Have you ever wondered how accurately you really know what’s in your warehouse right now? Many businesses assume their inventory records are correct—until a stockout or overstock issue reveals otherwise. Conducting a proper inventory count isn’t just about tallying items; it’s about gaining control over one of your business’s most valuable assets. Whether you run a small retail store or manage a global supply chain, accurate inventory counts form the foundation of efficient operations and sound financial management.

Inventory counting is the process of verifying and recording the quantity of goods a company owns at a specific point in time. It helps ensure that the numbers in your system match the physical stock on hand, preventing discrepancies that can lead to revenue losses, inaccurate financial statements, or poor customer experiences. Beyond compliance and bookkeeping, regular counts support data-driven decision-making, enabling businesses to forecast demand more precisely and plan their purchasing cycles effectively.

Inaccurate inventory data can have ripple effects across departments—from finance and sales to procurement and customer service knowledge management. A single error in stock records can delay shipments, inflate costs, and erode trust. That’s why establishing a structured and technology-driven inventory count process is critical. Modern businesses are increasingly turning to automation tools and integrated systems to reduce manual errors and improve real-time visibility into their stock levels.

This is where Deskera ERP comes in. Designed for businesses of all sizes, Deskera ERP automates and simplifies inventory counting through barcode scanning, batch tracking, and real-time data synchronization. Its intuitive dashboard helps you track stock across multiple locations, reconcile discrepancies instantly, and generate accurate reports in just a few clicks. By digitizing your inventory counting process, Deskera ERP ensures that your business operates with precision, efficiency, and confidence—no matter how complex your inventory setup may be.

What Is an Inventory Count?

An inventory count, also known as a physical inventory or stocktake, is the process of physically verifying and recording the quantity and condition of goods a business has in stock at a specific time. It serves as a direct check against the inventory data stored in the company’s system, helping ensure that recorded quantities accurately reflect what is actually available. By conducting inventory counts, businesses can identify discrepancies caused by errors, theft, or damage and take corrective action to maintain data integrity.

The main purpose of an inventory count is to confirm the accuracy of inventory records and provide a clear picture of a company’s assets. It allows businesses to determine whether their current stock levels align with demand, supporting more efficient purchasing, production, and sales decisions. For instance, manufacturers rely on accurate counts to ensure essential raw materials are available for production, while retailers use them to prevent overstocking or stockouts that can affect customer satisfaction.

Beyond basic stock verification, inventory counting plays a significant role in financial reporting and operational performance. Inaccurate inventory data can distort profit margins, inflate costs, or misstate the value of assets on the balance sheet. Conversely, accurate inventory counts help produce reliable financial statements, improve cash flow management, and support better supply chain coordination with vendors and distributors.

