Have you ever walked into a factory and noticed machines standing still or workers waiting for tasks to begin? That’s what manufacturers call idle time—moments when resources are available but not being used productively. While it might seem minor, idle time adds up quickly, silently eating into efficiency, profitability, and customer satisfaction.

In manufacturing, idle time can arise from multiple factors—whether it’s a machine breakdown, material shortage, delayed instructions, or even workforce inefficiencies. Unlike planned downtime, idle time is unproductive and often unexpected, making it one of the costliest hidden challenges in operations. Left unchecked, it leads to higher production costs, missed delivery deadlines, and frustrated employees.

The impact goes beyond the shop floor. Idle time affects financial performance, disrupts supply chains, and diminishes overall competitiveness in an industry where every second counts. That’s why understanding its causes and adopting strategies to minimize idle time is crucial for manufacturers aiming to maximize output and maintain a competitive edge.

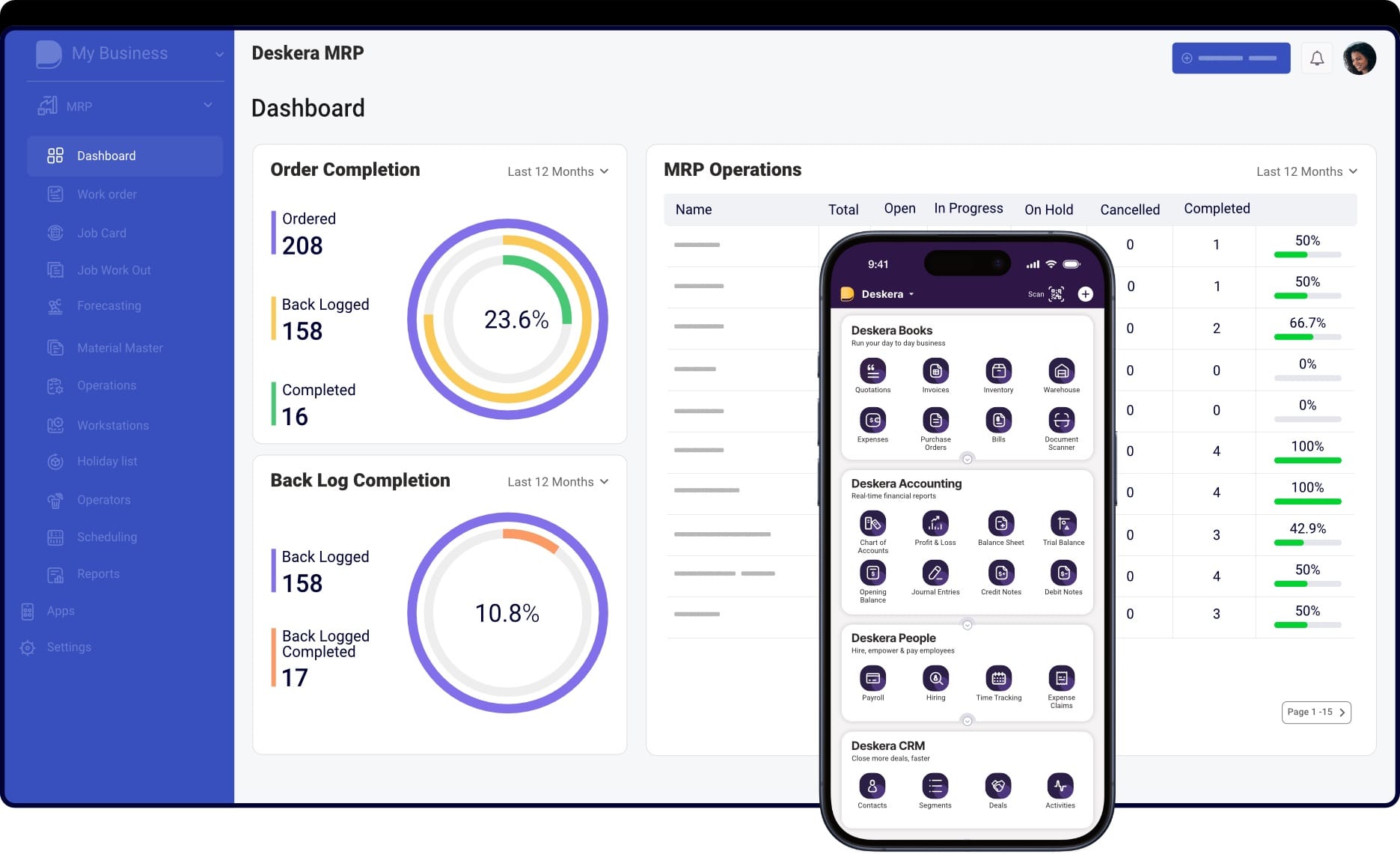

This is where technology steps in. A modern solution like Deskera Manufacturing ERP helps reduce idle time by streamlining production scheduling, tracking material availability in real time, and ensuring preventive maintenance of machinery. With features like demand forecasting, AI-powered insights, and mobile accessibility, Deskera empowers manufacturers to optimize workflows, eliminate bottlenecks, and keep resources engaged at all times.

What is Idle Time in Manufacturing?

Idle time in manufacturing, often called waiting time, refers to the period when machines, equipment, or employees are available for work but remain unproductive due to interruptions, inefficiencies, or delays. Unlike downtime—which may be planned for maintenance or unplanned due to sudden breakdowns—idle time occurs when resources are ready and capable of producing output but are prevented from doing so.

