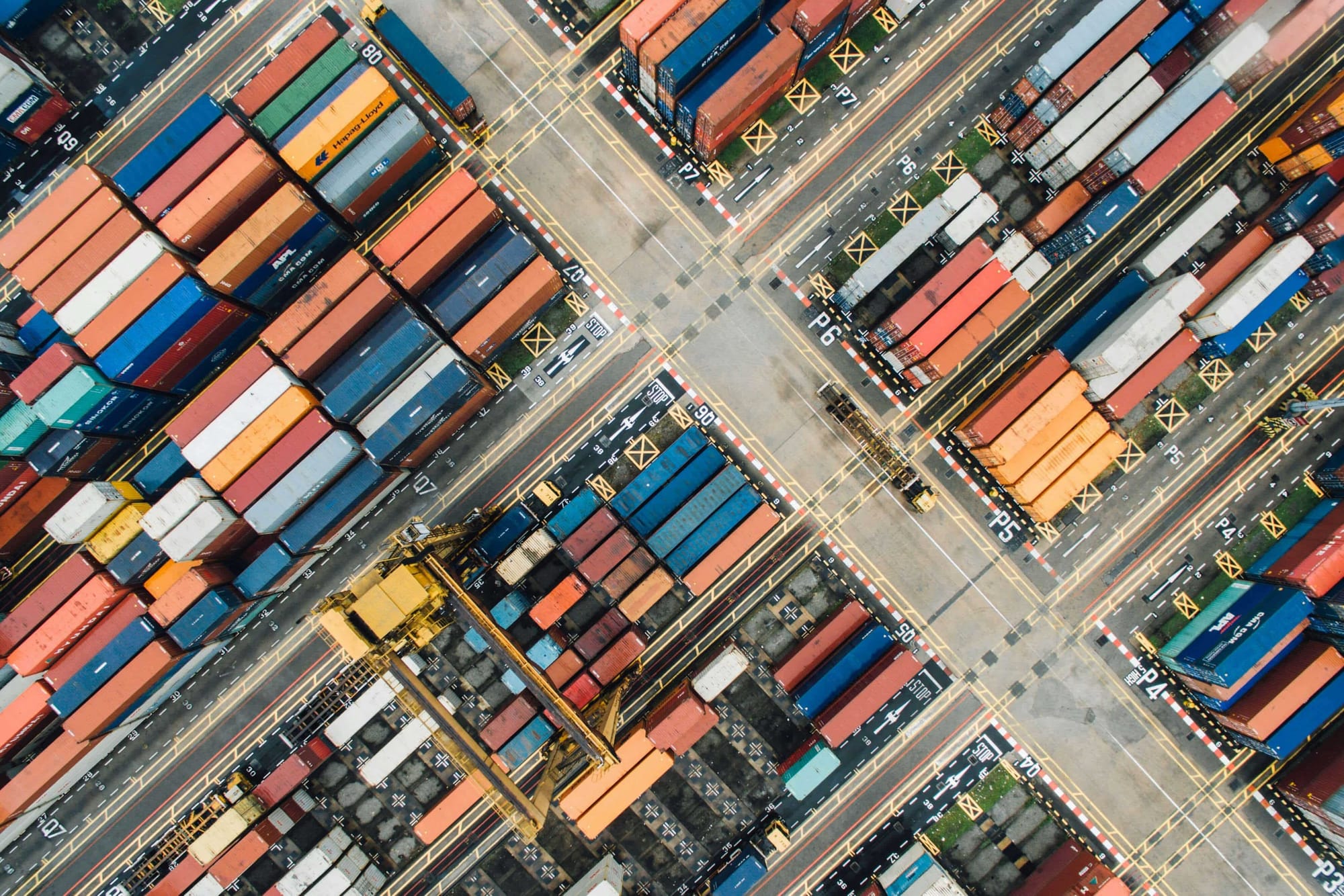

Is your business finding it challenging to keep up with rising customer expectations, fluctuating demand, and complex logistics operations? In today’s fast-paced global marketplace, companies are increasingly turning to Third-Party Logistics (3PL) providers to streamline their supply chains and deliver products faster and more efficiently. However, simply outsourcing logistics isn’t enough — the real power lies in 3PL integration, which connects your internal systems with external logistics partners for seamless coordination, visibility, and automation across your supply chain.

Statistics show that the 3PL market is growing rapidly, projected to reach $1.4 trillion globally by 2025 and an impressive $1.88 trillion by 2030. This surge highlights how businesses are recognizing the strategic value of logistics partnerships. In fact, 90% of Fortune 500 companies use 3PLs, with 91% of users reporting improved customer satisfaction thanks to faster fulfillment and data-driven decision-making. Integration plays a central role in this success, with 66% of logistics leaders increasing their outsourcing budgets and 61% of shippers identifying supply chain change management as critical to maintaining competitiveness.

