Leather is a timeless material that has been used for centuries to create a variety of products. However, the production of leather is not without its environmental and social costs. The leather industry has a significant impact on the environment due to its use of water, chemicals, and energy, as well as the waste generated during the production process.

The global market for sustainable leather products is expected to grow by a compound annual growth rate of 4.7% between 2021 and 2028, according to a report by Grand View Research.

Additionally, the industry has been criticized for its labor practices, including the use of child labor and poor working conditions in some regions. In recent years, there has been a growing movement towards reducing waste and maximizing efficiency in leather production. By adopting sustainable and innovative practices, the industry can minimize its impact on the environment and promote social responsibility.

In this article, we will explore strategies for reducing waste and maximizing efficiency in leather production, as well as the benefits and challenges associated with these efforts.

- Importance of Reducing Waste and Maximizing Efficiency in the Leather Industry

- Understanding the Leather Production Process

- Strategies for Reducing Waste and Maximizing Efficiency in Leather Production

- Benefits of Waste Reduction and Efficiency Maximization in Leather Production

- Challenges and Potential Solutions

- Advantages of Implementing MRP and ERP Systems in Leather Production Business

- How can Deskera Help You?

- Key Takeaways

- Related Articles

Importance of Reducing Waste and Maximizing Efficiency in the Leather Industry

First and foremost, the production of leather has a significant impact on the environment, and reducing waste can help minimize this impact. Leather production consumes large amounts of water, energy, and chemicals, and generates significant amounts of waste, including solid waste and wastewater, which can harm ecosystems and pollute water sources.

Secondly, reducing waste and maximizing efficiency can result in significant cost savings for companies in the leather industry. By adopting sustainable and innovative practices, companies can reduce their resource consumption and production costs, which can ultimately improve their profitability.

Lastly, reducing waste and maximizing efficiency in the leather industry can promote social responsibility by improving working conditions and reducing the negative impact on communities where leather production takes place. This can enhance the reputation of companies in the leather industry and help them attract customers who value sustainability and social responsibility.

In essence, reducing waste and maximizing efficiency in the leather industry is essential to minimize the industry's environmental impact, improve profitability, and promote social responsibility.

Understanding the Leather Production Process

Understanding the leather production process is crucial for identifying areas where waste can occur and developing strategies to reduce waste and maximize efficiency, leading to a more sustainable and socially responsible leather industry.

In order to address the issue of waste reduction and efficiency maximization in the leather industry, it is essential to have a comprehensive understanding of the leather production process.

Overview of the Leather Production Process

The leather production process is a multi-step process that involves various stages, each of which contributes to the final product's quality and durability. The following is an overview of the leather production process:

- Pre-tanning: This is the initial stage of leather production that involves the preparation of the raw material. The hides or skins are washed, soaked, and de-haired to remove any impurities and prepare them for tanning.

- Tanning: This stage involves treating the hides or skins with chemicals to stabilize and preserve them. Tanning can be done using either vegetable or mineral tanning agents, such as chromium salts, which are commonly used in commercial tanning.

- Post-tanning: After the hides or skins are tanned, they undergo further processing to enhance their durability, texture, and appearance. This can involve operations such as dyeing, fatliquoring, and finishing.

- Cutting and sewing: The tanned leather is then cut and sewn into various products, such as shoes, jackets, bags, and furniture.

Throughout the leather production process, there are various opportunities for waste to occur, such as through excessive use of chemicals or water. By understanding each stage of the production process, companies can identify areas where waste can occur and develop strategies to reduce waste and maximize efficiency, leading to a more sustainable and socially responsible leather industry.

Steps Involved in Leather Production

The steps involved in leather production can be divided into the following categories:

Preparing the hides or skins

This involves cleaning, washing, and removing any impurities from the hides or skins. This step also includes soaking the hides or skins in water to make them more pliable for the tanning process.

Tanning

This is the process of treating the hides or skins with chemicals to stabilize and preserve them. There are several types of tanning methods, including vegetable tanning, chrome tanning, and synthetic tanning.

Post-tanning

After the hides or skins have been tanned, they undergo further processing to enhance their quality and appearance. This includes processes such as dyeing and finishing.

Cutting and sewing

Once the leather has been processed, it is cut and sewn into various products, such as shoes, jackets, bags, and furniture.

