Unplanned equipment failures remain one of the biggest threats to manufacturing productivity. Even well-maintained plants struggle with sudden breakdowns, rising maintenance costs, and unpredictable production delays. As factories move toward higher automation and shorter delivery cycles, every minute of equipment downtime directly impacts customer commitments and profitability—making reliability a strategic priority, not just an operational one.

This is where Total Productive Maintenance (TPM) stands out. TPM goes beyond routine maintenance by empowering operators, eliminating chronic losses, and establishing a culture where reliability is everyone’s responsibility. Its impact is measurable: implementing TPM can significantly boost performance—one case study reported a 20% increase in OEE and more than 200 extra hours of equipment availability after applying a TPM and reliability-focused framework. For manufacturing leaders, such gains can translate into smoother production flow, higher throughput, and reduced firefighting on the shop floor.

In today’s competitive environment, TPM also pairs naturally with digital transformation. Modern manufacturing demands real-time data, predictive insights, and connected workflows—capabilities that amplify TPM’s effectiveness and make continuous improvement sustainable. By combining TPM’s structured approach with the right digital tools, plants can shift from reactive maintenance to reliability-driven operations.

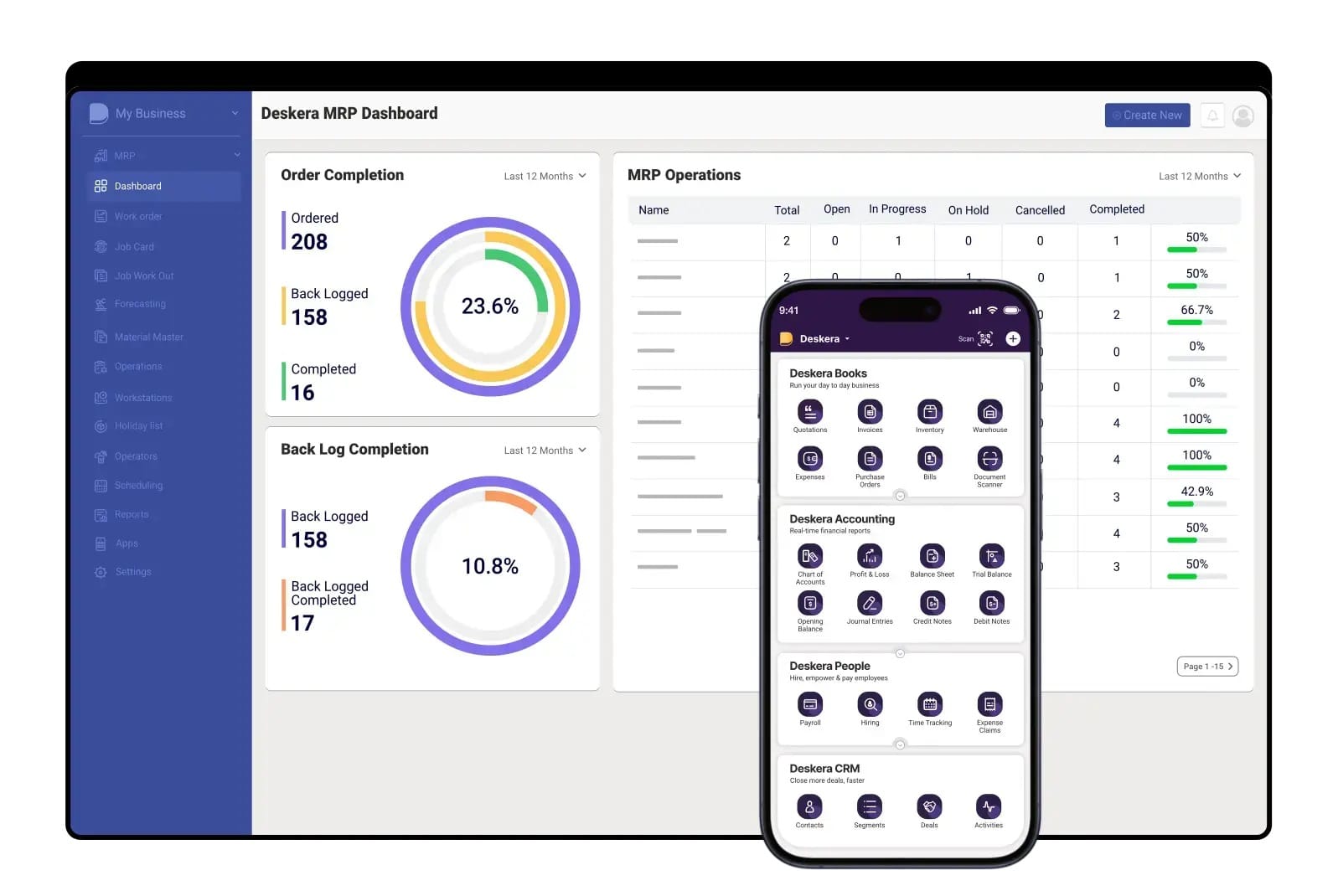

This is exactly where Deskera MRP strengthens the TPM journey. With real-time shop floor visibility, automated work order scheduling, material planning, and built-in maintenance tracking, Deskera MRP ensures leaders always know the true pulse of production. Its mobile-first design keeps operators, supervisors, and maintenance teams aligned, while AI-driven insights help identify bottlenecks and optimize machine performance. Together, TPM and Deskera MRP form a powerful foundation for high reliability and consistent operational excellence.

What Is Total Productive Maintenance (TPM)?

Total Productive Maintenance (TPM) is a holistic, company-wide approach to equipment maintenance designed to achieve perfect production—that means no breakdowns, no slow cycles or small stops, no defects, and no accidents. At its core, TPM aims to maximize equipment effectiveness by ensuring machines operate at peak performance with minimal interruptions.

Unlike traditional maintenance, where equipment care is handled primarily by maintenance teams, TPM bridges the gap between production and maintenance. It empowers operators to take ownership of their machines through routine checks, cleaning, basic servicing, and early detection of issues. This shared responsibility helps eliminate reactive, “fix-it-when-it-breaks” thinking and replaces it with a proactive, prevention-first mindset.

TPM also focuses on improving Overall Equipment Effectiveness (OEE) by reducing downtime, minimizing quality losses, and ensuring equipment runs at optimal speed. Small, cross-functional teams—often involving production, maintenance, quality, and safety—work together to strengthen preventive and autonomous maintenance practices, standardize work processes, and address recurring root causes of equipment inefficiencies.