In simple terms, idle time represents lost productivity. For example, a machine may sit unused while waiting for raw materials to arrive, or employees may remain inactive due to delayed instructions or system failures. While some idle time is inevitable in manufacturing operations, excessive idle time signals inefficiencies that can impact profitability, order fulfillment, and employee morale.

It’s important to distinguish idle time from downtime. Downtime indicates that work cannot be performed due to scheduled maintenance, repairs, or unavoidable stoppages. Idle time, on the other hand, implies that production could have taken place, but obstacles—such as poor scheduling, late shipments, or workforce underutilization—kept resources from being productive.

In practice, idle time can manifest in various ways:

- Machines waiting for inputs or maintenance.

- Employees waiting for work assignments or approvals.

- Delivery trucks waiting to be loaded or unloaded.

By definition, idle time highlights inefficiency in operations. Recognizing and managing it effectively is critical for manufacturers to ensure resources are used optimally, reduce costs, and improve throughput.

Idle Time vs. Downtime

Although they sound similar, idle time and downtime are two distinct concepts in manufacturing, and understanding the difference is crucial for accurate performance tracking.

Idle Time

- Refers to periods when machines, equipment, or employees are available and capable of working but remain unproductive due to waiting or inefficiencies.

- Example: A machine waiting for raw materials, or workers waiting for instructions.

- Key aspect: Work could have been performed if conditions were properly managed.

Downtime

- Refers to periods when machines or processes are not operational and cannot produce due to planned or unplanned stoppages.

- Example: Scheduled maintenance, unexpected breakdowns, or power outages.

- Key aspect: Work cannot be performed because the resource is unavailable.

In short, idle time highlights inefficiency, while downtime highlights unavailability. Both reduce overall productivity, but idle time is particularly significant because it often indicates preventable issues such as mismanagement, poor planning, or supply chain delays.

