Data-driven procurement refers to the practice of using data and analytics to inform and optimize the procurement process. It involves collecting, analyzing, and leveraging data to make informed decisions about purchasing goods and services.

This article covers the following:

- Enhancing Efficiency and Cost Savings: How Data-Driven Procurement Revolutionizes Manufacturing

- Leveraging Big Data: Unlocking Insights for Smarter Procurement Decisions

- Driving Competitive Advantage: How Data-Driven Procurement Transforms Manufacturing Operations

- Streamlining Supply Chain Management: The Role of Data in Procurement Optimization

- From Reactive to Proactive: How Data-Driven Procurement Mitigates Risks in Manufacturing

- The Rise of Predictive Analytics: Harnessing Data for Demand Forecasting and Inventory Management

- Supplier Collaboration in the Digital Era: Maximizing Value through Data-Driven Procurement

- Unleashing Innovation: How Data-Driven Procurement Fuels Product Development in Manufacturing

- The Future of Procurement: Embracing Artificial Intelligence and Machine Learning in Manufacturing

- Overcoming Challenges: Implementing a Successful Data-Driven Procurement Strategy in Manufacturing.

Enhancing Efficiency and Cost Savings: How Data-Driven Procurement Revolutionizes Manufacturing

Data-driven procurement is revolutionizing the manufacturing industry by enhancing efficiency and generating cost savings. By leveraging data and advanced analytics, manufacturers can make informed decisions, optimize their supply chains, and streamline procurement processes. Here are several ways data-driven procurement is transforming manufacturing:

Demand Forecasting: Accurate demand forecasting is crucial for efficient procurement. By analyzing historical data, market trends, and external factors, manufacturers can predict demand patterns with greater precision. This helps optimize inventory levels, reduce stockouts, and minimize carrying costs. Data-driven demand forecasting also enables manufacturers to align procurement activities with actual customer demand, reducing lead times and improving customer satisfaction.

Supplier Performance Evaluation: Data-driven procurement allows manufacturers to evaluate supplier performance objectively. By monitoring key performance indicators (KPIs) such as delivery timeliness, quality, and pricing, manufacturers can identify top-performing suppliers and negotiate better contracts. Real-time data analytics enable manufacturers to track supplier performance, address issues promptly, and make data-backed decisions regarding supplier selection and relationship management.

Strategic Sourcing: Data-driven procurement enables manufacturers to identify the most cost-effective sourcing strategies. By analyzing supplier data, market trends, and pricing information, manufacturers can identify opportunities to consolidate suppliers, negotiate better prices, and reduce procurement costs. Advanced analytics tools can evaluate various scenarios, helping manufacturers make informed decisions on sourcing strategies that balance cost, quality, and lead times.

Risk Management: Data-driven procurement allows manufacturers to proactively manage supply chain risks. By integrating data from various sources such as market trends, supplier data, and geopolitical factors, manufacturers can identify potential risks and develop contingency plans. Real-time data analytics enable quick detection of disruptions and enable manufacturers to take timely action, mitigating the impact on production schedules and costs.

Process Automation: Automation plays a critical role in data-driven procurement. By leveraging technologies like artificial intelligence (AI) and machine learning (ML), manufacturers can automate routine procurement tasks, such as purchase order creation, supplier performance tracking, and invoice processing. Automation not only reduces manual effort but also minimizes errors, improves data accuracy, and accelerates procurement cycles.

Total Cost of Ownership (TCO) Analysis: Data-driven procurement allows manufacturers to perform comprehensive TCO analysis. By considering factors beyond the initial purchase price, such as maintenance costs, product quality, and supplier reliability, manufacturers can make more informed procurement decisions. TCO analysis helps identify cost-saving opportunities and supports strategic decision-making that optimizes long-term value rather than focusing solely on upfront costs.

Continuous Improvement: Data-driven procurement fosters a culture of continuous improvement within manufacturing organizations. By collecting and analyzing data throughout the procurement process, manufacturers can identify inefficiencies, bottlenecks, and areas for improvement. With actionable insights derived from data, manufacturers can implement process enhancements, optimize supplier relationships, and drive operational excellence.

