In 2026, when customers expect same-day delivery, real-time order visibility, and seamless buying experiences across channels, what truly separates efficient businesses from struggling ones? The answer lies in a smart, technology-driven distribution strategy. At its core, a distribution strategy defines how products move from manufacturers to end customers in the most efficient, cost-effective, and reliable manner—directly influencing customer satisfaction, operating margins, and long-term competitiveness.

As supply chains grow more complex and customer expectations continue to rise, traditional distribution models are no longer enough. Businesses must navigate rising logistics costs, frequent disruptions, and unpredictable demand while maintaining high service levels. A well-structured distribution strategy helps organizations determine the right channels, optimal inventory placement, and most efficient fulfillment methods to ensure products reach the right customers at the right time.

In 2026, distribution strategies are increasingly shaped by digital transformation. Omnichannel fulfillment, direct-to-consumer models, and data-driven decision-making are redefining how goods flow through the supply chain. Real-time analytics, automation, and integrated systems now enable businesses to forecast demand more accurately, optimize routes, and maintain visibility across complex distribution networks—turning distribution from a cost center into a competitive advantage.

This is where Deskera ERP plays a critical role in enabling modern distribution strategies. Deskera ERP provides a unified platform for inventory management, order processing, and demand forecasting, offering real-time visibility across warehouses and distribution channels. By integrating distribution operations with finance and core business processes, Deskera helps organizations improve delivery performance, reduce inefficiencies, and scale their distribution networks with confidence in 2026 and beyond.

What Is a Distribution Strategy?

A distribution strategy is a company’s structured plan for moving products or services from the point of production to the final customer. It defines the channels, methods, and processes used across this journey—shaping everything from inventory storage and logistics to order fulfillment and post-sale customer experience. In essence, it determines how efficiently and effectively a business delivers value to its market.

At a strategic level, a distribution strategy involves deliberate decisions that directly influence both customer satisfaction and business performance. These decisions include selecting the right distribution channels (direct, indirect, exclusive, or hybrid), determining the balance between in-house capabilities and third-party partners, defining geographic reach, and choosing the systems that coordinate operations. The goal is not just to move inventory, but to do so in a way that aligns with business objectives such as market expansion, cost optimization, brand control, and faster delivery.

An effective distribution strategy is inherently cross-functional. C-suite leaders set the overall direction by approving investments, defining growth priorities, and establishing key partnerships. Operations teams translate that strategy into execution by managing warehouses, transportation networks, and fulfillment workflows, while proactively identifying risks and inefficiencies. At the same time, marketing and sales teams play a critical role by generating demand, maintaining brand consistency across channels, and building strong relationships with customers and distribution partners.

Ultimately, a distribution strategy must be designed around the target customer and product characteristics. How and where customers prefer to buy, the nature of the product itself, and the required level of service all influence the chosen approach. Many organizations adopt multiple or overlapping distribution strategies to reach different customer segments, expand their market presence, and remain flexible as business conditions and customer expectations evolve.

Elements of a Distribution Strategy

An effective distribution strategy is built on a set of interconnected elements that balance operational realities with customer expectations and business goals. These elements guide how products are stored, moved, and delivered, while ensuring the strategy remains flexible enough to adapt to competitive pressures and changing market conditions.

Product Type and Characteristics

The nature of the product directly influences distribution decisions. Factors such as size, shelf life, handling requirements, and value determine storage conditions, packaging standards, and delivery methods. For example, perishable goods may require temperature-controlled logistics, while high-value or luxury products often demand secure handling and premium presentation to protect brand perception.

Target Audience and Buying Behavior

Understanding how and where customers prefer to buy is central to selecting the right distribution channels. Different customer segments have varying expectations around convenience, delivery speed, and purchasing platforms. Younger, digitally native audiences may favor mobile commerce and rapid delivery, while other segments may prioritize in-store availability or personalized service. Aligning distribution with these preferences improves accessibility and customer satisfaction.

Budget and Cost Structure

Distribution strategies must align with financial constraints and profitability goals. Organizations with larger budgets may invest in owned warehouses, automation, and advanced technology, while cost-conscious businesses often rely on third-party logistics providers to maintain flexibility. The key is balancing service levels with sustainable cost management.

