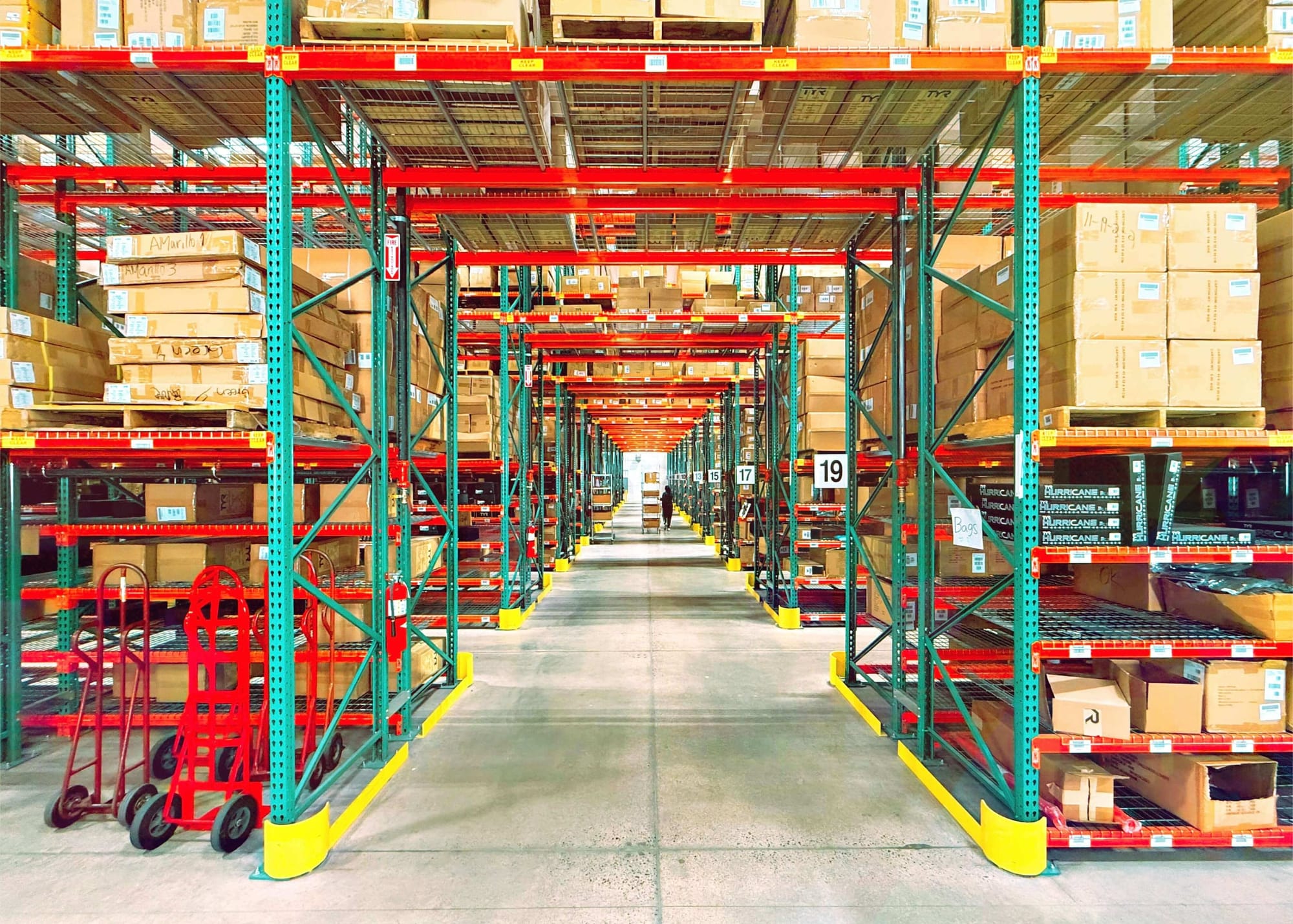

Ever wondered how leading warehouses maintain near-perfect inventory accuracy without halting operations for time-consuming physical counts? The answer lies in inventory cycle counting — a systematic, ongoing process that helps businesses track stock levels efficiently while keeping daily operations uninterrupted. Rather than counting every single item at once, cycle counting divides the task into manageable segments, allowing teams to identify errors and adjust records throughout the year.