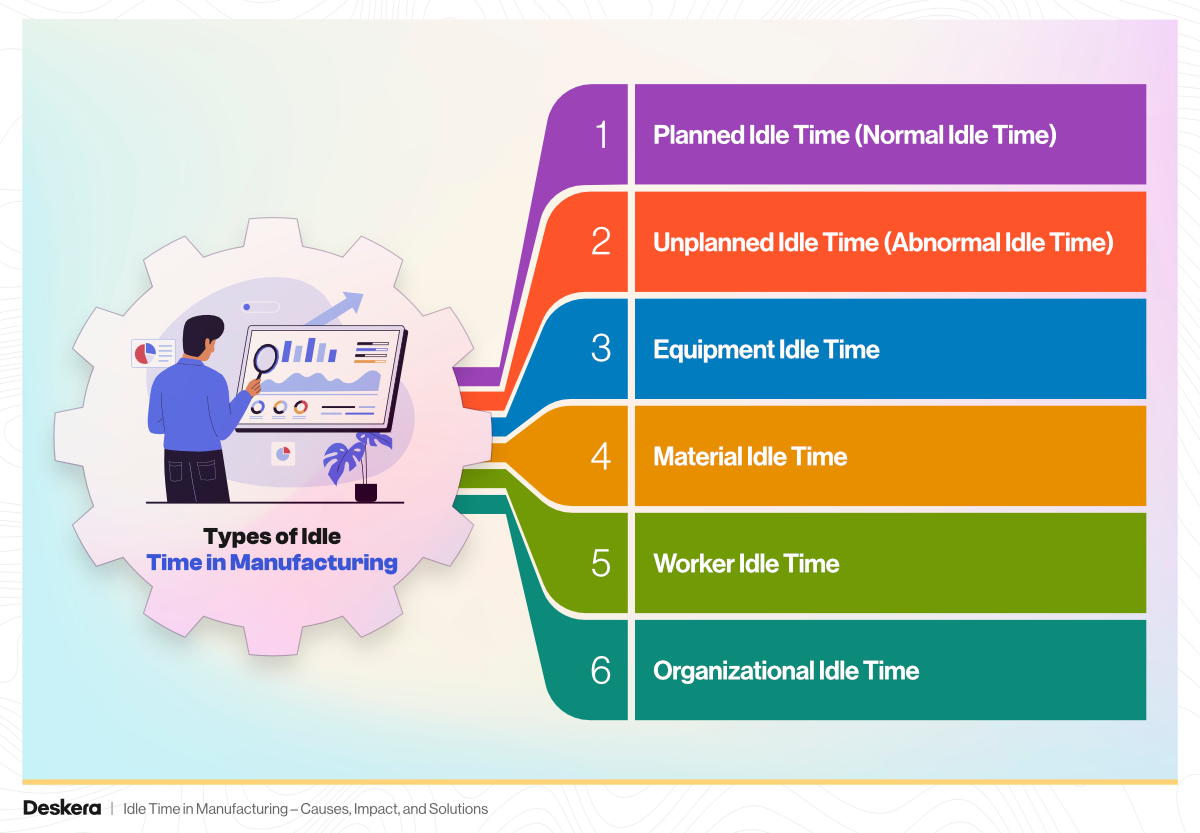

Types of Idle Time in Manufacturing

Idle time can be classified into different categories based on its cause and controllability. Understanding these types helps manufacturers identify inefficiencies and apply the right corrective measures. Broadly, idle time can be grouped as planned (normal) idle time and unplanned (abnormal) idle time, but it can also be further broken down into equipment, material, worker, and organizational idle time.

1. Planned Idle Time (Normal Idle Time)

Planned idle time, also known as normal idle time, refers to the pauses that are scheduled or unavoidable within a production cycle. While it reduces output temporarily, it is often necessary to ensure smooth operations in the long run.

Examples include:

- Employee breaks (lunch, coffee, shift changes).

- Machines turned off to prevent overheating.

- Scheduled maintenance activities.

- Waiting periods between dependent processes.

2. Unplanned Idle Time (Abnormal Idle Time)

Unplanned idle time, or abnormal idle time, occurs unexpectedly and is usually disruptive. It often stems from inefficiencies, poor planning, or sudden breakdowns, leading to wasted resources and missed deadlines.

Examples include:

- Shortages of raw materials or parts.

- Unexpected machine breakdowns.

- Power outages or technical failures.

- Workflow bottlenecks or dependency delays.

3. Equipment Idle Time

This occurs when machinery or assets remain unused even though they are available for work. Causes can include mechanical breakdowns, lack of preventive maintenance, or inefficient scheduling. Prolonged equipment idle time not only affects productivity but also adds to depreciation costs.

4. Material Idle Time

Material idle time arises when production halts due to the unavailability of raw materials or components. Supply chain disruptions, poor inventory management, or delays in vendor deliveries often cause this type of idle time.

5. Worker Idle Time

This type occurs when employees are present but not engaged in productive work. It may result from poor task allocation, waiting for inputs, or inadequate training. Worker idle time directly impacts labor utilization rates and overall efficiency.

6. Organizational Idle Time

Organizational idle time stems from management or process inefficiencies, such as poor coordination between departments, unclear communication, or flawed scheduling practices. This type is often preventable through better planning and the adoption of lean manufacturing practices.

In summary, planned idle time is unavoidable and often necessary, while unplanned idle time signals inefficiency and requires immediate action. By breaking idle time down into specific categories—equipment, material, worker, and organizational—manufacturers can pinpoint root causes and develop targeted solutions to reduce productivity losses.

How to Calculate Idle Time

Idle time is measured by comparing the time that was planned for production against the time that was actually productive. The standard formula is:

Idle Time = Scheduled Production Time – Actual Production Time

- Scheduled Production Time: The duration management planned for a machine, system, or employee to be active.

- Actual Production Time: The time the machine or employee was actually productive.

Example 1: Machine Idle Time

Suppose a machine is scheduled to run for 12 hours in a day. Due to material shortages and technical issues, it only runs for 8 hours.

