A survey conducted by the American Association of Pesticide Safety Educators found that 84% of growers believe that pests have become more resistant to chemical control over the past five years, highlighting the need for new chemical formulations.

Additionally, a report by Transparency Market Research found that the demand for plant-based pest control products, which are seen as safer and more environmentally friendly than traditional chemical formulations, is on the rise. The report projects that the global market for plant-based pest control products will grow at a CAGR of 8.1% from 2020 to 2027.

In fact, according to a report by Research and Markets, the global market for biopesticides, a type of pest control formulation made from natural substances, is projected to reach $8.82 billion by 2025, growing at a CAGR of 15.6% from 2020 to 2025.

Lastly, according to a report by MarketsandMarkets, the global market for pest control products, including chemical formulations, is projected to reach $27.5 billion by 2025, growing at a CAGR of 5.04% from 2020 to 2025.

Thus, as is evident from these statistics, the development of new pest control chemical formulations is an ongoing and essential process to ensure effective and sustainable pest control solutions that minimize harm to humans, non-target organisms, and the environment.

New pest control chemical formulations may incorporate advances in technology and science, such as new modes of action, nanotechnology, and biotechnology, to enhance their effectiveness and safety. Additionally, new formulations may be designed to minimize the environmental impact of pest control chemicals and improve sustainability.

Existing chemical formulations have limitations, such as the development of resistance, safety concerns, and regulatory requirements. As a result, there is a constant need for the development of new pest control chemical formulations that are effective, safe, and compliant with regulations.

The development of new formulations involves a complex process as well as numerous considerations to be taken into account. This article will be your guide for all by covering the following topics:

- What is Pest Control Chemical Formulation?

- What is the Aim of Pest Control Chemical Formulations?

- What are the Different Forms of Pest Control Chemical Formulations?

- Why do we Need New Pest Control Chemical Formulations?

- What are the Steps for Developing New Pest Control Chemical Formulations?

- What is the Importance of Developing New Pest Control Chemical Formulations?

- Opportunities Associated with Developing New Pest Control Chemical Formulations

- Challenges Associated with Developing New Pest Control Chemical Formulations

- How will Continuous Innovation Help in Developing New Pest Control Chemical Formulations?

- How will Technological Advancements and Automation Help in Developing New Pest Control Chemical Formulations?

- Ensuring Sustainability through Developing New Pest Control Chemical Formulations

- How can the Implementation of MRP Software Help in Developing New Pest Control Chemical Formulations?

- How will New Pest Control Chemical Formulations be Regulated?

- FAQs related to Developing New Pest Control Chemical Formulations

- How can Deskera Help in Developing New Pest Control Chemical Formulations?

- Key Takeaways

- Related Articles

What is Pest Control Chemical Formulation?

Pest control chemical formulation refers to the process of developing and manufacturing chemical products designed to control or eliminate pests.

These formulations are typically mixtures of active ingredients, which are responsible for the product's ability to control pests, and other ingredients, which are added to improve the product's performance and stability.

Pest control chemical formulations come in different forms, such as sprays, baits, granules, and powders, and are used in various settings, including residential, agricultural, and commercial environments.

The aim of pest control chemical formulations is to eliminate or control pest populations while minimizing the risk to human health and the environment.

What is the Aim of Pest Control Chemical Formulations?

The aim of pest control chemical formulations is to control or eliminate pest populations while minimizing the risk to human health and the environment. Pest control chemical formulations are designed to be effective against specific pests while also being safe to use around humans, pets, and other non-target organisms.

The primary goal of these formulations is to reduce the damage caused by pests, such as damage to crops, buildings, and human health while minimizing the impact on the environment. Effective pest control chemical formulations can help prevent the spread of disease, reduce economic losses, and improve the quality of life for humans and animals.

What are the Different Forms of Pest Control Chemical Formulations?

There are several different forms of pest control chemical formulations, including:

- Sprays: These formulations are liquids that are typically applied using a spray bottle or a specialized sprayer. They can be used to treat surfaces, such as walls, floors, and furniture, as well as directly on pests.

- Baits: Baits are usually solid or semi-solid formulations that are designed to attract pests to eat them. They may be used to control pests, such as rodents, ants, or cockroaches.

- Powders: Powders are dry formulations that can be applied directly to surfaces or used as dusting agents. They are often used to control pests such as fleas, ticks, and bed bugs.

- Granules: Granular formulations are small, dry pellets or beads that can be spread over a large area, such as a lawn or garden. They are often used to control pests, such as ants and other crawling insects.

- Gels: Gel formulations are thick, sticky liquids that are applied using a syringe or other specialized applicator. They can be used to control pests, such as cockroaches, and other crawling insects.

Each type of pest control chemical formulation has its unique properties and application methods, which are designed to target specific pests and minimize the risk of exposure to humans and non-target organisms.

Why do we Need New Pest Control Chemical Formulations?

There are several reasons why we need new pest control chemical formulations:

- Resistance: Pests can develop resistance to existing chemical formulations over time, making them less effective. New formulations with different modes of action can help address this issue.

- Safety: Existing chemical formulations may pose risks to humans, non-target organisms, and the environment. New formulations can be designed to be safer and more targeted.