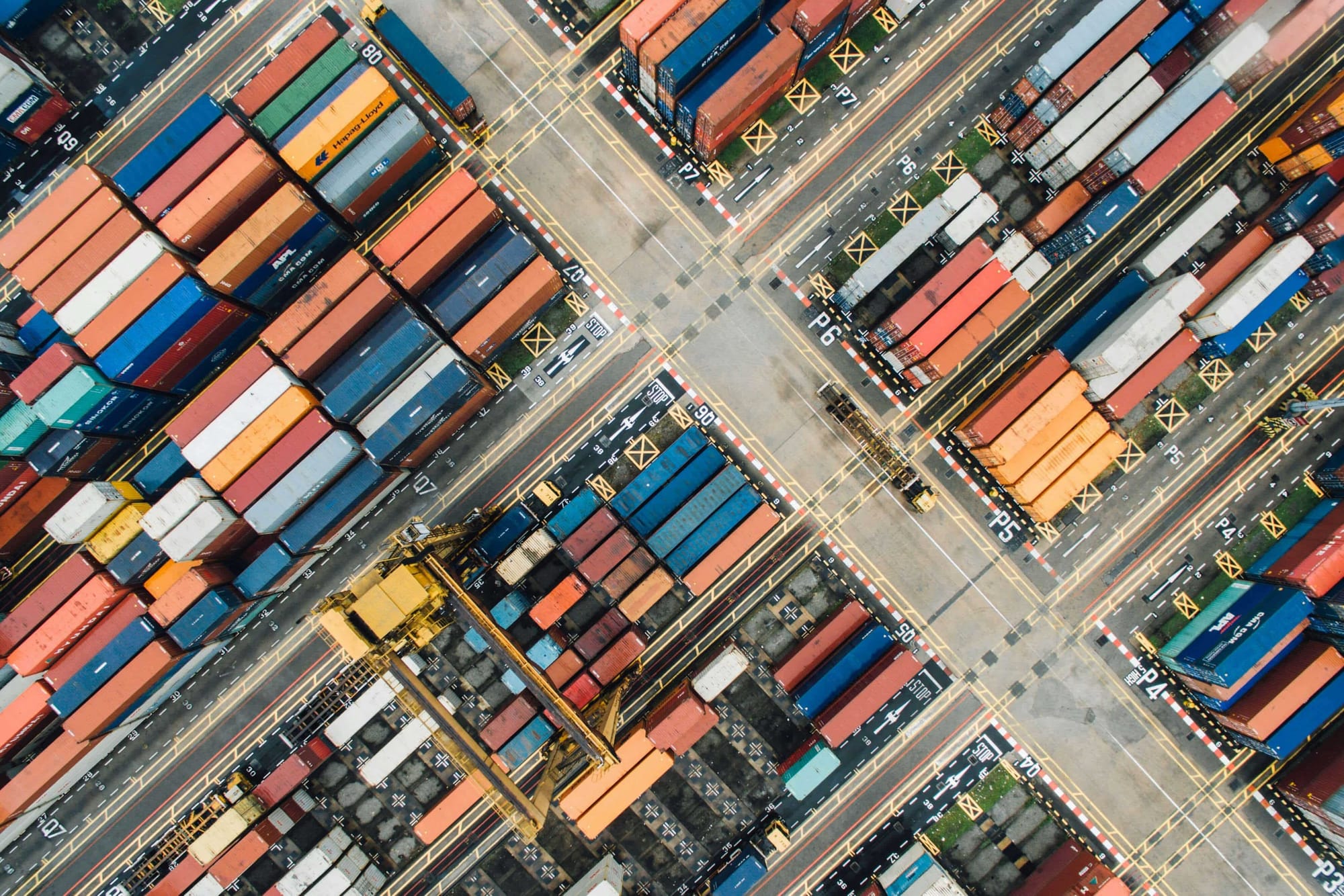

In today’s competitive logistics and manufacturing landscape, accuracy and efficiency are non-negotiable. Even a small mismatch between physical and recorded inventory can lead to stockouts, overstocking, or delayed deliveries — all of which directly impact profitability and customer satisfaction. Cycle counting serves as a proactive approach to minimize such errors, ensuring inventory data remains reliable and up to date.

Moreover, this method empowers warehouse managers to operate smarter, not harder. By focusing on high-value or high-turnover items more frequently, businesses can allocate resources more effectively and enhance operational transparency. As warehouses grow in size and complexity, adopting a structured cycle counting program becomes essential to streamline processes and maintain real-time visibility into stock movements.