Competitive Landscape

Competitor strategies play a significant role in shaping distribution choices. If competitors dominate certain retail channels or regions, alternative approaches such as direct-to-consumer models or niche market focus may provide differentiation. Identifying gaps in competitor coverage can also uncover opportunities for expansion and competitive advantage.

Market Conditions and External Factors

Economic, regulatory, and logistical conditions continuously influence distribution viability. Fluctuations in fuel costs, labor availability, trade regulations, and customer expectations can all impact delivery models and channel performance. To remain resilient, businesses must monitor these conditions closely and adapt their distribution strategies through data-driven insights and ongoing optimization.

Key Components of an Effective Distribution Strategy in 2026

In 2026, an effective distribution strategy goes beyond moving products efficiently—it integrates channels, technology, partners, and customer experience into a cohesive system. Leading organizations combine operational precision with strategic flexibility to meet evolving customer expectations, manage costs, and scale sustainably.

The following components collectively define a modern, future-ready distribution strategy.

Channel Selection and Mix

Choosing the right mix of distribution channels is foundational to success. Businesses must decide how to balance direct, indirect, and hybrid channels based on customer preferences, product characteristics, and growth goals. A well-optimized channel mix ensures broad market coverage while maintaining control over pricing, branding, and service levels across both digital and physical touchpoints.

Omnichannel Presence

Modern distribution strategies require a seamless omnichannel presence that connects e-commerce platforms, mobile apps, owned stores, third-party retailers, and social commerce channels. Shared inventory visibility, consistent pricing, coordinated promotions, and unified customer service ensure customers receive a consistent experience regardless of where they interact with the brand.

Inventory Positioning and Fulfillment Models

Strategic inventory placement is critical for meeting delivery expectations while controlling costs. Businesses must determine where inventory should be stored—centralized warehouses, regional distribution centers, micro-fulfillment hubs, or retail locations—and which fulfillment models to use, such as ship-from-warehouse, ship-from-store, or click-and-collect. Effective positioning reduces lead times, minimizes stockouts, and improves capital efficiency.

Demand Forecasting and Capacity Planning

Accurate demand forecasting enables organizations to align production, inventory, and distribution capacity with actual market needs. By analyzing historical data, seasonality, and real-time demand signals, companies can anticipate volume fluctuations, prevent overstocking or shortages, and ensure logistics and warehouse capacity can support peak demand periods.

Hyperlocal and On-Demand Delivery

As delivery speed becomes a key differentiator, hyperlocal fulfillment models play an increasingly important role. Micro-fulfillment centers, dark stores, smart lockers, and partnerships with last-mile delivery providers allow companies to offer same-day or even two-hour delivery options. This proximity-based approach improves responsiveness while reducing last-mile costs.

Partner and Distributor Management

For businesses that rely on third-party distributors, retailers, or logistics providers, strong partner management is essential. This includes defining clear performance expectations, maintaining transparent communication, aligning incentives, and monitoring service levels. Effective collaboration ensures consistent execution, protects brand standards, and reduces channel conflict.

Sustainable Distribution Practices

Sustainability is now a core consideration in distribution strategy design. Companies are optimizing transportation routes, adopting low-emission vehicles, using recyclable or reusable packaging, and improving energy efficiency across warehouses and fulfillment centers. Tracking and reporting sustainability metrics also supports regulatory compliance and strengthens brand trust.

Technology and Data Integration

Technology acts as the backbone of modern distribution strategies. Integrated ERP, WMS, TMS, and analytics platforms provide real-time visibility across inventory, orders, and shipments. Data integration enables faster decision-making, predictive insights, and continuous optimization across channels, partners, and fulfillment operations.

Advanced Supply Chain Technology

Beyond foundational systems, advanced technologies such as IoT, AI, machine learning, robotics, and blockchain further enhance distribution performance. These tools support real-time tracking, intelligent forecasting, automated warehousing, and secure data sharing—driving greater accuracy, speed, and resilience.

Premium Customer Experience

Ultimately, every distribution decision impacts the customer. A modern strategy prioritizes fast and reliable delivery, transparent tracking, easy returns, and personalized service across channels. Value-added services and loyalty programs further strengthen relationships, turning efficient distribution into a long-term competitive advantage.