- Regulatory requirements: Regulatory requirements for pest control chemicals are constantly evolving. New formulations may be necessary to comply with changing regulations.

- Emerging pests: New pests may emerge that are not effectively controlled by existing chemical formulations. New formulations can be developed to address these pests.

- Sustainability: There is increasing demand for sustainable pest control solutions that minimize the use of chemicals and reduce environmental impact. New formulations can be developed with sustainability in mind.

- Technology advances: Advances in technology and science can enable the development of more effective and safer pest control chemical formulations. New formulations may incorporate these advances for improved pest control.

Overall, new pest control chemical formulations are needed to address the evolving challenges of pest control and ensure that effective, safe, and sustainable pest control solutions are available.

What are the Steps for Developing New Pest Control Chemical Formulations?

Developing new pest control chemical formulations is a complex process that requires multiple steps. Here are the general steps involved in developing new pest control chemical formulations:

Identify the Target Pest

The first step is to identify the target pest or pests that the new formulation will control. This involves understanding the biology and behavior of the pest, as well as the economic and environmental impact it has.

Identifying the target pest is a critical step in developing new pest control chemical formulations. This is because different pests have unique biological characteristics, and developing a chemical formulation that can effectively control a particular pest requires an understanding of these characteristics.

For example, some pests may have a hard exoskeleton that can protect them from certain types of pesticides, while others may have developed resistance to commonly used chemicals. Identifying the specific target pest allows researchers to tailor the chemical formulation to overcome these challenges.

Furthermore, knowing the target pest can help researchers determine the best mode of action for the pesticide. For example, some pests may be controlled by disrupting their reproductive cycle, while others may be better controlled by targeting their nervous system.

Identifying the target pest can help researchers select the appropriate mode of action for the pesticide, increasing its effectiveness and reducing the risk of unintended environmental impacts.

Finally, knowing the target pest can help researchers determine the appropriate dosage and application method for the pesticide. Different pests may require different concentrations of the pesticide or may be better controlled with a specific application method, such as a spray or bait.

By identifying the target pest, researchers can optimize the dosage and application method to ensure maximum efficacy with minimal environmental impact.

Overall, identifying the target pest is a crucial step in developing new pest control chemical formulations, as it allows researchers to tailor the chemical to the unique characteristics of the pest, select the appropriate mode of action, and optimize the dosage and application method for maximum effectiveness and minimal environmental impact.