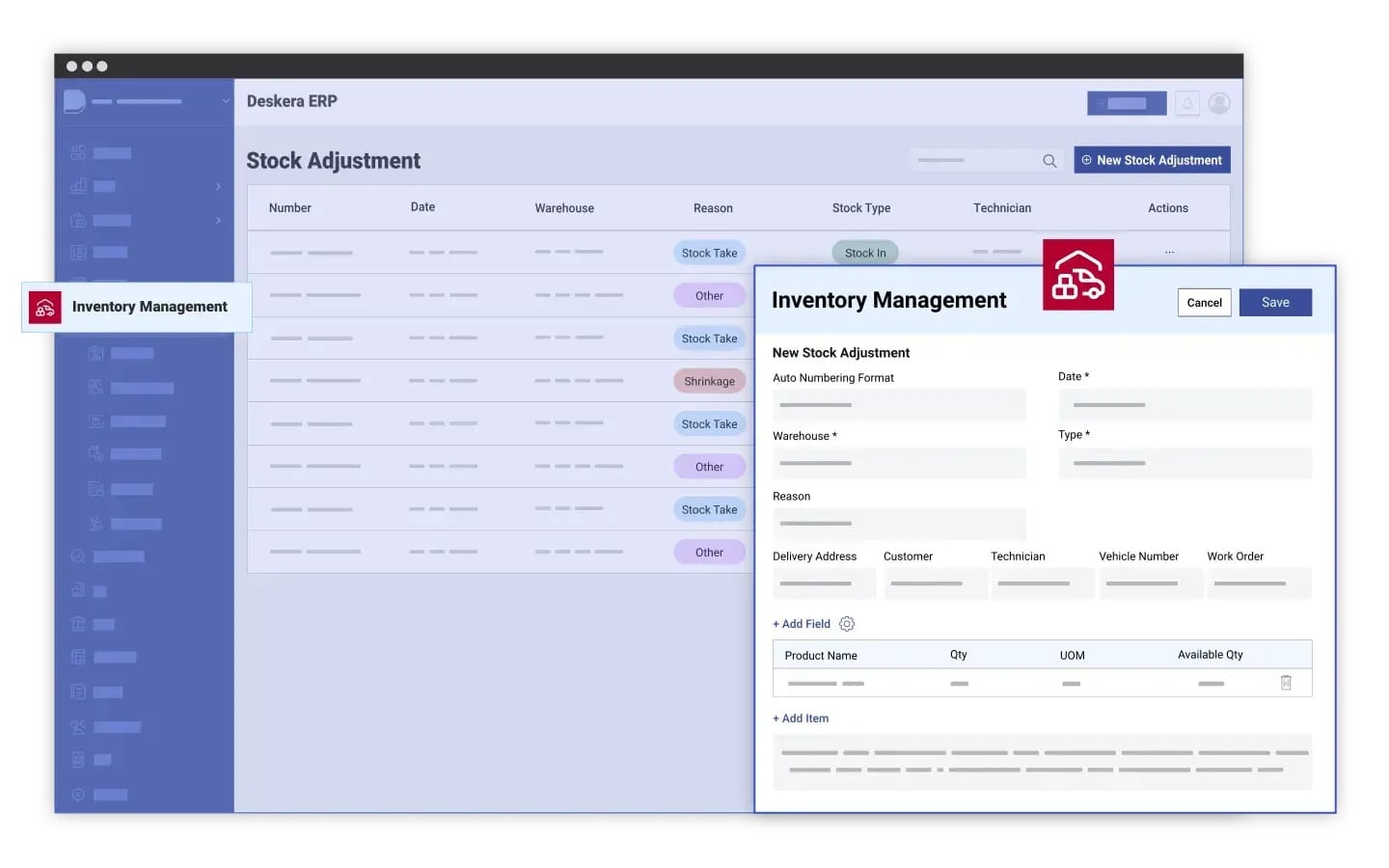

This is where Deskera ERP makes a real difference. With its integrated inventory management features, Deskera automates cycle counting, updates stock data in real time, and provides clear visibility across all warehouse operations. Its AI-powered assistant, David, helps track discrepancies, generate reports, and optimize stock levels — all from a single, easy-to-use platform. By combining automation with actionable insights, Deskera ERP enables businesses to maintain accuracy, efficiency, and control across every stage of their warehouse operations.

What Is Inventory Cycle Counting?

Inventory cycle counting is a systematic inventory auditing method where a small, manageable portion of stock is counted on a regular schedule—daily, weekly, or monthly—rather than performing a full physical count all at once. This approach enables businesses to verify stock levels, identify discrepancies early, and maintain accurate inventory records without interrupting daily warehouse operations.

In simple terms, cycle counting is like conducting “mini audits” throughout the year instead of shutting down operations for a massive year-end inventory count. Warehouse staff count selected SKUs or specific storage locations on a rotating basis, ensuring that every item is verified over time. This process helps synchronize what’s physically available on shelves with what’s recorded in the inventory management system.

Cycle counting is especially valuable for large warehouses or businesses managing a diverse range of products. It not only ensures ongoing inventory accuracy but also helps prevent costly issues such as stockouts, overstocking, and order delays. By continuously validating stock data, companies can respond faster to supply chain changes and make more informed decisions about replenishment and purchasing.

Unlike traditional physical audits, which can halt operations and require extensive manpower, cycle counting integrates seamlessly into everyday workflows. When supported by technology—such as ERP and Warehouse Management Systems (WMS)—it becomes even more efficient. These systems allow for real-time updates, automated scheduling, and instant error detection, ensuring that businesses maintain precise inventory visibility at all times.

Cycle Counting vs. Physical Inventory Count

While both cycle counting and physical inventory counts aim to ensure inventory accuracy, they differ significantly in approach, frequency, and operational impact. Understanding these differences helps businesses choose the method best suited to their warehouse size, complexity, and goals.

Below is a detailed comparison highlighting how each method functions and where cycle counting holds an advantage over traditional physical counts.

1. Definition and Approach

Cycle Counting: Cycle counting involves counting a small, manageable portion of inventory on a recurring schedule—daily, weekly, or monthly. It’s a continuous auditing process that allows warehouses to verify stock accuracy throughout the year without halting operations.

Physical Inventory Count: A physical inventory count is a comprehensive audit where the entire inventory is counted at once, often annually or semi-annually. This process typically requires shutting down normal operations to ensure an accurate count across all stock items.

2. Frequency and Timing

Cycle Counting: Performed regularly in smaller segments, such as by product category, warehouse zone, or value class. This flexibility allows businesses to identify and fix discrepancies in real time.

Physical Inventory Count: Usually done once or twice a year, requiring extensive preparation and manpower. Because it’s infrequent, discrepancies might go unnoticed for long periods.

3. Impact on Operations

Cycle Counting: Has minimal operational disruption since it integrates seamlessly into daily warehouse activities. Staff can perform counts alongside normal duties, ensuring continuous accuracy.

Physical Inventory Count: Often requires halting warehouse operations, suspending shipments, and dedicating full days—or even weeks—to counting. This leads to downtime, labor costs, and possible delays in order fulfillment.

4. Accuracy and Error Detection

Cycle Counting: Encourages consistent monitoring and quicker detection of errors. Since discrepancies are caught early, corrective measures can be taken promptly, maintaining high data accuracy.

