health. To ensure compliance with environmental regulations, leather manufacturers must meet certain requirements related to water quality.

The key requirements for water quality include:

- Effluent limits: Regulatory agencies set specific effluent limits for pollutants that leather manufacturers must not exceed in their wastewater discharges. These limits are based on the type of pollutant, the size of the facility, and the specific requirements of the regulatory agency.

- Wastewater treatment: Leather manufacturers must install and maintain wastewater treatment systems to remove pollutants from their wastewater before it is discharged into the environment. These treatment systems must be designed, installed, and operated according to regulatory standards.

- Monitoring: Leather manufacturers must monitor their wastewater to ensure that they are meeting the effluent limits set by regulatory agencies. They must install and maintain monitoring equipment and provide the results to regulatory agencies upon request.

- Recordkeeping and reporting: Leather manufacturers must keep detailed records of their wastewater discharges, monitoring results, and compliance activities. These records must be made available to regulatory agencies upon request and kept for a specified period.

- Spill prevention and response: Leather manufacturers must have spill prevention and response plans in place to minimize the impact of accidental spills or releases of pollutants to waterways.

By complying with these critical requirements, leather manufacturers can minimize their impact on water quality, protect public health and the environment, and meet regulatory requirements. It is essential for leather manufacturers to prioritize water quality compliance to ensure that their operations are sustainable, responsible, and in line with environmental regulations.

Waste Management:

Waste management is an essential aspect of environmental compliance for leather manufacturers. Leather manufacturing processes generate significant waste, including solid waste and hazardous waste that can harm the environment and public health if not managed properly. To ensure compliance with environmental regulations, leather manufacturers must meet certain requirements related to waste management.

The key requirements for waste management include:

- Waste characterization: Leather manufacturers must identify and classify their waste according to regulatory requirements. They must determine if their waste is hazardous or non-hazardous and characterize it based on its physical and chemical properties.

- Storage: Leather manufacturers must store their waste correctly to prevent spills or releases to the environment. They must keep waste containers closed, labeled, and stored in designated areas that are secure and protected from weather conditions.

- Transportation: Leather manufacturers must transport their waste using registered and licensed transporters that comply with regulatory requirements. They must ensure that waste is properly packaged, labeled, and documented during transportation.

- Treatment and disposal: Leather manufacturers must treat and dispose of their waste according to regulatory requirements. Hazardous waste must be disposed of in a hazardous waste landfill or treated by an authorized facility. Non-hazardous waste must be disposed of in a landfill or treated by a licensed facility.

- Recordkeeping and reporting: Leather manufacturers must keep detailed records of their waste generation, storage, transportation, treatment, and disposal activities. These records must be made available to regulatory agencies upon request and must be kept for a specified period of time.

Overall, complying with these key requirements for air quality, water quality, and waste management is essential for leather manufacturers to operate in a responsible and sustainable manner, protect the environment, and meet regulatory requirements.

Importance of Complying with Environmental Regulations

Complying with environmental regulations is of utmost importance for businesses in all industries, including leather manufacturing. Environmental regulations are put in place by governments and regulatory agencies to protect the environment and public health, as well as to ensure that businesses operate in a responsible and sustainable manner. There are several reasons why it is important for leather manufacturers to comply with these regulations:

Protecting the environment:

Environmental regulations help protect the environment by reducing pollution and waste, conserving natural resources, and preserving ecosystems. Compliance with these regulations is essential to prevent environmental damage and ensure that the natural resources used in leather manufacturing are preserved for future generations.

Ensuring public health and safety:

Environmental regulations also aim to protect public health and safety by regulating the use and disposal of hazardous materials and pollutants. Compliance with these regulations is essential to prevent exposure to harmful substances and ensure that workers and local communities are safe.

Meeting legal requirements:

Compliance with environmental regulations is a legal requirement, and failure to comply can result in fines, legal action, and reputational damage. By complying with these regulations, leather manufacturers can avoid legal and financial penalties and maintain their reputation as a responsible and sustainable business.

This way they can maintain an adept financial planning and work towards profitable outcomes.

Meeting consumer expectations:

Consumers are increasingly concerned about the environmental impact of the products they buy and are more likely to choose products from companies that prioritize sustainability and ethical practices. Compliance with environmental regulations is therefore essential for leather manufacturers to meet consumer expectations and maintain a competitive edge.