Ultimately, TPM is about making equipment reliability a cultural habit. By involving every department and every operator, TPM builds a unified commitment to asset health, operational consistency, and continuous improvement. The result is a production environment where machines are more available, processes are more predictable, and productivity increases sustainably over time.

Core Pillars That Power Total Productive Maintenance (TPM)

The strength of any TPM program lies in its structured foundation. TPM is built on eight interconnected pillars that collectively help manufacturers eliminate breakdowns, reduce defects, and create a safer, more reliable production environment. Each pillar targets a different source of loss, ensuring that equipment runs at peak efficiency and operators stay deeply involved in maintaining asset health.

Below is a clear, manufacturing-leader-friendly breakdown of the eight pillars:

1. 5S Workplace Organization

5S forms the groundwork for TPM by ensuring a clean, organized, and disciplined environment.

- Sort – Remove unnecessary items.

- Straighten – Arrange tools and materials for easy access.

- Shine – Clean and inspect the work area.

- Standardize – Set clear standards for organization.

- Sustain – Maintain habits through routine practices.

A tidy and standardized workplace makes it easier to spot issues early—like leaks, cracks, or unusual wear—preventing them from becoming major failures.

2. Autonomous Maintenance

Operators take ownership of daily equipment care, including cleaning, lubrication, and basic inspections. This:

- Improves operator understanding of the machine

- Detects problems early

- Reduces dependency on maintenance teams

- Minimizes downtime and unplanned failures

3. Focused Improvement (Kobetsu Kaizen)

Cross-functional teams work together to remove chronic losses and inefficiencies.

- Encourages small, incremental improvements

- Targets recurring issues

- Builds a continuous improvement culture across the shop floor

4. Planned Maintenance

Maintenance activities are scheduled based on equipment condition, historical data, and failure patterns.

- Reduces unplanned stoppages

- Ensures maintenance occurs during non-production windows

- Optimizes spare parts usage and inventory

5. Quality Maintenance

The goal is zero defects by preventing quality issues at the source.

- Uses Root Cause Analysis to eliminate recurring problems

- Stops defects early, reducing scrap and rework costs

- Improves customer satisfaction through consistent quality

6. Early Equipment Management

Insights from TPM activities are used to design or purchase equipment that is easy to maintain, operate, and troubleshoot.

- Reduces startup issues in new machines

- Simplifies maintenance

- Helps new equipment reach optimal performance faster

7. Training and Education

Skill-building ensures everyone—operators, technicians, supervisors, and managers—understands their TPM roles.

