The strategic partnership between Deskera ERP and OpenBOM, a leading Product Lifecycle Management (PLM) software, marks an exciting collaboration that promises to revolutionize the way businesses manage their operations, from product design to manufacturing and beyond.

In an era where seamless data integration and efficiency are paramount, this partnership seeks to provide a holistic solution that streamlines critical processes, enhances collaboration, and drives innovation in the realm of enterprise resource planning and product development.

This introduction explores the potential of this dynamic alliance, highlighting the benefits it brings to businesses seeking to optimize their operations and gain a competitive edge in the market.

The topics covered in this article are:

All About OpenBOM

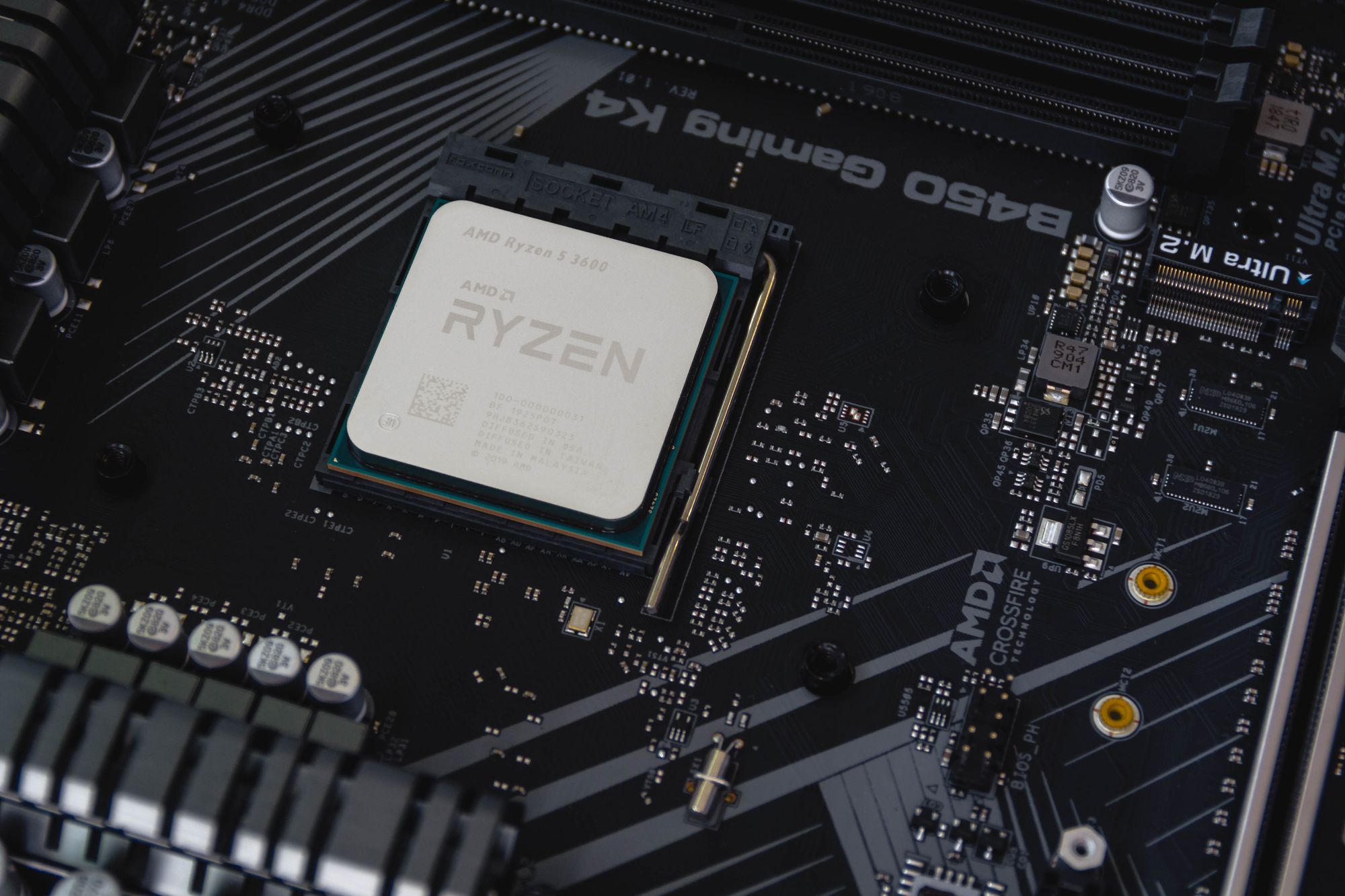

OpenBOM is a modern cloud-based platform and software solution designed to streamline and simplify Bill of Materials (BOM) management and Product Data Management (PDM) for businesses, particularly in the manufacturing and engineering sectors.

OpenBOM enables organizations to efficiently collaborate, organize, and track product information throughout the entire product development lifecycle.