In conclusion, complying with environmental regulations is essential for leather manufacturers to protect the environment, public health, and safety, meet legal requirements, and meet consumer expectations. By prioritizing sustainability and responsible manufacturing practices, leather manufacturers can build a reputation as a responsible and ethical business, while also ensuring their long-term success and viability.

Worker Safety and Health Compliance for Leather Manufacturing

Leather manufacturing processes involve the use of various chemicals and machinery that can pose health and safety risks to workers. Therefore, worker safety and health compliance is a critical aspect of leather manufacturing.

To ensure compliance with regulations and protect workers' safety and health, leather manufacturers must implement measures to identify and manage workplace hazards.

Key Requirements for Personal Protective Equipment, Hazard Communication, and Workplace Safety

Personal protective equipment (PPE), hazard communication, and workplace safety are critical aspects of compliance for leather manufacturers. To protect workers' safety and health, leather manufacturers must meet specific requirements related to PPE, hazard communication, and workplace safety.

PPE or Personal Protective Equipment

Personal protective equipment (PPE) is a crucial component of worker safety and health in leather manufacturing. PPE can protect workers from exposure to hazardous chemicals, physical hazards, and other workplace hazards. To ensure compliance with regulations and protect workers' safety and health, leather manufacturers must meet certain requirements related to PPE.

The key requirements for PPE in leather manufacturing include:

- Hazard assessment: Leather manufacturers must conduct a hazard assessment to identify workplace hazards and determine the need for PPE. The hazard assessment should consider the potential risks associated with the chemicals, machinery, and other equipment used in the workplace.

- Selection of appropriate PPE: Leather manufacturers must select appropriate PPE based on the hazards identified in the hazard assessment. The PPE should be suitable for the specific task and provide adequate protection against the identified hazards.

- Training: Leather manufacturers must provide workers with training on the proper use, maintenance, and disposal of PPE. Workers should understand the limitations of the PPE, how to inspect and maintain it, and when to replace it.

- Fit testing: Leather manufacturers must conduct fit testing for certain types of PPE, such as respirators. Fit testing ensures that the PPE provides adequate protection and fits properly.

- Maintenance and replacement: Leather manufacturers must maintain and replace PPE as necessary. PPE should be inspected regularly for damage or wear and replaced as needed.

It is essential for leather manufacturers to prioritize PPE compliance to ensure that their operations are sustainable, responsible, and in line with environmental regulations.

Hazard Communication

This is a critical aspect of compliance for leather manufacturers. Hazard communication refers to the process of identifying workplace hazards and communicating information about these hazards to workers. This information allows workers to understand the dangers they may be exposed to and take appropriate measures to protect themselves.

To ensure compliance with regulations and protect workers' safety and health, leather manufacturers must meet certain requirements related to hazard communication.

The key requirements for hazard communication in leather manufacturing include:

- Hazard identification: Leather manufacturers must identify and evaluate the hazards associated with their operations. This may include troubles related to chemicals, machinery, and other equipment used in the workplace.

- Labeling: Leather manufacturers must label hazardous chemicals with information about the hazards they pose and how to handle them safely. Labels should include the product name, hazard warnings, and instructions for safe use.

- Safety data sheets (SDS): Leather manufacturers must provide workers with safety data sheets (SDS) for hazardous chemicals used in the workplace. SDSs provide information about the hazards associated with the chemical, including information on health effects, handling, and emergency procedures.

- Training: Leather manufacturers must provide workers with training on the hazards associated with their job and the measures they should take to protect themselves. This training should cover hazard identification, labeling, and SDSs, as well as safe handling and storage practices.

- Updating hazard communication: Leather manufacturers must update hazard communication when new hazards are identified or when changes are made to chemicals or processes in the workplace.

Workplace Safety

Workplace safety refers to the measures taken to prevent workplace injuries and illnesses. To ensure compliance with regulations and protect workers' safety and health, leather manufacturers must meet certain requirements related to workplace safety.

The key requirements for workplace safety in leather manufacturing include:

- Written safety programs: Leather manufacturers must develop written safety programs that identify and address hazards in the workplace. These programs should include policies and procedures for hazard identification, control measures, training, and emergency response.

- Emergency preparedness: Leather manufacturers must have plans in place to respond to emergencies, such as fires or chemical spills. These plans should include evacuation procedures, emergency contacts, and procedures for dealing with hazardous materials.

- Machine guarding: Leather manufacturers must ensure that machinery and equipment are adequately guarded to prevent workers from coming into contact with hazardous moving parts. Guards should be in place on all machinery and equipment that poses a potential hazard.