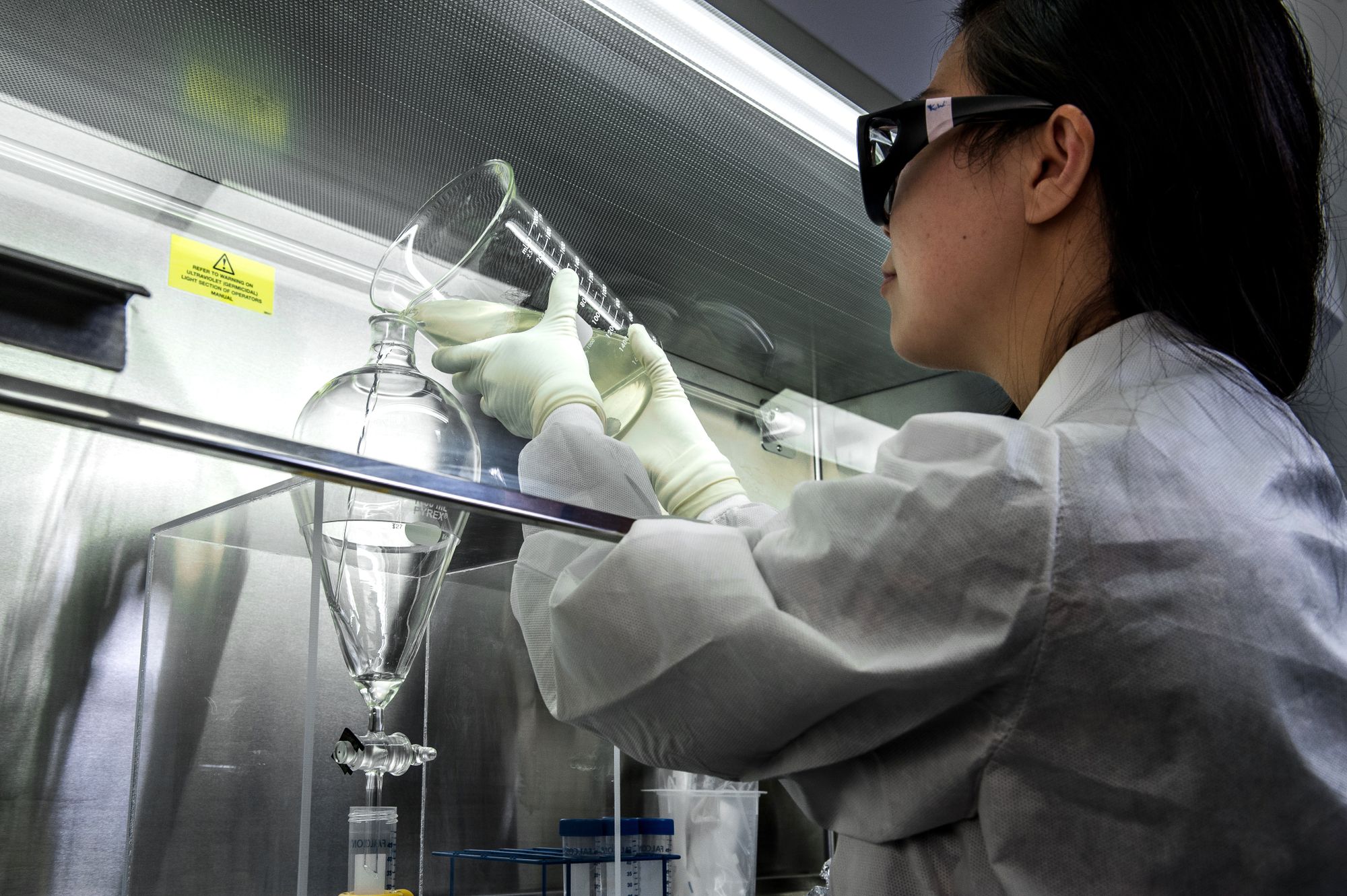

Research and Development

The next step is to conduct research and development to develop a new pest control chemical formulation. This involves testing different active ingredients, adjuvants, and formulations to determine the most effective combination.

Research and development (R&D) play a critical role in developing new pest control chemical formulations. By investing time and resources in R&D, scientists can develop innovative solutions for pest control that are more effective, efficient, and safe for the environment.

Here are some ways in which R&D can help in developing new pest control chemical formulations:

- Identification of new active ingredients: Through R&D, scientists can identify new active ingredients that are effective in controlling pests. They can screen a large number of compounds and evaluate their effectiveness against different pests. This can lead to the discovery of new chemicals that can be used in pest control formulations.

- Optimization of formulation: R&D can also help optimize the formulation of existing pest control chemicals. This can involve modifying the concentration, composition, and delivery method of the active ingredient. By optimizing the formulation, scientists can improve the efficacy and safety of the chemical.

- Development of new delivery systems: R&D can also lead to the development of new delivery systems for pest control chemicals. For example, scientists can develop new sprayers, baits, or traps that can deliver the chemical more effectively to the target pest. This can increase the efficacy of the chemical while reducing the amount of chemical needed.

- Evaluation of safety and efficacy: R&D can also involve testing the safety and efficacy of new pest control formulations. This can involve laboratory and field trials to evaluate the effectiveness of the chemical against the target pest, as well as its impact on non-target species and the environment.

Overall, R&D is essential for developing new pest control chemical formulations that are effective, efficient, and safe for the environment. By investing in R&D, scientists can continue to develop new solutions for pest control that are more sustainable and effective than existing methods. This will also help in improving customer retention, revenue, and net profit ratio.

Testing

Once a potential formulation has been developed, safety and efficacy testing is conducted to evaluate its safety and efficacy. This involves testing the formulation in laboratory and field conditions to determine its performance.

Testing plays a crucial role in the development of new pest-control chemical formulations. Testing helps to evaluate the efficacy, safety, and environmental impact of the new formulation. Here are some ways in which testing helps in developing new pest-control chemical formulations:

- Efficacy testing: Testing is carried out to determine the effectiveness of the new pest control chemical formulation against the target pest. This involves testing the formulation in laboratory and field conditions to determine its efficacy in controlling the target pest. This information helps to optimize the formulation and improve its efficacy.

- Safety testing: Testing is carried out to determine the safety of the new pest control chemical formulation for humans, animals, and the environment. Safety testing involves evaluating the toxicity and exposure risks associated with the formulation. This information helps to optimize the formulation and improve its safety.

- Environmental impact testing: Testing is carried out to determine the potential environmental impact of the new pest control chemical formulation. This involves evaluating the impact of the formulation on non-target species, ecosystems, and the environment. This information helps to optimize the formulation and reduce its impact on the environment.

- Residue testing: Testing is carried out to determine the level of residue that remains on crops or in the environment after the application of the new pest control chemical formulation. Residue testing is important to ensure that the formulation meets regulatory requirements and is safe for consumption.

Overall, testing helps to optimize the formulation of the new pest control chemical and ensure that it is safe and effective for use. Testing also helps to ensure that the formulation meets regulatory requirements and can be approved for use in pest control. It also ensures that your business will not have to incur additional business expenses in the form of penalty and increased operating costs or manufacturing costs due to failed new formulations or sub-par quality of them.

Regulatory Approval

Regulatory approval is a crucial step in the development of new pest-control chemical formulations. Regulatory approval ensures that the new formulation meets the required safety, efficacy, and environmental standards set by regulatory bodies.

Here are some ways in which regulatory approval helps in developing new pest-control chemical formulations:

- Safety: Regulatory approval ensures that the new pest control chemical formulation is safe for human and animal health, as well as the environment. The regulatory approval process evaluates the toxicity, exposure risks, and potential hazards associated with the formulation. This helps to identify any safety issues and ensures that the formulation meets the required safety standards.

- Efficacy: Regulatory approval also ensures that the new pest control chemical formulation is effective in controlling the target pest. The regulatory approval process evaluates the efficacy of the formulation in laboratory and field conditions. This helps to identify any efficacy issues and ensures that the formulation meets the required efficacy standards.