Overall, data-driven procurement empowers manufacturers with actionable insights, enabling them to optimize their supply chains, reduce costs, and improve efficiency. By leveraging advanced analytics, automation, and real-time data, manufacturers can make informed decisions that enhance their competitive advantage in the dynamic manufacturing landscape.

Unlocking Insights for Smarter Procurement Decisions

By utilizing technology and analytical tools, organizations can gain valuable insights into their procurement operations, suppliers, market trends, and other relevant factors. These insights can then be used to drive cost savings, mitigate risks, improve supplier relationships, and enhance overall procurement efficiency.

Here are some key steps to unlock insights for smarter procurement decisions:

Data Collection: Gather relevant data from various sources, including internal systems (e.g., ERP, procurement software) and external sources (e.g., market reports, supplier information). This data may include spending data, supplier performance metrics, contract information, market pricing, and more.

Data Analysis: Utilize analytics tools and techniques to analyze the collected data. This can involve performing spend analysis, identifying trends, conducting supplier performance evaluations, assessing risks, and conducting market research. Advanced analytics methods such as predictive modeling and machine learning can provide deeper insights and identify patterns that may not be easily apparent.

Supplier Evaluation: Evaluate and assess supplier performance based on relevant metrics such as quality, delivery timeliness, pricing, and compliance. This evaluation can help identify high-performing suppliers and uncover potential areas for improvement or risk mitigation.

Risk Management: Identify and assess potential risks associated with the procurement process, including supplier risks, market risks, geopolitical risks, and regulatory compliance risks. By understanding these risks, organizations can develop appropriate mitigation strategies and contingency plans.

Cost Optimization: Analyze spending data to identify cost-saving opportunities. This may involve consolidating suppliers, negotiating better pricing and terms, implementing strategic sourcing initiatives, and optimizing inventory levels. Leveraging insights from data analysis can help organizations make informed decisions to drive cost savings while maintaining quality.

Market Intelligence: Stay updated on market trends, industry benchmarks, and supplier dynamics. Monitor changes in pricing, availability, and market conditions that may impact procurement decisions. This information can be obtained through market research, supplier networks, industry events, and engaging with key stakeholders.

Collaboration and Communication: Foster collaboration between procurement teams, stakeholders, and suppliers. Share insights and collaborate on strategic initiatives to drive continuous improvement and innovation in the procurement process. Effective communication ensures that insights are shared and integrated into decision-making processes.

Continuous Improvement: Establish a feedback loop and continuously measure performance against set targets and metrics. Regularly reassess procurement strategies and processes to identify areas for improvement and adjust accordingly.

By unlocking insights through data analysis, strategic thinking, and continuous improvement, organizations can make smarter procurement decisions that optimize costs, enhance supplier relationships, mitigate risks, and drive overall business value.

Driving Competitive Advantage: How Data-Driven Procurement Transforms Manufacturing Operations

Data-driven procurement has the potential to significantly transform manufacturing operations and drive competitive advantage. By leveraging data analytics and advanced technologies, manufacturers can make more informed decisions, streamline processes, and optimize their supply chain. Here are some key ways in which data-driven procurement can bring about these transformations:

Improved Supplier Selection: Data-driven procurement enables manufacturers to evaluate suppliers based on various factors such as pricing, quality, delivery performance, and reliability.

By analyzing historical data and supplier performance metrics, manufacturers can identify the best suppliers that meet their specific requirements. This leads to better supplier selection, reduced risk, and improved overall supply chain performance.

Demand Forecasting and Inventory Optimization: Accurate demand forecasting is critical for manufacturers to optimize their inventory levels and avoid stockouts or excess inventory.

By leveraging data from multiple sources such as sales data, customer demand patterns, and market trends, manufacturers can develop sophisticated forecasting models.

These models help in predicting demand with greater accuracy, allowing manufacturers to optimize inventory levels, reduce carrying costs, and improve customer satisfaction.