- Idle Time = 12 – 8 = 4 hours

Example 2: Employee Idle Time

An employee is scheduled for an 8-hour shift, excluding breaks. However, due to waiting for instructions and system downtime, the employee is only productive for 6.5 hours.

- Idle Time = 8 – 6.5 = 1.5 hours

Example 3: Conveyor Belt Scenario

A conveyor belt is scheduled to run 10 hours daily. Accounting for 15 minutes to power up, 15 minutes to shut down, and a 1-hour scheduled shift change, the effective scheduled production time is 8.5 hours. If an operator arrives late and the machine only runs for 7.5 hours, the idle time is:

- Idle Time = 8.5 – 7.5 = 1 hour

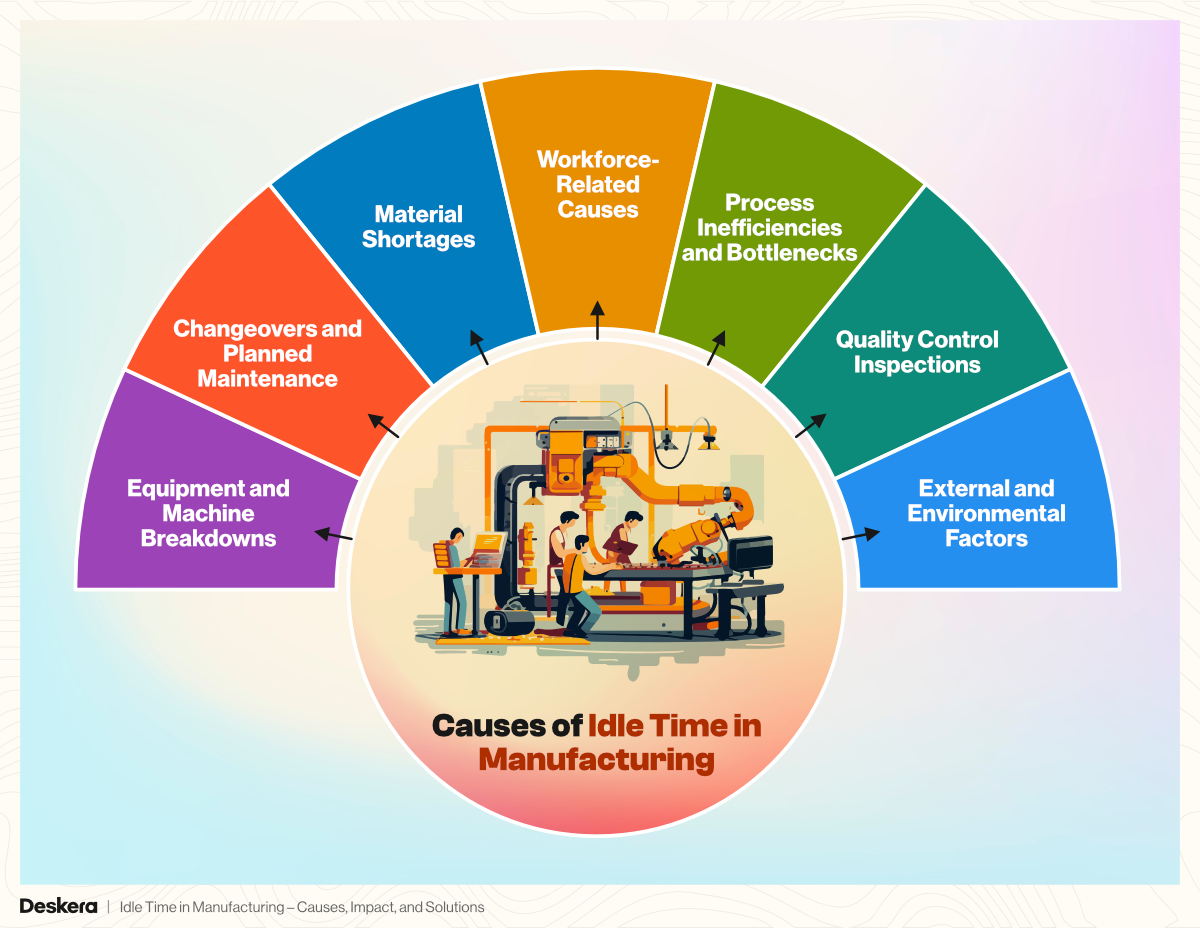

Causes of Idle Time in Manufacturing

Idle time in manufacturing arises when workers or machines are unproductive despite being scheduled for use. While some idle time is unavoidable, excessive idle periods often point to systemic inefficiencies. These causes can be broadly categorized into equipment-related, material-related, workforce-related, process-related, and external factors.