- Environmental impact: Regulatory approval ensures that the new pest control chemical formulation does not have any negative environmental impact. The regulatory approval process evaluates the potential environmental impact of the formulation on non-target species, ecosystems, and the environment. This helps to identify any environmental issues and ensures that the formulation meets the required environmental standards.

- Market access: Regulatory approval is necessary for the new pest control chemical formulation to be sold and used in the market. Without regulatory approval, the formulation cannot be marketed or used for pest control purposes. Regulatory approval helps to ensure that the formulation meets the required regulatory standards and can be approved for use in pest control.

Overall, regulatory approval is a critical step in the development of new pest control chemical formulations. It ensures that the formulation is safe, effective, and environmentally friendly, and can be approved for use in pest control.

Regulatory approval helps to protect human and animal health, as well as the environment while ensuring that effective pest control solutions are available to farmers and other users. This will improve your cash flow, and lead to an increase in your net revenue.

Manufacturing

Manufacturing plays an important role in developing new pest-control chemical formulations. Once regulatory approval has been obtained, the formulation can be manufactured at a larger scale and made available to end-users. This involves optimizing the manufacturing process to produce the formulation at a consistent quality and cost-effectiveness.

Here are some ways in which manufacturing helps in developing new pest-control chemical formulations:

- Scale-up: Manufacturing helps to scale up the production of the new pest control chemical formulation from the laboratory to commercial production. This involves optimizing the manufacturing process to produce the formulation at a larger scale and to ensure consistent quality.

- Quality control: Manufacturing helps to ensure consistent quality of the new pest control chemical formulation. Quality control measures are put in place to ensure that the formulation meets the required standards and is safe and effective for use.

- Cost-effectiveness: Manufacturing helps to optimize the cost-effectiveness of the new pest control chemical formulation. This involves evaluating the manufacturing process to identify areas where costs can be reduced without compromising on quality. This will lead to improvement in your business metrics and operational metrics.

- Availability: Manufacturing helps to ensure that the new pest control chemical formulation is available to end-users. The formulation needs to be manufactured and distributed to the end users in a timely and efficient manner. This will keep your customers satisfied, thereby encouraging returning customers as well as customer loyalty.

Overall, manufacturing is essential for developing new pest-control chemical formulations. It helps to scale up production, ensure consistent quality, optimize cost-effectiveness, and make the formulation available to end-users. By ensuring efficient manufacturing processes, the new formulation can be produced at a larger scale and made available to farmers and other users at an affordable price.

Monitoring and Improvement

After the formulation has been launched in the market, it needs to be monitored and improved over time. This involves evaluating its safety, efficacy, and environmental impact and making improvements to optimize its performance.

Monitoring and improvement are crucial aspects of developing new pest-control chemical formulations. These processes help to identify any issues with the formulation and make improvements to optimize its efficacy, safety, and environmental impact. Here are some ways in which monitoring and improvement help in developing new pest control chemical formulations:

- Monitoring efficacy: Monitoring the efficacy of the new pest control chemical formulation helps to identify any issues with its effectiveness in controlling the target pest. This involves evaluating the formulation in laboratory and field conditions to determine its performance. This information helps to identify any issues and make improvements to the formulation to optimize its efficacy.

- Monitoring safety: Monitoring the safety of the new pest control chemical formulation helps to identify any issues with its toxicity or exposure risks. This involves evaluating the formulation in laboratory and field conditions to determine its safety. This information helps to identify any safety issues and make improvements to the formulation to optimize its safety.

- Monitoring environmental impact: Monitoring the environmental impact of the new pest control chemical formulation helps to identify any issues with its impact on non-target species, ecosystems, and the environment. This involves evaluating the formulation in laboratory and field conditions to determine its environmental impact. This information helps to identify any environmental issues and make improvements to the formulation to reduce its impact on the environment.

- Making improvements: Based on the monitoring results, improvements can be made to the formulation to optimize its efficacy, safety, and environmental impact. This may involve adjusting the formulation's composition or application method to address any issues identified during monitoring.

Overall, monitoring and improvement are critical for developing new pest-control chemical formulations. They help to identify any issues with the formulation and make improvements to optimize its performance, safety, and environmental impact.

By continually monitoring and improving the formulation, it can be optimized to provide effective pest control while minimizing any negative impact on human health, animal health, and the environment.

What is the Importance of Developing New Pest Control Chemical Formulations?

Developing new pest control chemical formulations is important for several reasons:

Resistance Management

Developing new pest control chemical formulations is important for resistance management because pests can develop resistance to chemicals that are commonly used for pest control. Resistance occurs when a pest population develops the ability to survive exposure to a pesticide that previously controlled the population.

When resistance occurs, the pesticide becomes less effective, and higher doses or more frequent applications are needed to achieve the same level of control. This can lead to increased costs, reduced effectiveness, and potentially negative impacts on human health and the environment.

Developing new pest control chemical formulations can help slow down or prevent the development of resistance by using different modes of action or targeting different parts of the pest's biology. For example, a new formulation may use a different mechanism of action that the pest has not previously encountered, making it less likely to develop resistance.

In addition, developing new formulations can also help to preserve the effectiveness of existing pesticides by reducing the frequency of use and delaying the onset of resistance. This can extend the useful life of existing pesticides, reducing the need for farmers to constantly seek out new solutions and helping to sustainably manage pest populations over the long term.