Importance of a Distribution Strategy

A well-defined distribution strategy is critical to ensuring that products reach the right customers at the right time and through the right channels. Beyond simply moving goods, it directly influences operational efficiency, customer satisfaction, market reach, and long-term profitability. In an increasingly competitive and omnichannel-driven environment, optimizing distribution is essential for sustainable business growth.

Improved Operational Efficiency and Cost Optimization

An effective distribution strategy streamlines supply chain processes by eliminating unnecessary steps, optimizing transportation routes, and improving warehouse utilization.

Better inventory visibility reduces losses from overstocking or stockouts, while efficient coordination across production, warehousing, and logistics lowers overall operational costs. Together, these efficiencies enable faster time-to-market and stronger margin control.

Enhanced Customer Experience

Distribution plays a central role in shaping the customer experience. Reliable product availability, faster deliveries, and transparent order tracking build trust and satisfaction.

Omnichannel distribution models further enhance convenience by offering flexible options such as online ordering, in-store pickup, and easy returns—creating a consistent and seamless brand experience across all touchpoints.

Expanded Market Reach and Accessibility

A strong distribution strategy enables businesses to reach customers across local, national, and international markets. By leveraging multiple channels and strategic partnerships, companies can access new geographies, customer segments, and sales platforms. This broader reach increases brand visibility and ensures products are available where and when customers want them.

Competitive Advantage and Agility

Companies with fast, flexible, and dependable distribution capabilities are better positioned to respond to shifting demand and market disruptions. An optimized distribution strategy allows organizations to pivot quickly, adjust fulfillment models, and stay ahead of competitors by consistently meeting or exceeding customer expectations.

Increased Sales, Revenue, and Customer Loyalty

When products are easy to find and delivered on time, customers are more likely to complete purchases and return for repeat business. Consistent availability and dependable delivery strengthen customer trust, drive loyalty, and directly contribute to higher sales volumes and long-term revenue growth.

Alignment with Business Growth Objectives

A distribution strategy aligned with business goals supports scalable growth. Whether the objective is cost reduction, market expansion, or brand positioning, distribution decisions help translate strategic intent into execution.

By continuously refining the strategy as customer preferences and market conditions evolve, businesses can unlock new opportunities while maintaining operational resilience.

Types of Distribution Strategies

Distribution strategies differ based on the level of control a company wants, the breadth of market reach it needs, and the type of customer experience it aims to deliver.

Some approaches prioritize scale and accessibility, while others focus on brand control and high-touch engagement. Many organizations use a combination of these strategies to serve different products, regions, or customer segments effectively.

Direct Distribution

Direct distribution involves selling products straight to end customers through owned channels such as company websites, mobile apps, physical stores, or dedicated sales teams.

This approach gives businesses full control over branding, pricing, customer data, and the overall buying experience. It also enables faster feedback and stronger customer relationships.

However, direct distribution requires significant investment in inventory management, fulfillment, and customer support, making it more suitable for high-value, brand-sensitive, or experience-driven offerings.

Indirect Distribution

Indirect distribution relies on third-party intermediaries such as wholesalers, distributors, retailers, or online marketplaces to reach customers. By outsourcing logistics and local sales efforts, companies can expand their reach quickly and operate with lower internal complexity.

The trade-off is reduced visibility and control over the customer experience. This model works well for mass-market products, fast-moving consumer goods, and businesses expanding into new or international markets.

Intensive Distribution

Intensive distribution focuses on maximum availability by placing products in as many outlets as possible. The goal is convenience and volume rather than brand control, making it ideal for low-cost, high-frequency purchases.

This strategy requires strong logistics capabilities and high inventory availability to support widespread placement across supermarkets, convenience stores, and other high-traffic locations.

Selective Distribution

Selective distribution involves partnering with a limited number of authorized sellers that meet specific standards related to service quality, brand alignment, or location.

This approach balances reach and control, allowing companies to protect brand equity while still accessing multiple sales points. It is commonly used by mid-range to premium brands in industries such as electronics, fashion, and home appliances.

Exclusive Distribution

Exclusive distribution restricts product availability to one or very few partners within a defined market or territory. This strategy enhances brand prestige, supports premium pricing, and allows companies to invest deeply in training and customer experience at the point of sale. While exclusivity strengthens brand positioning, it also limits market exposure and increases reliance on selected partners.

Dual Distribution

Dual distribution combines direct and indirect channels, allowing companies to sell through their own platforms while also partnering with third-party retailers or distributors.