3PL integration empowers businesses to break down data silos and gain real-time visibility into inventory, shipping, and order fulfillment. By connecting systems such as ERP, inventory, and warehouse management software, companies can synchronize operations, reduce manual errors, and accelerate deliveries — all while enhancing customer experience. This technological alignment ensures that logistics becomes not just an operational necessity but a driver of strategic growth.

This is where Deskera ERP comes in. Designed for modern, growing businesses, Deskera ERP enables seamless 3PL integration by connecting your order management, inventory, and logistics workflows in one unified platform. With features like real-time inventory tracking, automated shipping updates, AI-powered insights through David, and mobile accessibility, Deskera empowers you to manage your logistics operations with speed and precision. Whether you’re optimizing warehouse efficiency or scaling global fulfillment, Deskera ERP simplifies the complexity of supply chain management — turning integration into your competitive edge.

What is 3PL Integration?

3PL integration is the process of connecting a company’s internal systems—such as its eCommerce platform, inventory management tools, ERP software, or order management system—with a Third-Party Logistics (3PL) provider’s systems. This connection allows both parties to exchange data automatically and operate from a single, up-to-date source of truth. By integrating these systems, businesses can eliminate manual data entry, streamline logistics processes, and ensure that every part of the supply chain communicates seamlessly.

When effectively implemented, 3PL integration automates key logistics tasks such as order processing, inventory synchronization, shipping label generation, and tracking updates. For instance, when a customer places an order online, the integration automatically sends order details to the 3PL for fulfillment, updates stock levels across all sales channels, and syncs shipment tracking data back to the storefront—keeping both the business and the customer informed in real time. Without integration, these steps often require manual coordination, which can lead to delays, mismatched inventory counts, and fulfillment errors.

Beyond operational efficiency, 3PL integration also enables businesses to monitor critical KPIs such as fulfillment speed, error rates, and delivery accuracy. This visibility helps decision-makers identify bottlenecks, optimize workflows, and respond faster to changes in demand. The rise of automation technologies underscores its importance—according to Fortune Business Insights, the global logistics automation market is projected to grow from over $88 billion in 2025 to nearly $213 billion by 2032, reflecting the growing reliance on integrated logistics systems for cost efficiency and flexibility.

Ultimately, 3PL integration empowers companies to manage larger order volumes, support multiple sales channels, and deliver superior customer experiences. It forms the backbone of modern supply chain management—where automation, data accuracy, and real-time collaboration are no longer optional but essential for success in today’s competitive market.

Why 3PL Integration Matters for Modern Businesses

In an era where customer expectations revolve around speed, accuracy, and transparency, 3PL integration has become more than a logistics convenience—it’s a strategic necessity. Modern businesses operate across multiple channels, manage complex supply chains, and serve diverse markets. Without a unified logistics framework, these operations can quickly become inefficient, error-prone, and costly.

By integrating with a 3PL provider, companies can automate repetitive tasks, improve communication, and gain real-time visibility across their entire fulfillment network. The result is faster deliveries, higher customer satisfaction, and better use of resources. Below are some of the key reasons why 3PL integration is essential for today’s businesses.

1. Real-Time Data Visibility

3PL integration provides end-to-end visibility across all stages of the supply chain—from order placement to final delivery. By syncing data between your ERP, inventory, and logistics systems, businesses can monitor order statuses, shipment progress, and stock levels in real time. This transparency helps prevent stockouts, overstocking, and shipping delays, while enabling data-driven decisions that improve operational agility.

2. Streamlined Order Fulfillment

With integrated systems, orders flow automatically from your eCommerce platform or ERP to the 3PL for picking, packing, and shipping. This automation eliminates manual entry and reduces errors, ensuring faster and more accurate order processing. Whether you’re fulfilling hundreds or thousands of orders daily, integration ensures consistency, speed, and reliability—key factors for building customer trust.

3. Cost Efficiency and Resource Optimization

By automating communication between systems, businesses can reduce labor costs, eliminate redundant processes, and minimize human errors. Integration also optimizes resource allocation, as warehouse operations, shipping routes, and inventory levels are better aligned. Over time, this leads to significant savings on operational expenses and improved return on logistics investment.

4. Enhanced Customer Experience

Modern consumers expect accurate tracking updates and timely deliveries. Through 3PL integration, customers receive real-time order confirmations, shipping notifications, and delivery updates directly from the system. This transparency not only boosts satisfaction but also strengthens brand loyalty—especially when customers can rely on consistent and predictable delivery experiences.