Environmental Safety

Developing new pest control chemical formulations is important for environmental safety because many chemicals used for pest control can have negative impacts on the environment. These impacts can include:

- Contamination of water sources: Pesticides can be washed into streams, rivers, and other bodies of water, where they can harm aquatic organisms and contaminate drinking water supplies.

- Harm to non-target organisms: Pesticides can harm organisms that are not the intended target, such as beneficial insects, birds, and mammals.

- Soil contamination: Pesticides can persist in the soil and affect soil quality, potentially harming plants and soil-dwelling organisms.

- Air pollution: Pesticides can contribute to air pollution, which can harm human health and the environment.

Developing new pest control chemical formulations that are more targeted and have lower environmental impacts can help to reduce these risks. For example, formulations that break down more quickly in the environment, have lower toxicity to non-target organisms, or target pests more specifically can help to minimize the environmental impacts of pest control.

In addition, many countries have strict regulations and guidelines for pesticide use and developing new formulations that comply with these regulations while still providing effective pest control is essential for protecting the environment and human health.

Efficacy

Developing new pest control chemical formulations is important for efficacy because pests can develop resistance to chemicals that are commonly used for pest control.

When resistance occurs, the pesticide becomes less effective, and higher doses or more frequent applications are needed to achieve the same level of control. This can lead to increased costs, reduced effectiveness, and potentially negative impacts on human health and the environment.

Developing new formulations that are more effective at controlling pests can help to overcome the problem of resistance and reduce the need for repeated applications.

For example, a new formulation may use a different mechanism of action that the pest has not previously encountered, making it more effective at controlling the population.

In addition, developing new formulations can also help to improve the overall effectiveness of pest control by targeting specific pests more effectively.

For example, a new formulation may be designed to target a specific life stage of a pest, such as the larval stage, which can be more susceptible to certain types of pesticides.

Overall, developing new pest control chemical formulations that are more effective can help to improve pest control outcomes, reduce the need for repeated applications, and minimize negative impacts on human health and the environment.

Cost Effectiveness

Developing new pest control chemical formulations is important for cost-effectiveness because pest control can be a significant expense for farmers and other users. Developing new formulations that are more cost-effective can help to reduce the overall cost of pest control and make it more accessible to a wider range of users.

New formulations can be developed to be more cost-effective in several ways. For example, a new formulation may be more concentrated, allowing users to apply smaller amounts of the product while still achieving effective control. This can help to reduce the amount of product needed, resulting in cost savings for the user.

In addition, new formulations can be developed to have longer residual activity, reducing the need for repeated applications and further reducing the overall cost of pest control. New formulations may also be designed to be easier to apply, reducing the time and labor required for pest control activities.

Overall, developing new pest control chemical formulations that are more cost-effective can help to make pest control more accessible to farmers and other users, reduce the overall cost of pest control, and increase the sustainability of pest management practices.

Regulation Compliance

Developing new pest control chemical formulations is important for regulation compliance because many countries have strict regulations and guidelines for pesticide use, including maximum residue limits and safety standards for human and environmental health. New formulations must comply with these regulations in order to be approved for use.

Developing new formulations that comply with regulations can help to ensure that users can use pest control products safely and effectively without the risk of harming human health or the environment.

For example, new formulations can be developed that have lower toxicity to non-target organisms or that break down more quickly in the environment, reducing the risk of contamination.

In addition, developing new formulations that comply with regulations can help to reduce the risk of legal penalties for non-compliance. Penalties for non-compliance with pesticide regulations can be severe and can include fines, legal action, and even imprisonment in some cases.

Overall, developing new pest control chemical formulations that comply with regulations is essential for ensuring the safety and efficacy of pest control products, protecting human health and the environment, and avoiding legal penalties for non-compliance.

Opportunities Associated with Developing New Pest Control Chemical Formulations

Developing new pest control chemical formulations can offer several opportunities, including:

- Improved efficacy: New pest control chemical formulations can be designed to be more effective in controlling pests than existing formulations. This can lead to better pest management outcomes and potentially reduce the use of pesticides.

- Increased cost-effectiveness: New formulations can be developed to be more cost-effective, reducing the overall cost of pest control and making it more accessible to a wider range of users.

- Reduced environmental impact: New formulations can be designed to be more environmentally friendly than existing formulations, reducing the impact on non-target organisms and the surrounding ecosystem.

- Targeted pest control: Developing new formulations can allow for more targeted pest control, which can minimize the impact on beneficial insects and other organisms while still effectively controlling the target pest.

- Market opportunities: New formulations can offer opportunities to enter new markets or expand existing markets by offering unique formulations with differentiated features.

- Improved safety: New formulations can be designed with improved safety features, such as reduced toxicity or reduced risk of exposure to humans and other animals.

- Regulatory compliance: As regulations around pesticide use become more stringent, developing new formulations that meet regulatory requirements can ensure continued access to key markets.

- Intellectual property: Developing new formulations can lead to the creation of intellectual property that can be protected through patents, providing a competitive advantage in the market.

Challenges Associated with Developing New Pest Control Chemical Formulations

Developing new pest control chemical formulations can also present several challenges, including:

- Research and development costs: Developing new chemical formulations can be expensive and time-consuming, involving extensive research and testing to ensure efficacy, safety, and regulatory compliance.