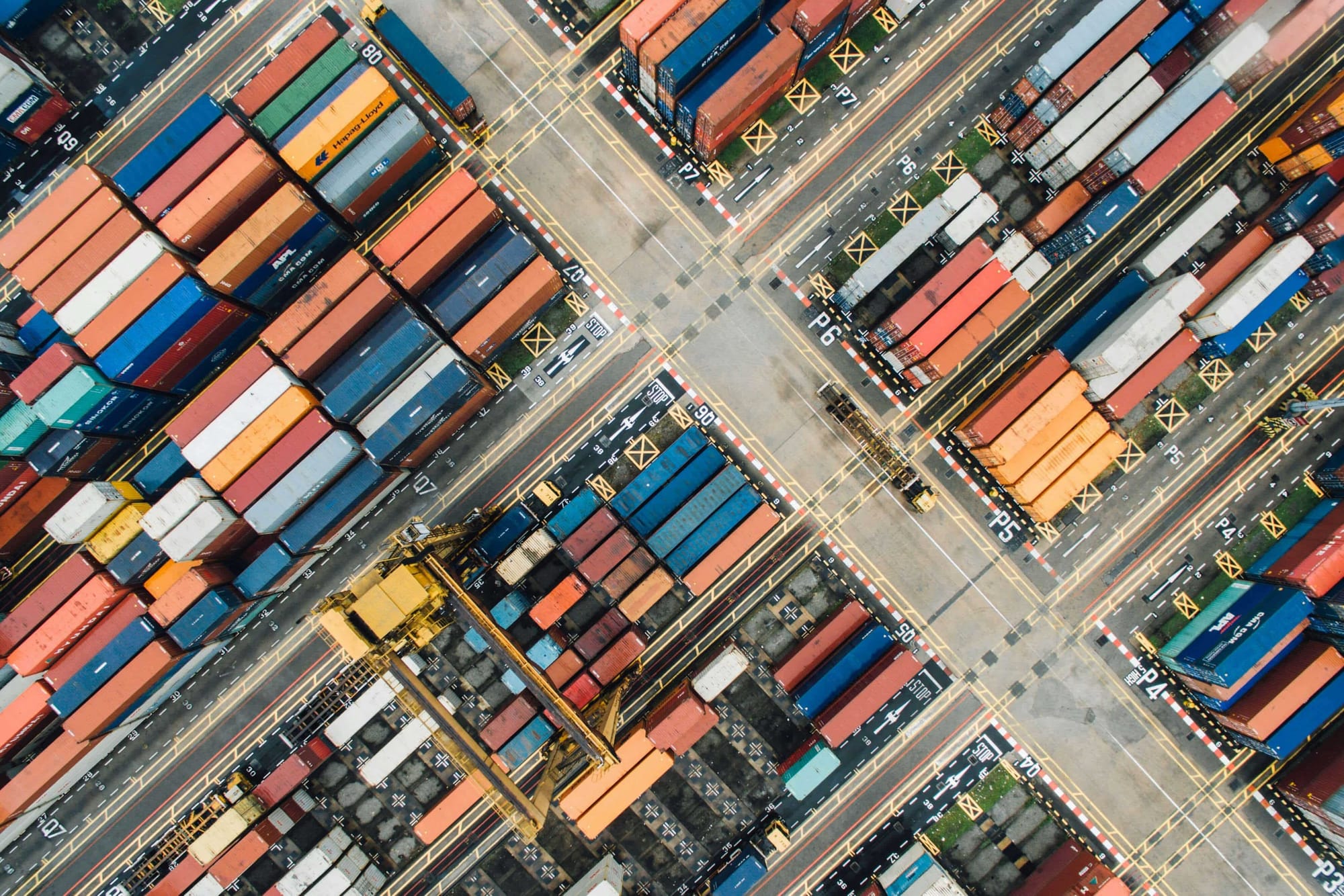

In modern business environments, inventory counts are often supported by inventory management systems or ERP software to simplify data collection, minimize human error, and improve real-time visibility. Automated tools like barcode scanners, RFID tags, and cloud-based inventory systems make the process faster and more reliable—turning what was once a labor-intensive task into a strategic advantage for maintaining accuracy and efficiency across the supply chain.

Types of Inventory Counts

Every business has unique operational needs, and the method used for inventory counting should align with its size, industry, and complexity. From periodic full stocktakes to ongoing automated systems, choosing the right type of inventory count can greatly influence accuracy, efficiency, and decision-making. Below are the most common types of inventory counts and how they work.

1. Full Physical Inventory Count

A full physical inventory count involves manually counting every item in stock at a specific point in time, usually at the end of a financial period. This type of count provides a complete and accurate snapshot of a company’s inventory and is often required for auditing and financial reporting.

Advantages: It ensures a thorough reconciliation between actual stock and recorded data.

Challenges: It is time-consuming and can disrupt regular operations, as normal business activities often need to pause during the count.

2. Cycle Counting

Cycle counting is a continuous process of counting a small subset of inventory regularly—daily, weekly, or monthly—based on item importance or sales frequency. Instead of counting all items at once, businesses divide their inventory into categories and count them in rotation.

Advantages: This method maintains ongoing accuracy without halting operations. It also helps detect and correct discrepancies quickly.

Challenges: Requires careful planning and consistent execution to ensure all items are eventually verified.

3. Spot Counting (Ad-Hoc or Random Sampling)

A spot count, also known as ad-hoc or random sampling, involves counting a small, randomly selected portion of inventory to check accuracy. It’s often used to investigate potential discrepancies or verify high-value or fast-moving items.

Advantages: Quick and flexible; ideal for identifying issues between scheduled counts.

Challenges: Provides only a partial view of inventory accuracy and depends heavily on the sampling method used.

4. Perpetual Inventory Counting

In a perpetual inventory system, records are continuously updated in real-time as transactions occur—such as sales, purchases, or stock adjustments. This approach relies heavily on technology, using tools like barcode scanners, RFID tags, or ERP systems.

Advantages: Provides instant visibility into stock levels and reduces the need for manual counts.

Challenges: Requires robust software and accurate data input to prevent discrepancies from accumulating over time.