- Electrical safety: Leather manufacturers must ensure that electrical systems and equipment are installed, maintained, and used in accordance with safety standards. Workers must be trained in safe work practices related to electrical systems and equipment.

- Walking and working surfaces: Leather manufacturers must ensure that walking and working surfaces are free from hazards, such as slip and trip hazards. Floors should be kept clean and dry, and workers should use appropriate footwear.

Importance of Complying with Worker Safety and Health Regulations

Complying with worker safety and health regulations is crucial for leather manufacturers to ensure the well-being of their workers, maintain a positive work environment, and minimize the risk of workplace injuries and illnesses. Failing to comply with these regulations can result in severe consequences, including fines, legal action, and damage to the company's reputation.

By complying with worker safety and health regulations, leather manufacturers can:

- Protect workers' health and safety: Complying with worker safety and health regulations helps to protect workers from workplace injuries, illnesses, and fatalities. This not only benefits workers themselves, but also ensures that the company has a healthy and productive workforce.

- Meet legal requirements: Complying with worker safety and health regulations is a legal requirement, and failing to do so can result in fines, legal action, and damage to the company's reputation.

- Avoid workplace accidents and injuries: Complying with worker safety and health regulations helps to minimize the risk of workplace accidents and injuries. This not only protects workers but also helps to reduce costs associated with workers' compensation, lost productivity, and increased insurance premiums.

- Improve company reputation: By prioritizing worker safety and health compliance, leather manufacturers can build a positive reputation among their employees, customers, and the wider community. This can help to attract and retain talent, improve customer loyalty, and increase market share.

In summary, complying with worker safety and health regulations is critical for leather manufacturers to ensure the well-being of their workers, meet legal requirements, avoid workplace accidents and injuries, and improve their reputation. By prioritizing compliance, leather manufacturers can create a safe and healthy work environment that benefits everyone involved.

Chemical Management Compliance For Leather Manufacturing

Chemical management compliance is a critical aspect of leather manufacturing to ensure the safety of workers, the environment, and consumers. Chemicals are commonly used in leather manufacturing for various processes, such as tanning, dyeing, and finishing. However, some chemicals can pose a risk to human health and the environment if not managed properly.

Therefore, leather manufacturers must comply with regulations related to chemical management to ensure the safe use, handling, and disposal of chemicals.

The key requirements for chemical management compliance in leather manufacturing include:

- Chemical inventory: Leather manufacturers must maintain an up-to-date inventory of all chemicals used in their operations. The inventory should include information on the quantity, location, and handling requirements for each chemical.

- Hazard communication: Leather manufacturers must ensure that all workers are trained in the hazards associated with the chemicals they use and are provided with appropriate personal protective equipment (PPE) when handling chemicals.

- Storage and handling: Leather manufacturers must store and handle chemicals in a way that minimizes the risk of spills, leaks, and other accidents. Chemicals should be stored in appropriate containers and in designated areas away from heat sources and incompatible materials.

- Disposal: Leather manufacturers must dispose of chemicals in accordance with local, state, and federal regulations. This may include labeling, transporting, and disposing of chemicals at a licensed facility.

- Recordkeeping: Leather manufacturers must maintain records related to chemical inventory, hazard communication, storage and handling, and disposal. These records must be kept up-to-date and readily available for inspection.

It is essential for leather manufacturers to prioritize chemical management compliance to ensure that their operations are sustainable, responsible, and in line with environmental regulations.

Key Requirements for Chemical Handling, Storage, and Disposal

Chemical handling, storage, and disposal are critical aspects of chemical management in leather manufacturing. Improper handling, storage, or disposal of chemicals can pose significant risks to workers, the environment, and the surrounding community.

Therefore, leather manufacturers must comply with regulations related to chemical handling, storage, and disposal to ensure the safe use, storage, and disposal of chemicals.

The key requirements for chemical handling, storage, and disposal in leather manufacturing include:

- Chemical labeling: All chemicals must be labeled with information such as the chemical name, hazards, and appropriate handling procedures.

- Chemical storage: Chemicals must be stored in appropriate containers and in designated areas away from heat sources and incompatible materials. They should be stored in a well-ventilated area and protected from direct sunlight.

- Chemical handling: Workers must be trained in safe chemical handling procedures, and provided with appropriate personal protective equipment (PPE) when handling chemicals. This includes gloves, goggles, and respirators, as appropriate.