Real-Time Market Intelligence: Data-driven procurement provides manufacturers with real-time market intelligence, allowing them to stay updated on market trends, competitor activities, and pricing fluctuations.

By analyzing external data sources such as social media, industry reports, and market trends, manufacturers can gain valuable insights into customer preferences, emerging technologies, and changing market dynamics. This enables proactive decision-making and the ability to quickly adapt to market changes, thereby gaining a competitive edge.

Risk Mitigation: Data-driven procurement helps manufacturers identify and mitigate risks in the supply chain. By analyzing supplier data, manufacturers can assess supplier performance, financial stability, and potential risks such as geopolitical events, natural disasters, or transportation disruptions. This allows manufacturers to proactively manage risks, develop contingency plans, and ensure business continuity.

Process Efficiency and Cost Savings: Data analytics can optimize procurement processes by automating manual tasks, improving efficiency, and reducing costs.

For example, by implementing automated procurement systems and leveraging machine learning algorithms, manufacturers can streamline purchase order processing, invoice matching, and supplier performance evaluation. This reduces manual errors, speeds up processes, and frees up resources to focus on more strategic activities.

Enhanced Collaboration and Supplier Relationships: Data-driven procurement facilitates collaboration and transparency between manufacturers and suppliers.

By sharing relevant data and performance metrics, manufacturers can establish stronger partnerships with suppliers, leading to better communication, improved collaboration, and mutual growth. This can result in reduced lead times, improved product quality, and increased innovation.

Overall, data-driven procurement transforms manufacturing operations by enabling manufacturers to make data-backed decisions, optimize processes, mitigate risks, and build stronger supplier relationships. By harnessing the power of data analytics, manufacturers can gain a competitive advantage in an increasingly complex and dynamic marketplace.

Streamlining Supply Chain Management: The Role of Data in Procurement Optimization

Data plays a crucial role in streamlining supply chain management, particularly in the context of procurement optimization. By harnessing and analyzing data effectively, organizations can make informed decisions, improve operational efficiency, and enhance overall supply chain performance.

Here are some key ways in which data contributes to procurement optimization:

Demand Forecasting: Accurate demand forecasting is essential for efficient procurement. By analyzing historical sales data, market trends, and other relevant factors, organizations can predict future demand patterns and adjust their procurement strategies accordingly. This helps in preventing stockouts or overstocking, reducing inventory holding costs, and optimizing order quantities.

Supplier Performance Evaluation: Data allows organizations to evaluate the performance of their suppliers objectively. By tracking metrics such as on-time delivery, product quality, lead times, and pricing, organizations can identify the most reliable and cost-effective suppliers. This data-driven supplier evaluation facilitates better supplier selection, negotiation, and relationship management, ultimately leading to improved procurement outcomes.

Inventory Management: Data-driven inventory management is critical to maintaining optimal inventory levels. By monitoring real-time inventory data, including stock levels, turnover rates, and lead times, organizations can avoid stockouts and minimize excess inventory.

Advanced analytics techniques, such as inventory optimization models, can also help identify the optimal reorder points, safety stock levels, and replenishment strategies based on historical data and demand patterns.

Cost Analysis: Data analysis enables organizations to perform comprehensive cost analysis across the procurement process. By capturing and analyzing data related to purchase prices, transactional costs, transportation costs, and other cost components, organizations can identify cost-saving opportunities.

This data-driven cost analysis can help negotiate better pricing with suppliers, optimize shipping and logistics routes, and identify areas for process improvement to reduce overall procurement costs.

Risk Management: Data can support effective risk management in procurement. By monitoring various risk indicators such as supplier financial health, geopolitical factors, and natural disasters, organizations can proactively identify and mitigate potential risks in the supply chain.

Data analytics techniques, such as predictive modeling and scenario analysis, can also help anticipate and mitigate supply chain disruptions, ensuring continuity of supply and minimizing the impact on procurement operations.

Continuous Improvement: Data-driven insights enable organizations to drive continuous improvement in procurement processes. By capturing data on key performance indicators (KPIs) such as order cycle time, supplier performance metrics, and cost savings achieved, organizations can identify areas for improvement and implement targeted initiatives. Regular analysis of procurement data can help identify bottlenecks, streamline processes, and optimize the overall procurement function.