5. Tag Counting

Tag counting involves placing a physical tag on each item or batch of inventory during the count. Each tag records item details and quantities, which are later cross-verified and entered into the inventory system.

Advantages: Ideal for stores or warehouses without defined storage locations; provides visual confirmation of counted items.

Challenges: Labor-intensive and can be time-consuming to manage manually unless supported by scanning tools.

6. Blind Counting

In a blind inventory count, the counting team does not have access to existing inventory records while performing the count. Afterward, results are compared with system data to identify discrepancies.

Advantages: Reduces bias and ensures an unbiased count.

Challenges: May require more time and personnel, as counters must record all quantities independently.

7. Incremental Counting

Incremental counting divides the inventory into smaller, manageable sections that are counted over time. Unlike cycle counting, it focuses on limited areas or categories without a set rotation schedule.

Advantages: Keeps stock data updated regularly while minimizing disruption.

Challenges: Requires careful tracking to ensure that all inventory areas are eventually covered.

By understanding and implementing the right type of inventory count, businesses can maintain accurate stock records, improve operational efficiency, and make better data-driven decisions.

Many companies use a combination of these methods to balance accuracy with practicality—especially when supported by modern tools like Deskera ERP, which automates cycle counts, streamlines reconciliation, and provides real-time visibility across multiple locations.

How Does Inventory Count Work?

While every company’s inventory counting method can differ based on size, industry, and tools used, the overall process follows a structured approach to ensure accuracy and consistency.

Below is a step-by-step overview of how an effective inventory count is conducted:

1. Determine the Scope

The first step is to define the scope of your inventory count. Identify which products, materials, or storage areas will be included. Many businesses focus on high-value, fast-moving, or critical items first. At this stage, you should also clarify the goals of your count—whether it’s to verify record accuracy, uncover discrepancies, or assess overall stock levels.

2. Prepare for the Count

Proper preparation is crucial for an accurate and efficient count. Start by organizing the warehouse or stockroom so that items are easily accessible and correctly labeled. Gather necessary tools such as count sheets, barcode scanners, RFID readers, or mobile devices. Communicate the counting schedule and procedure to all involved employees to avoid confusion and disruptions.

3. Assign Roles and Responsibilities

Once the plan is in place, assign specific areas and tasks to your counting team based on their experience and familiarity with the inventory. Each participant should understand the counting process, especially if using electronic or mobile tools. Having clear roles—such as counters, verifiers, and recorders—ensures smooth coordination and prevents duplication or oversight.

4. Conduct the Physical Count

Begin counting items systematically, one section at a time. Record quantities accurately, either on paper count sheets or directly into your inventory software. Pay close attention to high-turnover items and those prone to loss or damage. During this stage, it’s also essential to identify expired, damaged, or obsolete stock that should be removed from your records.

5. Verify and Reconcile Data

After the first round of counting, perform a verification check. A second team or supervisor should review counts, especially for high-value items. Compare the results against your inventory system and highlight any discrepancies. This step helps identify errors due to miscounts, misplaced stock, or system inaccuracies.

6. Investigate Discrepancies

If mismatches are found between the physical and recorded quantities, investigate the causes. Common reasons include theft, damage, recording errors, or unprocessed transactions. Reviewing recent inventory movements in your ERP system can help pinpoint issues. Once confirmed, adjust your records to reflect the correct quantities.

7. Report and Analyze Results

After final verification, compile a comprehensive report summarizing the count results, discrepancies, and corrective actions. Share this with relevant departments—such as management, finance, and procurement. Analyze the data to identify trends like recurring errors, overstocking, or stockouts. Use these insights to improve your inventory management process.

8. Automate for Efficiency with ERP Software

While manual counting can be effective, it’s time-consuming and prone to errors. Adopting ERP systems like Deskera ERP can streamline the entire inventory count process. Deskera ERP automates data collection through barcode scanning and mobile tracking, ensures real-time synchronization of physical and digital records, and provides analytics for better decision-making. With features like automated stock adjustments and detailed reporting, Deskera helps businesses maintain accurate inventory levels with minimal manual intervention.

A well-executed inventory count not only ensures record accuracy but also provides valuable insights into your business’s operational health. By pairing structured processes with the right technology, you can transform inventory counting from a tedious chore into a strategic advantage.

Why Inventory Count Matters

Have you ever wondered why some businesses always seem to have products available when customers need them—while others constantly deal with shortages or excess stock? The answer often lies in how accurately they track and manage their inventory. Inventory count isn’t just about numbers on a spreadsheet—it’s a critical process that drives financial accuracy, customer satisfaction, and overall business efficiency.