This hybrid approach expands market reach and provides flexibility to serve different customer segments. However, it requires careful channel management to avoid conflicts related to pricing, promotions, or customer ownership.

Omnichannel Distribution

Omnichannel distribution integrates online and offline channels into a unified customer experience. Customers can browse, purchase, return, or receive support through multiple touchpoints while enjoying consistent pricing, promotions, and availability. This strategy improves convenience and loyalty but depends heavily on real-time inventory visibility and strong system integration.

Reverse Distribution

Reverse distribution focuses on moving products back from customers to the company for returns, repairs, recycling, refurbishment, or disposal. It is increasingly important for sustainability initiatives, regulatory compliance, and industries with high return rates. While it adds logistical complexity, reverse distribution can reduce waste, recover value, and strengthen brand trust.

Common Distribution Strategy Challenges in 2026

As distribution networks become more complex and customer expectations continue to rise, businesses face a new set of challenges in designing and executing effective distribution strategies.

In 2026, these challenges extend beyond logistics efficiency to include technology integration, sustainability, and experience consistency across channels.

Managing Omnichannel Complexity

Operating across multiple online and offline channels increases operational complexity. Businesses must synchronize inventory, pricing, promotions, and order fulfillment in real time.

Without unified systems, omnichannel strategies often lead to inventory imbalances, order delays, and inconsistent customer experiences.

Rising Logistics and Fulfillment Costs

Transportation, warehousing, labor, and fuel costs continue to increase, putting pressure on margins. Same-day and next-day delivery expectations further inflate last-mile expenses, making it difficult for businesses to balance speed with cost efficiency.

Inventory Imbalances and Demand Volatility

Unpredictable demand, shorter product life cycles, and frequent market disruptions make accurate inventory planning challenging.

Overstocking ties up working capital, while stockouts result in lost sales and damaged customer trust. Maintaining optimal inventory levels across multiple locations remains a persistent issue.

Limited End-to-End Visibility

Many organizations still lack real-time visibility across their distribution networks. Disconnected systems and siloed data make it difficult to track inventory movement, monitor partner performance, and respond quickly to disruptions, leading to reactive rather than proactive decision-making.

Partner and Channel Conflict

Companies using both direct and indirect channels often face conflicts related to pricing, promotions, and customer ownership. Poorly aligned incentives and unclear governance can strain partner relationships and weaken overall distribution performance.

Last-Mile Delivery Challenges

The last mile remains one of the most expensive and operationally complex parts of distribution. Urban congestion, failed delivery attempts, labor shortages, and customer availability all impact delivery reliability and cost, especially for hyperlocal and on-demand models.

Sustainability and Regulatory Pressures

Businesses are under increasing pressure to reduce their environmental footprint and comply with evolving regulations. Implementing sustainable distribution practices—such as low-emission transport, recyclable packaging, and emissions reporting—adds complexity and requires additional investment.

Technology Integration Gaps

While advanced technologies offer significant benefits, integrating ERP, WMS, TMS, and analytics platforms remains a challenge. Legacy systems, data silos, and lack of skilled resources can prevent organizations from fully realizing the value of digital distribution.

How to Build a Distribution Strategy Step by Step

Building an effective distribution strategy requires a structured, goal-driven approach that aligns customer expectations with operational capabilities. In 2026, successful strategies are data-driven, flexible, and designed to scale as markets and demand evolve.

The following steps provide a practical framework for creating a resilient distribution strategy.

Step 1: Define Business Goals and Success Metrics

Start by clarifying what the distribution strategy needs to achieve. Common objectives include faster delivery, cost reduction, wider market reach, improved service levels, or stronger brand control.

Defining clear KPIs—such as order fulfillment rate, delivery lead time, or distribution cost per unit—ensures progress can be measured and optimized over time.

Step 2: Understand Your Customers and Demand Patterns

Analyze who your customers are, where they are located, and how they prefer to buy. Evaluate buying behavior across channels, delivery speed expectations, and service requirements. Understanding demand patterns, seasonality, and regional variations helps shape channel selection and fulfillment decisions.

Step 3: Select the Right Distribution Channels

Choose a channel mix that aligns with customer preferences, product characteristics, and growth objectives. This may include direct-to-consumer, retail partners, distributors, marketplaces, or a hybrid model. Each channel should have a defined role to avoid overlap, inefficiencies, or internal competition.