In summary, data plays a pivotal role in procurement optimization by enabling organizations to make informed decisions, improve efficiency, and enhance supply chain performance.

By leveraging data effectively, organizations can gain a competitive edge, reduce costs, and ensure a streamlined and efficient procurement process.

From Reactive to Proactive: How Data-Driven Procurement Mitigates Risks in Manufacturing

In today's fast-paced and competitive manufacturing industry, companies face numerous risks that can impact their supply chain, production, and overall business performance.

To effectively address these risks, organizations are shifting from reactive procurement approaches to proactive strategies driven by data analysis. By harnessing the power of data, manufacturers can make informed decisions, optimize their procurement processes, and mitigate risks before they escalate. This article explores how data-driven procurement is transforming the manufacturing landscape and enabling proactive risk management.

Real-Time Visibility and Demand Forecasting: Data-driven procurement provides manufacturers with real-time visibility into their supply chain and market demands.

By integrating data from various sources such as IoT sensors, supplier databases, and market trends, organizations can gain accurate insights into inventory levels, production capacities, and customer demands.

This visibility enables proactive planning, allowing manufacturers to anticipate potential disruptions, adjust their procurement strategies, and maintain optimal inventory levels.

Supplier Performance and Risk Assessment: Data-driven procurement facilitates supplier performance evaluation and risk assessment. Manufacturers can analyze supplier data to assess their reliability, delivery times, quality standards, and financial stability.

By tracking supplier performance metrics, such as on-time delivery rates and product defect rates, organizations can identify potential bottlenecks or vulnerabilities in their supply chain.

This data-driven approach empowers manufacturers to proactively manage supplier relationships, mitigate risks, and explore alternative sourcing options if necessary.

Predictive Maintenance and Spare Parts Management: Manufacturing equipment downtime can significantly impact production schedules and lead to supply chain disruptions.

Data-driven procurement leverages predictive maintenance techniques by analyzing machine data, sensor readings, and historical maintenance records. By identifying patterns and anomalies, organizations can anticipate equipment failures, schedule preventive maintenance, and optimize spare parts inventory. This proactive approach minimizes unplanned downtime, reduces maintenance costs, and ensures uninterrupted production.

Continuous Improvement and Cost Optimization: Data-driven procurement enables continuous improvement and cost optimization by identifying inefficiencies and optimizing procurement processes.

Through data analysis, manufacturers can uncover bottlenecks, streamline workflows, and identify cost-saving opportunities. For instance, analyzing historical purchase data and supplier performance metrics can help negotiate favorable pricing terms and identify alternative suppliers offering better value for money. By optimizing procurement processes, manufacturers can reduce costs, enhance operational efficiency, and mitigate financial risks.

Risk Analytics and Scenario Planning: Data-driven procurement empowers manufacturers to conduct risk analytics and scenario planning. By leveraging historical data, market trends, and risk indicators, organizations can assess the impact of potential risks and develop proactive mitigation strategies.

For instance, using predictive analytics, manufacturers can model various scenarios such as natural disasters, supply chain disruptions, or market fluctuations.

This proactive approach allows organizations to implement contingency plans, diversify their supplier base, and ensure business continuity in the face of uncertainties.

Data-driven procurement has emerged as a crucial tool for mitigating risks in the manufacturing industry. By leveraging real-time data analytics, manufacturers can transition from reactive to proactive procurement strategies.

The ability to gain visibility, assess supplier performance, optimize maintenance practices, and drive cost efficiencies empowers organizations to mitigate risks and maintain a competitive edge.

Embracing data-driven procurement enables manufacturers to proactively identify and address potential disruptions, safeguard their supply chains, and enhance overall business resilience in an increasingly volatile marketplace.

The Rise of Predictive Analytics: Harnessing Data for Demand Forecasting and Inventory Management

Predictive analytics has indeed seen a significant rise in recent years, with organizations across various industries harnessing the power of data to improve demand forecasting and inventory management.