Throughout each stage of the leather production process, there are opportunities for waste to occur, such as through the excessive use of chemicals or water. By adopting sustainable and innovative practices, companies in the leather industry can reduce waste and maximize efficiency, leading to a more socially responsible and sustainable industry.

Areas where Waste can Occur in Leather Production

There are several areas where waste can occur in leather production, including:

- Water usage: Leather production requires significant amounts of water for soaking, washing, and rinsing. This can result in a significant amount of wastewater that requires treatment before being released into the environment.

- Chemical usage: Leather production also involves the use of various chemicals, such as tanning agents, dyes, and finishing chemicals. The excessive use of these chemicals can result in harmful waste byproducts that can pollute the environment.

- Energy consumption: The leather production process requires significant amounts of energy, such as electricity and fuel, for heating, drying, and processing.

- Solid waste: The leather production process can generate solid waste, such as trimmings, scraps, and dust, which can be difficult to dispose of sustainably.

- Packaging: The leather industry often relies on plastic packaging, which can contribute to waste generation and pollution.

By identifying these areas where waste can occur, companies in the leather industry can develop strategies to reduce waste and maximize efficiency, such as adopting sustainable production methods, implementing waste management strategies, and exploring alternative materials and packaging options.

Impact of Waste on the Environment and the Economy

Waste generated by leather production can have significant negative impacts on the environment and the economy.

Environmental Impact:

- Water pollution: Leather production requires large amounts of water, which can become contaminated with chemicals and other pollutants during the production process. This contaminated wastewater can be harmful to aquatic life and can pollute local waterways and ecosystems.

- Land pollution: The solid waste generated during leather production, such as trimmings and scraps, can accumulate in landfills and take years to decompose, contributing to soil pollution and greenhouse gas emissions.

- Air pollution: The chemicals used in the leather production process, such as tanning agents and dyes, can release harmful fumes and particulate matter into the air, contributing to poor air quality.

Economic Impact:

- Cost of waste disposal: Disposing of waste generated by leather production can be expensive and can impact a company's bottom line.

- Health costs: The negative health effects of exposure to hazardous waste generated by leather production can result in increased healthcare costs for employees and nearby communities.

- Consumer demand: With an increasing focus on sustainability, consumers are becoming more conscious of the environmental impact of the products they purchase. Companies that do not prioritize sustainability in their production process may face decreased consumer demand and a loss of market share.

By adopting sustainable practices and exploring alternative materials, companies in the leather industry can improve their environmental performance while also benefiting from increased cost savings and consumer demand.

Strategies for Reducing Waste and Maximizing Efficiency in Leather Production

The leather production process can generate significant waste and have negative impacts on the environment and the economy. Therefore, it is important for companies in the leather industry to implement strategies to reduce waste and maximize efficiency.

This section will provide an overview of the various strategies that companies can implement to achieve these goals, including water conservation, chemical management, energy efficiency, waste management, material efficiency, and transparency and traceability measures.

By adopting these strategies, companies can improve their environmental performance, reduce costs, and increase their competitiveness in the market.

Adopting Cleaner Production Methods

Adopting cleaner production methods is an effective strategy for reducing waste and minimizing the environmental impact of leather production. Cleaner production refers to the continuous application of an integrated preventive strategy applied to processes, products, and services to increase eco-efficiency and reduce risks to human health and the environment.

Some examples of cleaner production methods that can be adopted in leather production include:

- Low-impact tanning: Low-impact tanning methods, such as vegetable or chrome-free tanning, use less water and fewer hazardous chemicals, resulting in lower levels of waste and pollution.

- Natural dyes: Natural dyes, made from plant-based materials, can replace synthetic dyes that can be harmful to the environment and human health.

- Improved process controls: Implementing process controls, such as pH and temperature monitoring, can reduce the need for excessive water and chemical usage, resulting in less waste generation.

- Closed-loop systems: Closed-loop systems can help reduce water usage by recycling and reusing water in the production process.

- Green chemistry: Green chemistry involves the use of safer, eco-friendly chemical alternatives that reduce the environmental impact of leather production.

Utilizing Waste as a Resource

Utilizing waste as a resource is another effective strategy for reducing waste and maximizing efficiency in leather production. Rather than disposing of waste materials, companies can find ways to reuse or repurpose them. Some examples of utilizing waste as a resource in leather production include:

- Recycling leather scraps: Leather scraps can be recycled into new leather products or used as a raw material for other products, such as furniture upholstery or accessories.