- Enhances operator autonomy

- Equips maintenance teams with modern techniques

- Builds leadership support for TPM practices

8. Safety, Health, and Environment

Aims for a workplace with zero accidents and zero unsafe conditions.

- Identifies and removes safety risks

- Ensures compliance with safety protocols

- Promotes a healthy, stable working environment

9. TPM in Administration

TPM principles extend beyond the shop floor to administrative and support functions.

- Improves efficiency in procurement, scheduling, and documentation

- Eliminates office-related bottlenecks that affect production

- Builds organization-wide alignment

What Is TPM Used For?

Total Productive Maintenance (TPM) is used to eliminate equipment-related losses and create a production environment where reliability, efficiency, and quality are consistently maintained. Instead of relying on reactive, after-the-fact fixes, TPM builds a proactive maintenance culture—one where operators, technicians, and supervisors work together to protect equipment health and prevent issues before they can disrupt production.

TPM integrates preventive, autonomous, and corrective maintenance with strong safety and quality practices. It ensures machines run exactly as intended, reducing operational variability and helping manufacturers boost productivity without increasing stress on people or equipment. Ultimately, TPM is used to drive higher OEE, reduce total maintenance costs, and unlock the full value of existing assets.

TPM achieves this by targeting six major types of production losses, which are the root causes behind downtime, inefficiency, and poor quality.

1. Unexpected Breakdowns

Breakdowns are one of the most expensive forms of manufacturing loss, often bringing production to a halt. TPM strengthens preventive maintenance schedules, encourages daily operator checks, and improves equipment inspections to detect issues early.

Through autonomous maintenance, operators can identify leaks, unusual noises, loose components, or early wear—allowing the maintenance team to fix problems before they escalate. This reduces emergency repairs, lowers spare parts consumption, and keeps equipment available when needed.

2. Setup and Adjustment Losses

Changeovers, startup adjustments, and condition shifts often delay production. TPM helps streamline these processes through standard operating procedures (SOPs), visual controls, and equipment conditioning practices.

With clear guidelines for cleaning, alignment, tooling, and setup, operators can complete changeovers faster and with fewer errors. This leads to more productive hours per shift and smoother transitions between batches or product variants.

3. Stoppages and Minor Stops

Small interruptions—like sensor misreads, jams, misfeeds, or minor equipment abnormalities—may seem insignificant but can accumulate into large productivity losses.

TPM addresses these by improving equipment condition, refining operator routines, and resolving small issues immediately instead of allowing them to turn into chronic problems. As machines run with fewer interruptions, the production line becomes more stable and predictable.

4. Speed Losses

Even when equipment is running, it may perform below its designed speed due to friction, wear, poor lubrication, misalignment, or operational inefficiencies. TPM identifies these hidden speed losses through better data collection, standardized operating conditions, and continuous improvement practices. Once eliminated, machines can run closer to their optimal cycle time—boosting throughput without increasing stress on assets.

5. Quality Defects

Defects, rework, and scrap are direct indicators of underlying equipment or process issues. TPM focuses on improving equipment precision and reliability, which in turn stabilizes process consistency and reduces variability.

Techniques like Root Cause Analysis help identify the exact reason behind recurring defects—whether mechanical, operational, or procedural. As sources of defects are eliminated, products meet quality standards consistently, reducing both waste and customer complaints.

6. Equipment and Capital Investment Losses

Poorly maintained equipment wears out faster and consumes more resources. TPM maximizes the useful life of machines by keeping them in optimal operating condition. With fewer breakdowns and higher reliability, manufacturers can delay large capital expenditures and make better use of existing assets. TPM also helps identify equipment that is underutilized, improperly sized, or inefficient—guiding smarter investment decisions in the future.

In essence, TPM is used to transform equipment from a source of unpredictable risk into a consistent, high-performing asset. By systematically eliminating the six major equipment losses, TPM enables manufacturers to increase productivity, protect equipment health, and build a culture of shared responsibility across the entire plant.

How Does Total Productive Maintenance (TPM) Work?

TPM works through a structured, five-step implementation process designed to restore equipment to optimal condition, eliminate the root causes of downtime, and build a culture where operators and maintenance teams work together to protect asset performance.

Below is a clear breakdown of how TPM works in practice.

1. Identify a Pilot Area

The TPM journey starts small—with a single pilot area or machine that represents the best opportunity for early success.

How companies typically choose pilot equipment:

Best practice:

- If you're new to TPM, start with the easiest-to-improve equipment.

- If you have moderate/strong TPM capability, target the bottleneck machine.

- Involve operators, technicians, production managers, and supervisors to build early buy-in.

- Set up a visual project board to track plans, photos, improvements, checklists, and progress.