By leveraging advanced analytical techniques and machine learning algorithms, predictive analytics enables businesses to make more informed decisions and optimize their supply chain operations.

Demand forecasting is a critical aspect of inventory management, as it helps businesses anticipate customer demand patterns and plan their inventory levels accordingly. Traditional forecasting methods often relied on historical sales data and basic statistical models.

However, with the advent of predictive analytics, businesses can now incorporate a wide range of data sources, such as customer demographics, market trends, social media sentiment, and even weather patterns, to create more accurate and granular demand forecasts.

Predictive analytics models can analyze vast amounts of historical data and identify complex patterns and correlations that might not be apparent through manual analysis.

These models can then generate forecasts that consider multiple factors and variables, providing a more holistic view of future demand. By leveraging these insights, businesses can optimize their inventory levels, minimize stockouts and overstock situations, and ensure that the right products are available at the right time and in the right quantities.

Furthermore, predictive analytics can help organizations dynamically adjust their inventory management strategies in response to changing market conditions. For example, if a sudden surge in demand is predicted for a particular product, businesses can proactively increase their stock levels to meet customer needs. On the other hand, if a decline in demand is anticipated, inventory levels can be adjusted accordingly to prevent excess inventory and associated costs.

In addition to demand forecasting, predictive analytics can also assist in identifying potential supply chain bottlenecks and optimizing procurement processes.

By analyzing historical supplier data, market trends, lead times, and other relevant factors, businesses can gain insights into potential disruptions or delays in the supply chain.

This proactive approach allows them to take appropriate actions, such as identifying alternative suppliers or adjusting production schedules, to mitigate risks and ensure smooth operations.

Overall, the rise of predictive analytics has transformed the way businesses approach demand forecasting and inventory management. By harnessing the power of data and advanced analytical techniques, organizations can make more accurate predictions, optimize inventory levels, and enhance overall supply chain efficiency.

As technology continues to evolve, we can expect further advancements in predictive analytics, leading to even more sophisticated and precise forecasting and inventory management capabilities.

Supplier Collaboration in the Digital Era: Maximizing Value through Data-Driven Procurement

Supplier collaboration in the digital era refers to the practice of leveraging data and technology to enhance procurement processes and maximize the value derived from supplier relationships.

By embracing digital tools and harnessing the power of data analytics, organizations can establish stronger partnerships with suppliers, streamline procurement activities, and drive better business outcomes.

Here are some key aspects of supplier collaboration in the digital era and how it can help maximize value through data-driven procurement:

Enhanced Supplier Visibility: Digital platforms and data analytics enable organizations to gain greater visibility into their supplier network. They can access real-time information about supplier capabilities, performance, and availability, allowing for informed decision-making. This visibility helps in identifying potential risks, evaluating supplier performance, and optimizing sourcing strategies.

Strategic Supplier Selection: Data-driven procurement allows organizations to analyze historical supplier data, market trends, and performance metrics to make more informed decisions when selecting suppliers. By leveraging insights derived from data, organizations can identify suppliers with the right capabilities, quality standards, and pricing structures to meet their specific requirements.

Improved Supplier Relationship Management: Digital tools facilitate effective communication and collaboration between buyers and suppliers. Collaborative platforms, such as supplier portals and online marketplaces, enable seamless information sharing, order tracking, and performance evaluation. This fosters stronger relationships, reduces manual errors, and enhances overall supplier satisfaction.

Demand Forecasting and Inventory Optimization: By analyzing historical data and market trends, organizations can improve their demand forecasting accuracy.

This helps suppliers better align their production and delivery schedules with the buyer's needs, leading to optimized inventory levels and reduced costs. Data-driven procurement enables organizations to minimize stock-outs, eliminate excess inventory, and enhance supply chain efficiency.

Continuous Performance Monitoring: Data analytics allows organizations to monitor supplier performance on an ongoing basis. Key performance indicators (KPIs) can be tracked and analyzed to identify areas for improvement, such as delivery reliability, quality control, and responsiveness. Real-time monitoring helps organizations address any issues promptly and proactively manage supplier relationships.