Physical Inventory Count: Provides a one-time snapshot of stock accuracy. While it offers a complete overview, errors that occur between counts can go unnoticed for months, leading to inaccuracies in reporting and planning.

5. Resource and Cost Efficiency

Cycle Counting: More cost-effective in the long run because it distributes effort over time and eliminates the need for large-scale shutdowns. It also reduces overtime and stress on staff.

Physical Inventory Count: Resource-intensive, requiring significant labor, time, and planning. The cost of operational downtime and potential loss in productivity can be substantial, especially for larger warehouses.

6. Integration with Technology

Cycle Counting: Easily integrated into modern ERP and warehouse management systems. Tools like Deskera ERP automate scheduling, track discrepancies in real time, and update inventory data instantly—enhancing visibility and accuracy without manual effort.

Physical Inventory Count: While ERP tools can assist with recording data, the process still requires manual counting and reconciliation, offering less flexibility for dynamic, fast-moving operations.

Cycle counting is a proactive, continuous, and efficient approach to maintaining inventory accuracy, while physical inventory counts are comprehensive but disruptive. For growing businesses and large warehouses, adopting cycle counting—especially with ERP integration—ensures real-time visibility, operational efficiency, and consistent stock accuracy without the downtime of traditional full counts.

Purpose of Inventory Cycle Counting

Inventory cycle counting serves as a cornerstone of effective warehouse management by ensuring that inventory data remains accurate, reliable, and up to date.

The purpose of this process goes beyond just counting items—it’s about creating a structured approach to maintaining operational accuracy, reducing errors, and supporting smarter decision-making.

By conducting regular cycle counts, businesses can identify discrepancies early, enhance warehouse efficiency, and maintain customer satisfaction through consistent product availability.

Below are the key objectives that highlight the true purpose of inventory cycle counting:

1. Correct Mapping of Inventory

One of the main purposes of inventory cycle counting is to ensure that every item in the warehouse is correctly located and mapped. Accurate location data helps reduce picking errors, streamline order fulfillment, and improve overall warehouse organization. By regularly verifying stock placement, businesses can prevent misplacements and improve the speed and accuracy of their logistics operations.

2. Accurate Analysis of Stock

Cycle counting provides an ongoing method to verify that the physical stock matches the data recorded in warehouse management or ERP systems. This alignment between physical and digital records is crucial for reliable forecasting, demand planning, and purchasing decisions. Accurate stock analysis also minimizes the risk of overstocking or stockouts, helping maintain optimal inventory levels across all locations.

3. Reconciliation of Missing Items

Regular cycle counts make it easier to detect missing items, damaged goods, or data discrepancies promptly. When mismatches occur, staff can investigate and correct errors before they escalate into larger issues. This proactive reconciliation not only saves time and costs but also builds confidence in the accuracy of warehouse operations and inventory reports.

Process of Inventory Cycle Counting

The process of inventory cycle counting follows a structured approach to ensure inventory accuracy without the disruption of full physical counts.

By dividing counting tasks into smaller, manageable cycles, businesses can continuously validate stock records while keeping daily operations running smoothly.

The process typically involves planning, execution, data analysis, and reconciliation, each playing a vital role in maintaining accurate inventory control.

Here’s a detailed breakdown of each step in the cycle counting process:

1. Planning and Scheduling

The first step in the cycle counting process is strategic planning and scheduling. Businesses determine which items to count and how often, often using ABC analysis to set priorities:

- A-items: High-value or fast-moving items, counted more frequently.

- B-items: Moderate-value items, counted periodically.

- C-items: Low-value or slow-moving items, counted occasionally.

This prioritization ensures that critical inventory items are verified regularly, minimizing financial discrepancies and improving record accuracy. A well-defined schedule allows teams to perform counts without interrupting other warehouse activities.

2. Execution

Once the schedule is set, the next step is executing the count. Warehouse staff are assigned specific areas, SKUs, or product categories to verify. Using tools such as barcode scanners, RFID devices, or inventory management software, staff record real-time data directly into the system.

To maintain accuracy, the process should be clearly structured and standardized. Automated tools not only speed up the process but also reduce manual errors, ensuring that the collected data reflects the true stock levels.

3. Data Analysis

After the counting phase, the recorded data is analyzed and compared with the existing inventory records. This data analysis step identifies discrepancies between the physical count and system records.

When inconsistencies appear, staff must investigate their causes—whether due to data entry errors, misplaced items, or possible losses. This analytical review helps determine patterns of inaccuracies and offers insights into improving operational processes. Accurate analysis leads to informed decision-making and enhances long-term inventory precision.

4. Reconciliation

The final stage, reconciliation, ensures all discrepancies found during analysis are corrected. Staff update the inventory management or ERP system to reflect accurate quantities and investigate any root causes of differences.

This step strengthens the reliability of the inventory system and improves the accuracy of future cycle counts. Regular reconciliation not only builds confidence in data integrity but also promotes a culture of accountability and precision in warehouse operations.

Types of Inventory Cycle Counting Methods

There’s no single way to perform an inventory cycle count — the right method depends on your warehouse layout, item movement, and operational goals. Each method offers unique benefits for ensuring inventory accuracy and efficiency. The goal is to identify discrepancies quickly while minimizing disruption to day-to-day activities.