5. Scalability and Flexibility

As businesses grow, so do their logistics demands. 3PL integration enables scalable operations, allowing companies to expand into new markets or sales channels without disrupting workflows. Whether it’s handling seasonal spikes, international shipping, or multi-warehouse coordination, integrated logistics ensures that scaling up doesn’t compromise efficiency or service quality.

6. Actionable Insights for Continuous Improvement

Integrated systems generate valuable data that can be used for performance tracking and process optimization. By analyzing metrics such as delivery times, order accuracy, and fulfillment costs, businesses can identify areas for improvement and adapt strategies accordingly. These insights turn logistics from a cost center into a competitive advantage.

Key Components of a Successful 3PL Integration

Integrating a Third-Party Logistics (3PL) provider with your business systems requires more than just connecting software—it demands a thoughtful approach to data flow, automation, and collaboration. Successful 3PL integration ensures that every part of your supply chain operates in sync, from order placement to delivery confirmation. By understanding the key components that drive this integration, businesses can unlock smoother operations, greater transparency, and measurable improvements in efficiency and customer satisfaction.

1. Data Synchronization

At the heart of every successful 3PL integration is real-time data synchronization. This ensures that information such as order status, shipment tracking, and inventory updates flows seamlessly between your ERP, warehouse, and 3PL systems. Accurate, synchronized data eliminates discrepancies, reduces manual intervention, and allows all stakeholders to make timely, informed decisions.

2. Centralized Order and Inventory Management

A robust 3PL integration enables centralized management of orders and inventory across multiple sales channels. When an order is placed, it automatically triggers updates in both your internal system and the 3PL’s platform. This automation helps prevent stockouts, double-selling, and delays in fulfillment—ensuring that product availability reflects real-time warehouse conditions and maintaining consistency across channels.

3. Automated Shipping and Tracking

With integration in place, the entire shipping workflow can be automated from label generation to delivery tracking. The system can automatically assign shipping carriers, create airway bills, and send tracking numbers to customers. This not only speeds up fulfillment but also enhances transparency, as both your business and your customers can monitor shipments in real time.

4. Seamless Communication Between Systems

A critical success factor in 3PL integration is maintaining clear, automated communication between your business systems and logistics partners. Integration via APIs or EDI ensures that updates—such as order changes, returns, or shipment exceptions—are shared instantly. This reduces miscommunication, improves coordination, and helps maintain service-level agreements (SLAs).

5. Analytics and Reporting

Comprehensive analytics are essential to measure logistics performance and optimize operations. Integrated systems collect data from multiple touchpoints, allowing you to track KPIs such as fulfillment time, shipping costs, delivery accuracy, and inventory turnover. These insights support data-driven decisions that help reduce inefficiencies and continuously improve supply chain performance.

6. Security and Compliance

With increasing volumes of sensitive data flowing between systems, data security and regulatory compliance become crucial. A strong 3PL integration includes secure data transfer protocols, access controls, and compliance with standards like GDPR and ISO. This ensures that business and customer data remain protected at every stage of the supply chain.

Types of 3PL Integration

There are several forms of 3PL integration, each designed to meet specific business needs, technical environments, and growth goals. Understanding the differences between these integration types helps businesses choose the best fit for their size, order complexity, and supply chain strategy.

While some integration types are quick and cost-effective, others offer deeper customization, scalability, and compliance capabilities. The choice often depends on factors such as business model, product type, order volume, and technical infrastructure. Below are the most common types of 3PL integrations and what they offer.

1. eCommerce Integration

An eCommerce integration connects online storefronts—like Shopify, WooCommerce, or Magento—directly with a 3PL provider’s systems. This setup automates order transfers, inventory updates, and shipping confirmations, minimizing manual intervention. It allows customers to access real-time shipment tracking while enabling faster and more accurate fulfillment.

Most eCommerce platforms offer prebuilt connectors, making this type of integration quick to set up and ideal for startups or small online retailers. However, it may offer limited customization compared to more complex integration methods.

2. Marketplace Integration

Marketplace integrations link major platforms like Amazon, eBay, or Walmart Marketplace to 3PL systems. These integrations automatically sync product availability, order details, and shipment data for multichannel fulfillment.

They are especially useful for businesses expanding into multiple marketplaces, helping maintain consistent service levels and inventory visibility across all sales channels. Like eCommerce integrations, marketplace setups are relatively simple but may lack advanced customization features for complex operations.