2. Restore Equipment to Prime Operating Condition

Once the pilot area is selected, TPM begins by returning the equipment to a “like-new” condition using 5S and Autonomous Maintenance.

A. Apply 5S to Create Basic Equipment Conditions

Teams clean, organize, and standardize the work area so deterioration becomes visible.

Typical 5S actions:

- Photograph the current condition

- Clear unused tools, waste, and debris

- Organize tools with shadow boards

- Deep clean the equipment and surrounding area

- Photograph the improved condition

- Create a 5S checklist

- Perform daily → weekly audits to sustain the standard

This reveals hidden defects (leaks, loose bolts, wear, contamination) and builds operator ownership.

B. Launch Autonomous Maintenance

Operators are trained to routinely clean, inspect, and lubricate their equipment.

Key activities:

- Identify and label inspection points

- Improve visibility (e.g., replace opaque guards with transparent ones)

- Mark all set points on the machine

- Identify lubrication points and plan lubrication during changeovers

- Train operators to detect abnormalities early

- Create an autonomous maintenance checklist

- Audit the process regularly

This shifts everyday equipment care to operators and frees technicians for higher-value maintenance tasks.

3. Start Measuring OEE

TPM depends on data, and the most important metric is Overall Equipment Effectiveness (OEE).

OEE = Availability × Performance × Quality

To improve OEE, you must understand the exact causes behind downtime and losses.

What this step includes:

- Track OEE manually or with software

- Capture reasons for every unplanned stop

- Include an “unallocated” category to avoid guesswork

- Collect data for at least two weeks

- Review OEE after every shift

This reveals patterns such as recurring jams, slow cycles, or long changeovers.

Teams then create a Top Loss Report—helping identify the small number of issues causing most downtime.

4. Address and Reduce Major Losses

Once major losses are visible, TPM applies the principle of Focused Improvement (Kaizen).

How TPM teams eliminate losses:

- Select one major loss (typically the biggest unplanned stop).

- Form a cross-functional team (operators + maintenance + supervisors).

- Collect evidence—photos, observations, physical samples.

- Conduct root cause analysis (5 Whys, Fishbone diagrams, Pareto analysis).

- Propose and implement corrective actions during scheduled downtime.

- Restart production and monitor results.

- Standardize the fix if successful—otherwise repeat the investigation.

This continuous cycle systematically removes the causes of breakdowns, slow cycles, and defects.

5. Implement Planned (Proactive) Maintenance

The final step is building a proactive maintenance system that prevents failures before they occur.

A. Identify Components That Require Planned Maintenance

- Items that wear

- Items that repeatedly fail

- Stress points detected using thermography or vibration analysis

B. Set Baseline Maintenance Intervals

- Wear-based intervals

- Predicted failure intervals

- Time-based preventive maintenance

- Work-order generation for all planned tasks

C. Optimize Maintenance Using Feedback Loops

- Maintain component log sheets

- Perform monthly maintenance audits

- Adjust intervals based on actual component condition

- Add new components to the plan as needed

This stabilizes reliability, extends asset life, and reduces emergency maintenance.

6. Quality Maintenance (QM)

This pillar focuses on building processes and equipment conditions that prevent defects from occurring in the first place. It aims for zero defects by identifying critical quality conditions, early detection mechanisms, and building-in quality controls.

Key activities:

- Establishing equipment conditions that prevent quality issues

- Identifying quality-critical components

- Implementing mistake-proofing (Poka-Yoke)

- Reducing rework, scrap, and inconsistent quality outcomes

- Using statistical tools to validate root causes

Why it's important: TPM is incomplete without quality assurance integrated directly into maintenance and operations.

7. Early Equipment Management (EEM)

This applies TPM learnings to the design and installation of new equipment. The aim: ensure new assets are maintenance-friendly, reliable, and easier to operate from day one.

Key activities:

- Leveraging operator and maintenance feedback in new equipment design

- Simplifying lubrication, inspection, and cleaning tasks

- Reducing installation and commissioning times

- Ensuring early detection of design flaws

- Building equipment that supports autonomous maintenance

Why it's important: It prevents future losses before equipment enters production.

8. Safety, Health & Environment (SHE)

A critical pillar ensuring that TPM improvements never compromise safety. In TPM, zero accidents is a non-negotiable target.

Key activities:

- Eliminating occupational hazards

- Designing maintenance tasks that avoid risks

- Training staff on hazard identification

- Implementing ergonomic improvements

- Establishing safe behaviors for autonomous maintenance

Why it's important: Reliable equipment and safe equipment must go hand in hand.