Here’s why conducting accurate inventory counts truly matters for every organization.

1. Accurate Financial Reporting

At its core, an inventory count ensures that your financial records reflect the real value of stock on hand. Since inventory is a major asset on a company’s balance sheet, even small inaccuracies can lead to significant financial distortions.

Overstating inventory levels inflates asset values and profits, while understating them reduces perceived profitability. Both scenarios can result in incorrect tax filings, compliance issues, and loss of stakeholder trust.

Regular and accurate inventory counts help businesses maintain transparency in financial reporting and avoid penalties or misrepresentations.

2. Effective Inventory Management

Accurate counts are the backbone of efficient inventory management. When businesses know exactly what’s in stock, they can maintain optimal inventory levels—avoiding costly stockouts or overstocking.

Overstocking ties up working capital and increases holding costs, whereas stockouts lead to missed sales and customer dissatisfaction.

Consistent and precise inventory counts allow for better forecasting, timely reordering, and improved operational efficiency. This balance helps ensure that your supply chain runs smoothly and cost-effectively.

3. Enhancing Customer Satisfaction

Customer loyalty often depends on how well a business can deliver what it promises. When inventory counts are accurate, businesses can fulfill customer orders promptly and completely.

Inaccurate data can cause order delays or incomplete shipments, leading to frustration and potential loss of future sales. Reliable inventory information ensures that customers get what they want, when they want it—boosting satisfaction, trust, and long-term retention.

4. Reducing Operational Costs

Maintaining accurate inventory counts directly impacts your bottom line. Errors in stock records often result in unnecessary emergency reorders, expedited shipping costs, or excess storage expenses.

Additionally, keeping surplus inventory can increase insurance and obsolescence costs. By keeping precise counts, businesses minimize waste, improve cash flow, and allocate resources more strategically. This leads to leaner operations and higher profitability.

5. Improving Decision-Making

Sound decision-making relies on reliable data—and inventory counts provide exactly that. When businesses have accurate insights into what’s selling and what’s not, they can plan production schedules, marketing campaigns, and purchasing more effectively.

Misleading data, on the other hand, can cause overproduction, missed opportunities, and poor demand forecasting. Regular inventory counts support better planning and help businesses align their decisions with real-world conditions.

6. Strengthening Asset Tracking and Valuation

For many organizations, a large portion of capital is tied up in assets like equipment, machinery, or long-term stock. Regular inventory counts help track these assets, determine their location and condition, and ensure they’re properly valued.

This is not only useful for internal management but also for audits, insurance claims, and financial assessments. In essence, accurate inventory data enhances visibility and accountability across your operations.

7. Preventing Shrinkage, Theft, and Loss

Regular inventory counts act as a powerful deterrent against theft and carelessness. When employees know that stock is routinely monitored, they are more likely to handle inventory responsibly.

Counts also help identify and address issues like shrinkage, misplaced goods, or administrative errors early—preventing small losses from turning into large financial setbacks.

8. Supporting Insurance and Compliance Requirements

In the event of disasters such as fires or floods, having updated inventory records simplifies the process of filing insurance claims. Accurate records allow you to quickly verify losses and recover compensation.

Moreover, many regulatory and accounting standards require businesses to maintain up-to-date inventory data—making consistent counts not just a best practice, but a compliance necessity.

9. Guiding Location and Space Optimization

Accurate inventory data helps businesses make smarter storage and layout decisions. By knowing which items move fastest and which occupy valuable space without frequent turnover, companies can optimize warehouse layouts for efficiency. This data-driven approach helps reduce picking time, improve workflow, and enhance overall warehouse productivity.

10. Enabling Scalable Growth with ERP Integration

In today’s competitive business environment, manual inventory counts are no longer enough. Advanced ERP systems like Deskera ERP automate and simplify the entire inventory management process—from real-time tracking to reporting and reconciliation.

With features such as barcode and RFID scanning, cloud synchronization, and intelligent forecasting, Deskera ERP ensures that your inventory data is always accurate and up to date. This integration not only reduces errors but also provides actionable insights for better business growth and scalability.

In summary, accurate inventory counts are much more than a routine business task—they’re a foundation for operational success. They improve financial accuracy, reduce waste, enhance customer satisfaction, and empower data-driven decisions. Whether you’re a small business or a global enterprise, maintaining precise inventory counts ensures stability, agility, and long-term growth.