Here are some key aspects and features of OpenBOM:

- Cloud-Based Platform: OpenBOM is cloud-based, which means users can access their data from anywhere with an internet connection. This fosters collaboration among distributed teams, allowing for real-time updates and seamless communication between different stakeholders.

- Bill of Materials Management: OpenBOM's primary focus is on BOM management. It allows users to create, edit, and organize BOMs easily. This is essential in industries like manufacturing, where BOMs are central to product design, production planning, and quality control.

- Parts and Inventory Management: Users can define, track, and manage individual parts and components, including their quantities and suppliers. This is crucial for maintaining accurate inventories and ensuring that the right parts are used in the right products.

- Collaboration and Sharing: OpenBOM simplifies collaboration by enabling multiple users to access and edit BOMs simultaneously. It offers various sharing options, making it easy to involve suppliers, contractors, and other stakeholders in the design and manufacturing process.

- Integration with CAD and PLM Systems: OpenBOM integrates with popular Computer-Aided Design (CAD) and Product Lifecycle Management (PLM) systems, such as Autodesk, SOLIDWORKS, and Onshape. This integration allows for the seamless transfer of data between design and BOM management, reducing errors and redundancy.

- Version Control: OpenBOM maintains a detailed version history of BOMs, ensuring that users can track changes over time and revert to earlier versions if needed.

- Data Visualization and Reporting: The platform provides tools for data visualization, reporting, and analysis. Users can create charts, graphs, and reports to gain insights into their BOMs, parts, and inventory.

- Supplier Collaboration: OpenBOM simplifies communication and collaboration with suppliers. It allows users to share BOMs and parts lists with suppliers, request quotes, and manage procurement effectively.

- Quality Control and Compliance: The platform supports compliance tracking and quality control by allowing users to attach documents, specifications, and other relevant information to BOMs and parts.

- Security and Data Protection: OpenBOM takes data security seriously and offers role-based access control to protect sensitive information. It also complies with industry standards for data protection and privacy.

- Customization and Scalability: OpenBOM is adaptable to various industries and business sizes. It can be customized to fit specific workflows and requirements, making it a flexible solution for diverse organizations.

OpenBOM simplifies and streamlines the often complex and time-consuming process of managing Bill of Materials, improving efficiency, reducing errors, and promoting collaboration.

This platform has gained popularity in industries where accurate BOMs are critical, such as aerospace, automotive, electronics, and more. It empowers companies to bring their products to market faster, with greater accuracy and cost-effectiveness.

Benefits of Partnership Between Deskera and OpenBOM

A partnership between OpenBOM and Deskera could offer several benefits, especially for businesses looking to streamline their operations and enhance their productivity.

OpenBOM is primarily focused on Bill of Materials (BOM) and product data management, while Deskera provides comprehensive enterprise resource planning (ERP) and business management solutions. Here are some advantages of such a partnership:

- End-to-End Data Integration: Integration between OpenBOM and Deskera would enable the seamless flow of data from the design and BOM management phase to the broader ERP system. This would ensure consistency and accuracy in data across the entire product lifecycle.