Step 4: Design Inventory Positioning and Fulfillment Models

Determine where inventory should be stored and how orders will be fulfilled. Options include centralized warehouses, regional distribution centers, micro-fulfillment hubs, or ship-from-store models. The goal is to balance speed, cost, and inventory efficiency while maintaining high service levels.

Step 5: Plan Demand Forecasting and Capacity

Use historical data, market insights, and predictive analytics to forecast demand accurately. Align production, warehousing, transportation, and labor capacity with anticipated volumes. Proactive capacity planning reduces the risk of stockouts, delays, and excess inventory during demand fluctuations.

Step 6: Establish Partner and Distributor Governance

If third-party partners are involved, define clear roles, performance expectations, and service-level agreements. Strong partner management includes regular performance reviews, transparent communication, and aligned incentives to ensure consistent execution across the distribution network.

Step 7: Integrate Technology and Data Systems

Implement integrated systems such as ERP, WMS, and TMS to enable real-time visibility across inventory, orders, and shipments. Data integration supports faster decision-making, improves coordination across channels and partners, and enables continuous optimization of distribution performance.

Step 8: Build Sustainability into the Strategy

Incorporate sustainability considerations into transportation, packaging, and facility operations. Optimize routes to reduce emissions, adopt eco-friendly materials, and track sustainability metrics. Sustainable distribution not only supports compliance but also strengthens brand credibility.

Step 9: Test, Measure, and Optimize Continuously

A distribution strategy is not static. Monitor performance against defined KPIs, identify bottlenecks, and refine processes regularly. Use data insights and customer feedback to adjust channels, fulfillment models, and capacity as market conditions and expectations evolve.

Tips for Choosing the Right Distribution Strategy for Your Product or Service

Selecting the right distribution strategy is crucial to ensure your product reaches the right customers efficiently, cost-effectively, and with a strong brand experience.

An effective strategy aligns your product type, target audience, operational capabilities, and business objectives while adapting to market changes and competition.

The following tips provide a step-by-step guide to help you make informed distribution decisions.

1. Consider the Type of Product or Service

The nature of your product affects how it should be distributed. Products are often categorized based on purchase behavior:

- Routine purchases: Low-cost, frequently bought items like toothpaste or snacks benefit from intensive distribution for maximum accessibility.

- Limited purchases: Mid-range items like clothing or small appliances suit selective distribution, balancing reach with control.

- Extensive purchases: High-value, high-consideration items like cars or luxury goods often require exclusive distribution to maintain brand prestige and personalized service.

2. Determine Your Target Audience

Identify your ideal customers and understand their purchasing habits, preferences, and preferred channels. This helps align your distribution strategy with where and how your audience wants to buy:

- Direct channels for audiences active on social media or e-commerce platforms.

- Indirect channels for customers who prefer physical retail experiences.

3. Assess Your Warehouse Capabilities and Logistics

Evaluate your internal capabilities including storage capacity, workforce, and budget. Determine whether you can manage direct fulfillment efficiently or should rely on third-party partners:

- Direct distribution requires robust internal logistics.

- Indirect distribution leverages partners to reduce operational burden.

4. Factor in Costs and Margins

Analyze the total cost of delivering your product through each potential distribution channel. Consider warehousing, transportation, labor, and channel fees, ensuring the strategy aligns with profitability goals and pricing structure.

5. Maintain Legal and Regulatory Compliance

Ensure your chosen channels comply with local and international regulations, including import/export laws, safety standards, and environmental guidelines. Noncompliance can cause delays, fines, or block market entry.

6. Define Clear Business Goals

Align your distribution strategy with overarching business objectives, such as expanding market reach, enhancing customer experience, or protecting brand equity. Goals guide decision-making and help prioritize trade-offs.

7. Establish Channel Rules of Engagement

Set clear roles, responsibilities, pricing policies, and promotional guidelines for all channels and partners. Incentives should align with these rules to minimize conflicts and maintain consistency across your network.

8. Track Key Performance Indicators (KPIs)

Monitor metrics such as order accuracy, delivery times, inventory turnover, customer satisfaction, and distribution costs. KPI tracking allows you to evaluate performance and identify areas for improvement.