- Composting: Leather shavings and scraps can be composted to produce organic fertilizer for plants and crops.

- Biogas production: Organic waste materials from leather production, such as hair and fleshings, can be used to produce biogas through anaerobic digestion, which can then be used as a renewable energy source.

- Water treatment: Wastewater from leather production can be treated and reused for non-potable purposes, such as cleaning or irrigation.

By utilizing waste as a resource, companies in the leather industry can reduce the amount of waste sent to landfills, conserve resources, and reduce their environmental impact. This can also lead to cost savings, as reusing waste materials can reduce the need for virgin raw materials. Additionally, utilizing waste as a resource can help companies meet their sustainability goals and enhance their reputation as environmentally responsible businesses.

Implementing Sustainable Sourcing Practices

Sustainable sourcing refers to the procurement of raw materials in a manner that is environmentally, socially, and economically responsible. Some examples of sustainable sourcing practices that can be implemented in leather production include:

- Traceability: Ensuring traceability in the supply chain can help companies identify and address any environmental or social issues associated with their raw material sourcing.

- Sustainable farming practices: Sourcing leather from suppliers that practice sustainable farming methods, such as regenerative agriculture or agroforestry, can reduce the environmental impact of leather production.

- Animal welfare standards: Ensuring that animal welfare standards are met throughout the supply chain can improve the ethical and social sustainability of leather production.

- Local sourcing: Sourcing raw materials locally can reduce transportation emissions and support local communities.

By implementing sustainable sourcing practices, companies in the leather industry can reduce their environmental and social impact, enhance their reputation as responsible businesses, and meet the growing demand for sustainable and ethical products from consumers.

Additionally, sustainable sourcing practices can help companies build stronger relationships with their suppliers and create long-term value for all stakeholders involved in the supply chain.

Reducing Energy Consumption in Production

Leather production is an energy-intensive process, and reducing energy consumption can help companies lower their operational costs and reduce their carbon footprint. Some examples of reducing energy consumption in leather production include:

- Energy-efficient equipment: Investing in energy-efficient machinery and equipment, such as boilers and compressors, can help companies reduce their energy consumption and lower their operating costs.

- Renewable energy sources: Utilizing renewable energy sources, such as solar or wind power, can help companies reduce their reliance on non-renewable energy sources and lower their carbon footprint.

- Energy management systems: Implementing energy management systems, such as real-time monitoring and control of energy use, can help companies identify areas where energy consumption can be reduced.

- Lighting and heating controls: Installing lighting and heating controls, such as motion sensors or timers, can help companies reduce energy consumption in their facilities.

Additionally, implementing energy-saving measures can help companies meet regulatory requirements and enhance their reputation as environmentally responsible businesses.

Recycling and Reusing Waste Materials

Leather production involves the use of various materials, chemicals, and processes that generate a significant amount of waste. Recycling and reusing waste materials can help reduce waste and maximize efficiency in leather production.

Recycling involves collecting and processing waste materials such as leather scraps, trimmings, and offcuts, and turning them into new products. For example, leather scraps can be shredded and reprocessed into new leather products, such as belts or small leather goods. Recycling not only reduces waste but also saves resources by reducing the need for new raw materials.

Reusing waste materials involves finding new uses for materials that would otherwise be discarded. For example, leather scraps can be used to make leather furniture or clothing accessories, such as patches or appliques. By reusing waste materials, leather manufacturers can reduce the amount of waste sent to landfills and maximize the value of their raw materials.

By adopting recycling and reusing practices, leather manufacturers can minimize their environmental impact and increase their efficiency. These practices not only help reduce waste but also reduce the need for new raw materials, save energy, and conserve natural resources. Additionally, by reducing waste, manufacturers can lower their disposal costs and potentially increase their profits.

Investing in Technology and Innovation

Technology and innovation can help companies improve their processes, reduce waste, and enhance their environmental performance. Some examples of technology and innovation in leather production include:

- Digitalization: Digitalization can help companies improve their supply chain management, reduce waste, and enhance their production processes. For example, digital tools can be used to optimize production planning, reduce energy consumption, and track material usage.

- Automation: Automation can help companies reduce the labor required for leather production, increase productivity, and reduce waste. For example, automated cutting machines can help reduce material waste, while automated dyeing processes can help reduce water usage.

- Chemical innovations: New chemicals and treatments can help companies reduce the environmental impact of leather production. For example, eco-friendly tanning methods can reduce the use of hazardous chemicals, while water-based finishes can reduce the use of solvents.