Here are the most common types of inventory cycle counting methods used across warehouses and manufacturing facilities:

1. ABC or Pareto-Based Cycle Counting

This is one of the most widely used methods, where items are classified into categories based on their value and importance:

- A-items: High-value or fast-moving products counted frequently (weekly or monthly).

- B-items: Moderate-value or medium-demand products counted less frequently (quarterly).

- C-items: Low-value or slow-moving products counted occasionally (once or twice a year).

This method ensures that critical inventory items—those that impact profitability or operations the most—are always accurate and up to date.

2. Control Group Cycle Counting

In this method, a small, fixed group of items is counted repeatedly over a set period. The purpose is to detect systemic issues in the counting process, such as procedural errors or misplacements. Once accuracy improves within the control group, the same refined process is applied to the rest of the inventory.

This approach helps improve the reliability of counting procedures and identify recurring problems early.

3. Random Sample Cycle Counting

As the name suggests, this technique involves counting a random selection of items from the inventory. It’s particularly useful for large warehouses where counting all SKUs is impractical. The random selection ensures unbiased results and helps maintain overall accuracy without a strict schedule.

Warehouse Management Systems (WMS) often assist by suggesting which items to sample based on parameters such as movement frequency, value, or past error rates.

4. Location or Area-Based Cycle Counting

This method divides the warehouse into physical zones — such as aisles, racks, or bins — and counts one area at a time on a rotating schedule. Over a set period, the entire warehouse is covered.

This approach is ideal for warehouses with complex layouts or multiple storage zones, ensuring that no area is overlooked during the counting process.

5. Usage or Movement-Based Cycle Counting

Also known as velocity counting, this method prioritizes items based on how frequently they move. Fast-moving or high-turnover items are counted more frequently than slower-moving ones.

This method minimizes stock errors for high-demand products and helps ensure smooth order fulfillment for frequently shipped goods.

6. Opportunity-Based Cycle Counting

This is a flexible and event-driven approach to cycle counting. Counts are triggered by specific operational events — for example, when inventory levels drop below a threshold, new stock arrives, or an order discrepancy occurs.

This method allows immediate verification when inventory data may be unreliable, keeping records accurate in real time.

7. Periodic and Perpetual Counting

- Periodic Counting: Involves counting selected items at fixed intervals (weekly, monthly, or quarterly). It spreads out the workload while maintaining consistent accuracy across time.

- Perpetual Counting: Uses automated systems like ERP or POS software to update stock data continuously as transactions occur. This provides real-time visibility but may still require periodic physical verification to ensure accuracy.

Each inventory cycle counting method offers unique advantages depending on business size, product type, and warehouse complexity. Many organizations use a combination of these methods — for example, pairing ABC analysis with location-based counting — to create a customized approach that balances accuracy, efficiency, and cost-effectiveness.

Benefits of Inventory Cycle Counting

Inventory cycle counting goes beyond just verifying stock levels — it’s a strategic approach to maintaining continuous inventory accuracy, improving decision-making, and optimizing warehouse efficiency.

Instead of conducting time-consuming annual physical audits, businesses that adopt cycle counting gain real-time visibility, better forecasting, and lower operational costs — all while keeping operations running smoothly.

Below are the key benefits that make inventory cycle counting indispensable to modern warehouse and inventory management.

1. Improves Order Fulfillment Process

Regular cycle counting ensures that the right products are always available and stored in their correct locations. This accuracy enables warehouse staff to pick, pack, and ship items promptly, improving delivery timelines and reducing fulfillment errors. As a result, businesses achieve faster turnaround times and higher customer satisfaction.

2. Enhances Demand Forecasting

Accurate and up-to-date inventory records allow businesses to track product movement and identify demand patterns. By understanding which items sell faster, companies can optimize reorder points, plan procurement cycles effectively, and prevent costly stockouts or excess inventory.

3. Improves Inventory Accuracy and Data Integrity

Cycle counting identifies and corrects discrepancies between recorded and actual stock, keeping data current. Reliable inventory data strengthens decision-making across departments — from procurement and finance to sales and customer service — reducing errors and enhancing trust in reporting systems.

4. Increases Operational Efficiency and Lowers Costs

Unlike traditional physical counts that require complete shutdowns, cycle counts are performed in small batches during normal working hours. This approach minimizes disruption, reduces labor costs, and saves time. It also helps avoid costly overstocking or emergency restocking.

5. Boosts Customer Satisfaction

When inventory data is accurate, businesses can fulfill customer orders faster and more reliably. Accurate stock levels mean fewer canceled orders, fewer backorders, and improved delivery timelines — all of which lead to stronger customer trust and customer loyalty.

6. Detects Shrinkage and Prevents Losses

Frequent cycle counts allow businesses to spot inconsistencies quickly — such as theft, damage, or misplacement. Early detection reduces financial losses, enhances accountability, and discourages internal shrinkage or theft within warehouse operations.

7. Ensures Audit Readiness and Regulatory Compliance

Cycle counting maintains continuous accuracy in inventory records, ensuring they are always audit-ready. This simplifies compliance with accounting and tax standards and reduces the stress of year-end financial audits.

8. Improves Resource Utilization

By breaking inventory audits into smaller, scheduled segments, staff workloads are distributed more efficiently. Warehouse employees can conduct cycle counts without disrupting other daily tasks, leading to better use of labor and improved productivity.