9. Continuously Optimize

Use KPI data and partner feedback to refine your distribution strategy. Adjust channels, fulfillment models, and logistics to respond to changing demand, market trends, and operational insights.

10. Leverage Technology

Invest in ERP, WMS, TMS, and analytics tools to improve inventory visibility, streamline fulfillment, enhance forecasting, and support real-time decision-making. Technology ensures your distribution strategy is agile, efficient, and scalable.

Benefits of a Well-Planned Distribution Strategy

A well-planned distribution strategy is more than just a logistics tool—it is a key driver of business success. By aligning operational efficiency, cost management, and customer satisfaction, it directly strengthens competitiveness and supports long-term growth.

Here are the key benefits of implementing a strategic distribution approach.

Reduction of Operating Costs

Optimized distribution minimizes expenses related to transportation, warehousing, and inventory management. Companies can:

- Consolidate shipments to lower volume costs.

- Optimize transportation routes to save fuel and time.

- Avoid excess inventory and reduce unnecessary storage expenses.

Improved Delivery Times

Effective distribution ensures products reach customers quickly, even across international markets—a critical advantage in sectors like e-commerce and food delivery. This is achieved through:

- Strategically placed warehouses near key markets.

- Cross-docking and other processes that reduce intermediate storage time.

- Real-time route optimization for faster transportation.

Increased Customer Satisfaction

Timely and accurate deliveries build strong customer relationships and enhance brand loyalty. A strategic distribution plan guarantees:

- Consistent product availability online and in stores.

- Damage-free and error-free deliveries.

- Higher trust, repeat business, and stronger customer retention.

Ability to Adapt to Market Changes

Markets and logistics environments are constantly evolving. A well-planned distribution strategy enables companies to:

- Reallocate inventory to match regional demand.

- Scale operations during peak seasons or promotional campaigns.

- Adjust routes or channels in response to disruptions or regulatory changes.

Increased Market Competitiveness

Efficient distribution differentiates a business from competitors by providing faster delivery, lower costs, and more flexible services. This strengthens market positioning and supports expansion into new regions or customer segments.

Leveraging Technology

Modern distribution strategies depend on advanced technologies such as ERP, WMS, TMS, and analytics platforms. These systems help:

- Track shipments and inventory in real time.

- Analyze operational data for informed decision-making.

- Enable agile execution and continuous optimization of distribution processes.

Sustainability Benefits

Optimized distribution also reduces environmental impact by cutting transportation distances, improving route efficiency, and minimizing waste—supporting corporate sustainability goals and regulatory compliance.

Key Metrics to Measure Distribution Strategy Performance

Measuring the effectiveness of a distribution strategy is crucial to ensure that products reach customers efficiently, cost-effectively, and with a positive experience. Tracking the right metrics allows businesses to identify bottlenecks, optimize operations, and make data-driven decisions.

Here are the key metrics to monitor for distribution strategy performance.

Order Fulfillment Rate

This metric measures the percentage of customer orders delivered on time and in full. A high fulfillment rate indicates efficient inventory management, accurate order processing, and reliable logistics. Low rates may signal issues with stock levels, warehouse processes, or transportation.

Delivery Lead Time

Delivery lead time tracks the average time taken from receiving an order to delivering it to the customer. Shorter lead times enhance customer satisfaction and competitiveness, while longer lead times highlight inefficiencies in warehousing, route planning, or fulfillment processes.

Inventory Turnover

Inventory turnover measures how often inventory is sold and replaced within a given period. High turnover reflects effective demand forecasting and inventory positioning, while low turnover indicates excess stock, inefficient distribution, or misaligned demand planning.

Distribution Cost per Unit

This metric evaluates the total cost of distributing a product—including transportation, warehousing, packaging, and handling—divided by the number of units shipped. Lower costs per unit indicate operational efficiency, while higher costs may suggest waste, poor route optimization, or underutilized resources.

Order Accuracy Rate

Order accuracy tracks the percentage of orders delivered correctly without errors or damages. High accuracy reduces returns, improves customer satisfaction, and strengthens brand loyalty.

On-Time Delivery Rate

This KPI measures the proportion of orders delivered within the promised timeframe. It reflects the reliability of transportation networks, logistics planning, and inventory placement. Consistently high rates strengthen trust and repeat business.