- Sustainable materials: Developing new sustainable materials, such as leather made from plant-based materials, can help companies reduce their environmental impact and meet the growing demand for sustainable products from consumers.

By investing in technology and innovation, companies in the leather industry can enhance their environmental performance, reduce waste, and meet the growing demand for sustainable and eco-friendly products. Additionally, investing in technology and innovation can help companies stay competitive in a rapidly evolving market and enhance their reputation as innovative businesses.

Benefits of Waste Reduction and Efficiency Maximization in Leather Production

Reducing waste and maximizing efficiency in leather production can bring numerous benefits to companies, the environment, and society as a whole. By reducing waste, companies can lower their operational costs, increase productivity, and improve their overall financial performance.

Additionally, reducing waste can help companies meet regulatory requirements, enhance their environmental performance, and improve their reputation as environmentally responsible businesses. Maximizing efficiency can also help companies reduce their carbon footprint, conserve resources, and enhance their sustainability.

Furthermore, reducing waste and maximizing efficiency can lead to job creation, economic growth, and a healthier environment, benefitting both society and the planet as a whole.

Reduced Environmental Impact

Reducing waste and maximizing efficiency in leather production can significantly reduce the environmental impact of the industry. By implementing cleaner production methods, sustainable sourcing practices, and recycling waste materials, companies can reduce their carbon footprint and conserve resources.

This can lead to a reduction in greenhouse gas emissions, energy consumption, and water usage, as well as a decrease in waste sent to landfills. By reducing their environmental impact, companies in the leather industry can help protect natural resources and ecosystems, preserve biodiversity, and mitigate the effects of climate change.

Additionally, reducing environmental impact can enhance the reputation of companies as environmentally responsible businesses, which can lead to increased customer loyalty, improved brand image, and potential financial benefits.

Cost Savings

By adopting cleaner production methods and sustainable sourcing practices, companies can reduce their operational costs, such as energy and water consumption, and waste disposal fees. By utilizing waste as a resource and recycling materials, companies can reduce the amount of raw materials needed for production, thereby reducing material costs.

Furthermore, by investing in technology and innovation, companies can improve their production processes and reduce labor costs. In addition to reducing costs, waste reduction and efficiency maximization can also lead to increased profitability and improved financial performance, as companies are able to produce more products at a lower cost.

Overall, reducing waste and maximizing efficiency can bring significant financial benefits to companies in the leather industry.

Improved Product Quality

By adopting cleaner production methods, companies can reduce the use of hazardous chemicals, which can improve the health and safety of workers and consumers. Sustainable sourcing practices can also ensure the quality of the materials used in leather production, leading to higher quality products.

Additionally, by recycling and reusing waste materials, companies can ensure consistency in product quality, as well as reduce defects and errors in production. Investing in technology and innovation can also lead to improved product quality, as automated processes can ensure precision and accuracy in production.

By improving product quality, companies can enhance customer satisfaction, improve brand loyalty, and increase sales.

Increased Competitiveness in the Global Market

Companies that can demonstrate their commitment to reducing waste and increasing efficiency can also improve their reputation and brand image, making them more attractive to environmentally conscious consumers. By adopting sustainable practices, companies can meet the growing demand for environmentally responsible products and differentiate themselves from competitors who do not prioritize sustainability.

Furthermore, by reducing costs and improving product quality, companies can offer competitive pricing and high-quality products that can help them stand out in the global market. Finally, by investing in technology and innovation, companies can stay ahead of the curve and remain competitive in an ever-changing market.

Overall, reducing waste and maximizing efficiency can help companies in the leather industry stay competitive and thrive in the global market.

Challenges and Potential Solutions

While reducing waste and maximizing efficiency in leather production can bring many benefits, there are also some challenges that need to be addressed. One of the main challenges is the lack of awareness and understanding of sustainable practices among industry players, which can make it difficult to implement new strategies.

Additionally, some sustainable practices may require significant investment in technology and infrastructure, which can be a barrier for small and medium-sized enterprises. Finally, the global nature of the industry and varying regulations and standards across different countries can also present challenges in implementing sustainable practices.

However, potential solutions to these challenges include education and awareness-raising initiatives, government incentives and support for sustainable practices, and collaboration among industry players to share knowledge and resources.

Overall, addressing these challenges can help promote sustainability in the leather industry and ensure a more environmentally responsible and economically viable future for the sector.