9. Enables Real-Time Inventory Visibility

When integrated with advanced systems like Deskera ERP, cycle counting provides instant updates to inventory data across multiple warehouse locations. Managers can access real-time visibility into stock levels, product movements, and order status — supporting better forecasting and operational agility.

10. Supports Data-Driven Decision-Making

Accurate, continuously updated inventory data feeds valuable insights into purchasing, production, and sales strategies. Businesses can leverage this data to optimize stock levels, refine pricing, and plan promotions effectively, leading to smarter business decisions.

11. Reduces the Need for Full Physical Counts

Cycle counting significantly decreases reliance on annual or quarterly physical counts, which are time-consuming and expensive. By maintaining accuracy throughout the year, companies can minimize major operational disruptions while still achieving near-perfect inventory precision.

12. Minimizes Human Error through Automation

With barcode scanners, RFID systems, and ERP integrations, cycle counting automates much of the manual work involved in counting. This not only reduces human error but also accelerates the process — allowing for more frequent and reliable audits.

13. Enhances Warehouse Flexibility

Cycle counting allows managers to design count schedules based on business needs — daily, weekly, or monthly — and prioritize by value or volume using ABC analysis. This flexibility ensures that critical stock items are counted more often, maintaining focus where it matters most.

14. Strengthens Financial Accuracy

Accurate inventory records directly impact balance sheets and profit calculations. By maintaining real-time data, businesses can report more precise cost of goods sold (COGS), valuation, and profitability metrics — supporting accurate financial reporting and improved decision-making.

15. Supports Continuous Improvement and Training

Cycle counting exposes recurring discrepancies or weak areas in warehouse operations, providing insights into staff performance or procedural inefficiencies. Managers can use this data to retrain employees, redesign storage layouts, or refine operational policies — fostering a culture of continuous improvement.

16. Measures and Improves Inventory Record Accuracy (IRA)

Businesses can evaluate their accuracy with the Inventory Record Accuracy (IRA) metric:

Basic IRA formula:

IRA = (Matched Inventory / Total Items Counted) × 100

Value-based IRA formula:

IRA = [1 - (Sum of Absolute Variance / Sum of Total Inventory)] × 100

Monitoring IRA helps organizations benchmark inventory reliability, identify problem areas, and drive measurable improvements over time.

In conclusion, inventory cycle counting is not merely a counting method — it’s a strategic, continuous improvement process that enhances efficiency, financial precision, and customer satisfaction.

With Deskera ERP, businesses can automate the entire cycle counting process, track discrepancies in real time, and access unified reports across multiple warehouses — empowering them to make smarter, faster, and more accurate inventory decisions.

Challenges of Inventory Cycle Counting and How to Avoid Them

Inventory cycle counting delivers immense operational and financial benefits, but it’s not without its challenges. If not executed properly, even the best-designed cycle counting program can lead to errors, inefficiencies, and inaccurate stock data. Understanding these challenges — and knowing how to prevent them — is key to maintaining reliable inventory accuracy and uninterrupted warehouse performance.

1. Misplaced or Untracked Items

Challenge:

One of the most common issues during cycle counting is misplaced inventory. Items may be moved, stored in the wrong location, or transferred between bins without updating the system — leading to discrepancies in counts.

How to Avoid It:

Implement barcode or RFID tracking to ensure every product movement is recorded in real time. Use clear labeling systems and train employees to update the system whenever inventory is relocated. Periodic location audits can also help detect misplaced items early.

2. Human Error and Inconsistent Counting

Challenge:

Manual counting introduces the risk of miscounts, skipped items, and data entry errors — especially in large or complex warehouses. Repetitive tasks may also lead to fatigue or complacency among staff, reducing accuracy.

How to Avoid It:

Use handheld scanners, mobile devices, or inventory management software to automate data capture. Rotate counting teams regularly and perform cross-verification to minimize individual bias or error. Proper training and spot audits help maintain consistency.

3. Incomplete or Outdated System Records

Challenge:

When inventory systems contain outdated or inaccurate information, cycle counts are based on flawed data. This leads to errors that are compounded over time, making reconciliation difficult.

How to Avoid It:

Before starting any count, review and clean up master data. Ensure that your warehouse management system (WMS) or ERP software reflects accurate item details, SKU codes, and locations. Integrate counting tools directly with your ERP system, such as Deskera ERP, to keep data synchronized in real time.

4. Disruptions to Daily Operations

Challenge:

Cycle counting can temporarily disrupt warehouse activities, especially in high-traffic zones or during peak business hours. Stopping operations to perform counts can delay order picking, packing, or shipping.

How to Avoid It:

Schedule counts during low-activity periods or use a rotational counting plan that isolates small sections of the warehouse at a time. Implement real-time WMS or ERP tools that allow counts to occur without halting operations. Deskera ERP, for instance, enables background updates to stock records while day-to-day processes continue seamlessly.

5. Resource Allocation and Labor Constraints

Challenge:

For smaller businesses, dedicating time and personnel for frequent counts can strain limited resources. Without proper scheduling or automation, this can increase operational costs and reduce productivity.

How to Avoid It:

Use automated alerts and scheduled counting cycles within your ERP system to balance workloads efficiently. Train multi-skilled staff who can perform counts during idle periods. Over time, automation reduces labor dependency and frees employees for higher-value tasks.