Customer Satisfaction and Returns

Customer feedback and return rates are indirect but powerful indicators of distribution effectiveness. Low return rates and positive satisfaction scores demonstrate that products are delivered correctly, on time, and in good condition.

Warehouse and Transport Efficiency

Metrics such as warehouse picking accuracy, average warehouse dwell time, and transportation utilization rates help evaluate the efficiency of internal logistics operations. Optimizing these ensures faster delivery and lower costs.

Flexibility and Responsiveness

Track the ability to adapt to unexpected demand fluctuations, supply chain disruptions, or market changes. Metrics might include order rerouting times, emergency shipment handling, or downtime caused by disruptions.

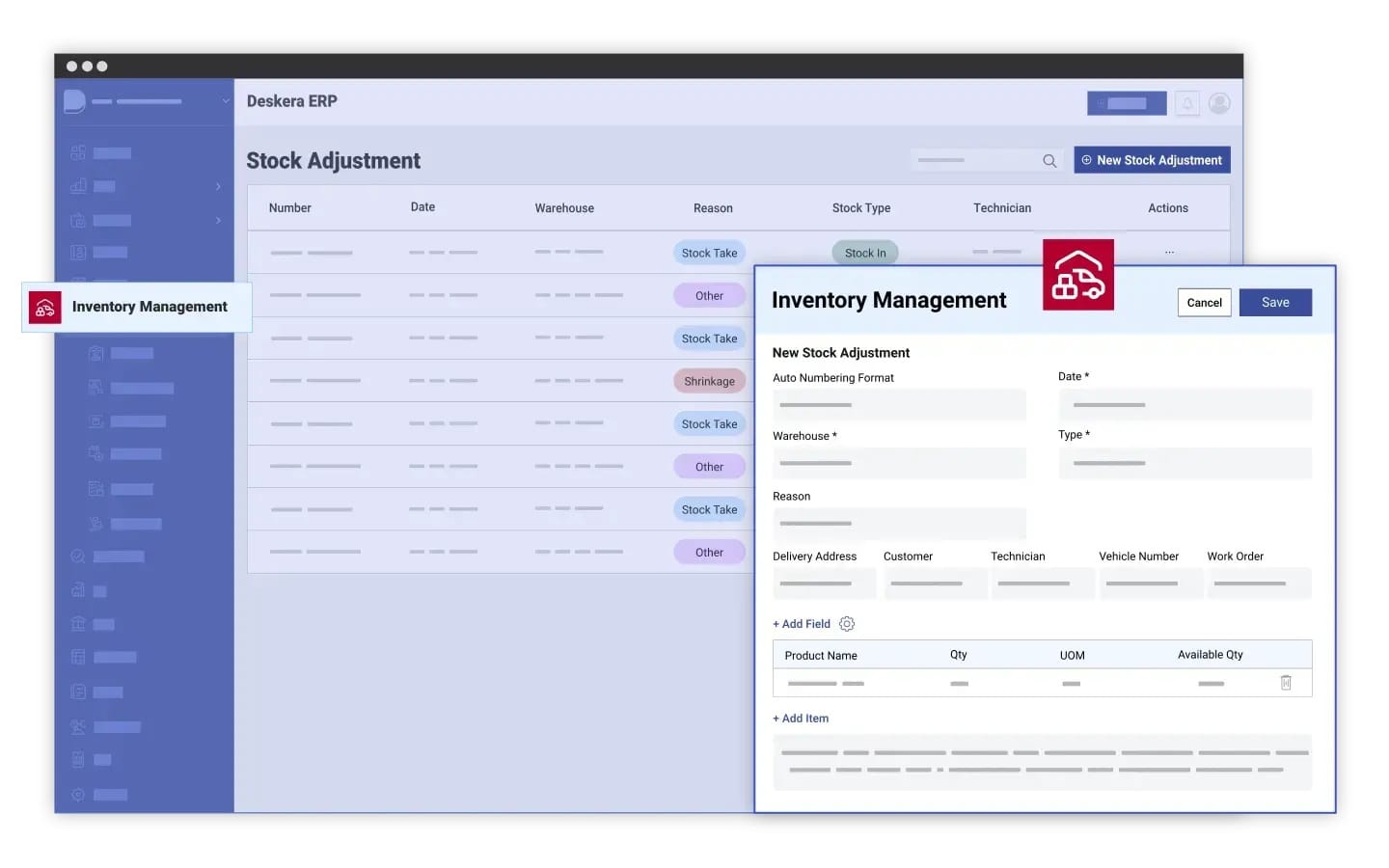

How Deskera ERP Supports Modern Distribution Strategies

In an era where distribution efficiency, real‑time visibility, and integrated operations are critical to competitive advantage, Deskera ERP provides a unified platform that helps businesses streamline their distribution processes and make smarter decisions.