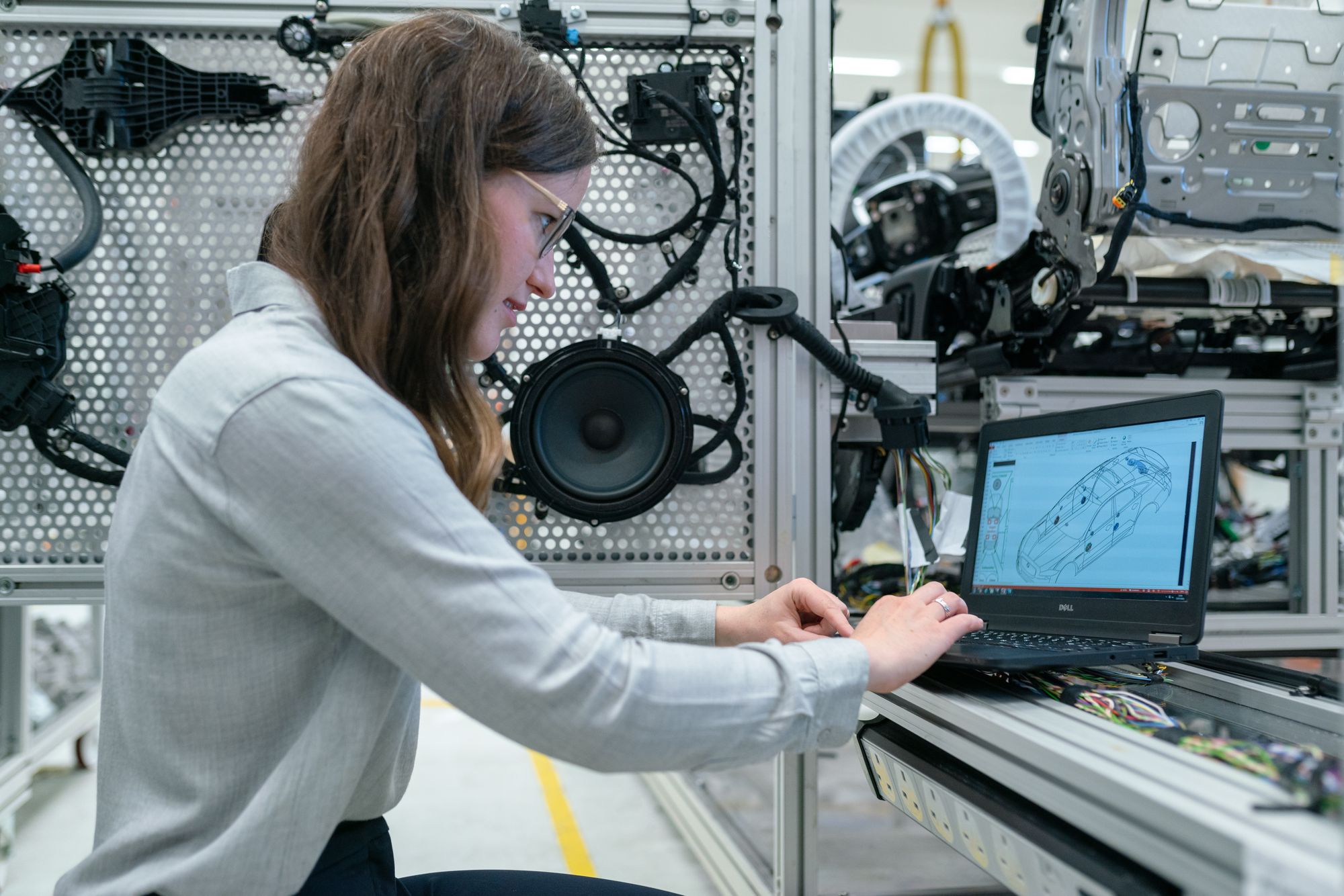

- Streamlined Product Development: Engineers and designers can leverage OpenBOM's capabilities for BOM management and collaboration, while Deskera's ERP system can facilitate efficient production planning, resource allocation, and procurement. This synergy simplifies the transition from design to production.

- Improved Inventory Management: Integration allows businesses to maintain a more accurate and up-to-date view of their inventory levels. This is crucial for optimizing stock levels, reducing carrying costs, and ensuring the availability of components when needed.

- Real-Time Cost Control: By linking OpenBOM's product design and cost data with Deskera's ERP financial and accounting modules, businesses gain real-time insights into cost structures, helping them make informed financial decisions.

- Enhanced Customer Service: Combining customer data from Deskera with product information from OpenBOM enables customer service teams to access comprehensive information when addressing inquiries, tracking orders, and resolving issues, which ultimately improves the customer experience.

- Efficient Procurement: Deskera's procurement module can benefit from OpenBOM's data by making sure that the right parts are sourced from the right suppliers at the right time. This streamlines the procurement process and reduces delays and errors.

- Production Optimization: The partnership can lead to better resource allocation and production planning. OpenBOM's accurate BOM data can help Deskera's ERP system schedule production and allocate resources more efficiently.

- Regulatory Compliance and Quality Control: OpenBOM's product compliance and quality control features can be integrated with Deskera's ERP system to ensure that products meet regulatory requirements and quality standards.

- Data Security and Access Control: A partnership can ensure that sensitive data is well-protected and that access to information is controlled, meeting compliance and data security requirements.

- Scalability and Flexibility: Both OpenBOM and Deskera are scalable solutions that can adapt to the evolving needs of businesses. This partnership can provide flexibility and robustness for businesses of various sizes and industries.

- Faster Time-to-Market: The seamless transfer of data between OpenBOM and Deskera can eliminate bottlenecks in product development and production, potentially leading to a quicker time-to-market for new products.

- Data Analytics and Reporting: The combined data from OpenBOM and Deskera can be used to generate comprehensive reports and analytics, aiding businesses in making data-driven decisions and improving overall efficiency.

In summary, a partnership between OpenBOM and Deskera has the potential to create a comprehensive and integrated solution for businesses that wish to optimize their product development, production, financial management, and customer service operations.

This integration can lead to improved efficiency, cost control, and agility, ultimately enhancing the competitiveness and success of the organization.

Key Takeaways

The partnership between Deskera and OpenBOM streamlines operations, enhances efficiency, promotes real-time data access, and supports effective collaboration.

It offers benefits such as improved inventory management, cost control, quality compliance, and a competitive advantage, making it a scalable and secure solution for businesses of various sizes and industries.

Related Articles