6. System Integration Challenges

Challenge:

Integrating cycle counting with legacy systems or disconnected software can lead to inconsistent records and reporting delays. Data mismatches between warehouse and accounting systems often cause reconciliation issues.

How to Avoid It:

Ensure your cycle counting process is integrated with a unified ERP platform that consolidates all inventory, purchasing, and financial data. With Deskera ERP, cycle counting is seamlessly linked to your warehouse and accounting modules, ensuring instant synchronization and improved accuracy across departments.

7. Lack of Standardized Procedures

Challenge:

When each employee follows their own approach to counting or reporting discrepancies, errors multiply quickly. A lack of clear policies results in inconsistent practices and unreliable data.

How to Avoid It:

Develop and document standard operating procedures (SOPs) for all cycle counting activities. Define clear steps for item selection, counting frequency, reconciliation, and error correction. Regularly review and refine these SOPs to adapt to operational changes.

8. Failure to Update or Reconcile Records Promptly

Challenge:

Sometimes, discrepancies identified during a count are noted but not immediately corrected in the system. This leads to recurring errors and inaccurate stock levels in future counts.

How to Avoid It:

Always reconcile discrepancies immediately after each count session. Assign clear accountability — one team for counting and another for verification and updates. Leverage real-time syncing through ERP software so that any adjustments are instantly reflected in the inventory master.

9. Overlooking Training and Process Adherence

Challenge:

Even with robust systems in place, untrained staff can unintentionally skip counts, scan incorrect SKUs, or overlook reconciliation steps. Lack of process discipline can make the entire program ineffective.

How to Avoid It:

Provide continuous training and refresher sessions for warehouse staff. Incorporate audit trails to monitor compliance and identify recurring process gaps. Tools like Deskera’s AI assistant, David, can guide staff during counting tasks and ensure adherence to best practices.

10. Handling Complex or High-Value Inventory

Challenge:

Counting fragile, high-value, or bulk items can be time-consuming and prone to mistakes. Specialized inventory — like serialized or batch-controlled items — requires extra care during verification.

How to Avoid It:

Use batch and serial number tracking within your ERP or WMS. Implement customized cycle count schedules for these items to ensure they receive the attention they require. Deskera ERP simplifies this by allowing you to automate counts for specific item categories or high-value SKUs.

11. Ignoring Data Analytics and Performance Monitoring

Challenge:

Without tracking metrics like Inventory Record Accuracy (IRA) or discrepancy rate, businesses can’t measure whether cycle counting is actually improving inventory accuracy.

How to Avoid It:

Regularly review performance KPIs after each cycle. Use your ERP system’s reporting dashboards to identify error trends, recurring problem zones, or training needs. Deskera ERP provides built-in analytics to help managers assess accuracy and refine cycle counting strategies.

In summary, while challenges in cycle counting are inevitable, most can be avoided through technology integration, proper planning, and consistent training.

By adopting Deskera ERP, businesses can automate cycle counting, reduce manual effort, and achieve real-time synchronization across warehouses — ensuring that your counts are not only accurate but also effortlessly efficient.

Best Practices for Effective Inventory Cycle Counting

Implementing inventory cycle counting is not just about counting items—it’s about establishing a reliable, repeatable process that enhances warehouse accuracy and efficiency. By following best practices, businesses can minimize human error, maintain accurate records, and reduce disruptions to daily operations.

Below are some proven strategies to help streamline your inventory cycle counting process.

1. Categorize Items Using the ABC Method

Begin by classifying inventory items into Class A, B, and C categories based on their value and turnover rates. Class A items, which contribute most to revenue, should be counted more frequently, while Class C items can be checked less often.

Why it matters:

This targeted approach ensures resources are focused on the most critical inventory, improving accuracy and efficiency without overburdening staff.

2. Develop a Clear Cycle Counting Plan

Before implementing cycle counting, outline what items to count, how often, and who will conduct the counts. Establish a written schedule and procedure that all staff can follow consistently.

Pro Tip:

Perform counts for Class A items monthly, Class B quarterly, and Class C annually to maintain accuracy year-round.

3. Conduct Counts During Low-Activity Periods

To prevent operational disruptions, schedule counts during slow or off-peak periods. This allows employees to work without pressure and ensures accurate results.

Why it matters:

Low-activity periods minimize stock movement, reducing errors that occur when items are picked or moved during counting.

4. Train and Rotate Staff for Accuracy

Provide proper training to staff on cycle counting procedures, data entry, and error investigation. Rotate counting teams regularly to prevent bias, collusion, or fatigue.

Pro Tip:

Conduct mock or test cycle counts to assess employee readiness and refine your standard operating procedures (SOPs).

5. Use Technology to Automate and Accelerate Counting

Modern tools like barcode scanners, RFID systems, and warehouse management systems (WMS) streamline data collection and ensure real-time updates.

Benefits:

- Reduces manual data entry errors

- Speeds up counting and reconciliation

- Enables perpetual inventory tracking for ongoing accuracy

Example:

Deskera ERP’s integrated inventory module automates data syncing and provides real-time visibility into stock levels, simplifying the entire cycle counting process.

6. Count Inventory in Small Batches

Breaking the count into smaller, manageable sections makes the process less overwhelming and more precise.

Why it works:

Small batch counting helps focus attention on specific SKUs or zones, improving accuracy and reducing oversight.