- Regulatory hurdles: Obtaining regulatory approval for new chemical formulations can be a lengthy and complicated process, requiring extensive testing and documentation to demonstrate safety and efficacy.

- Resistance development: Pests can develop resistance to chemical formulations over time, which can reduce their effectiveness and require the development of new formulations or alternative pest management strategies. This will require ongoing research and development to stay ahead of resistance.

- Environmental impact: Even with improved formulations, pesticides can have negative impacts on non-target organisms and the environment. Developing formulations that are both effective and environmentally friendly can be challenging.

- Public perception and acceptance: Pesticides have faced increasing scrutiny in recent years due to concerns about their potential impacts on human health and the environment. Developing new formulations that are safe and effective while also addressing these concerns can be challenging.

- Supply chain challenges: Developing new chemical formulations can require access to specialized equipment and materials, which may not be readily available or affordable.

- Competing technologies: There are alternative pest control technologies available, such as biological control or integrated pest management, which may be more effective or desirable in certain situations, posing competition to new chemical formulations.

- Safety concerns: Developing new formulations can pose safety concerns for researchers and users, especially during the testing and evaluation phase.

- Limited availability of active ingredients: Limited availability of active ingredients can be a challenge for the development of new pest control chemical formulations for several reasons. Firstly, limited availability may mean that the active ingredient is not available in sufficient quantities to be used in the formulation. This could limit the range of formulations that can be created, as well as the efficacy and effectiveness of the product. Additionally, limited availability of an active ingredient may mean that manufacturers must look to alternative sources of the same active ingredient, which may be more expensive and/or require a longer lead time. This could ultimately increase the cost of the product or delay its release to the market.

How will Continuous Innovation Help in Developing New Pest Control Chemical Formulations?

Continuous innovation can play a crucial role in developing new pest-control chemical formulations that are more effective, safer, and more sustainable. Here are some ways that continuous innovation can help in this regard:

- Improved efficacy: Continuous innovation can lead to the development of new active ingredients or improved formulations that are more effective in controlling pests. This can help reduce the amount of pesticide needed and, in turn, reduce the negative impact of pesticides on the environment and human health.

- Reduced toxicity: Innovation can help develop new pest control chemicals that are less toxic to non-target organisms and the environment. This can help reduce the negative impact of pesticides on the ecosystem and human health.

- Target specificity: Innovation can help in the development of target-specific formulations that only affect the target pest and do not harm other beneficial insects or non-target organisms. This can help reduce the negative impact of pesticides on the environment.

- Reduced resistance: Continuous innovation can help develop new pest control chemicals or formulations that are less prone to resistance from pests. This can help reduce the need for higher dosages or more frequent applications, which can lead to an increased negative impact on the environment and human health.

- Sustainability: Innovation can help develop new pest control chemicals or formulations that are more sustainable, biodegradable, and environmentally friendly. This can help reduce the negative impact of pesticides on the environment and human health.

In conclusion, continuous innovation can lead to the development of new pest control chemical formulations that are more effective, safer, and more sustainable. This can help reduce the negative impact of pesticides on the environment and human health and ensure a more sustainable future for agriculture and pest control practices.

How will Technological Advancements and Automation Help in Developing New Pest Control Chemical Formulations?

Technological advancements and automation can significantly help in developing new pest control chemical formulations in several ways:

- High-throughput screening: Automation can speed up the process of testing and screening large numbers of chemical compounds for their efficacy against pests. This can help identify promising candidates for further development more quickly and efficiently.

- Computer-aided design: Computer-aided design can be used to simulate the interactions between chemicals and pests, allowing researchers to optimize formulations before conducting experiments in the lab.

- Precision delivery: Automation can help deliver pest control chemicals with greater precision and accuracy, reducing the number of chemicals required and minimizing the risk of exposure to non-target organisms.

- Improved safety: Advances in technology can help develop safer pest control chemical formulations by identifying and eliminating toxic or hazardous ingredients, reducing the risk of environmental contamination, and improving the efficiency of chemical delivery.

- Monitoring and control: Automation can help monitor and control the effectiveness of pest control chemical formulations by collecting and analyzing data in real time, allowing for adjustments to be made quickly if needed.

Overall, technological advancements and automation can improve the efficiency and safety of the process of developing new pest-control chemical formulations, leading to more effective pest-control products with fewer negative impacts on the environment and human health.

Ensuring Sustainability through Developing New Pest Control Chemical Formulations

Developing new pest control chemical formulations can be an effective way to ensure sustainability by reducing the negative impact of conventional pesticides on the environment and human health.

Here are some considerations to keep in mind when developing new pest control chemical formulations for sustainability:

- Use of natural and non-toxic ingredients: Consider using natural or non-toxic ingredients in the formulation to reduce the negative impact on the environment and human health. Examples of natural ingredients that can be used for pest control include essential oils, plant extracts, and microorganisms.

- Target-specific formulations: Develop formulations that target specific pests, rather than broad-spectrum pesticides that can harm beneficial insects and other non-target organisms. This can help reduce the negative impact of pesticides on the ecosystem.

- Biodegradability: Ensure that the formulation is biodegradable and breaks down easily in the environment to reduce its persistence and accumulation in the ecosystem.

- Reduced dosage: Develop formulations that require lower doses for effective pest control. This can help reduce the negative impact of pesticides on the environment and human health.

- Regulatory compliance: Ensure that the formulation meets regulatory requirements for safety, efficacy, and environmental impact.

By considering these factors when developing new pest control chemical formulations, we can help ensure sustainability and reduce the negative impact of conventional pesticides on the environment and human health.

How can Implementation of MRP Software Help in Developing New Pest Control Chemical Formulations?

The implementation of Material Requirements Planning (MRP) software can help in developing new pest control chemical formulations in several ways:

- Inventory management: MRP software can help manage inventory levels by tracking the availability of raw materials and finished goods, ensuring that the necessary ingredients and equipment are available when needed for the formulation process.

- Production planning: MRP software can assist with production planning by calculating the necessary quantities of ingredients required for each formulation, enabling the optimization of production schedules and minimizing waste.

- Quality control: MRP software can be used to monitor the quality of raw materials and finished products, identifying any issues or defects that may arise during the formulation process.

- Cost control: MRP software can help manage costs associated with the formulation process by tracking expenses, identifying opportunities for cost savings, and reducing waste.

- Data analysis: MRP software can analyze data related to the formulation process, such as yield rates, inventory levels, and production schedules, providing valuable insights that can be used to optimize the formulation process and improve product quality.

By implementing MRP software, companies can streamline their formulation process, reduce costs, and improve the quality of their pest control chemical formulations. This can lead to more effective and efficient pest control products that are better for the environment and human health.

How will New Pest Control Chemical Formulations be Regulated?

New pest control chemical formulations are regulated by government agencies responsible for pesticide regulation and registration. The regulations are in place to ensure that the use of these formulations is safe for the environment and human health. Here are some of the regulatory steps involved in the registration of new pest control chemical formulations:

- Pre-registration studies: Before a new pesticide can be registered, the manufacturer is required to conduct a series of tests to determine the safety and efficacy of the pesticide. These studies include tests on toxicity, environmental fate, and residue levels.

- Registration submission: Once the pre-registration studies are completed, the manufacturer submits an application for registration to the regulatory agency, which includes all of the necessary data and information about the pesticide.

- Evaluation: The regulatory agency evaluates the data submitted by the manufacturer and conducts its own risk assessments to determine the safety and efficacy of the pesticide.

- Labeling: If the pesticide is approved, the regulatory agency will specify the conditions of use, including the recommended rates, application methods, and any precautions to be taken.

- Post-registration monitoring: After the pesticide is registered, the regulatory agency continues to monitor its use and effects on the environment and human health. If any problems arise, the agency may require additional studies or take regulatory action to restrict or cancel the pesticide's registration.

Overall, the regulation of new pest control chemical formulations is a comprehensive and rigorous process that is designed to ensure that they are safe and effective when used according to the label instructions.

FAQs related to Developing New Pest Control Chemical Formulations

- What is a pest control chemical formulation?

A pest control chemical formulation is a combination of active ingredients, solvents, and other additives that are used to control pests, such as insects, rodents, and weeds.

- Why do we need new pest control chemical formulations?

New pest control chemical formulations are needed to address evolving pest populations, environmental concerns, and regulatory requirements, as well as to improve efficacy and safety.

- What are the main challenges in developing new pest control chemical formulations?

The main challenges in developing new pest control chemical formulations include identifying effective active ingredients, formulating stable and effective products, obtaining regulatory approval, and scaling up production.

- How are active ingredients selected for pest control chemical formulations?

Active ingredients are selected based on their efficacy, safety, availability, and compatibility with other ingredients in the formulation.

- What types of active ingredients are commonly used in pest control chemical formulations?

Commonly used active ingredients in pest control chemical formulations include insecticides, herbicides, fungicides, and rodenticides.

- What are the different types of formulations?

Different types of formulations include liquids, powders, granules, gels, and baits.

- What is the process for developing a new pest control chemical formulation?

The process typically involves identifying a target pest, conducting laboratory and field trials to evaluate the efficacy and safety of potential active ingredients, selecting the most promising active ingredient, and formulating it with appropriate inactive ingredients.

- What safety considerations are involved in developing pest control chemical formulations?

Safety considerations include potential toxicity to humans and non-target organisms, as well as environmental impact.

- What role does formulation chemistry play in developing pest control products?

Formulation chemistry plays a key role in developing pest control products by ensuring that the active ingredient is delivered effectively and efficiently to the target pest.

- How are new formulations tested for safety?

Safety testing involves assessing the potential toxicity of the formulation to humans and non-target organisms, as well as evaluating its potential impact on the environment.

- How are pest control chemical formulations regulated?

Pest control chemical formulations are regulated by government agencies to ensure that they are safe and effective.

- What are some of the most common active ingredients used in pest control chemical formulations?

Common active ingredients include pyrethroids, neonicotinoids, and organophosphates.

- How do pest control chemical formulations differ from organic or natural pest control products?

Pest control chemical formulations typically use synthetic active ingredients, while organic or natural pest control products use naturally occurring substances, such as plant extracts or microorganisms.

- How long does it take to develop a new pest control chemical formulation?