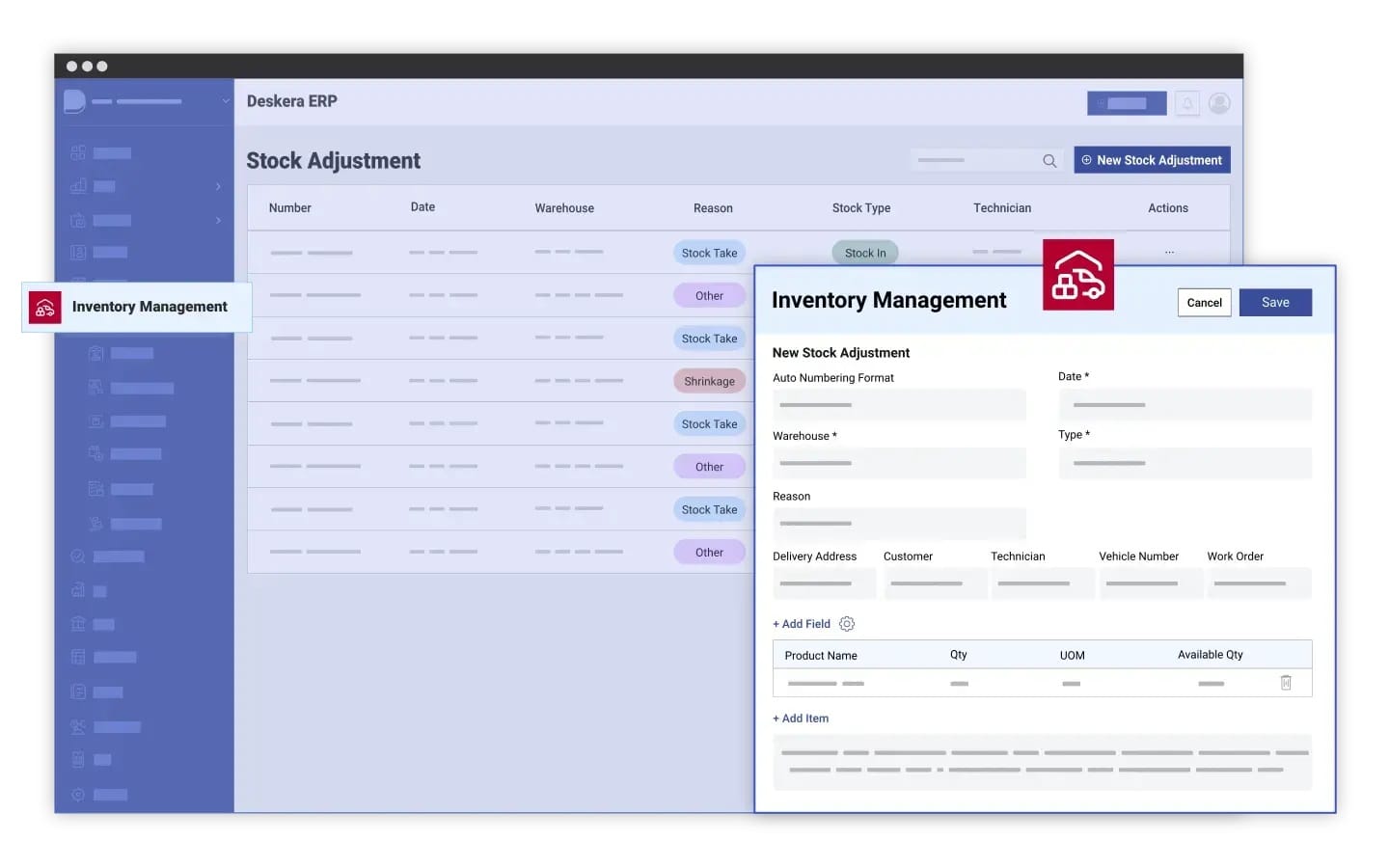

3. Inventory Management Integration

By connecting inventory management software with a 3PL’s systems, businesses gain real-time visibility of stock levels across warehouses and sales channels. This integration improves accuracy, reduces stockouts, and ensures efficient restocking.

Although highly beneficial for scaling operations, inventory integrations often require custom API work or advanced data mapping. This makes them slightly more complex to implement than basic eCommerce or marketplace integrations—but far more powerful for businesses managing large product catalogs or multiple warehouses.

4. Order Management System (OMS) Integration

An OMS integration bridges a company’s order management software with its 3PL provider, enabling smoother order routing, fulfillment tracking, and returns processing. It centralizes order data across multiple sales channels, eliminating the need to connect each one individually.

While OMS integrations deliver strong visibility and control, they often involve more configuration and testing than plug-and-play solutions. This type of integration is best suited for businesses handling large order volumes or operating across multiple regions.