Common Challenges in Inventory Counting

While inventory counting is essential for maintaining accurate stock records and ensuring operational efficiency, it’s rarely a straightforward process. Businesses often encounter a variety of obstacles that can disrupt workflows, reduce accuracy, and increase costs.

Understanding these challenges—and how to overcome them—can help companies refine their inventory management practices and maintain reliable data.

1. Human Error

One of the most common challenges in inventory counting is human error. Manual counting leaves room for mistakes such as miscounting, double-counting, or entering incorrect data into the system.

In large warehouses or retail environments with thousands of SKUs, even a small oversight can result in significant discrepancies between recorded and actual stock.

Fatigue, distractions, and lack of training further increase the likelihood of such errors. To minimize human error, businesses can use barcode scanners, RFID systems, or mobile apps that automate data capture and ensure accuracy.

2. Time-Consuming Process

Physical inventory counts can be extremely time-consuming, particularly for businesses with vast inventories or multiple storage locations. Traditional full inventory counts often require halting daily operations—such as receiving, shipping, or sales—which can lead to delays and revenue loss.

This challenge makes it difficult for companies to conduct frequent counts without affecting productivity. Implementing cycle counting, where smaller sections of inventory are counted regularly, can help maintain accuracy without major disruptions.

3. Operational Disruptions

Inventory counts, especially full-scale or year-end ones, often require businesses to pause their regular activities to avoid duplicate transactions or stock movement errors.

For retail stores, this means temporarily stopping sales; for warehouses, it means halting dispatch and replenishment. These operational pauses can lead to lost productivity and dissatisfied customers. Scheduling counts during off-peak hours or automating them with inventory software can significantly reduce such disruptions.

4. Unrecorded or Delayed Transactions

Another challenge is unrecorded or delayed transactions, which can distort the accuracy of counts. For instance, if new stock arrives or items are sold during the count but aren’t yet recorded in the system, it creates mismatches between physical and system data.

Real-time inventory management software that automatically updates stock levels as transactions occur can help eliminate this problem and ensure that records remain current throughout the process.

5. High Costs and Resource Constraints

Inventory counting can be resource-intensive, requiring dedicated staff, specialized equipment, and time away from regular duties. For small and medium-sized businesses, these costs can quickly add up.

Balancing the need for accuracy with the cost of execution is a constant struggle. Automating parts of the process with technology or conducting partial counts more frequently can help reduce labor costs while maintaining accuracy.

6. Inconsistent Counting Methods

Using inconsistent counting procedures across departments or locations can lead to discrepancies and confusion. For example, if one warehouse uses manual methods while another uses barcode scanning, reconciling data becomes complex.

Establishing standardized procedures and using centralized inventory management systems ensures uniformity and consistency in counting methods across all locations.

7. Inadequate Training and Communication

Employees involved in the counting process need to understand the system, methodology, and purpose behind it. Poor training often results in miscounts, incorrect labeling, or incomplete data entry.

Similarly, lack of communication between departments can lead to duplicated efforts or missed items. Businesses can overcome this challenge by clearly defining roles, providing training on inventory systems, and maintaining open communication throughout the count.

8. Data Reconciliation Challenges

Once the physical count is complete, reconciling the results with the recorded data can be complex—especially when dealing with multiple warehouses or diverse product categories.

Identifying and investigating discrepancies requires time and expertise, and errors can persist if reconciliation is rushed or inconsistent. Using integrated ERP systems simplifies reconciliation by consolidating data from all sources and highlighting discrepancies automatically.

9. Environmental and Logistical Issues

Warehouse conditions such as poor lighting, cluttered storage, or misplaced labels can make it harder to perform accurate counts. Similarly, counting items stored in multiple locations or those that are perishable or fragile adds logistical complexity. Proper organization, clear labeling, and the use of mobile devices for digital logging can help overcome these challenges.

In summary, while inventory counting poses challenges like human error, time constraints, and operational disruptions, technology-driven approaches can transform this process into a smooth, data-driven function. With tools like Deskera ERP, businesses can maintain accurate, real-time inventory records—laying the foundation for better financial control, improved decision-making, and sustained growth.

Best Practices for Accurate Inventory Counts

Accurate inventory counting is crucial for maintaining smooth operations, improving decision-making, and ensuring reliable financial reporting. Even minor errors in counting can lead to major discrepancies that affect everything from order fulfillment to profitability.

To ensure precision and consistency, businesses should adopt structured processes, leverage technology, and prioritize training. Here are the best practices that can help achieve accurate and efficient inventory counts.