By bringing together inventory, order management, demand planning, procurement, and analytics, Deskera enables organizations to manage complex distribution networks with greater accuracy and agility.

Centralized Order and Inventory Visibility

Deskera ERP consolidates order and inventory data across all locations—warehouses, retail outlets, and online channels—into one system. This real‑time visibility helps businesses prevent stockouts and overstocking, track order progress, and coordinate fulfillment efficiently across channels.

Advanced Demand Forecasting and Planning

With built‑in forecasting tools, Deskera analyzes historical sales trends, seasonality, and market patterns to predict demand more accurately. These insights help businesses optimize inventory levels, align production plans, and reduce carrying costs while improving service levels.

Automated Workflows and Alerts

Deskera automates routine tasks such as order processing, stock reordering, purchase approvals, and shipment notifications. Automated alerts for low stock, delayed deliveries, or other supply anomalies help teams act proactively rather than reactively.

Integrated Procurement and Vendor Management

The system includes centralized vendor information and tools to manage supplier performance, purchase orders, delivery schedules, and procurement approvals. This strengthens supplier relationships and enhances coordination across the supply chain.

Seamless Channel Integration

Deskera ERP integrates key business functions—including finance, sales, procurement, inventory, and CRM—ensuring consistent data flow and eliminating silos. This unified approach supports smoother coordination between distribution channels and internal teams.

Scalable, Cloud‑Based Platform

Being cloud‑based, Deskera ERP scales with business growth, accommodating multiple warehouses, new sales channels, and increasing order volumes without significant infrastructure costs. It also enables remote access to critical data and processes from anywhere, enhancing flexibility and responsiveness.

Analytics and Performance Insights

Deskera ERP’s reporting capabilities transform operational data into actionable insights. Businesses can track key distribution KPIs such as fulfillment times, inventory turnover, and delivery performance, enabling continuous optimization of their distribution strategy.

By integrating these capabilities into a single, scalable platform, Deskera ERP helps businesses manage modern distribution challenges more effectively—supporting faster delivery, better customer experiences, and more efficient operations.

Key Takeaways

- A distribution strategy defines how a company delivers products or services from production to the end customer, shaping customer experience, operational efficiency, and market reach.

- A well-planned distribution strategy reduces costs, improves delivery times, boosts customer satisfaction, and strengthens market competitiveness.

- Key elements include product type, target audience, budget, competition, and market conditions, all of which influence channel selection and logistics planning.

- Companies can choose from direct, indirect, selective, exclusive, intensive, dual, hybrid, omnichannel, and reverse distribution models to match product type, audience, and business goals.

- Modern distribution strategies rely on channel mix, inventory positioning, demand forecasting, partner management, technology integration, omnichannel presence, hyperlocal delivery, sustainability, advanced supply chain tech, and premium customer experience.

- Businesses face challenges such as rising logistics costs, demand fluctuations, channel conflicts, and the complexity of managing multiple sales channels simultaneously.

- A structured approach—assessing products, understanding customers, analyzing costs, defining goals, choosing channels, and continuously monitoring performance—ensures a distribution strategy aligns with business objectives.

- Evaluating product characteristics, target audience, warehouse capabilities, business goals, and KPIs ensures the chosen strategy optimizes efficiency, customer satisfaction, and growth potential.

- Optimized distribution lowers costs, shortens delivery times, increases customer satisfaction, improves adaptability, strengthens competitiveness, leverages technology, and supports sustainability.

- Tracking KPIs such as order fulfillment rate, delivery lead time, inventory turnover, distribution cost per unit, order accuracy, on-time delivery, and customer satisfaction helps businesses evaluate and optimize distribution effectiveness.

- Deskera ERP provides centralized inventory and order management, demand forecasting, automated workflows, integrated vendor and channel management, analytics, and a scalable cloud-based platform to optimize modern distribution operations.

Related Articles