Risk Mitigation: The digital era offers advanced tools for risk management in procurement. Data analytics can be used to assess supplier risks, such as financial stability, compliance, and geopolitical factors.

By leveraging predictive analytics and real-time monitoring, organizations can identify and mitigate potential risks, ensuring continuity in the supply chain and minimizing disruptions.

Cost Optimization: Data-driven procurement enables organizations to analyze spending patterns, identify cost-saving opportunities, and negotiate better terms with suppliers.

By leveraging data insights, organizations can optimize procurement processes, consolidate suppliers, and negotiate favorable pricing based on market conditions and supplier performance.

In summary, supplier collaboration in the digital era leverages data and technology to maximize the value derived from supplier relationships. By embracing data-driven procurement practices, organizations can enhance supplier visibility, improve supplier selection, strengthen supplier relationships, optimize inventory levels, monitor performance, mitigate risks, and optimize costs. These capabilities empower organizations to make more informed decisions, drive operational efficiencies, and achieve better business outcomes.

Unleashing Innovation: How Data-Driven Procurement Fuels Product Development in Manufacturing

Data-driven procurement is a powerful tool that can significantly fuel product development in the manufacturing industry. By harnessing the vast amounts of data available throughout the procurement process, manufacturers can gain valuable insights and make informed decisions that drive innovation. Here's how data-driven procurement can unleash innovation in manufacturing:

Improved Supplier Selection: Data-driven procurement enables manufacturers to evaluate and select suppliers based on various metrics, such as quality, cost, delivery time, and reliability.

By analyzing historical supplier data, manufacturers can identify the most reliable and high-performing suppliers for their product development needs. This ensures that the right suppliers are chosen, which is crucial for sourcing high-quality components and materials that form the foundation of innovative products.

Real-Time Market Intelligence: By leveraging data from external sources, such as market trends, consumer preferences, and competitor analysis, manufacturers can gain real-time market intelligence.

This information helps them identify emerging trends, anticipate customer demands, and align their product development strategies accordingly. Access to timely and accurate market data allows manufacturers to stay ahead of the competition and create innovative products that meet the evolving needs of their target market.

Demand Forecasting and Inventory Optimization: Data-driven procurement facilitates accurate demand forecasting by analyzing historical sales data, market trends, and other relevant factors.

This helps manufacturers optimize their inventory levels and ensure that they have the right amount of raw materials and components on hand to meet customer demand.

By minimizing stockouts and excess inventory, manufacturers can streamline their product development processes, reduce costs, and allocate resources more efficiently, thus freeing up resources for innovation.

Enhanced Collaboration and Communication: Data-driven procurement promotes collaboration and communication between manufacturers and their suppliers. By sharing relevant data and insights, manufacturers can work closely with suppliers to identify opportunities for innovation.

For example, collaborative discussions around product specifications, cost-saving initiatives, and quality improvements can lead to the development of innovative products and processes. Transparent and efficient communication facilitated by data-driven procurement fosters a collaborative ecosystem that drives innovation throughout the supply chain.

Continuous Improvement: Data-driven procurement provides manufacturers with detailed analytics and performance metrics across the procurement process. By analyzing this data, manufacturers can identify bottlenecks, inefficiencies, and areas for improvement.

Continuous improvement efforts lead to streamlined procurement processes, reduced lead times, and cost savings, which can be reinvested in product development initiatives.

The iterative nature of data-driven procurement ensures that manufacturers are constantly optimizing their operations and fostering an environment conducive to innovation.

In conclusion, data-driven procurement plays a pivotal role in fueling product development in manufacturing. By leveraging data throughout the procurement process, manufacturers can make informed decisions, optimize operations, and foster collaboration, ultimately driving innovation.

Manufacturers that embrace data-driven procurement stand to gain a competitive edge by creating innovative products that meet customer needs while improving efficiency and reducing costs.

The Future of Procurement: Embracing Artificial Intelligence and Machine Learning in Manufacturing

The future of procurement in manufacturing is indeed being shaped by the rapid advancement of artificial intelligence (AI) and machine learning (ML) technologies.