1. Standardize Counting Procedures

Consistency is the foundation of accurate inventory counts. Establish clear, standardized counting procedures and ensure that every team member follows them. Provide written guidelines outlining how to count, record, and handle discrepancies.

Pair experienced employees with newer staff to balance efficiency and accuracy. Encouraging a standardized approach reduces confusion and ensures that data remains consistent across departments and count cycles.

2. Schedule Regular Counts

Rather than waiting for an annual stocktake, conduct cycle counts at regular intervals. This approach allows businesses to check smaller sections of inventory more frequently without disrupting daily operations.

Regular counts help identify discrepancies early, minimize large year-end adjustments, and maintain consistent data accuracy. Scheduling these counts during off-peak hours can further reduce operational disruption.

3. Leverage Technology for Automation

Manual counting increases the likelihood of human error, especially in large-scale operations. Adopting technology-driven tools such as barcode scanners, RFID systems, and cloud-based inventory management software ensures real-time updates and reduces manual data entry mistakes.

Using an ERP system like Deskera ERP further enhances accuracy by automating stock tracking, synchronizing sales and purchase data, and generating instant reports for decision-making.

4. Train and Empower Employees

Proper employee training is essential to minimize counting errors and ensure procedural compliance. Staff should understand why inventory accuracy matters and how their role impacts broader business operations.

Offer training sessions on data entry, handling scanning equipment, and following standard counting protocols. Encouraging accountability and incentivizing accurate counts can further motivate teams to maintain precision.

5. Maintain Organized and Labeled Storage

A well-organized warehouse or storage space speeds up counting and reduces confusion. Clearly label all shelves, bins, and items to facilitate quick identification and tracking. Keeping inventory areas clean and systematically arranged helps counters locate products easily and ensures items are not missed or double-counted.

6. Cross-Verify Inventory Data

Cross-verification between physical counts and system records helps identify inconsistencies and prevent discrepancies. Compare inventory data with sales, purchase, and production records to confirm accuracy. This verification not only ensures reliable financial reporting but also strengthens data credibility across departments.

7. Continuously Review and Improve

Inventory management should be a dynamic process that evolves with business needs. Regularly review your counting methods, analyze recurring errors, and refine processes based on feedback and performance metrics. By continuously improving your strategy, you can enhance efficiency, accuracy, and operational control.

By following these best practices, businesses can minimize errors, save time, and improve financial accuracy. Combined with modern solutions like Deskera ERP, companies can automate inventory counting, streamline workflows, and gain real-time visibility into stock movements — ensuring that every count adds value to business growth and efficiency.

How Technology Simplifies Inventory Counting

Inventory counting has evolved far beyond clipboards and spreadsheets. In today’s fast-paced business world, technology plays a crucial role in streamlining and simplifying the inventory counting process. By integrating automated tools, businesses can improve accuracy, save time, and reduce the operational strain that comes with manual stocktaking.

Let’s explore how modern technology is transforming inventory counting into a more efficient, reliable, and data-driven process.

1. Barcode Scanners and RFID Systems

Manual data entry often leads to counting errors, but tools like barcode scanners and RFID (Radio Frequency Identification) systems eliminate much of that risk. Barcode scanners allow employees to quickly scan items, automatically updating quantities in the system.

RFID tags go a step further, enabling real-time tracking of stock through radio signals—no line-of-sight scanning required. These technologies not only increase speed but also improve accuracy and traceability across large warehouses or multiple locations.

2. Cloud-Based Inventory Management Software

Cloud technology has revolutionized inventory management by enabling real-time access to inventory data from anywhere. Businesses can now view, update, and synchronize stock counts across different warehouses instantly.

This centralization eliminates data silos and ensures everyone— from warehouse staff to finance teams—works with the same up-to-date information. Cloud-based systems also offer better scalability, allowing growing businesses to manage increasing inventory volumes effortlessly.

3. Mobile Devices and Apps

With mobile inventory apps, employees can perform counts directly from smartphones or tablets. These apps often integrate with ERP or warehouse management systems, allowing for seamless updates and error-free data collection. Mobile counting enhances flexibility, making it easier for staff to perform counts in various locations and at any time, even offline.

4. Integration with ERP Systems

An ERP system like Deskera ERP takes automation to the next level by integrating inventory counting with other business functions such as purchasing, sales, and accounting.