- Spill response: Leather manufacturers must have a spill response plan in place in case of accidental spills or leaks. Workers should be trained in spill response procedures, and spill response equipment, such as spill kits and absorbent materials, should be readily available.

- Chemical disposal: Leather manufacturers must dispose of chemicals in accordance with local, state, and federal regulations. This may include labeling, transporting, and disposing of chemicals at a licensed facility.

- Recordkeeping: Leather manufacturers must maintain records related to chemical handling, storage, and disposal. These records must be kept up-to-date and readily available for inspection.

Importance of Complying with Chemical Management Regulations

Complying with chemical management regulations is of utmost importance for leather manufacturers as it ensures the safety of workers, protects the environment, and safeguards the health of the surrounding community. Failure to comply with chemical management regulations can result in legal liabilities, fines, and negative publicity, which can harm a company's reputation.

Additionally, non-compliance with chemical management regulations can result in hazardous working conditions for employees. Exposure to chemicals, whether through inhalation or skin contact, can result in serious health issues, such as skin irritation, respiratory problems, and even cancer.

By complying with chemical management regulations, leather manufacturers can ensure that workers are provided with adequate training, protective equipment, and a safe working environment.

Furthermore, complying with chemical management regulations also reduces the risk of environmental pollution. Chemicals that are not disposed of properly can contaminate soil, water, and air, and have long-lasting effects on the environment. Complying with regulations ensures that chemicals are properly stored, transported, and disposed of in a manner that minimizes environmental impact.

In conclusion, complying with chemical management regulations is not only a legal requirement, but also a moral and ethical responsibility for leather manufacturers. By prioritizing safe and responsible chemical management, leather manufacturers can protect their workers, the environment, and the community, while also maintaining their reputation and credibility in the market.

Compliance and Reporting Requirements for Leather Manufacturers

Compliance requirements refer to the specific regulations and standards that leather manufacturers must comply with, while reporting requirements refer to the documentation and reporting obligations that leather manufacturers must fulfill.

The compliance and reporting requirements for leather manufacturers may vary depending on the location and type of operations. However, some of the general compliance and reporting requirements for leather manufacturers are:

- Environmental permits: Leather manufacturers must obtain permits from regulatory agencies to operate legally. These permits specify the environmental standards and limits that leather manufacturers must comply with.

- Environmental monitoring: Leather manufacturers must monitor the emissions from their operations and the impact of their activities on the environment. They must also maintain records of environmental monitoring activities and report the results to regulatory agencies.

- Hazardous waste reporting: Leather manufacturers must report the generation, storage, and disposal of hazardous waste to regulatory agencies.

- Health and safety reporting: Leather manufacturers must report workplace injuries and illnesses, as well as incidents that could have resulted in injuries or illnesses, to regulatory agencies.

- Chemical reporting: Leather manufacturers must report information about the chemicals they use, store, and dispose of to regulatory agencies.

- Audits and inspections: Regulatory agencies may conduct periodic audits and inspections of leather manufacturers' operations to ensure compliance with regulations.

By complying with these requirements, leather manufacturers can demonstrate their commitment to responsible and sustainable operations, and ensure that they operate within the law. Failure to comply with compliance and reporting requirements can result in legal liabilities, fines, and negative publicity, which can harm a company's reputation.

In conclusion, leather manufacturers must prioritize compliance and reporting requirements to ensure that they operate responsibly, protect their workers and the environment, and maintain their credibility in the market.

Key Requirements for Recordkeeping, Reporting, and Inspections

Recordkeeping, reporting, and inspections are critical requirements for leather manufacturers to ensure compliance with regulations and operate responsibly. These requirements are designed to provide transparency and accountability in the manufacturing process, and to ensure that manufacturers are operating within the law.

Some of the key requirements for recordkeeping, reporting, and inspections for leather manufacturers include:

- Recordkeeping: Leather manufacturers must maintain accurate and complete records of their operations, including production, waste management, and chemical usage. These records must be kept for a specified period of time and must be made available for inspection upon request by regulatory agencies.

- Reporting: Leather manufacturers must submit regular reports to regulatory agencies that detail their compliance with regulations. These reports may include information on emissions, waste management, and chemical usage.

- Inspections: Regulatory agencies may conduct periodic inspections of leather manufacturing facilities to ensure compliance with regulations. These inspections may include reviewing records, observing operations, and collecting samples for analysis.

- Corrective action: If regulatory agencies identify non-compliance during an inspection or review of records, leather manufacturers may be required to take corrective action to address the issue.