1. Equipment and Machine Breakdowns

Unexpected equipment failures are one of the most common sources of idle time. Mechanical malfunctions, electrical issues, or software glitches can bring production lines to a halt. Even minor disruptions, if left unresolved, can snowball into hours of lost productivity. Preventive maintenance, predictive analytics, and having a responsive maintenance team can help reduce this risk.

2. Changeovers and Planned Maintenance

Not all idle time is unplanned. Scheduled maintenance, equipment reconfiguration, and production changeovers often result in deliberate pauses. While necessary, inefficiently managed changeovers can consume more time than needed. Streamlined setup procedures, lean practices, and strategic scheduling during off-peak periods help minimize the impact.

3. Material Shortages

Supply chain disruptions and poor inventory management often leave machines and workers idle while waiting for raw materials. A lack of parts for maintenance can also extend idle time. Effective inventory management, close supplier collaboration, and demand forecasting ensure materials are available when needed, preventing costly stoppages.

4. Workforce-Related Causes

Idle time can also stem from labor-related factors:

- Employee Breaks and Shift Changes: Poorly coordinated breaks or overlapping shift transitions create gaps in productivity.

- Absenteeism and Personal Events: Employee unavailability due to personal reasons or emergencies can slow down operations.

- Lack of Awareness or Training: New hires unfamiliar with protocols may inadvertently extend idle time. Cross-training and structured onboarding programs help reduce these inefficiencies.

5. Process Inefficiencies and Bottlenecks

Misaligned job scheduling, communication breakdowns, or workflow bottlenecks can leave employees waiting for instructions or for upstream tasks to complete. Poor planning, administrative errors, or delayed decision-making also contribute to unproductive time. Using digital tools for scheduling, real-time communication platforms, and clear SOPs can reduce such delays.

6. Quality Control Inspections

While essential for ensuring product standards, lengthy or poorly integrated quality inspections can halt production unnecessarily. Automated inspection systems or in-line testing solutions can help balance quality assurance with operational efficiency.

7. External and Environmental Factors

Certain causes lie beyond management’s control. Natural disasters, severe weather conditions, or sudden market fluctuations may force facilities to pause operations. Similarly, system-wide failures like power outages or IT crashes leave both workers and assets idle until recovery. While these cannot always be avoided, building resilience through contingency planning and backup systems helps mitigate the impact.

Idle time in manufacturing stems from a mix of internal inefficiencies and uncontrollable external factors. Identifying these causes is the first step to implementing targeted strategies—whether through preventive maintenance, better workforce planning, or smarter supply chain management.

Impact of Idle Time in Manufacturing

Idle time doesn’t just pause production—it creates a ripple effect that impacts costs, efficiency, employee morale, and customer satisfaction. Understanding these impacts helps manufacturers recognize why reducing idle time is a strategic priority.

1. Increased Operational Costs

Idle time directly translates into wasted labor hours, higher overhead, and underutilized resources. Workers still draw wages even when not producing, while equipment depreciation and utility costs continue. Over time, this raises the cost per unit and reduces overall profitability.

2. Reduced Production Efficiency

When machines or workers remain idle, production capacity decreases. This leads to longer lead times and missed deadlines, disrupting delivery schedules. A plant running at less than full capacity also struggles to meet peak demand, limiting growth opportunities.

3. Supply Chain Disruptions

Idle time at one stage of production often creates bottlenecks downstream. For example, a delay in material processing may halt assembly lines, leading to a chain reaction across the supply chain. These disruptions reduce agility and increase dependency on costly last-minute adjustments.

4. Lower Product Quality

Extended idle time can affect product quality indirectly. Frequent stop-start production cycles increase the chances of errors, defects, or inconsistencies. Additionally, rushed efforts to make up for lost time may compromise quality standards.

5. Decline in Employee Morale and Engagement

Consistent idle time can demotivate employees. Workers may feel disengaged or underutilized when their skills aren’t fully tapped. In some cases, prolonged idle time leads to frustration, lack of accountability, or even increased turnover rates.

6. Customer Dissatisfaction

Longer production cycles and missed deadlines inevitably impact customers. Late deliveries or inconsistent product availability erode trust, damage brand reputation, and may push clients toward competitors. In industries with tight deadlines, such as automotive or electronics, even small delays can result in major customer losses.