9. Administrative & Support Functions TPM

Often overlooked, this pillar ensures that TPM is supported by lean and efficient administrative workflows (procurement, planning, documentation, inventory, etc.)

Key activities:

- Improving spare parts management

- Reducing delays in work orders

- Standardizing documentation and reporting

- Removing bottlenecks from administrative processes

- Aligning HR, finance, and planning functions with TPM goals

Why it's important: TPM cannot succeed if supporting processes create delays or inefficiency.

10. Training & Skill Development

Though it is not one of the original eight pillars, modern TPM frameworks (including JIPM) treat training as essential for sustainability.

Key activities:

- Training operators for autonomous maintenance

- Developing maintenance technicians for predictive tools

- Cross-functional skill-building

- Standardized work training

- Building a culture of continuous learning

Why it's important: TPM fails without capable and confident operators and maintenance teams.

11. Culture, Leadership & Cross-Functional Alignment

TPM is as much a cultural transformation as it is a technical one. Your current section doesn’t include leadership responsibilities, communication strategy, or employee engagement, which are central to TPM success.

Key activities:

- Forming TPM steering committees

- Setting TPM KPIs and visual management boards

- Conducting daily Gemba walks

- Holding Kaizen events

- Celebrating wins to build momentum

Why it's important: TPM requires organization-wide participation, not just maintenance teams.

Benefits of Implementing Total Productive Maintenance (TPM)

Implementing TPM delivers both direct operational improvements and indirect cultural advantages that strengthen long-term manufacturing performance.

By eliminating equipment losses, building operator ownership, and promoting proactive maintenance practices, TPM enhances productivity while creating a safer, more engaged workplace.

Below are the core benefits supported by TPM frameworks and industry case studies.

1. Higher OEE and Reduced Unplanned Downtime

TPM significantly reduces unexpected equipment failures by strengthening preventive and autonomous maintenance activities. With machines running reliably and predictably, manufacturers experience higher availability, fewer production interruptions, and smoother process flow. This directly boosts Overall Equipment Effectiveness (OEE), enabling plants to produce more with the same assets and labor.

2. Improved Product Quality and Fewer Defects

By stabilizing machine conditions and eliminating sources of variability, TPM enhances product quality and reduces scrap, rework, and defect-related costs.

Quality maintenance, root cause analysis, and continuous improvement ensure that equipment consistently performs within optimal standards. This leads to more reliable production output and increased customer satisfaction.

3. Lower Manufacturing and Maintenance Costs

TPM transitions organizations from reactive repairs to proactive maintenance, reducing expensive emergency breakdowns, overtime labor, spare part consumption, and waste.

Over time, equipment lasts longer, consumes fewer resources, and operates more efficiently. The combined effect is a measurable reduction in total manufacturing and maintenance costs.

4. Safer Workplaces and Fewer Accidents

Through routine inspections, standardized cleaning, and strong equipment management practices, TPM eliminates hazardous conditions before they escalate.

Operators gain awareness of risks, maintenance tasks become safer, and work areas stay organized. This results in fewer accidents, lower safety-related costs, and a culture where safety and reliability move hand in hand.

5. Faster Changeovers and Higher Productivity

TPM streamlines equipment setup, adjustment, and startup procedures, reducing the time required to switch between products or batches.

Standard work, visual controls, and operator ownership help eliminate delays and errors. Shorter changeovers lead to increased productive time, more flexibility in scheduling, and faster response to customer demand.

6. Cleaner, More Organized Work Environment (5S Impact)

The foundation of TPM—5S—creates a workplace that is visually organized, clean, and easy to manage. Issues like leaks, abnormal wear, and loose components become visible immediately.

This improves efficiency, strengthens discipline on the shop floor, and enables operators to maintain equipment more effectively without relying on reactive fixes.

7. Stronger Employee Ownership and Engagement

TPM actively involves operators in maintaining and caring for their equipment, giving them a sense of responsibility and pride.

As workers gain technical knowledge and problem-solving skills, their confidence, motivation, and engagement increase. This fosters a collaborative culture where teams work together to protect reliability and improve performance.

8. Better Cross-Functional Collaboration and Knowledge Sharing

TPM brings maintenance, operations, engineering, quality, and supervisory teams together to solve equipment issues. Cross-functional Kaizen teams accelerate learning and build shared expertise.

This ensures faster problem resolution, greater alignment on production goals, and an organization-wide culture of continuous improvement.

9. Reduced Environmental Impact

By maintaining equipment properly and eliminating leaks, defects, and inefficient processes, TPM helps reduce waste, emissions, and energy consumption.