Barriers to Implementing Waste Reduction and Efficiency Maximization Strategies

Implementing waste reduction and efficiency maximization strategies in the leather industry can face several barriers, including lack of awareness, financial constraints, and regulatory challenges.

Firstly, there is a lack of awareness and understanding of sustainable practices in the industry, which can make it difficult to implement new strategies. Many stakeholders may not be aware of the potential benefits of waste reduction and efficiency maximization, or they may not know how to implement these strategies effectively.

Secondly, implementing sustainable practices can require significant investment in technology and infrastructure, which can be a barrier for small and medium-sized enterprises with limited financial resources.

Finally, the leather industry operates in a global market with varying regulations and standards across different countries. This can make it challenging to implement sustainable practices that are consistent with regulatory requirements in different regions.

However, there are potential solutions to these barriers. These include education and awareness-raising initiatives to increase knowledge and understanding of sustainable practices, government incentives and support for sustainable initiatives, and collaboration among industry players to share knowledge and resources.

Addressing these barriers can help promote sustainability in the leather industry and ensure a more environmentally responsible and economically viable future for the sector.

Possible Solutions to Overcome these Barriers

There are several potential solutions to overcome the barriers to implementing waste reduction and efficiency maximization strategies in the leather industry:

- Education and awareness-raising: Industry stakeholders can be educated about the benefits of sustainable practices, and how to implement these strategies effectively. This can be done through workshops, training programs, and online resources.

- Financial support: Government incentives and support can help small and medium-sized enterprises to invest in sustainable technologies and infrastructure. Financial support can include tax breaks, grants, and low-interest loans.

- Collaboration: Collaboration among industry players can help share knowledge and resources, and promote the adoption of sustainable practices. This can be done through industry associations, partnerships, and knowledge-sharing platforms.

- Regulation: Governments can set regulatory standards and requirements for sustainable practices, providing clear guidance for the industry. This can create a level playing field and encourage more widespread adoption of sustainable practices.

- Technology and innovation: Investment in research and development can help create new, more sustainable technologies and processes for leather production. This can help reduce waste and increase efficiency, while also improving the environmental impact of the industry.

Overall, a combination of these solutions can help overcome the barriers to implementing waste reduction and efficiency maximization strategies in the leather industry, promoting sustainability and ensuring a more environmentally responsible and economically viable future for the sector.

Collaboration and Partnerships in the Industry

By sharing knowledge and resources, stakeholders can work together to identify best practices and promote the adoption of sustainable practices throughout the supply chain.

One way to foster collaboration is through industry associations and initiatives. For example, the Leather Working Group (LWG) is a global membership organization that promotes sustainable environmental practices in the leather industry. The LWG has developed a protocol for the environmental assessment of leather production facilities, which helps ensure that environmental standards are met across the industry.

Similarly, the Sustainable Apparel Coalition (SAC) is an industry group that works to promote sustainable practices in the apparel and footwear industries, including leather production.

Collaboration can also occur through partnerships between industry players, including suppliers, manufacturers, and retailers. For example, a retailer may partner with a manufacturer to promote sustainable practices throughout the supply chain, including the sourcing of sustainable materials, reducing waste, and improving energy efficiency.

Overall, collaboration and partnerships can help promote sustainability in the leather industry by sharing knowledge, resources, and best practices. This can help drive the adoption of sustainable practices throughout the supply chain and promote a more environmentally responsible and economically viable future for the sector.

Advantages of Implementing MRP and ERP Systems in Leather Production Business

Implementing MRP (Material Requirements Planning) and Enterprise Resource Planning (ERP) systems in a leather production business can offer several advantages, including:

- Improved Inventory Management: MRP systems can help manage inventory levels by providing real-time data on raw material and product inventory, ensuring that production runs smoothly and efficiently.

- Increased Production Efficiency: By automating and streamlining production cycles, ERP systems can help minimize waste, reduce lead times, and improve overall production efficiency.

- Enhanced Supply Chain Visibility: MRP and ERP systems can provide real-time data on the entire supply chain, including suppliers, manufacturers, and customers. This can help identify potential bottlenecks and supply chain disruptions, enabling proactive management and optimization.

- Improved Decision-Making: With access to real-time data and analytics, managers can make more informed decisions about production, inventory, and other business processes, leading to improved productivity and profitability.