7. Strategic and Competitive Setbacks

Idle time eats into a company’s long-term competitiveness. Inefficient use of resources limits scalability, reduces margins, and restricts investment in innovation. Businesses that fail to address idle time may find themselves outpaced by competitors adopting leaner, more efficient processes.

The impact of idle time in manufacturing goes beyond lost hours—it drives up costs, slows production, disrupts supply chains, lowers employee morale, and weakens customer trust. By addressing idle time proactively, manufacturers can safeguard profitability and maintain a strong competitive edge.

Strategies to Reduce Idle Time in Manufacturing

While idle time is inevitable to some extent, manufacturers can significantly reduce its frequency and impact with the right strategies. By combining technology, process optimization, and workforce empowerment, companies can turn lost hours into productive outcomes.

1. Define and Measure Idle Time

The first step is to clearly define what idle time means for your operations—whether it’s waiting for raw materials, machine breakdowns, or employee inactivity. Once defined, set Key Performance Indicators (KPIs) and track them using digital tools. Accurate measurement provides visibility into bottlenecks and helps teams prioritize corrective actions.

2. Implement Preventive and Predictive Maintenance

Unexpected machine failures are one of the biggest causes of idle time. A structured preventive maintenance schedule keeps equipment running smoothly, while predictive maintenance powered by IoT sensors and data analytics helps identify potential failures before they occur. This proactive approach reduces breakdowns and extends machine life.

3. Optimize Scheduling and Resource Allocation

Efficient scheduling ensures machines and employees are utilized effectively. Aligning workforce shifts with production demands, avoiding overstaffing, and staggering breaks can prevent unnecessary idle time. Leveraging manufacturing scheduling software allows real-time visibility and quick adjustments when unexpected delays arise.

4. Streamline Inventory and Material Management

Material shortages are a common trigger for idle time. Adopting just-in-time inventory practices, setting up reorder alerts, and collaborating closely with suppliers reduces the risk of production halts. Digital inventory management systems also improve stock visibility, ensuring materials are available when needed.

5. Train and Cross-Train Employees

Idle time often occurs when workers are underutilized or lack clarity on their tasks. Regular training and cross-training ensure employees are equipped to handle multiple roles, cover for absent colleagues, and adapt during workflow disruptions. A well-trained workforce not only minimizes idle time but also boosts agility and engagement.

6. Improve Communication and Standardize Processes

Miscommunication or unclear work orders can lead to unnecessary waiting periods. Standard Operating Procedures (SOPs), visual guides, and clear documentation reduce ambiguity. Real-time communication tools, team huddles, and project management platforms further ensure tasks are executed smoothly without delays.

7. Apply Lean Manufacturing Principles

Adopting lean practices such as Single-Minute Exchange of Die (SMED) can drastically reduce changeover times. Continuous improvement methodologies help identify inefficiencies, eliminate waste, and foster a culture where idle time is actively reduced.

8. Monitor, Analyze, and Continuously Improve

Tracking idle time using time-tracking software or ERP systems provides actionable insights. Regularly reviewing reports, analyzing trends, and encouraging employee feedback allows manufacturers to refine workflows and continuously improve operations. Even small reductions in idle time can add up to major efficiency gains.

Reducing idle time in manufacturing requires a multi-pronged approach—clear definitions, preventive maintenance, optimized scheduling, streamlined inventory, effective training, strong communication, lean methodologies, and continuous monitoring. By implementing these strategies, manufacturers can boost productivity, cut costs, and maintain a more resilient production environment.