These technologies have the potential to revolutionize the procurement process, enabling manufacturers to make more informed decisions, optimize their supply chains, and drive efficiency and cost savings. Here are some key ways in which AI and ML are being embraced in procurement in the manufacturing industry:

Demand Forecasting and Inventory Optimization: AI and ML algorithms can analyze large volumes of historical data, market trends, and customer behavior to accurately forecast demand for manufacturing products.

This enables manufacturers to optimize their inventory levels, reduce stockouts, and minimize holding costs. By leveraging real-time data and advanced analytics, manufacturers can make more accurate predictions and adjust their procurement strategies accordingly.

Supplier Selection and Relationship Management: AI and ML can assist in selecting the right suppliers by analyzing various factors such as price, quality, reliability, and past performance.

These technologies can also monitor supplier performance in real-time, identifying potential risks and providing recommendations for proactive action. Additionally, AI-powered chatbots and virtual assistants can enhance supplier communication and streamline the procurement process.

Strategic Sourcing and Negotiations: AI can analyze vast amounts of data from multiple sources, including market pricing information, supplier catalogs, and historical procurement data, to optimize sourcing decisions.

Machine learning algorithms can identify patterns and insights that human analysts may miss, enabling manufacturers to negotiate better prices, terms, and contracts with suppliers. This can lead to significant cost savings and improved supplier relationships.

Supply Chain Risk Management: AI and ML can play a crucial role in mitigating supply chain risks. By continuously monitoring data from multiple sources, including weather forecasts, political developments, and economic indicators, AI algorithms can identify potential disruptions and provide early warnings. Manufacturers can proactively take steps to mitigate risks, such as finding alternative suppliers or adjusting production schedules.

Process Automation: AI and ML technologies can automate repetitive and time-consuming procurement tasks, such as purchase order processing, invoice matching, and contract management.

Robotic Process Automation (RPA) can streamline these processes, reducing manual errors and freeing up procurement professionals to focus on more strategic activities. Additionally, AI-powered chatbots and virtual assistants can handle routine inquiries and provide real-time support to both internal stakeholders and suppliers.

Data-Driven Insights and Decision Making: AI and ML can analyze vast amounts of procurement data and provide actionable insights to support decision-making.

By leveraging predictive analytics, manufacturers can optimize their procurement strategies, identify cost-saving opportunities, and make informed decisions about sourcing, inventory management, and supplier relationships.

However, it's important to note that the successful implementation of AI and ML in procurement requires careful consideration of data quality, integration with existing systems, and change management within the organization. Additionally, ethical considerations, such as data privacy and bias, should be addressed to ensure the responsible and fair use of AI and ML technologies.

In conclusion, the future of procurement in manufacturing lies in embracing AI and ML. By harnessing the power of these technologies, manufacturers can enhance efficiency, reduce costs, mitigate risks, and gain a competitive edge in an increasingly complex and dynamic global marketplace.

Overcoming Challenges: Implementing a Successful Data-Driven Procurement Strategy in Manufacturing

Implementing a successful data-driven procurement strategy in manufacturing can present several challenges. However, with careful planning and execution, these challenges can be overcome. Here are some key steps to consider:

Define Clear Objectives: Clearly define the objectives of your data-driven procurement strategy. Determine the specific areas where data can provide insights and improvements, such as supplier selection, inventory management, cost optimization, or risk mitigation.

Establish Data Governance: Develop a robust data governance framework to ensure data quality, integrity, and security. This includes defining data ownership, establishing data collection and storage protocols, and implementing data validation processes.

Invest in Data Infrastructure: Build or enhance your data infrastructure to support the collection, storage, and analysis of procurement-related data. This may involve implementing a data warehouse, and data management tools, and integrating data sources from various systems such as Enterprise Resource Planning (ERP), Supplier Relationship Management (SRM), and Customer Relationship Management (CRM) systems.

Data Integration: Integrate data from multiple sources to gain a holistic view of your procurement operations. This may involve consolidating data from ERP systems, supplier databases, market intelligence platforms, and external sources such as industry reports or economic indicators.