- Better Customer Service: By providing real-time data on inventory levels, production schedules, and delivery times, MRP and ERP systems can help improve customer service, leading to increased customer satisfaction and loyalty.

Overall, implementing MRP and ERP systems in a leather production business can help improve productivity, efficiency, and profitability, while also enhancing supply chain visibility and customer service.

How can Deskera Help You?

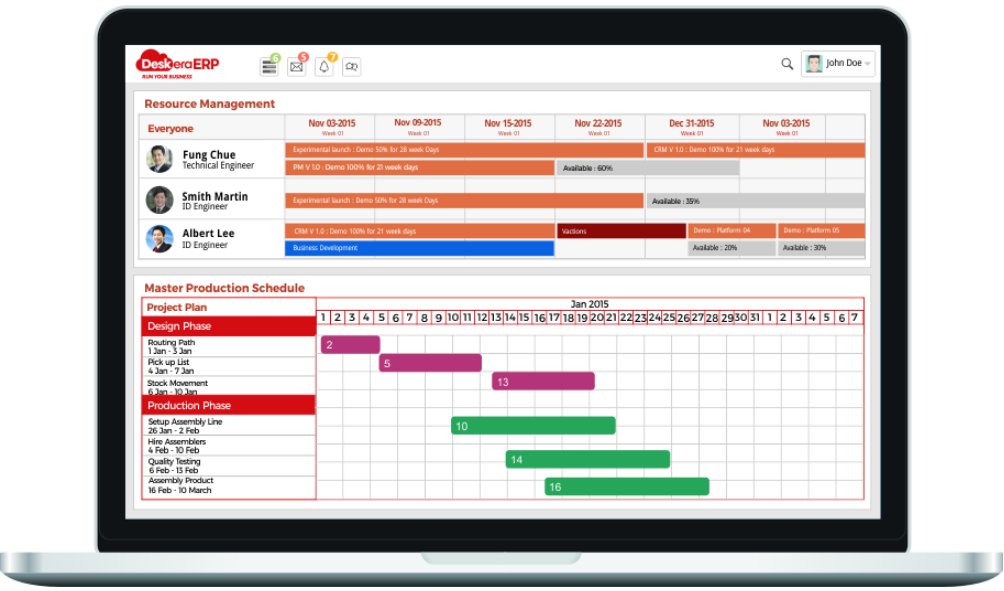

Deskera ERP and MRP systems help you to keep your business units organized. The system's primary functions are as follows:

- Keep track of your raw materials and final items inventories

- Control production schedules and routings

- Keep a bill of materials

- Produce thorough reports

- Make your own dashboards

Deskera's integrated financial planning tools enable investors to better plan and track their investments. It can assist investors in making faster and more accurate decisions.

Deskera Books allows you to better manage your accounts and finances. Maintain good accounting practices by automating tasks like billing, invoicing, and payment processing.

Deskera CRM is a powerful solution that manages your sales and helps you close deals quickly. It not only enables you to perform critical tasks like lead generation via email, but it also gives you a comprehensive view of your sales funnel.

Deskera People is a straightforward tool for centralizing your human resource management functions.

Key Takeaways

- The leather production process involves several steps, including tanning, dyeing, and finishing, which can result in significant waste if not managed properly.

- Waste in the leather industry can have a negative impact on the environment, including pollution of waterways and landfills.

- The adoption of cleaner production methods, utilization of waste as a resource, and implementation of sustainable sourcing practices can all help reduce waste and improve efficiency in leather production.

- Reducing energy consumption and investing in technology and innovation can also help increase efficiency and reduce waste.

- Recycling and reusing waste materials, such as leather scraps and trimmings, can help minimize waste and promote sustainability.

- Adopting these strategies can have several benefits, including reduced environmental impact, cost savings, improved product quality, and increased competitiveness in the global market.

- However, implementing these strategies can face barriers, such as lack of awareness, upfront costs, and resistance to change.

- Possible solutions to overcome these barriers include collaboration and partnerships among industry players, government incentives and regulations, and public awareness campaigns.

- Industry associations and initiatives, such as the Leather Working Group and Sustainable Apparel Coalition, can help promote sustainable practices throughout the leather supply chain.

- Implementing Material Requirements Planning (MRP) and Enterprise Resource Planning (ERP) systems can also help improve efficiency and reduce waste in leather production.

- The leather industry must continue to evolve and adopt sustainable practices to meet the growing demand for environmentally responsible and socially conscious products.

Related Articles