This ensures that every stock movement—whether a sale, return, or purchase—is recorded automatically, minimizing discrepancies between physical and recorded inventory. Deskera ERP also provides advanced reporting and analytics tools, giving managers real-time insights into stock trends, discrepancies, and valuation metrics.

5. Automation and AI-Based Forecasting

Artificial intelligence (AI) and automation tools further simplify counting by predicting stock discrepancies and optimizing count schedules. AI-driven systems can identify unusual stock movements or suggest items that need recounting based on historical accuracy data. These predictive features help businesses save time and maintain high data accuracy without extensive manual oversight.

In summary, technology simplifies inventory counting by enhancing speed, accuracy, and visibility. Businesses that adopt barcode systems, cloud-based platforms, and ERP integrations can achieve more reliable inventory control with less effort. With advanced tools like Deskera ERP, companies can transform inventory counting from a tedious manual task into a strategic, automated process that supports accuracy, efficiency, and long-term growth.

How Deskera ERP Simplifies Inventory Counting

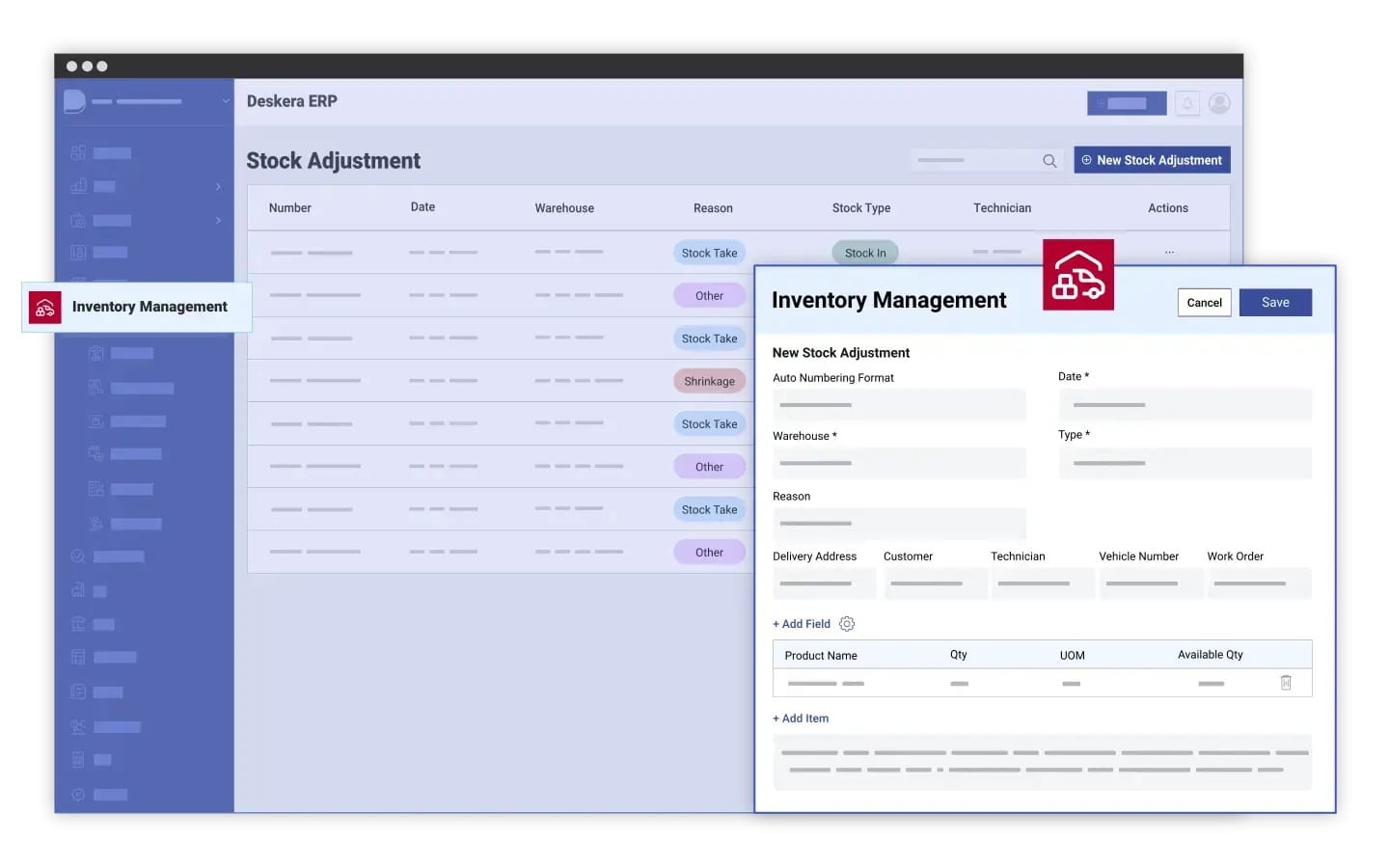

Counting inventory manually can be a complex and time-consuming task—especially for businesses managing multiple warehouses, diverse product lines, or fluctuating demand. This is where Deskera ERP makes a significant difference. Designed to streamline and automate the entire inventory management process, Deskera ERP simplifies inventory counting, minimizes errors, and ensures real-time accuracy across all business locations.

1. Real-Time Inventory Tracking

Deskera ERP provides real-time visibility into your inventory across multiple warehouses and sales channels. Every time a product is sold, returned, or restocked, the system updates automatically. This continuous synchronization reduces the need for frequent manual counts while ensuring that your recorded stock levels match physical quantities. With real-time tracking, businesses can identify discrepancies early and take corrective actions immediately.

2. Streamlined Counting with Barcode and SKU Management

With barcode and SKU integration, Deskera ERP enables faster and more accurate inventory counts. Employees can scan products directly using mobile devices, eliminating manual entry errors and saving valuable time. This digital approach ensures that each product is uniquely identified, making it easier to track movement, verify quantities, and maintain consistent records across all locations.

3. Automation and Error Reduction

Deskera ERP automates many manual tasks that typically lead to errors during inventory counts. Automated reconciliation features help detect mismatches between physical and system quantities, while smart alerts notify users of potential issues like stockouts or overstocking. This automation not only enhances accuracy but also saves time and labor costs, allowing teams to focus on higher-value tasks.

4. Comprehensive Reporting and Analytics