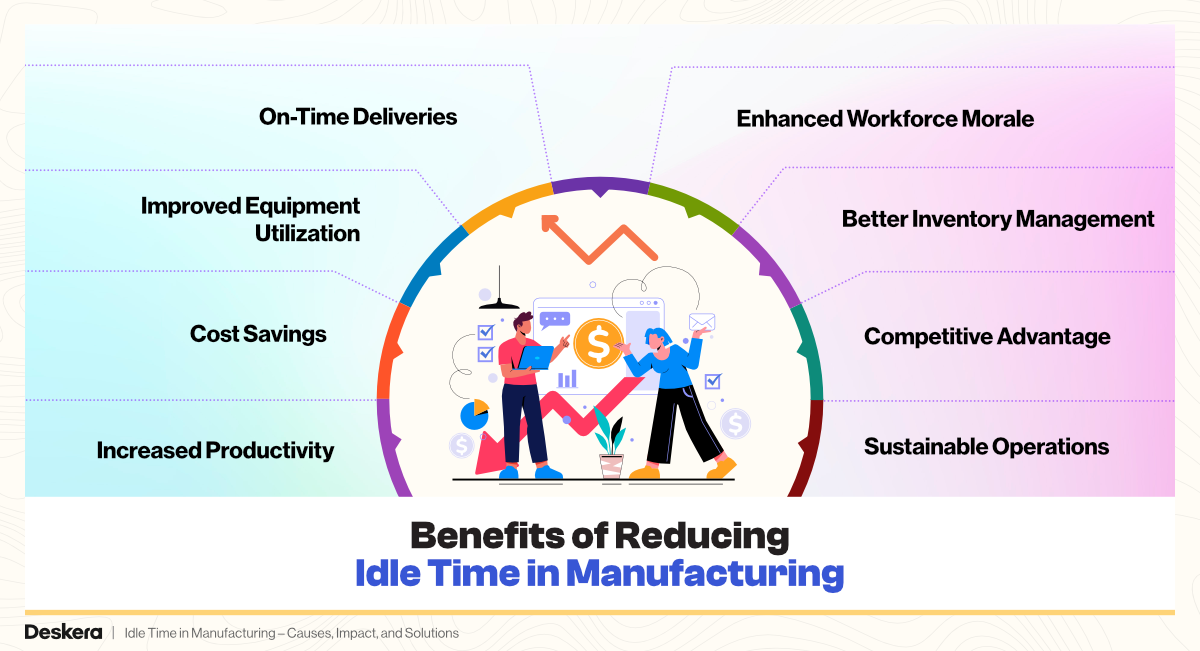

Benefits of Reducing Idle Time in Manufacturing

Idle time might seem like a minor pause in production, but when it accumulates, it can significantly drain resources. By actively reducing idle time, manufacturers not only boost efficiency but also create long-term competitive advantages. Below are the key benefits:

1. Increased Productivity

When machines and employees spend less time waiting, production output naturally rises. Streamlining processes ensures that every available resource is used effectively, allowing manufacturers to meet demand without overextending capacity.

2. Cost Savings

Idle time often translates to wasted labor costs, higher energy bills, and inefficient equipment usage. By minimizing it, companies save on unnecessary expenses while improving the return on their fixed and variable investments.

3. Improved Equipment Utilization

Reducing idle time means machines are used more effectively, maximizing their lifespan and justifying the capital spent on them. Preventive measures also reduce wear and tear, lowering maintenance and replacement costs.

4. On-Time Deliveries

Customer satisfaction heavily depends on timely deliveries. With fewer production delays, manufacturers can meet delivery schedules consistently, strengthening customer trust and improving brand reputation.

5. Enhanced Workforce Morale

Employees who spend long periods waiting often feel disengaged. By reducing idle time, workers remain engaged with meaningful tasks, boosting morale, job satisfaction, and overall performance.

6. Better Inventory Management

Idle time caused by material shortages often leads to overstocking as a safeguard. When idle time is reduced, manufacturers can rely on leaner inventory practices, which lower storage costs and reduce waste.

7. Competitive Advantage

A manufacturer with optimized processes and reduced idle time operates faster, more efficiently, and at lower costs than competitors. This creates opportunities for better pricing, higher profitability, and stronger market positioning.

8. Sustainable Operations

Minimizing idle time cuts down on wasted energy and resources, contributing to sustainability goals. Companies can lower their carbon footprint while aligning with modern environmental standards and customer expectations.

Reducing idle time is not just about saving minutes—it’s about creating a more productive, cost-efficient, employee-friendly, and sustainable manufacturing operation. The ripple effects include stronger customer relationships, healthier profit margins, and long-term industry competitiveness.

How to Use Idle Time

While idle time is often seen as wasted productivity, it doesn’t always have to be negative. When approached proactively, it can become an opportunity for growth, collaboration, and preparation. Instead of letting valuable minutes slip away, here are effective ways employees and organizations can make the most of idle time:

1. Invest in Continuous Learning

Idle moments can be directed toward skill development. Employees can use this time to take short online courses, complete certification modules, or explore industry trends. This not only enhances their personal growth but also increases the organization’s knowledge base.

2. Support Colleagues

Idle employees can step in to assist overworked teammates. Whether it’s helping with administrative tasks, sharing technical knowledge, or lending a hand in production bottlenecks, collaboration strengthens team morale and ensures smoother workflows.