5. ERP Integration

ERP integration connects enterprise systems—such as Deskera ERP—with 3PL providers to synchronize core business data, including accounting, procurement, customer management, and inventory. This enables cross-departmental visibility, unified reporting, and consistent data across the organization.

Though highly scalable, ERP integrations can be technically intensive, requiring configuration, customization, and data mapping. However, modern ERPs like Deskera simplify the process with built-in integration capabilities, making setup faster and less error-prone while offering long-term reliability.

6. Parcel Tracking Integration

A parcel tracking integration links shipping carriers and tracking platforms to a 3PL’s system. This allows businesses and customers to receive real-time delivery updates, improving transparency and post-purchase satisfaction. This integration is particularly vital for companies prioritizing fast and visible delivery experiences, as it helps manage carrier performance and enhances customer trust.

7. Electronic Data Interchange (EDI) Integration

EDI integration automates the exchange of standardized documents—such as purchase orders, shipment notices, and invoices—between business systems and 3PLs. It’s a long-standing method used in enterprise B2B and large retail operations, known for its reliability and security. While EDI setups can be complex and resource-intensive, they remain a backbone of large-scale logistics.

Benefits of 3PL Integration

While understanding why 3PL integration matters focuses on operational efficiency and real-time coordination, the benefits highlight the tangible advantages businesses gain from adopting integrated logistics systems. These advantages span cost reduction, improved customer experience, strategic growth, and better decision-making, making 3PL integration a key driver of long-term business success.

1. Cost Optimization and Resource Efficiency

Integrating with a 3PL allows businesses to significantly reduce operational costs by automating manual workflows such as order processing, inventory updates, and shipment tracking. Companies no longer need to invest heavily in warehouses, fleets, or fulfillment staff, converting fixed logistics costs into variable expenses.

Additionally, automated workflows reduce labor-intensive tasks and minimize errors that could result in returns or lost inventory. Businesses can also optimize resource allocation, ensuring staff focus on high-value tasks while logistics operations run smoothly in the background.

2. Enhanced Customer Experience and Loyalty

3PL integration enables accurate and timely order fulfillment, giving customers reliable delivery times and real-time tracking information. Automated notifications for order confirmation, shipping, and delivery help maintain transparency, reducing inquiries and complaints.

This improved reliability directly impacts customer satisfaction and loyalty, fostering repeat purchases and positive word-of-mouth. Companies can also customize notifications or alerts, providing a personalized experience that differentiates them from competitors.

3. Improved Inventory Management

Integrated 3PL systems provide real-time visibility into stock levels across warehouses, retail locations, and sales channels. Businesses can monitor incoming and outgoing shipments, allocate stock dynamically, and forecast demand more accurately.

This level of visibility reduces the risks of overstocking or stockouts, improves capital utilization, and ensures products are available where and when they are needed. It also makes handling returns and reorders more seamless, further supporting operational efficiency.

4. Operational Agility and Scalability

By linking internal systems with a 3PL provider, businesses gain the ability to scale operations quickly without disrupting existing workflows. Whether handling seasonal demand spikes, entering new markets, or onboarding new sales channels, integrated logistics systems make scaling smoother and less resource-intensive.

This agility allows companies to respond to changing market conditions faster, implement strategic initiatives more effectively, and maintain high service levels even during periods of growth or disruption.

5. Data-Driven Insights for Strategic Decisions

Integration generates rich, actionable data across inventory, orders, shipments, and fulfillment efficiency. Companies can leverage dashboards and analytics to monitor KPIs such as fulfillment speed, delivery accuracy, and operational costs.

These insights enable continuous improvement, allowing businesses to identify bottlenecks, reduce inefficiencies, optimize transportation routes, and better forecast demand. Over time, data-driven strategies help improve profitability, customer satisfaction, and overall supply chain performance.

6. Competitive Advantage

Integrated 3PL systems provide businesses with faster fulfillment, higher accuracy, and better visibility, all of which translate into a competitive edge. Companies can deliver reliable and predictable services, outperform competitors in delivery speed and transparency, and strengthen their market positioning.

Additionally, the ability to provide real-time updates, proactive communication, and seamless returns handling reinforces brand trust, helping businesses retain and attract customers.

7. Business Growth and Expansion

3PL integration supports long-term business growth by allowing companies to handle higher order volumes, complex product catalogs, and multiple warehouses without proportional increases in staff or infrastructure.

By automating logistics and synchronizing systems, businesses can expand into new regions, markets, or sales channels efficiently. The scalability of integrated systems ensures that growth is sustainable, reducing operational bottlenecks and supporting higher profitability.

8. Streamlined Fulfillment and Reduced Errors

Integrated systems automate order routing, shipment scheduling, and inventory updates, reducing manual intervention and the risk of human error. Accurate order fulfillment ensures fewer returns, minimized delays, and improved service quality, making supply chain operations more predictable and reliable.

Challenges in Implementing 3PL Integration

While 3PL integration offers significant benefits, implementing it can be complex and resource-intensive. Companies often encounter technical, operational, and strategic hurdles that, if unaddressed, can lead to delays, increased costs, or underperformance. Recognizing these challenges early allows businesses to plan effectively and mitigate risks.

1. High Implementation Costs

Integrating with a 3PL often involves significant investment in technology, infrastructure, and professional expertise. Costs can escalate if custom development, system upgrades, or unanticipated errors occur during implementation.

Mitigation: Plan the integration to match budget and operational requirements. Leverage existing systems where possible, explore off-the-shelf integration solutions, and build contingency budgets for unexpected expenses.

2. Complex System Integration

Connecting 3PL systems with existing ERP, OMS, inventory management, or eCommerce platforms can be challenging, particularly if legacy or customized software is involved. Differences in data models, communication protocols, and lack of standardized APIs can slow implementation.

Mitigation: Conduct a technical discovery phase to map data flows, identify gaps, and choose compatible integration methods such as prebuilt APIs or middleware. Engage IT teams early to plan for system compatibility and testing.

3. Data Inconsistency and Governance

Disparate systems often use different data formats, update frequencies, or naming conventions, which can lead to errors in orders, inventory records, and reporting. Inaccurate or inconsistent data can undermine the benefits of integration.

Mitigation: Establish clear data ownership, synchronization rules, and validation processes. Use data mapping tools, reconciliation checks, and standardized data formats to ensure accuracy across all connected systems.

4. Security and Compliance Risks

Exchanging customer, inventory, and order data with a 3PL increases exposure to cyber threats. Compliance with regulations such as GDPR or industry-specific requirements adds complexity to the integration process.

Mitigation: Implement strong security protocols, including end-to-end encryption and multi-factor authentication. Conduct regular audits, define clear contractual commitments to data protection, and train staff in cybersecurity best practices.

5. Misalignment of Business Goals and 3PL Capabilities

Integration can fail if the objectives of the business and the 3PL provider are not aligned. Without a mutual understanding of goals and deliverables, companies may face inefficiencies and unmet expectations.

Mitigation: Define clear integration objectives, performance metrics, and communication protocols upfront. Ensure both parties agree on workflows, responsibilities, and KPIs to prevent misunderstandings.

6. Underestimating Integration Complexity

Many organizations underestimate the time, effort, and coordination required to integrate multiple systems and processes. This can result in delays, operational disruptions, and frustration among teams.

Mitigation: Develop a detailed project plan, including timelines, resource allocation, and phased implementation strategies. Allow for testing, troubleshooting, and adjustments throughout the integration process.

7. Staff Training and Change Management

Integration isn’t just about systems—it also affects people and processes. Employees need training on new workflows, software, and collaboration protocols. Failure to onboard staff properly can reduce efficiency and create operational bottlenecks.

Mitigation: Provide early and ongoing training programs, involve employees during user acceptance testing (UAT), and communicate changes clearly to encourage adoption and buy-in.

8. Lack of Standardization Across Systems

Different systems often operate on unique formats and protocols, creating barriers to seamless data exchange. Without standardization, integration becomes more complex and error-prone.

Mitigation: Establish standardization agreements, define key data components for synchronization, and consider using multi-warehouse integration platforms to ensure smooth data transfer.

9. Scalability Challenges

Choosing a 3PL that cannot scale with your business growth can limit operational flexibility. Overlooking scalability may prevent the company from meeting increasing demand or expanding into new markets.

Mitigation: Select 3PL providers and integration solutions that support growth, multi-channel fulfillment, and the addition of new warehouses or sales channels without requiring major system overhauls.

These challenges highlight why careful planning, stakeholder engagement, and ongoing monitoring are essential for a successful 3PL integration. A structured approach ensures that businesses can maximize the benefits of integration while minimizing risks and disruptions.

3PL Integration Best Practices

Successful 3PL integration requires more than just technology—it demands careful planning, collaboration, and continuous optimization. Following proven best practices helps businesses reduce errors, maximize efficiency, and strengthen relationships with logistics partners. While strategies may differ depending on company size, industry, and operational goals, several principles are universally applicable.

1. Define Clear Operational Goals

Start by clearly identifying what your business aims to achieve with 3PL integration. Objectives may include:

- Real-time inventory updates

- Streamlined order processing

- Improved customer communication

- Faster fulfillment and reduced errors

Clearly defined goals guide technology selection, workflow design, and KPI identification, ensuring that integration efforts are aligned with overall business strategy. Document goals and benchmarks to measure success objectively.

2. Select the Right 3PL Partner

The success of integration depends heavily on choosing a logistics partner that aligns with your operational needs and company culture.

- Develop a detailed RFP outlining service requirements, KPIs, SLAs, and evaluation criteria.

- Vet providers through site visits, reference checks, cybersecurity audits, and review of their technology and infrastructure.

- Ensure the 3PL can scale with your business and supports your desired reporting and analytics requirements.

Selecting the right partner builds a foundation for mutual growth, collaboration, and continuous improvement.

3. Map Integration Points Thoroughly

Before implementation, collaboratively design system connections, data flows, and operational workflows between your internal systems and the 3PL.

- Connect inventory, ERP, OMS, and eCommerce platforms for seamless data exchange.

- Map transportation, returns, and trade compliance processes.

- Define reporting touchpoints, KPIs, and escalation protocols.

Testing every integration point ensures smooth operations, accurate hand-offs, and minimal disruption to customers.

4. Standardize Data and Ensure Accuracy

Data accuracy is critical for a reliable supply chain. Discrepancies in inventory, orders, or shipment details can compromise the integration.

- Establish standardized formats and protocols, such as EDI or unified data schemas.

- Implement validation rules and automated monitoring tools to ensure data consistency.

- Regularly review and audit data pipelines to identify and correct errors proactively.

Standardization reduces errors, simplifies troubleshooting, and makes future system expansions easier.

5. Implement a Phased Rollout

Rather than integrating all operations at once, use a phased approach, such as region-by-region or product line-by-product line.

- Start with one distribution center or process and monitor performance for 60–90 days.

- Refine operations before scaling to additional locations or product flows.

- Communicate migration schedules, operational changes, and key contacts clearly to internal teams and partners.

A phased rollout minimizes disruption, identifies bottlenecks early, and ensures smoother adoption.

6. Establish Security and Compliance Measures

3PL integration often involves sensitive customer, inventory, and financial data. Protecting this information is critical.

- Ensure encryption, access controls, and secure transfer protocols.

- Confirm that your 3PL follows the same security standards.

- Conduct regular audits and include data protection measures in contracts.

Maintaining robust security safeguards your business from cyber threats and ensures regulatory compliance.

7. Monitor Performance and Define KPIs

Track the effectiveness of your integration using well-defined KPIs, such as:

- Order accuracy

- Inventory variance

- Fulfillment speed

- System uptime

Continuous monitoring allows businesses to identify gaps, optimize workflows, and align operations with strategic objectives.

8. Foster Collaboration and Communication

Effective integration requires strong collaboration between your team and the 3PL provider.

- Establish clear communication channels for problem-solving.

- Share KPIs, updates, and expectations transparently.

- Solicit feedback regularly to improve processes.

Open communication ensures rapid issue resolution and stronger partnerships.

9. Plan for Continuous Improvement

Integration is not a one-time project. Businesses should adapt to evolving technology, customer needs, and market conditions.

- Incorporate feedback loops to learn from operational experiences.

- Stay updated on technological advancements and industry trends.

- Refine processes and workflows for ongoing optimization.

Continuous improvement ensures that 3PL integration remains efficient, scalable, and aligned with business growth.

This structure provides a step-by-step roadmap for businesses to implement 3PL integration successfully while emphasizing planning, security, collaboration, and adaptability.

Real-Life Case Studies of 3PL Integration

Examining real-world examples of 3PL integration demonstrates how companies can streamline logistics, improve customer experiences, and optimize supply chain operations. These case studies show the practical benefits of connecting internal systems with third-party logistics providers.

1. Amazon

Amazon, one of the world’s largest e-commerce companies, manages millions of customers and products globally. To handle this scale efficiently, Amazon outsources logistics to multiple 3PL providers, including UPS, FedEx, and DHL.

- Integration Strategy: Amazon uses 3PL integration orchestration solutions to coordinate its network of 3PLs, fulfillment centers, warehouses, and delivery partners.

- Results: This integration enables Amazon to offer fast and reliable delivery options, including Prime, Same-Day, and One-Hour delivery. It also helps optimize inventory, reduce logistics costs, and enhance customer satisfaction and loyalty.

2. Nike

Nike, a global leader in sportswear, manages a complex supply chain with diverse products and a wide-reaching customer base. The company partners with multiple 3PLs, such as DHL, Kuehne+Nagel, and CEVA Logistics.

- Integration Strategy: Nike leverages 3PL integration orchestration to synchronize its 3PLs, suppliers, manufacturers, distributors, and retail networks.

- Results: This integration allows Nike to deliver personalized services such as Nike By You and Nike Membership offerings. It also improves supply chain visibility, enhances agility, and supports sustainable practices by reducing the environmental impact of logistics.

3. Walmart

Walmart, one of the world’s largest retailers, operates thousands of stores and serves millions of customers worldwide. The company relies on 3PL partners like Schneider Logistics and FedEx Supply Chain to manage its logistics network.

- Integration Strategy: Walmart uses a 3PL integration orchestration solution to connect its network of 3PLs, warehouses, distribution centers, and stores.

- Results: This integration supports omnichannel capabilities, such as online ordering, in-store pickup, and home delivery. Walmart can optimize inventory, reduce logistics costs, and maintain high supply chain visibility and agility.

These examples illustrate that 3PL integration is not just a technical solution—it is a strategic enabler. By automating communication and synchronizing operations across internal systems and third-party providers, companies can achieve faster fulfillment, cost efficiency, and superior customer experiences.

How Deskera ERP Supports 3PL Integration

Integrating third-party logistics with internal business systems can be complex, but Deskera ERP simplifies the process by offering a centralized platform that connects your operations with 3PL providers. By leveraging automation, real-time data synchronization, and comprehensive reporting, Deskera ERP ensures smoother, more efficient logistics management.

1. Seamless System Connectivity

Deskera ERP allows businesses to connect their eCommerce platforms, inventory management, order management systems, and accounting modules directly with 3PL providers.

- Automates data exchange between your business systems and 3PLs

- Reduces manual errors and delays in order processing

- Maintains synchronized inventory levels across multiple locations

This integration ensures that your internal teams and 3PL partners are always working from up-to-date information, improving operational efficiency.

2. Real-Time Inventory and Order Visibility

Deskera ERP provides real-time dashboards for monitoring inventory levels, order statuses, and shipment tracking.

- Track inventory across warehouses and 3PL-managed facilities

- Receive automatic updates on fulfillment progress and delivery schedules

- Quickly identify stockouts or discrepancies for timely corrective action

Real-time visibility empowers businesses to make data-driven decisions and enhance overall supply chain performance.

3. Advanced Reporting and Analytics

Deskera ERP consolidates operational data from multiple sources, including 3PLs, into a single reporting platform.

- Generate insights on fulfillment speed, error rates, and inventory turnover

- Monitor key performance indicators (KPIs) to evaluate 3PL effectiveness

- Use predictive analytics for demand forecasting and capacity planning

These capabilities support continuous optimization and help businesses proactively address bottlenecks in their supply chain.

4. Scalable and Flexible Integration

Deskera ERP is designed to scale with your business, accommodating multiple 3PLs and sales channels as your operations grow.

- Supports multi-warehouse and multi-channel inventory management

- Easily incorporates new 3PL partners or geographic regions

- Flexible enough for businesses of all sizes, from startups to enterprises

This scalability ensures that Deskera ERP grows with your logistics needs, enabling long-term operational efficiency.

By centralizing logistics operations, providing real-time visibility, and automating workflows, Deskera ERP enables businesses to maximize the value of 3PL integration, reduce operational costs, and improve customer satisfaction.

Key Takeaways

- 3PL integration is rapidly becoming essential for modern businesses, enabling seamless coordination between internal systems and third-party logistics providers, improving efficiency, and enhancing customer satisfaction.

- 3PL integration connects a company’s internal systems with 3PL providers, automating data exchange, reducing errors, and enabling real-time visibility across inventory, orders, and shipments.

- Integrating with 3PLs allows businesses to scale operations, enhance customer experiences, improve supply chain agility, and reduce operational complexity.

- Businesses can leverage multiple integration types—eCommerce, marketplace, inventory management, OMS, ERP, parcel tracking, and EDI—each suited for specific workflows, sales channels, and business goals.

- 3PL integration delivers enhanced operational efficiency, cost reduction, better inventory management, real-time visibility, faster fulfillment, improved accuracy, and stronger customer satisfaction.

- Implementing 3PL integration can be complex due to system compatibility issues, data security concerns, high costs, lack of standardization, and the need for change management and staff training.

- Clear goal-setting, selecting the right 3PL partner, mapping integration points, standardizing data, phased rollout, robust security, KPI monitoring, strong collaboration, and continuous improvement are critical for successful 3PL integration.

- Companies like Amazon, Nike, and Walmart illustrate that strategic 3PL integration can optimize logistics operations, enhance supply chain visibility, and improve customer experience at scale.

- Deskera ERP centralizes operations, automates logistics tasks, provides real-time visibility, advanced analytics, and scalable system connectivity, enabling businesses to maximize the value of 3PL integration and streamline their supply chain.

Related Articles