- Training: Leather manufacturers must ensure that their employees are properly trained on recordkeeping, reporting, and inspection requirements, as well as compliance with regulations.

By meeting these requirements, leather manufacturers can demonstrate their commitment to responsible and sustainable operations, and ensure that they are operating within the law. Failure to comply with recordkeeping, reporting, and inspection requirements can result in legal liabilities, fines, and negative publicity, which can harm a company's reputation.

In conclusion, recordkeeping, reporting, and inspections are critical requirements for leather manufacturers to ensure compliance with regulations and operate responsibly. By prioritizing these requirements, leather manufacturers can protect their workers, the environment, and the community, while maintaining their credibility in the market.

Importance of Maintaining Accurate Records and Reporting Information in a Timely Manner

Maintaining accurate records and reporting information in a timely manner is crucial for leather manufacturers to ensure compliance with regulations, promote transparency, and avoid potential legal and financial consequences.

Firstly, accurate records provide evidence of compliance with regulations and demonstrate a commitment to responsible manufacturing practices. Without proper documents, it is difficult to demonstrate compliance with regulations, which can result in regulatory penalties, fines, and legal liabilities.

Secondly, timely reporting of information allows regulatory agencies to identify and address potential compliance issues quickly. This can prevent harm to workers, the environment, and the community, and mitigate the risk of costly enforcement actions.

Thirdly, accurate records and timely reporting can enhance a company's reputation for responsible and sustainable manufacturing practices. This can improve stakeholder confidence, attract customers, and enhance the company's competitiveness in the market.

On the other hand, failing to maintain accurate records and report information in a timely manner can result in legal liabilities, regulatory penalties, fines, and negative publicity. These consequences can harm a company's reputation, bottom line, and ability to operate in the market.

Thus, maintaining accurate records and reporting information in a timely manner is crucial for leather manufacturers to ensure compliance with regulations, promote transparency, and avoid potential legal and financial consequences.

By prioritizing these practices, leather manufacturers can demonstrate their commitment to responsible manufacturing practices and build stakeholder confidence.

What can Manufacturers do to Prioritize Compliance and Sustainability?

Manufacturers can take several steps to prioritize compliance and sustainability in their operations. Here are a few key actions they can take:

Develop a Comprehensive Compliance Program

This should include regular training for employees on regulations and best practices, as well as systems for tracking and reporting compliance metrics.

Conduct Regular Sustainability Assessments

This involves evaluating a company's environmental and social impact and identifying opportunities for improvement. Assessments can cover everything from waste reduction and energy efficiency to worker safety and community engagement.

Implement a Sustainability Strategy

Based on the results of sustainability assessments, companies can develop a strategy to prioritize sustainable practices and set measurable goals for improvement.

Engage Stakeholders

Manufacturers should engage with stakeholders including employees, customers, suppliers, and local communities to understand their concerns and priorities, and to ensure that sustainability and compliance efforts align with their expectations.

Invest in Technology and Innovation

Manufacturers can use technology and innovation to improve sustainability and compliance. For example, they can adopt digital systems to monitor and track compliance, implement renewable energy solutions to reduce carbon footprint, or invest in new materials and manufacturing processes that reduce environmental impact.

By taking these steps, manufacturers can prioritize compliance and sustainability in their operations and demonstrate their commitment to responsible manufacturing practices. This can help build stakeholder confidence, attract customers, and improve the company's competitiveness in the market.

How can MRP and ERP Systems Assist in Making Leather Production More Compliant?

MRP (Material Requirements Planning) and ERP (Enterprise Resource Planning) systems can assist leather manufacturers in making their production more compliant by providing a comprehensive framework for managing and tracking compliance-related activities.

Here are some ways in which these systems can help:

Centralized Data Management

MRP and ERP systems can centralize all data related to compliance requirements, including regulatory standards, reporting requirements, and inspection schedules. This ensures that all compliance-related information is readily available and accessible to relevant stakeholders.

Automated Tracking and Reporting

MRP and ERP systems can automate the tracking and reporting of compliance-related activities, such as chemical usage, waste management, and worker safety. This eliminates the need for manual tracking and reduces the risk of errors and omissions.

Real-time Monitoring

These systems can monitor compliance-related activities in real-time, such as emissions levels, energy usage, and worker safety incidents. This enables prompt identification of potential compliance issues, allowing companies to take corrective actions quickly.

Enhanced Visibility and Transparency

MRP and ERP systems provide enhanced visibility and transparency into compliance-related activities, allowing stakeholders to easily access information and monitor progress towards compliance goals.

Integration with Other Systems

These systems can be integrated with other software systems, such as environmental monitoring systems or quality control systems, allowing for a more comprehensive and integrated approach to compliance management.

In summary, MRP and ERP systems can assist leather manufacturers in making their production more compliant by providing a centralized, automated, and integrated approach to compliance management. By leveraging these systems, manufacturers can ensure compliance with regulatory requirements, promote transparency, and enhance stakeholder confidence in their operations.

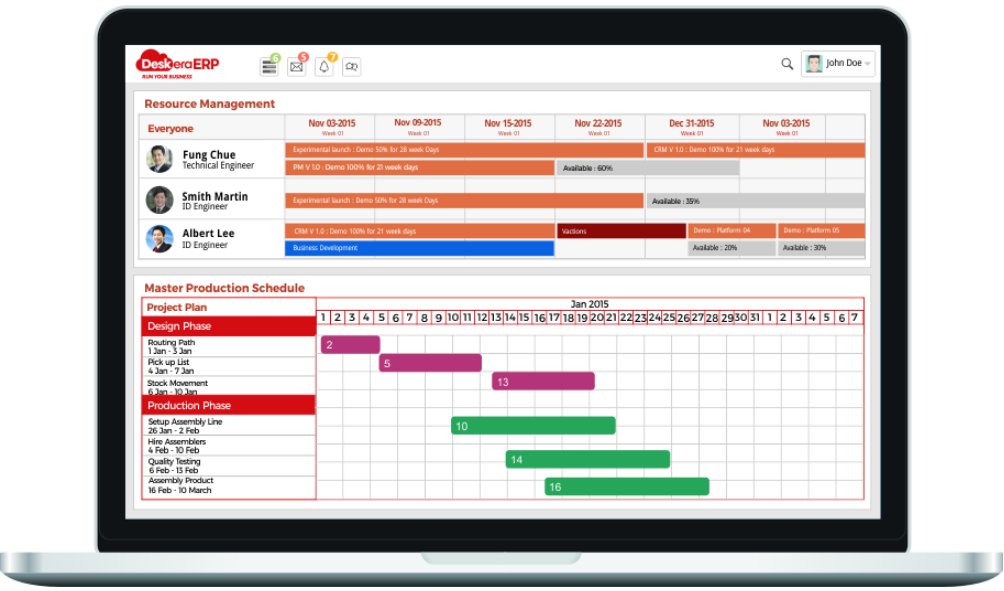

How can Deskera Help You?

Deskera ERP and MRP systems help you to keep your business units organized. The system's primary functions are as follows:

- Keep track of your raw materials and final items inventories

- Control production schedules and routings

- Keep a bill of materials

- Produce thorough reports

- Make your own dashboards

Deskera's integrated financial planning tools enable investors to better plan and track their investments. It can assist investors in making faster and more accurate decisions.

Deskera Books allows you to better manage your accounts and finances. Maintain good accounting practices by automating tasks like billing, invoicing, and payment processing.

Deskera CRM is a powerful solution that manages your sales and helps you close deals quickly. It not only enables you to perform critical tasks like lead generation via email, but it also gives you a comprehensive view of your sales funnel.

Deskera People is a straightforward tool for centralizing your human resource management functions.

Key Takeaways

- Compliance with environmental regulations is essential for leather manufacturers to maintain sustainability and protect the environment.

- Air quality, water quality, and waste management are key areas of environmental compliance that leather manufacturers must adhere to.

- Compliance with worker safety and health regulations is critical to ensure the well-being of employees and to avoid workplace accidents.

- Personal protective equipment, hazard communication, and workplace safety are key requirements for worker safety and health compliance.

- Chemical management compliance is important for leather manufacturers to prevent pollution and ensure safe handling, storage, and disposal of chemicals.

- Recordkeeping, reporting, and inspections are critical compliance and reporting requirements that leather manufacturers must follow to demonstrate compliance with regulations.

- Maintaining accurate records and reporting information in a timely manner is essential to avoid penalties and maintain compliance.

- Prioritizing compliance and sustainability requires a commitment from all levels of an organization, including senior management, production teams, and supply chain partners.

- Implementing MRP and ERP systems can assist leather manufacturers in making their production more compliant and sustainable by centralizing data management, automating tracking and reporting, and providing real-time monitoring.

Related Articles