Cleaner equipment operates more efficiently, and disciplined maintenance practices support pollution control measures. This contributes to sustainability goals and regulatory compliance across the facility.

10. More Reliable Asset Performance and Longer Equipment Life

With regular upkeep and controlled operating conditions, equipment deterioration slows dramatically. TPM ensures machines are cleaned, lubricated, adjusted, and inspected routinely, extending asset lifespan and reducing the need for capital replacements. This maximizes the return on investment for manufacturing equipment.

Challenges in Implementing TPM

While Total Productive Maintenance offers measurable gains in equipment reliability and plant efficiency, implementing it is far from straightforward.

TPM demands a deep cultural shift, disciplined execution, and coordinated effort across departments.

Many organizations struggle with people-related, process-related, and technology-related barriers that slow down adoption and limit expected results.

1. Resistance to Cultural Change

TPM requires employees—from operators to managers—to adopt new responsibilities, such as ownership of routine maintenance. Many teams resist this shift because it disrupts long-standing habits, demands accountability, and introduces new workflows. Without strong change management and leadership buy-in, cultural resistance can delay or derail TPM adoption.

2. Lack of Skilled Workforce

TPM involves preventive, autonomous, and predictive maintenance techniques that require technical knowledge and problem-solving skills. Many organizations struggle with skill gaps among operators who are expected to perform basic maintenance. Upskilling takes time, training investment, and continuous follow-up.

3. High Initial Investment of Time and Resources

Implementing TPM is not an overnight process. It requires dedicated training, consistent data collection, regular audits, cross-functional meetings, and equipment restoration efforts. For companies with already stretched teams, committing these resources initially can be challenging.

4. Inconsistent Management Support

TPM thrives only when leadership consistently supports it through budgets, recognition, manpower, and enforcement. In some companies, support weakens over time—leading to incomplete activities, poor adoption of autonomous maintenance, and declining discipline across teams.

5. Difficulty Sustaining Long-Term Momentum

TPM programs often start strong but lose momentum as priorities shift or initial enthusiasm fades. Daily activities like cleaning, inspection, and lubrication can become routine and overlooked if not continuously monitored. Maintaining engagement and visible results requires ongoing communication and measurable KPIs.

6. Data Collection and Monitoring Challenges

For TPM to work, teams must measure metrics such as equipment breakdowns, MTBF, MTTR, and OEE. In many factories, data is inaccurate, manually recorded, or inconsistent across departments. Poor-quality data leads to wrong decisions and reduced trust in the TPM program.

7. Lack of Standardization Across Departments

TPM needs uniform standards for cleaning, inspection, safety, lubrication, and documentation. When different teams follow different practices, it leads to inconsistent outcomes, confusion, and inefficiencies—hindering system-wide improvements.

8. Overloaded Operators and Team Members

TPM assigns machine operators responsibility for cleaning, routine inspections, lubrication, and early detection of issues. In factories where operators are already overloaded, adding TPM responsibilities without adjusting workloads leads to burnout and non-compliance.

9. Managing Multiple TPM Pillars Simultaneously

TPM has eight pillars. Implementing too many at once creates confusion and resource pressure. Factories often struggle to coordinate activities across Quality, Safety, Planned Maintenance, and Autonomous Maintenance, leading to fragmented execution.

10. Difficulty Embedding a Continuous Improvement Mindset

TPM demands constant problem-solving, kaizen activities, and root-cause analysis. Not all teams are used to proactive improvement practices. Shifting from a reactive maintenance culture to a preventive and predictive one requires ongoing coaching and structured processes.

How Digital Tools and ERP Systems Strengthen Total Productive Maintenance (TPM)

Digital transformation has significantly elevated the way manufacturers plan, execute, and monitor TPM activities. Modern ERP and MRP systems centralize equipment data, automate maintenance scheduling, and provide real-time insights that make TPM more predictable, measurable, and efficient.

Instead of relying on manual logs or reactive fixes, digital tools allow teams to prevent failures before they occur, standardize maintenance workflows, and enhance cross-functional collaboration.

Below are the key ways digital tools and ERP systems strengthen TPM:

1. Real-Time Equipment Monitoring and Analytics

Digital tools integrate IoT sensors, machine data, and shop-floor systems to track equipment health in real time. Manufacturers gain visibility into parameters like temperature, vibration, pressure, and motor load—allowing them to detect anomalies early. This predictive insight helps maintenance teams act before breakdowns occur, reducing downtime and keeping TPM activities aligned with actual machine performance.