Developing a new pest control chemical formulation can take several years, from initial research and development to regulatory approval and commercialization.

- Can existing pest control chemical formulations be modified to improve their efficacy or safety?

Yes, existing formulations can be modified to improve their efficacy or safety, for example, by changing the concentration of the active ingredient or adjusting the formulation chemistry.

- Are there any alternatives to chemical pest control formulations?

Yes, there are alternatives to chemical pest control formulations, including biological control, cultural control, and physical control methods.

- What are the potential risks associated with using pest control chemical formulations?

Potential risks include human exposure to toxic substances, harm to non-target organisms, and environmental pollution. However, these risks can be minimized through careful formulation and proper use of pest control products.

- What is the difference between a contact and systemic pesticide?

A contact pesticide kills pests on contact with the chemical, while a systemic pesticide is absorbed by the plant or pest and kills pests that feed on the plant.

- What is the difference between a broad-spectrum and a selective pesticide?

A broad-spectrum pesticide is designed to kill a wide range of pests, while a selective pesticide targets specific pests or groups of pests.

- What is resistance in pests, and how does it affect pest control chemical formulations?

Resistance occurs when pests develop a tolerance or immunity to a particular pesticide, making it less effective over time. This can lead to the need for more frequent or different applications of pest control chemical formulations.

- How can resistance in pests be managed?

Resistance can be managed by using multiple modes of action and rotating between different pest control chemical formulations.

- What is the role of adjuvants in pest control chemical formulations?

Adjuvants are added to pest control chemical formulations to improve the efficacy of the active ingredient, such as by increasing penetration into plant tissues or reducing evaporation.

- How can pest control chemical formulations be made more environmentally friendly?

Pest control chemical formulations can be made more environmentally friendly by using natural or low-toxicity active ingredients, reducing application rates, and minimizing drift and runoff.

How can Deskera Help in Developing New Pest Control Chemical Formulations?

Deskera MRP is a cloud-based software platform that can help in developing new pest control chemical formulations by providing a comprehensive suite of tools for managing research and development, quality control, and regulatory compliance. Here are some ways that Deskera can assist in this regard:

- Research and development: Deskera MRP can help manage the research and development process by providing tools for project management, data management, and collaboration. Researchers can use Deskera to track experiments, analyze data, and share results with team members.

- Quality control: Deskera MRP can help ensure that new pest control chemical formulations meet quality standards by providing tools for quality control and quality assurance. The platform can help manage quality inspections, track product specifications, and monitor production processes.

- Regulatory compliance: Deskera MRP can help ensure that new pest control chemical formulations comply with regulatory requirements by providing tools for regulatory compliance management. The platform can help manage regulatory submissions, track regulatory changes, and monitor compliance with applicable regulations.

- Supply chain management: Deskera MRP can help manage the supply chain for new pest control chemical formulations by providing tools for inventory management, procurement, and logistics. The platform can help track inventory levels, manage purchase orders, and monitor shipping and delivery.

- Reporting and analytics: Deskera MRP can provide insights into the performance of new pest control chemical formulations by providing tools for reporting and analytics. Researchers can use Deskera to generate reports on product performance, track key performance indicators, and identify areas for improvement.

Key Takeaways

A pest control chemical formulation is a combination of active ingredients, solvents, and other additives that are used to control pests, such as insects, rodents, and weeds.

New pest control chemical formulations are needed to address evolving pest populations, environmental concerns, and regulatory requirements, as well as to improve efficacy and safety.

Some of the reasons why new pest control chemical formulations might be needed are:

- Resistance

- Safety

- Regulatory requirements

- Emerging pests

- Sustainability

- Technology advances

The steps for developing new pest control chemical formulations are as follows:

- Identify the target pest

- Research and development

- Testing

- Regulatory approval

- Manufacturing

- Monitoring and improvement

Additionally, some of the other key takeaways related to developing new pest control chemical formulations are:

- Safety should always be the top priority. Any new chemical formulation must undergo rigorous testing to ensure that it is safe for humans, animals, and the environment.

- Effectiveness is important, but it is not the only consideration. A pest control chemical should be effective in controlling the target pest, but it should also minimize harm to non-target organisms and the environment.

- Consider the mode of action. Chemical formulations should be developed with a clear understanding of the mechanism by which they control pests. This helps to ensure that the formulation is effective, and it also helps to minimize the risk of pests developing resistance.

- Regulatory compliance is essential. New pest control chemical formulations must comply with all applicable regulations, including those related to safety, efficacy, and environmental impact.

- Collaborate with experts. Developing a new pest control chemical formulation is a complex process that requires expertise in many different areas. Collaboration with experts in chemistry, toxicology, environmental science, and other fields can help ensure that the formulation is safe, effective, and compliant with all regulations.

- Consider the entire product lifecycle. When developing a new pest control chemical formulation, it is important to consider the entire product lifecycle, from manufacturing to disposal. This can help identify opportunities to minimize the environmental impact of the formulation and improve sustainability.

Overall, Deskera MRP can provide a comprehensive suite of tools for managing the research and development, quality control, regulatory compliance, and supply chain management of new pest control chemical formulations. By using Deskera, researchers can streamline their workflows, improve their data management, and ensure that their products meet quality standards and regulatory requirements.

Related Articles