Accurate inventory counting is not just about knowing what’s in stock—it’s about understanding trends and making better decisions. Deskera ERP provides detailed reports and analytics on stock levels, valuation, and movement history. These insights enable businesses to identify slow-moving items, optimize reorder points, and forecast demand with greater precision. The result is a more strategic and data-driven approach to inventory management.

5. Seamless Integration Across Business Functions

One of Deskera ERP’s greatest strengths lies in its ability to integrate inventory management with other business processes, including procurement, sales, and accounting. This ensures that any change in inventory—such as a purchase order, return, or sales invoice—is automatically reflected across all relevant modules. This seamless integration creates a unified source of truth, eliminating data duplication and improving operational efficiency.

In summary, Deskera ERP transforms inventory counting from a tedious manual process into a streamlined, automated, and data-driven operation. With tools for real-time tracking, barcode integration, automation, and analytics, it helps businesses of all sizes achieve greater accuracy, save time, and make smarter inventory decisions. By adopting Deskera ERP, companies can ensure that their inventory counts are always up to date—supporting smoother operations, improved financial accuracy, and sustained business growth.

Key Takeaways

- An inventory count is the process of physically verifying and reconciling stock levels to ensure records match actual quantities. It plays a crucial role in identifying discrepancies, maintaining accurate financial data, and optimizing operational efficiency across warehouses.

- Different types of inventory counts—such as periodic, cycle, and perpetual counts—serve various business needs. Choosing the right method helps balance accuracy with operational efficiency, ensuring reliable stock data without disrupting daily operations.

- The inventory counting process involves planning, organizing, physically verifying stock, and reconciling discrepancies. Following a structured workflow supported by inventory management tools ensures accuracy, consistency, and better decision-making.

- Accurate inventory counts directly influence financial reporting, inventory management, customer satisfaction, and decision-making. They help prevent stock discrepancies, reduce costs, and improve cash flow—making them vital for business stability and growth.

- Inventory counting can be hindered by human error, time constraints, and unrecorded transactions. Addressing these challenges with proper planning, automation, and real-time data tracking is essential for ensuring reliable inventory records.

- Implementing standard procedures, training employees, scheduling regular counts, and leveraging technology are key best practices. These steps ensure consistency, accuracy, and efficiency in maintaining up-to-date inventory data.

- Modern technologies like barcode scanners, RFID systems, and cloud-based inventory software automate and simplify counting. They minimize manual errors, speed up data collection, and provide real-time visibility into inventory across multiple locations.

- Deskera ERP streamlines inventory counting through real-time tracking, barcode and SKU integration, automation, and data analytics. Its seamless integration across business functions ensures accuracy, transparency, and operational efficiency.

Related Articles