2. Automated Preventive and Autonomous Maintenance Scheduling

ERP and MRP systems automate maintenance calendars based on usage, condition, or time cycles. Operators receive timely alerts, checklists, and instructions to perform autonomous maintenance tasks consistently. Automated scheduling eliminates human error, ensures timely interventions, and keeps preventive maintenance routines fully aligned with TPM goals.

3. Centralized Data for Root Cause Analysis (RCA)

Digital systems consolidate historical maintenance logs, breakdown patterns, spare parts consumption, and operator notes. This unified data environment makes root cause analysis faster and more accurate. Teams can identify recurring issues, remove hidden losses, and continuously refine TPM strategies based on data-driven insights rather than guesswork.

4. Streamlined Communication and Cross-Functional Collaboration

ERP platforms ensure seamless communication between operators, technicians, production managers, and quality teams. Maintenance requests, action items, inspection results, and escalations can be tracked in a single system. This eliminates silos, supports faster decision-making, and promotes the collaborative culture needed for successful TPM adoption.

5. Enhanced Spare Parts Management and Inventory Control

Digital inventory systems track spare parts availability, reorder levels, supplier lead times, and usage patterns. By ensuring the right parts are available when needed, ERP systems prevent delays, reduce excess inventory, and support a smoother maintenance workflow. This is especially critical in TPM, where the goal is zero breakdowns and maximum equipment uptime.

6. Improved Compliance, Documentation, and Standardization

ERP-powered maintenance modules store digital SOPs, inspection sheets, safety guidelines, and maintenance histories. Standardizing these activities reduces variability, increases accuracy, and ensures compliance with safety and regulatory requirements. It also supports continuous improvement and audit readiness.

7. Predictive Maintenance Integrations for Higher OEE

Modern ERP/MRP systems integrate predictive maintenance models powered by AI and machine learning. These systems can forecast failure points, suggest optimal maintenance windows, and simulate the impact of different maintenance strategies. This results in better planning, increased equipment availability, and improved OEE—directly supporting TPM objectives.

Best Practices for Total Productive Maintenance (TPM) Success

Implementing TPM requires more than setting up maintenance schedules—it demands cultural change, disciplined execution, and alignment across teams. The following best practices help manufacturers build a sustainable TPM ecosystem that drives long-term reliability, productivity, and operator ownership.

1. Build a Strong Foundation with Leadership Commitment

TPM thrives when leadership sets clear expectations, allocates resources, and actively advocates for a proactive maintenance culture. Leaders must champion TPM principles, ensure cross-functional involvement, and remove operational barriers so teams can focus on continuous improvement.

2. Start with Small, High-Impact Pilots

Launching TPM across the entire facility at once can overwhelm teams. Instead, begin with pilot areas—critical machines or production lines with frequent issues. Early wins help build momentum, demonstrate ROI, and boost employee confidence before scaling TPM plant-wide.

3. Train and Empower Operators for Autonomous Maintenance

Operator involvement is at the core of TPM success. Provide structured training so operators can perform basic inspections, cleaning, lubrication, and early fault detection. This not only prevents minor issues from escalating but also fosters ownership and accountability on the shop floor.

4. Standardize Procedures and Create Visual Controls

Use checklists, SOPs, equipment labels, and visual indicators to guide daily maintenance tasks. Standardization ensures consistency, reduces errors, and simplifies onboarding. Visual management tools like dashboards and tagged faults help teams quickly identify abnormalities.

5. Strengthen Preventive and Predictive Maintenance Strategies

Preventive maintenance must be well-planned, accurately documented, and based on real equipment data. Integrating predictive maintenance tools—such as vibration analysis or IoT sensors—adds early warning capabilities, reducing unplanned failures and improving OEE.

6. Foster Cross-Functional Collaboration

TPM works best when production, maintenance, quality, and engineering teams collaborate seamlessly. Create small, focused improvement groups to address chronic losses, develop countermeasures, and optimize processes. This drives shared responsibility and continuous improvement.

7. Track OEE and Other TPM KPIs Consistently

Measure improvements using KPIs like Overall Equipment Effectiveness (OEE), MTTR, MTBF, breakdown rates, and quality yield. Regular tracking allows teams to identify hidden losses, prioritize actions, and validate the impact of TPM initiatives with data.

8. Celebrate Wins and Recognize Employee Contributions

Acknowledging teams for improved uptime, fewer defects, or successful autonomous maintenance builds motivation and long-term commitment. Recognition programs reinforce the TPM culture and encourage continuous engagement across the workforce.

Key Maintenance KPIs to Track for TPM Success

To ensure your TPM initiatives deliver measurable performance gains, you need to track the right KPIs—those that reflect equipment health, maintenance efficiency, cost control, and overall operational reliability.