7. Restrict Stock Movements During Counts

Lock stock modifications such as transfers or updates during active counting sessions. This ensures that recorded quantities align with physical stock levels.

Pro Tip:

Use your WMS or ERP system to temporarily freeze item transactions while the count is underway.

8. Verify and Document Each Cycle Count

Double-check counts, especially for high-value items, to ensure accuracy. Record all findings—quantities, discrepancies, and corrective actions—in a centralized system.

Why it matters:

Maintaining documentation builds accountability and helps track performance over time, which is vital for audits and continuous improvement.

9. Investigate and Correct Discrepancies Promptly

When mismatches occur, identify their root causes—such as miscounts, misplacements, or data entry errors—and correct them immediately.

Tip:

Use automated alerts in your ERP system to flag inconsistencies and streamline the reconciliation process.

10. Review and Improve Regularly

Cycle counting should evolve based on data insights. Track your accuracy rate and identify recurring issues to refine your approach.

Why it matters:

Regular reviews help enhance forecasting, strengthen internal controls, and reduce the need for time-consuming full physical counts.

11. Leverage Automation for Continuous Accuracy

Automated inventory management systems can run reports, flag low stock, and update records instantly. Leveraging automation ensures data integrity and eliminates repetitive manual tasks.

Example:

With Deskera ERP, businesses can automate inventory updates, run real-time reports, and monitor stock movement—ensuring continuous accuracy and reduced administrative workload.

How Deskera ERP Helps with Inventory Cycle Counting

While inventory cycle counting improves accuracy and efficiency, managing it manually can still be time-consuming and prone to human error. That’s where Deskera ERP comes in — a comprehensive, cloud-based platform designed to automate, streamline, and simplify every aspect of inventory management. With real-time visibility, intelligent automation, and AI-powered insights, Deskera ERP makes cycle counting faster, more accurate, and seamlessly integrated with your daily operations.

1. Real-Time Inventory Visibility

Deskera ERP provides a centralized dashboard where you can view live stock levels, item locations, and transaction histories. This real-time visibility ensures that when you perform cycle counts, the data you compare is always up-to-date and accurate.

2. Automated Data Synchronization

Deskera ERP automatically synchronizes all inventory movements—such as receipts, transfers, sales, and returns—across locations and channels. You get instant reconciliation between your physical count and digital records, ensuring consistency across your entire supply chain.

3. AI Assistant “David” for Smart Inventory Insights

Deskera’s built-in AI assistant, David, helps analyze discrepancies, predict potential stock issues, and even suggest optimal count frequencies for different product categories. This makes it easier to turn raw inventory data into actionable insights.

4. Barcode and RFID Integration

Deskera ERP supports barcode and RFID scanning, enabling teams to conduct fast, error-free counts. Scanning each item automatically updates inventory data in the system, eliminating manual entry and reducing counting time significantly.

5. ABC Analysis and Custom Count Scheduling

Deskera ERP enables ABC categorization of inventory items and allows you to schedule cycle counts based on item value, turnover, or frequency. This ensures that high-value or fast-moving items are counted more frequently without disrupting warehouse operations.

6. Detailed Reporting and Audit Trails

Every cycle count performed in Deskera ERP is automatically documented, creating detailed reports with count results, variances, and corrective actions. This maintains complete traceability for compliance audits and supports continuous improvement.

7. Mobile Accessibility for On-the-Go Counting

With Deskera’s mobile ERP app, teams can perform cycle counts directly from smartphones or tablets, making the process more flexible and efficient. Mobile access empowers staff to update counts instantly, even from remote warehouse sections, ensuring real-time accuracy.

8. Seamless Integration with Other Business Functions

Deskera ERP integrates cycle counting results with accounting, sales, and procurement modules, ensuring that changes in stock levels automatically reflect in financial statements and purchase planning. This provides a unified system of truth across departments and enhances transparency.

9. Continuous Improvement Through Analytics

With built-in analytics and dashboards, Deskera ERP helps businesses monitor cycle count performance over time. You can track accuracy rates, identify recurring discrepancies, and refine counting strategies using data-driven insights.

Key Takeaways

- Inventory cycle counting is a smarter, more efficient alternative to full physical inventory counts, enabling businesses to maintain accuracy and continuity in warehouse operations without major disruptions.

- The main goal of cycle counting is to ensure precise inventory mapping, reconcile discrepancies quickly, and maintain reliable stock records for improved operational control.

- A structured process—planning, execution, data analysis, and reconciliation—ensures consistent and accurate cycle counts while minimizing manual errors and operational interruptions.

- Unlike physical inventory counts that halt operations, cycle counting provides continuous accuracy with less downtime, making it ideal for modern, fast-paced warehouses.

- Different methods such as ABC analysis, random sampling, control group, usage-based, and location-based counting allow businesses to tailor their approach based on value, movement, and operational needs.

- Cycle counting improves accuracy, reduces stockouts, enhances decision-making, supports better financial reporting, and boosts overall warehouse efficiency.

- Common challenges—like misplaced items, system errors, and human mistakes—can be avoided with proper training, data validation, automation, and clear operating procedures.

- Establishing a clear counting plan, training staff, leveraging technology, maintaining documentation, and performing routine checks are crucial for reliable and efficient cycle counting.

- Deskera ERP automates and optimizes the entire cycle counting process with real-time data, barcode integration, AI-driven insights, and seamless synchronization across business functions.

Related Articles