Analytical Capabilities: Develop or acquire analytical capabilities to derive meaningful insights from the collected data. This may involve hiring data scientists or analysts who specialize in procurement analytics or utilizing advanced analytics tools and machine learning algorithms to identify patterns, trends, and opportunities.

Supplier Performance Management: Utilize data to assess and monitor supplier performance. Develop key performance indicators (KPIs) based on data insights to measure and track supplier performance in terms of quality, delivery, pricing, and responsiveness. Use this information to make informed decisions regarding supplier selection, negotiations, and contract management.

Predictive Analytics: Leverage predictive analytics to anticipate future demand, identify potential supply chain disruptions, and optimize inventory levels. By analyzing historical data, market trends, and external factors, you can make more accurate demand forecasts and align procurement activities accordingly.

Continuous Improvement: Implement a culture of continuous improvement by regularly reviewing and refining your data-driven procurement strategy. Analyze the impact of your decisions and actions, identify areas for improvement, and adjust your strategy accordingly. Encourage feedback and collaboration from stakeholders across the organization.

Change Management: Ensure effective change management throughout the implementation process. Educate and train employees on the benefits and usage of the data-driven procurement strategy. Address any resistance to change and promote a data-driven mindset across the organization.

Collaboration and Communication: Foster collaboration and communication between procurement teams, internal stakeholders, and suppliers. Share relevant data and insights with stakeholders, engage in proactive dialogue with suppliers, and explore opportunities for joint improvement initiatives.

By following these steps, manufacturers can overcome challenges and successfully implement a data-driven procurement strategy that enables them to make informed decisions, optimize costs, enhance supplier relationships, and drive overall operational efficiency.

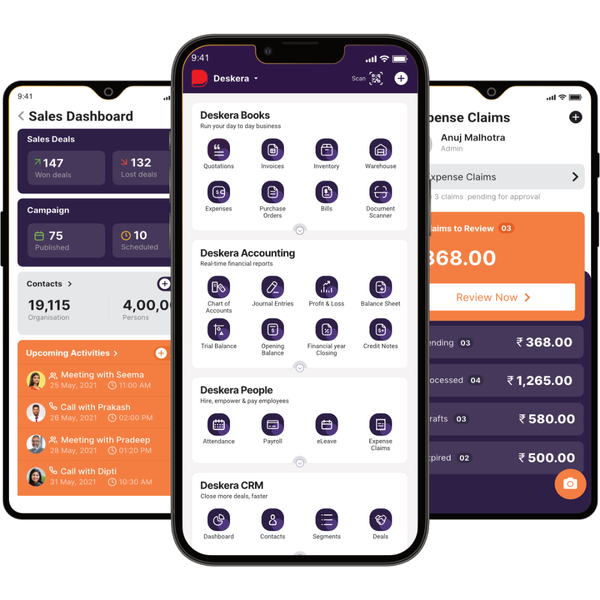

How Can Deskera Assist You?

Deskera ERP and MRP system can help you:

- Manage production plans

- Maintain Bill of Materials

- Generate detailed reports

- Create a custom dashboard

Deskera ERP is a comprehensive system that allows you to maintain inventory, manage suppliers, and track supply chain activity in real time, as well as streamline a variety of other corporate operations.

Deskera MRP allows you to closely monitor the manufacturing process. From the bill of materials to the production planning features, the solution helps you stay on top of your game and keep your company's competitive edge.

Deskera Books enables you to manage your accounts and finances more effectively. Maintain sound accounting practices by automating accounting operations such as billing, invoicing, and payment processing.

Deskera CRM is a strong solution that manages your sales and assists you in closing agreements quickly. It not only allows you to do critical duties such as lead generation via email, but it also provides you with a comprehensive view of your sales funnel.

Deskera People is a simple tool for taking control of your human resource management functions. The technology not only speeds up payroll processing but also allows you to manage all other activities, such as overtime, benefits, bonuses, training programs, and much more. This is your chance to grow your business, increase earnings, and improve the efficiency of the entire production process.

Related Articles: