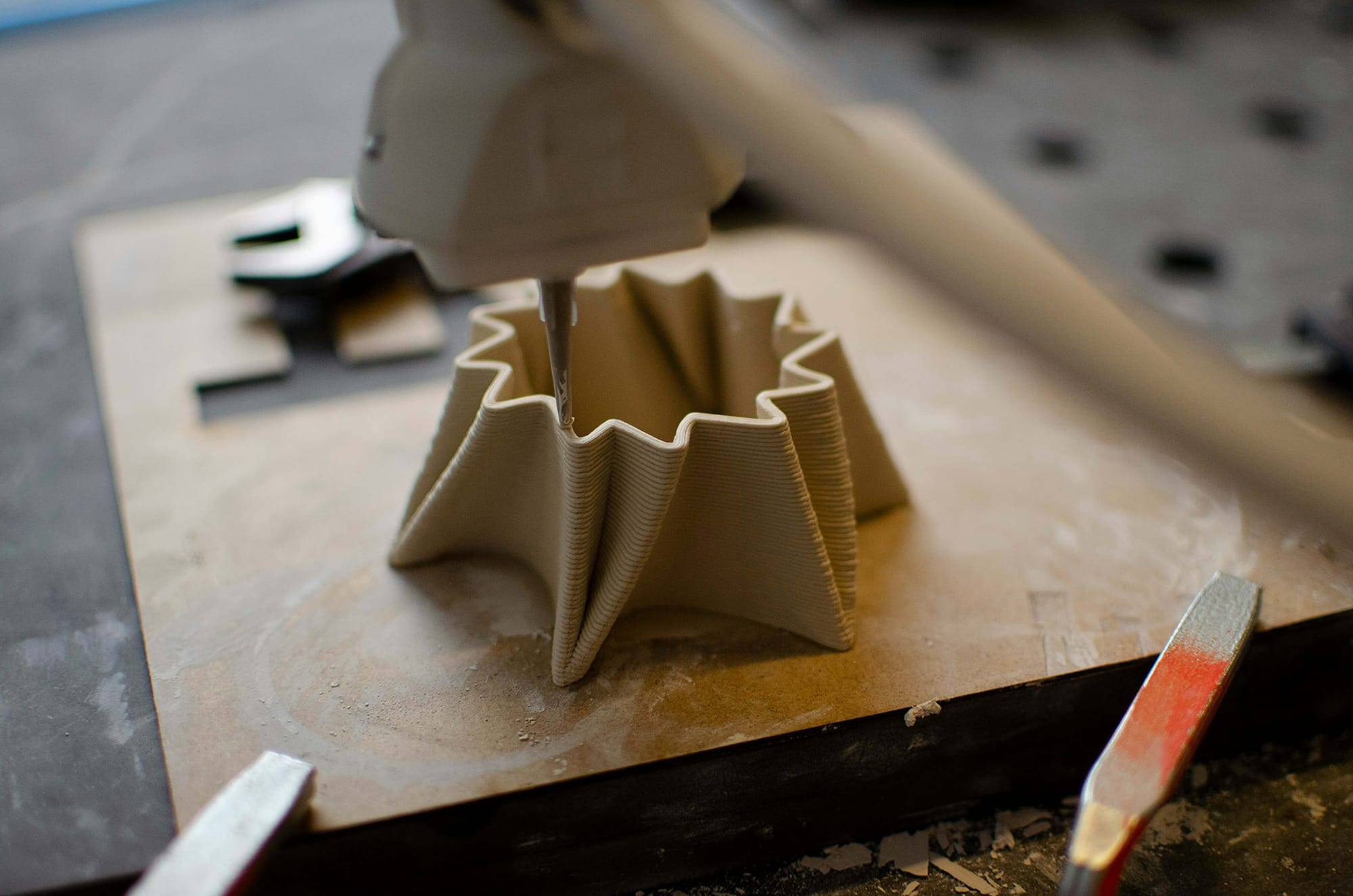

How do leading manufacturers deliver the same level of quality, day after day, without compromising on efficiency? The answer often lies in workflow management—a structured approach to aligning people, processes, and technology. In an industry where even the smallest error can lead to costly rework or customer dissatisfaction, workflow management becomes the foundation of consistency and quality.

The global adoption of workflow management solutions reflects its growing importance. Recent statistics show the workflow management market is set to surpass $168 billion by 2032, fueled by automation that enhances productivity and the widespread adoption of cloud-based systems. For manufacturers, this shift means more streamlined operations, faster decision-making, and fewer quality lapses. In essence, workflow management is no longer optional—it is a strategic necessity.

Consistency in manufacturing directly translates to brand trust, customer loyalty, and regulatory compliance. Whether it’s ensuring each product meets strict quality standards or reducing downtime across production lines, workflow management creates a repeatable system that minimizes risk. By embedding checks, monitoring tools, and collaboration workflows, manufacturers can ensure quality isn’t left to chance but is instead built into every stage of production.

This is where modern ERP platforms, like Deskera ERP, play a crucial role. Deskera offers automated workflows, real-time monitoring, and AI-powered insights that help manufacturers streamline processes from procurement to production. With features such as mobile accessibility, built-in reporting templates, and the AI Assistant David, Deskera ensures workflow management is not only efficient but also intelligent—empowering manufacturers to achieve both consistency and quality at scale.

What is Workflow Management?

Workflow management is the practice of designing, organizing, tracking, and optimizing a series of tasks—known as a workflow—to achieve a specific goal efficiently and consistently. At its core, it ensures that the right tasks are done by the right people, at the right time, and in the right way.

Unlike one-off task management, workflow management is a continuous process. Businesses regularly refine and adjust workflows to eliminate bottlenecks, reduce errors, and adapt to evolving needs—whether that’s new technologies like AI and automation, shifting customer expectations, or changing business priorities.

A well-managed workflow provides clarity by answering four essential questions:

- What needs to be done?

- Who is responsible for it?

- When should it be completed?

- How should it be accomplished?

By systematically documenting and monitoring these steps, organizations create standardized processes that improve efficiency, ensure consistent quality, and align daily tasks with long-term business goals.

For example, in manufacturing, workflow management might mean mapping every stage of production, from raw material sourcing to quality checks, ensuring each step flows smoothly into the next without delays or errors. In modern enterprises, workflow management often leverages automation, AI, and real-time tracking tools to further optimize processes.

Ultimately, workflow management helps businesses:

- Improve productivity and collaboration.

- Reduce wasted time and resources.

- Ensure compliance with industry standards.

- Deliver consistent, high-quality results.

Workflow Management vs Project Management vs Business Process Management

At first glance, workflow management, project management, and business process management may sound similar—but they serve very different purposes in how organizations run. Understanding the distinction is important, especially in manufacturing, where efficiency, consistency, and adaptability determine long-term success.

Workflow Management (WM)

Workflow management is all about the step-by-step execution of tasks that make up a repeatable process. It ensures routine activities—like quality checks, purchase approvals, or machine maintenance—are carried out consistently and efficiently. In manufacturing, workflow management provides structure and visibility, helping teams avoid bottlenecks and errors in daily operations.

Definition: The practice of designing, tracking, and optimizing the flow of tasks that make up a repeatable process.

Focus: Task execution and efficiency within a process.

Scope: Narrow and task-specific. It ensures that recurring work (e.g., purchase approvals, production runs, quality checks) flows smoothly.

Goal: Improve task consistency, reduce bottlenecks, and streamline daily operations.

Example in Manufacturing: Setting up a standardized workflow for machine maintenance or raw material approval.

Project Management (PM)

Unlike workflow management, project management is focused on unique, time-bound initiatives. A project has a defined start and end date, specific deliverables, and a set budget or scope. For manufacturers, this could mean setting up a new production facility, rolling out a new ERP system, or launching a product line. The goal is to deliver results on time, within scope, and with the desired quality.

Definition: The discipline of planning, executing, and closing unique, time-bound initiatives with defined goals.

Focus: Delivering a specific outcome within a set timeframe, budget, and scope.

Scope: Broader, one-time or finite. It doesn’t repeat regularly but has milestones and an end date.

Goal: Ensure projects are completed on time, within scope, and on budget.

Example in Manufacturing: Building a new production line, implementing a new ERP system, or constructing a warehouse.

Business Process Management (BPM)

Business process management takes a big-picture, strategic view. Instead of focusing on individual tasks or single projects, BPM analyzes and optimizes end-to-end processes that cut across departments. For manufacturing companies, this could involve redesigning the entire supply chain from procurement to customer delivery. The aim is long-term adaptability, efficiency, and alignment with overall business goals.

Definition: A holistic, organization-wide discipline for analyzing, improving, and optimizing entire business processes that cut across departments.

Focus: End-to-end processes across the enterprise.

Scope: Strategic and comprehensive, often involving multiple workflows and systems.

Goal: Achieve long-term efficiency, adaptability, and alignment with business objectives.

Example in Manufacturing: Redesigning the entire order-to-cash process, integrating procurement, production, inventory, and delivery for maximum efficiency.

Key Differences at a Glance

Types of Workflows

Workflows can be customized to fit the unique needs of any business process. Even two companies aiming for the same goal might use entirely different workflows to reach it.

Some managers prefer to adopt a single style across multiple functions, while others rely on different workflows depending on the task. Broadly, workflows fall into four main categories: sequential, state-machine, rules-driven, and parallel.

1. Sequential Workflows

A sequential workflow follows a strict step-by-step order. Each step must be completed before the next one begins. For example, in an employee expense management workflow, receipts are first submitted, then payment authorization takes place, followed by employee reimbursement.

Because these workflows rely heavily on smooth handoffs, timely communication between teams is essential. If one team delays in passing along completed work, the entire process slows down.

2. State-Machine Workflows

State-machine workflows are nonlinear and more flexible. Steps can move back and forth among teams and may require multiple rounds of approvals, revisions, or feedback.

A common example is a research and development (R&D) workflow, where schematics move between engineers, designers, and managers multiple times before final approval. Unlike sequential workflows, state-machine workflows don’t follow a rigid order—they adapt to collaboration needs.

3. Rules-Driven Workflows

Rules-driven workflows move sequentially but incorporate conditional rules or “if-then” statements. Depending on the situation, the workflow may branch into different paths.

For instance, when a customer orders clothing online:

- If the item is in stock, the order proceeds to packaging and shipping.

- If part of the order is out of stock, the system follows a different branch—sending updates to the customer and adjusting delivery timelines.

These workflows can quickly become complex, which is why many businesses use automation tools to manage branching paths efficiently.

4. Parallel Workflows

Parallel workflows allow multiple processes to run simultaneously toward a shared goal.

Consider a factory ordering raw materials:

- The accounts payable team logs expenses and begins the payment process.

- The loading dock manager schedules staff for unloading.

- The production team prepares to integrate the materials into the manufacturing schedule.

All these activities happen at the same time, without waiting for one another, ensuring speed and efficiency.

These four workflow types give businesses the flexibility to design processes that best match their operational needs. Sequential workflows provide structure, state-machine workflows encourage collaboration, rules-driven workflows handle complexity, and parallel workflows drive efficiency by allowing multiple tasks to progress simultaneously.

Components of Workflows

Every workflow is built around a core set of components that define how work starts, flows, and gets completed. By understanding these elements, managers can design workflows that are not only efficient but also adaptable to changing needs. The six essential components are: inputs, outputs, transformation, roles, conditions, and triggers.

1. Inputs

Inputs are the starting resources required for a workflow to begin—these can be raw materials, data, or instructions.

- In a manufacturing workflow, inputs might include raw materials, design specifications, or machine schedules.

- In a sales workflow, they could be customer inquiries, leads, or purchase orders.

Inputs provide the foundation for the tasks ahead and ensure teams have the necessary information or resources to act.

2. Outputs

Outputs represent the end result of the workflow. These could be tangible (like a finished product) or intangible (like customer satisfaction or improved knowledge).

- In manufacturing, outputs may include assembled goods, quality reports, or completed packaging.

- In sales, outputs could be a signed contract or an onboarded client.

Often, one workflow’s output becomes the input for another, creating a continuous chain of business processes.

3. Transformation

Transformation refers to the sequence of steps that convert inputs into outputs. Each step should move the process forward without redundancy or delay.

- In manufacturing, transformation might include stages like machining, assembly, testing, and packaging.

- In sales, it could mean qualifying a lead, preparing a demo, and closing a deal.

Efficient transformation steps are the backbone of streamlined workflows.

4. Roles

Roles define who is responsible for each step. Assigning clear responsibilities prevents confusion, duplication, and wasted effort.

- In manufacturing, roles could include operators, supervisors, quality inspectors, and logistics staff.

- In sales, roles might involve sales reps, technical specialists, and managers.

Clearly defined roles also improve accountability and communication during handoffs between teams.

5. Conditions

Conditions are the rules and criteria that govern how workflows progress. They often take the form of approvals, thresholds, or decision trees.

- In manufacturing, a condition might require a product to pass a quality check before moving to packaging.

- In sales, a condition could involve managerial approval for discounts above a certain percentage.

Conditions add flexibility but can also create complexity—making automation especially useful for keeping processes efficient.

6. Triggers

Triggers are the events that initiate a workflow. They ensure processes start at the right time, in response to the right circumstances.

- In manufacturing, triggers might include receiving a customer order, a machine calibration, or an inventory threshold being reached.

- In sales, a trigger could be a customer inquiry or an online purchase.

Without clear triggers, workflows risk starting too early, too late, or redundantly, wasting both time and resources.

Together, these components—inputs, outputs, transformation, roles, conditions, and triggers—form the backbone of effective workflow management. When managers design workflows with these in mind, they create processes that are clear, efficient, and resilient to change.

Benefits of Effective Workflow Management

When businesses embrace effective workflow management, they unlock more than operational efficiency. It becomes a strategic advantage that helps them reduce costs, accelerate delivery, and improve overall business performance. Below are the detailed benefits organizations can achieve:

1. Optimized Resource Utilization

One of the biggest challenges organizations face is the mismanagement of time, people, and materials. Workflow management ensures that every resource is used to its maximum potential. By assigning the right task to the right person and automating task allocation, businesses prevent overloading some employees while others remain underutilized.

- Example: In a customer service department, workflows automatically assign queries to available agents with the right skillset, reducing idle time and boosting resolution speed.

- Why it matters: This leads to lower costs, higher employee satisfaction, and a more balanced workload across the organization.

2. Reduced Bottlenecks and Delays

Bottlenecks often arise when a task stalls due to missing information, unclear ownership, or delayed approvals. Workflow management tools help visualize the entire process, identify choke points, and establish triggers or automated reminders to keep things moving.

- Example: In finance, invoice approvals often get delayed when managers are unavailable. With workflow automation, alternate approvers can be notified, ensuring vendors are paid on time.

- Why it matters: Eliminating bottlenecks minimizes downtime, keeps projects on schedule, and reduces frustration among team members.

3. Increased Productivity and Efficiency

Effective workflow management breaks complex projects into structured, repeatable steps. By automating routine tasks—like sending notifications, updating databases, or generating reports—employees can dedicate more time to critical, value-driven work.

- Example: HR teams can automate the onboarding process, from sending welcome emails to assigning training modules, allowing them to focus on employee engagement instead.

- Why it matters: Teams achieve more in less time, increasing both output and quality without burning out employees.

4. Stronger Cross-Functional Collaboration

Workflows act as a blueprint for how teams interact, ensuring everyone understands their role in the bigger picture. Collaboration platforms integrated with workflows provide transparency, making it easy for departments to share updates and track dependencies.

- Example: In product development, designers, engineers, and marketers can all track where a project stands, reducing miscommunication and rework.

- Why it matters: Clear collaboration reduces silos, strengthens accountability, and ensures everyone is aligned toward shared business goals.

5. Greater Transparency and Accountability

Every step of a workflow defines who is responsible and what the expected outcome should be. This visibility ensures that no task falls through the cracks and makes it easy to track progress in real time. Workflow systems also maintain audit trails that show who did what and when.

- Example: In legal or compliance-heavy industries, having a documented approval chain reduces the risk of oversight and creates accountability at each stage.

- Why it matters: Transparency builds trust, reduces finger-pointing, and helps leaders make better data-driven decisions.

6. Consistency and Improved Quality

When processes are standardized, tasks are completed in a uniform way, minimizing the risk of errors or omissions. This is particularly important for repetitive tasks or customer-facing services where consistency directly impacts brand reputation.

- Example: A retail company can standardize customer complaint resolution workflows, ensuring every customer receives a fair and timely response.

- Why it matters: Consistency enhances customer trust, improves service quality, and makes it easier to scale operations without losing efficiency.

7. Enhanced Compliance and Risk Management

Many industries—such as healthcare, finance, and manufacturing—are subject to strict regulations. Workflow management ensures compliance by embedding necessary checks, approvals, and documentation into each process. Automated audit trails also make it easy to demonstrate compliance during reviews or audits.

- Example: A pharmaceutical company can design workflows that ensure every batch of medicine goes through documented quality checks before distribution.

- Why it matters: Proactive compliance reduces legal risks, avoids penalties, and protects organizational credibility.

8. Scalability and Business Growth

As businesses grow, manual processes often break down under increased demand. Workflow management provides a scalable structure that adapts to new teams, larger workloads, or more complex processes. Automated systems can easily handle thousands of tasks without needing a proportional increase in manpower.

- Example: An e-commerce business experiencing seasonal spikes can use workflows to manage order fulfillment, returns, and customer support without compromising speed or quality.

- Why it matters: Scalability ensures growth does not come at the expense of efficiency, customer experience, or employee satisfaction.

In summary, effective workflow management delivers far-reaching benefits—streamlining operations, empowering employees, ensuring compliance, and supporting long-term growth. It’s not just about making work easier—it’s about making businesses stronger, more agile, and future-ready.

How Does Workflow Management Work?

Workflow management is a structured and systematic approach that helps organizations design, execute, monitor, and optimize their day-to-day operations. It ensures that tasks flow seamlessly from one stage to another, while minimizing bottlenecks, reducing errors, and improving efficiency.

Let’s look at how it works step by step, using a financial services company’s loan processing workflow as an example:

1. Process Identification and Mapping

The first step in workflow management is identifying and mapping processes. This means breaking down an entire workflow into smaller, manageable steps and visualizing how tasks move from initiation to completion.

- Example: In a financial services company, the loan processing workflow starts when a customer submits an application. The process then flows through credit checks, document verification, risk assessment, and finally, loan approval or rejection. By creating a clear visual map of these steps, the company can easily see dependencies, identify potential delays, and assign responsibilities.

2. Automation of Routine Tasks

Once processes are mapped, the organization identifies tasks that can be automated to reduce manual effort and errors. Workflow automation helps in saving time and ensuring consistency.

- Example: The company can automate initial credit checks using integrated software that pulls data from credit bureaus instantly. Similarly, document verification (such as ID proof and income documents) can be automated with AI tools, reducing turnaround time and improving accuracy.

3. Strategic Resource Allocation and Management

Efficient workflow management ensures that the right resources—whether human or technological—are allocated to the right tasks.

- Example: Routine checks are automated, but complex tasks such as risk assessment and final approval are reserved for experienced analysts. This balance ensures that human expertise is used where judgment is critical, while technology handles repetitive work.

4. Monitoring and Tracking Progress

Workflow management systems come with real-time monitoring dashboards that track task completion and highlight delays or bottlenecks.

- Example: If there’s an unusual surge in loan applications, the system might flag that credit checks are taking longer than expected. Managers receive alerts and can immediately assign more staff or adjust priorities to prevent backlogs.

5. Performance Analysis and Continuous Optimization

A crucial part of workflow management is analyzing performance data to identify inefficiencies and make improvements.

- Example: Suppose recurring delays are spotted during the risk assessment stage. The company might streamline documentation requirements, improve internal training, or assign additional experts to that stage. Over time, this continuous optimization ensures faster loan approvals and higher customer satisfaction.

6. Enhanced Communication and Collaboration

Workflow management tools promote seamless collaboration across departments by centralizing updates and making information easily accessible.

- Example: If the loan processing team approves a customer’s application, the system automatically updates the customer service team. This allows customer service representatives to immediately inform the client about their loan status, improving response time and client experience.

7. Compliance and Standardization

Organizations must comply with industry regulations and internal policies, and workflow management ensures these standards are embedded within every step.

- Example: Before a loan can be approved, the system verifies that all legal checks (such as KYC compliance, anti-fraud measures, and required documentation) have been completed. This reduces the risk of regulatory violations and ensures transparency.

8. Flexibility and Scalability

Modern workflow management systems are designed to adapt to business growth and changes in market conditions. They can handle new processes, adjust to higher volumes, and integrate with emerging technologies.

- Example: If the company expands its services to include business loans in addition to personal loans, the workflow system can be scaled to handle the additional complexity without disrupting existing operations. This flexibility ensures that the organization remains agile and competitive.

In summary, workflow management is not just about keeping tasks organized—it’s about creating a dynamic, efficient, and compliant system that continuously adapts to business needs. By combining automation, resource management, monitoring, and optimization, organizations can achieve consistency, improve quality, and maintain a strong competitive edge.

Challenges of Implementing Workflow Management (and How to Overcome Them)

While workflow management can dramatically improve efficiency, consistency, and quality, implementing it is not without challenges. Organizations often face obstacles that—if not addressed—can slow down adoption, frustrate employees, and undermine the system’s effectiveness. The good news? By anticipating these challenges and proactively planning solutions, companies can ensure a smoother and more successful transition.

Here are the most common challenges, along with strategies to overcome them:

1. Employee Resistance to Change

The challenge: Employees are often comfortable with existing routines and may view new workflows or software as unnecessary disruptions. Resistance grows when staff feel excluded from the design process or worry that automation may replace their roles.

How to overcome it:

- Communicate benefits clearly—show how workflows reduce repetitive tasks and make work easier, not harder.

- Involve employees early in workflow design, gathering their feedback and incorporating their insights.

- Provide practical training and ongoing support so staff feel confident using new tools and processes.

2. Communication Silos Between Teams

The challenge: When departments work in isolation, information often gets trapped, causing duplicated efforts, delays, or costly rework. For example, procurement might purchase raw materials before finance finalizes approvals, leading to wasted stock.

How to overcome it:

- Adopt collaborative workflow tools that make data accessible across departments.

- Encourage transparency with shared dashboards that track progress in real-time.

- Promote cross-functional check-ins so all teams stay aligned on goals and timelines.

3. Integration with Existing Systems

The challenge: Many organizations already use multiple tools—ERP, CRM, HR systems, etc.—making it difficult to integrate workflow management without creating complexity or delays.

How to overcome it:

- Choose flexible workflow software with robust integration capabilities (APIs, plug-ins).

- Start small by integrating workflows in phases, focusing on the most critical processes first.

- Engage IT teams early to avoid surprises with system compatibility.

4. Data Security and Compliance Concerns

The challenge: Workflow systems often manage sensitive information—from employee records to financial data. A poorly secured system risks data breaches or non-compliance with regulations.

How to overcome it:

- Implement strict access controls with role-based permissions.

- Choose tools with built-in compliance features relevant to your industry (GDPR, HIPAA, ISO standards, etc.).

- Conduct regular audits to ensure processes remain compliant as workflows evolve.

5. Risk of Oversimplification

The challenge: In the effort to streamline processes, businesses sometimes oversimplify workflows—stripping out important steps or ignoring task variations. This can result in errors, poor-quality outputs, or non-compliance.

How to overcome it:

- Balance simplicity with accuracy—include all critical steps while eliminating only true redundancies.

- Build flexibility into workflows using conditional rules or branching logic.

- Review workflows regularly with stakeholders to ensure they reflect real-world operations.

6. Unclear Roles and Ownership

The challenge: Without clearly defined responsibilities, workflows break down. Tasks get duplicated, delayed, or skipped entirely because “someone else” was assumed to be responsible.

How to overcome it:

- Assign explicit roles and accountability for each workflow step.

- Use approval chains and escalation rules to ensure decisions move forward smoothly.

- Document and share ownership structures so everyone understands their part in the process.

7. Misaligned Processes with Business Goals

The challenge: Sometimes workflows are optimized for the wrong objectives—for example, maximizing speed when the company’s real priority is quality or customization. This misalignment wastes resources and undermines strategy.

How to overcome it:

- Tie every workflow back to business goals before rolling it out.

- Review KPIs regularly to ensure workflows support evolving priorities.

- Engage leadership to validate alignment with strategic objectives.

Implementing workflow management can be challenging, but with the right preparation—clear communication, strong leadership support, flexible tools, and employee engagement—organizations can avoid common pitfalls and unlock the full potential of streamlined, consistent, and quality-driven workflows.

Best Practices for Workflow Management Success

Implementing workflow management is not a one-time project—it’s an ongoing process that requires planning, monitoring, and continuous refinement. Even the most carefully designed workflow can lose effectiveness over time if it isn’t reviewed and adapted to evolving business needs.

To ensure long-term success, managers should follow a set of proven best practices that keep workflows efficient, reliable, and aligned with organizational goals.

Here are the key best practices:

1. Document Everything Clearly

Why it matters: Missing steps or unclear instructions can cause costly errors, rework, or missed deadlines. Comprehensive documentation provides a “single source of truth” that keeps everyone aligned.

How to apply it:

- Map out each step of the workflow with visual aids like flowcharts or timelines.

- Specify roles, task owners, dependencies, and deadlines.

- Store documentation in a centralized, accessible platform where all team members can easily find updates.

- Record both successes and failures—so teams can repeat what works and avoid repeating mistakes.

2. Analyze Dependencies and Relationships

Why it matters: Not all tasks are sequential—some can run in parallel. Without identifying dependencies, workflows risk unnecessary delays or resource conflicts.

How to apply it:

- Identify which tasks rely on the completion of others (e.g., packaging depends on manufacturing).

- Where possible, restructure workflows so independent tasks run side by side.

- Synchronize timelines for dependent tasks to create a steady flow of work.

- Use project management or workflow tools to visualize dependencies and prevent bottlenecks.

3. Predict and Prevent Bottlenecks

Why it matters: Delays at one stage of a workflow can cascade, creating major slowdowns across the business. Spotting bottlenecks early keeps operations resilient.

How to apply it:

- Monitor workflows continuously using KPIs such as turnaround time, error rates, and task completion times.

- Identify recurring delays and address root causes—for example, by automating notifications or allocating more resources.

- Develop contingency plans for high-risk stages (e.g., alternate suppliers for raw materials).

- Use ERP or workflow management systems for real-time visibility into problem areas.

4. Embrace Automation Wherever Possible

Why it matters: Manual, repetitive tasks waste time, increase error risk, and drain employee morale. Automation improves both speed and accuracy.

How to apply it:

- Automate repetitive steps like approvals, data entry, and status updates.

- Use automation to trigger alerts, send reminders, or escalate issues before they become critical.

- Explore AI-driven insights that suggest improvements based on workflow data.

- Balance automation with human oversight—reserve manual intervention for tasks that require judgment or creativity.

5. Audit Workflows Regularly and Adjust

Why it matters: Business goals, technology, and customer expectations evolve over time—so should workflows. What works today may become inefficient tomorrow.

How to apply it:

- Conduct regular audits (quarterly or biannually) to assess performance and identify areas for improvement.

- Collect frontline feedback—employees using workflows daily often spot inefficiencies before managers do.

- Implement iterative improvements rather than massive overhauls to reduce disruption.

- Apply lessons learned from one workflow to others, spreading efficiency gains across the organization.

6. Leverage the Right Technology

Why it matters: Relying on email threads, spreadsheets, or manual checklists for workflow management creates confusion and increases the risk of errors.

How to apply it:

- Invest in a workflow management platform that supports automation, visualization, and collaboration.

- Choose tools that integrate seamlessly with existing systems (ERP, CRM, HR, etc.).

- Opt for cloud-based solutions to enable real-time updates and access across departments and locations.

- Prioritize user-friendly platforms—adoption will lag if the software is too complex.

7. Promote Communication and Collaboration

Why it matters: Even the best-designed workflow will break down if teams don’t communicate effectively. Silos cause duplication, delays, and missed opportunities.

How to apply it:

- Foster a culture of open communication where teams can share updates and raise issues quickly.

- Use collaboration tools with shared dashboards, chat functions, and progress tracking.

- Hold regular cross-functional reviews to keep all stakeholders aligned.

- Encourage transparency—everyone should know how their work fits into the bigger picture.

8. Empower Teams and Encourage Ownership

Why it matters: Workflows are only as strong as the people executing them. Empowered employees are more engaged, more accountable, and more likely to suggest improvements.

How to apply it:

- Clearly assign ownership for every step of the workflow.

- Provide training and resources to help employees succeed in their roles.

- Encourage staff to give feedback and propose adjustments when they see inefficiencies.

- Recognize and reward employees who contribute to workflow improvements.

Workflow management success is built on clarity, communication, technology, and continuous improvement. By documenting thoroughly, analyzing dependencies, automating smartly, and empowering teams, organizations can create workflows that aren’t just efficient today—but adaptable for tomorrow’s challenges.