3. Plan and Prepare for Upcoming Tasks

Downtime offers a chance to prepare ahead. Employees can use idle time to organize resources, set up documents, review briefs, or conduct background research. By doing so, they minimize delays once the actual work begins.

4. Engage in Process Improvement

Idle time can also be used to reflect on inefficiencies in workflows. Employees can suggest improvements, document pain points, or brainstorm solutions that could help reduce future idle time.

5. Tackle Backlog or Low-Priority Work

There are always pending tasks that get pushed aside during busy times. Idle time can be productively used to clear small but necessary activities such as updating reports, cleaning up workstations, or organizing digital files.

6. Focus on Well-being

Employees can also use idle moments for quick breaks, stretching, or mindfulness exercises. This promotes better health, reduces stress, and ensures they are energized when critical tasks resume.

Idle time doesn’t have to equal wasted time. When used wisely for learning, collaboration, preparation, or even well-being, it transforms from a cost into an investment in long-term productivity and employee engagement.

How Can Deskera Manufacturing ERP Help You Reduce Idle Time?

Reducing idle time requires real-time visibility, accurate planning, and streamlined coordination across production, inventory, and workforce management. Deskera Manufacturing ERP brings all of these capabilities into a single platform, helping manufacturers minimize idle time and boost efficiency.

1. Real-Time Production Monitoring

Deskera provides live tracking of machines, resources, and workflows. Managers can immediately detect bottlenecks, delays, or resource underutilization, allowing them to take corrective actions before idle time escalates.

2. Smarter Scheduling and Capacity Planning

With built-in MRP (Material Requirements Planning), Deskera ensures raw materials, tools, and labor are available exactly when needed. This minimizes waiting time caused by poor scheduling or supply shortages.

3. Automated Work Orders and Task Allocation

Deskera automates the creation and tracking of work orders, reducing manual errors and delays. Employees and machines are assigned tasks more efficiently, ensuring continuous workflow without unnecessary idle periods.

4. AI-Powered Assistant for Quick Insights

Deskera’s AI assistant, David, helps managers generate instant reports on idle time trends, machine usage, and labor efficiency. With these insights, leaders can make faster, data-driven decisions to prevent idle resources.

5. Mobile Accessibility for On-the-Go Management

With Deskera’s mobile app, supervisors can monitor production lines, inventory, and labor productivity in real time—even remotely. This prevents small disruptions from turning into prolonged idle time.

By aligning scheduling, production monitoring, and resource allocation, Deskera Manufacturing ERP doesn’t just reduce idle time—it transforms it into an opportunity for higher productivity, faster delivery, and lower costs.

Key Takeaways

- Idle time in manufacturing is inevitable, but when left unmanaged, it hampers productivity and profitability. Identifying its causes and leveraging tools like Deskera Manufacturing ERP can help minimize it effectively.

- Idle Time vs. Downtime: Idle time differs from downtime—idle time is when workers or machines are available but not productive, while downtime occurs when machines are non-operational due to breakdowns or maintenance.

- Formula to Calculate Idle Time: Using the formula Idle Time = (Standard Time – Actual Time Worked) helps manufacturers quantify productivity gaps, identify problem areas, and track improvements over time.

- Causes of Idle Time in Manufacturing: Factors such as equipment breakdowns, material shortages, scheduling inefficiencies, natural disasters, personal issues, and poor planning contribute to idle time. Recognizing these root causes is the first step in reducing them.

- Impact of Idle Time in Manufacturing: Idle time leads to reduced output, higher operational costs, poor delivery timelines, lower employee morale, and diminished competitiveness in the market.

- Strategy to Reduce Idle Time: A proactive strategy that combines predictive maintenance, efficient scheduling, employee cross-training, and lean practices can significantly reduce idle time and keep production flowing smoothly.

- Benefits of Reducing Idle Time in Manufacturing: Minimizing idle time improves efficiency, boosts profitability, enhances product quality, optimizes resource utilization, and strengthens customer satisfaction.

- How to Use Idle Time Productively: Instead of letting time go to waste, employees can use idle time to upskill, support colleagues, plan for future tasks, or complete admin work to add value to operations.

- How Deskera Manufacturing ERP Helps Reduce Idle Time: Deskera Manufacturing ERP reduces idle time through real-time production monitoring, smart scheduling, MRP-driven material planning, AI-powered insights, and mobile accessibility for quick decisions.

Related Articles