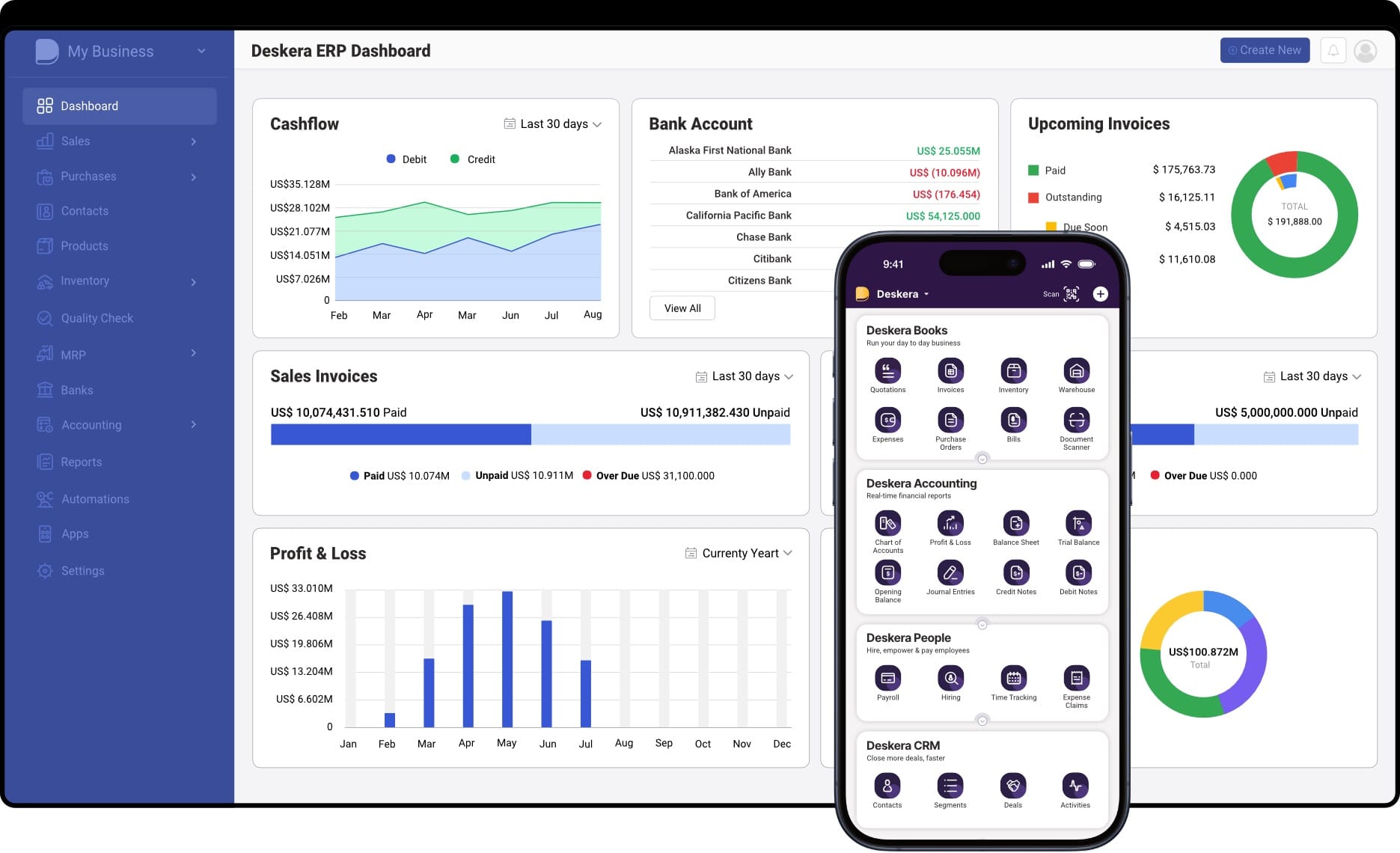

How Can Deskera ERP Help You with Workflow Management?

Implementing workflow management in manufacturing becomes far easier with the right digital tools—and this is where Deskera ERP stands out. Designed with automation, visibility, and collaboration in mind, Deskera ERP empowers manufacturers to streamline every aspect of their operations.

Here’s how it helps:

- Centralized Workflow Automation: Deskera ERP allows you to automate repetitive tasks such as purchase orders, approvals, and inventory updates. This not only reduces manual errors but also ensures consistency across processes.

- Seamless Integration Across Departments: Whether it’s production planning, procurement, finance, or sales, Deskera ERP connects workflows across teams. This unified approach ensures that data flows seamlessly, eliminating silos and delays.

- AI-Powered Assistance with David: With its built-in AI assistant, David, Deskera ERP simplifies reporting, data analysis, and forecasting. Instead of spending hours compiling reports, managers can generate insights instantly to make quick, informed decisions.

- Mobile Accessibility for Real-Time Updates: Deskera ERP is mobile-friendly, enabling managers and employees to access workflows, approve requests, or check inventory levels anytime, anywhere. This flexibility is particularly valuable in fast-paced manufacturing environments.

- Demand Forecasting & MRP Integration: Its robust Material Requirements Planning (MRP) feature ensures production workflows are aligned with demand. By forecasting requirements accurately, businesses can reduce waste, improve scheduling, and avoid stockouts.

- Advanced Reporting & Compliance Support: Deskera ERP comes with ready-to-use reporting templates, customizable dashboards, and compliance features that help businesses monitor efficiency and stay audit-ready at all times.

In short, Deskera ERP doesn’t just help you manage workflows—it transforms them into a growth engine by improving consistency, efficiency, and decision-making across your manufacturing operations.

Key Takeaways

- Workflow management ensures that manufacturing operations run in a structured, predictable, and efficient manner, reducing errors and improving product quality.

- While workflow management focuses on repeatable tasks, project management deals with unique, time-bound goals, and BPM optimizes end-to-end processes—together, they strengthen overall manufacturing efficiency.

- Workflow management enhances consistency, improves resource utilization, ensures compliance, boosts collaboration, and drives faster decision-making, resulting in better efficiency and profitability.

- Without structured workflows, manufacturers face bottlenecks, miscommunication, quality lapses, compliance risks, and reduced productivity.

- Standardizing processes, leveraging automation, integrating systems, and monitoring performance are crucial steps to achieve successful workflow management in manufacturing.

- Deskera ERP supports workflow automation, cross-department integration, AI-powered insights, demand forecasting, and real-time accessibility—making it an ideal solution for consistent and high-quality manufacturing operations.

Related Articles