These indicators help manufacturers identify gaps, evaluate improvement efforts, and support data-driven decisions that strengthen plant performance over time.

1. Availability

Availability measures the percentage of time equipment is actually ready for production. High availability indicates stable operations and effective preventive maintenance activities. TPM aims to reduce unplanned downtime and improve cleaning, inspection, and lubrication routines so machines remain consistently operational.

2. Mean Time Between Failures (MTBF)

MTBF tracks the average timeframe between equipment failures. A higher MTBF reflects better reliability, fewer breakdowns, and strong autonomous and planned maintenance execution. Increasing MTBF is one of the clearest signs that TPM is working.

3. Mean Time Between Planned Maintenance (MTBPM)

MTBPM measures how long equipment can run healthily between scheduled maintenance interventions. If MTBPM increases over time, it indicates assets are in better condition, operators are maintaining equipment well, and maintenance schedules are optimized.

4. Mean Time to Repair (MTTR)

MTTR reflects the average time required to repair a machine after a failure. TPM helps reduce MTTR by ensuring proper training, standard procedures, and ready access to spare parts. Lower MTTR means faster recovery and minimal impact on production.

5. Service Level (Maintenance Schedule Compliance)

Service level measures how effectively teams adhere to maintenance schedules—both in timing and duration. A high service level indicates disciplined execution, strong coordination between production and maintenance, and minimal delays. This is critical for achieving TPM’s goal of predictable, stable operations.

6. Internal Maintenance Cost

This KPI measures the total cost of internal maintenance labor, tools, and overhead. TPM aims to optimize internal workload by empowering operators to handle routine tasks and allowing maintenance teams to focus on higher-value activities, improving cost efficiency.

7. Material Cost (Spare Parts & Consumables)

This includes costs related to spare parts, lubricants, and other maintenance materials. TPM reduces material waste by preventing premature failures, improving lubrication practices, and standardizing inspection routines.

8. Third-Party Services Cost

For services like specialized repairs, calibrations, or outsourced maintenance, this KPI tracks external spending. TPM maturity reduces dependency on expensive third-party interventions by building internal capability and strengthening preventive practices.

9. Planned vs. Unplanned Maintenance Cost

This KPI compares how much is spent on scheduled activities versus reactive repairs. TPM seeks to shift investment toward planned maintenance—reducing breakdowns, emergency repairs, and unplanned downtime. A higher share of planned maintenance spending reflects a healthier, more predictable maintenance system.

How Deskera MRP Supports TPM & Plant Reliability

Deskera MRP offers a connected, real-time operational system that helps manufacturers execute TPM more consistently and effectively. With integrated inventory, work order management, MRP, quality control, and automated workflows, Deskera ensures equipment reliability, reduces downtime, and strengthens cross-functional coordination. Its mobile-first interface and built-in automation make TPM adoption easier for operators, technicians, and supervisors alike.

1. Centralized Equipment & Maintenance Data

Deskera allows you to maintain complete asset records—including past breakdowns, maintenance logs, spare parts usage, and operating information—in one unified system. This makes it easier to track equipment health, review recurring issues, and make informed maintenance decisions that support TPM objectives.

2. Automated Preventive Maintenance Schedules

With Deskera’s work order and task automation, teams can create recurring maintenance schedules for lubrication, cleaning, inspections, and part replacements. Alerts notify responsible teams when tasks are due, ensuring preventive maintenance stays consistent—reducing unplanned downtime and enabling TPM’s proactive maintenance approach.

3. Faster Issue Reporting & Work Order Execution

Deskera’s mobile app lets operators instantly raise maintenance requests, report abnormalities, or update task status directly from the shop floor. Maintenance teams receive real-time notifications, ensuring quicker response times and preventing minor abnormalities from escalating into major breakdowns.

4. Integrated Spare Parts & Inventory Management

Deskera’s inventory module tracks spare parts availability, automates reordering, and ensures critical components remain in stock. By linking inventory to work orders and maintenance tasks, Deskera eliminates delays due to missing parts and supports uninterrupted TPM activities.

5. Support for Root Cause Analysis through Traceable Data

Every maintenance activity in Deskera is automatically logged—providing a clear audit trail of failures, resolutions, spare parts used, and technician notes. This traceability helps maintenance managers identify patterns, perform root cause analysis, and eliminate chronic equipment problems.

6. Built-In Quality Control & Production Tracking

Deskera MRP includes quality checkpoints, inspection plans, batch tracking, and rejection logging. By connecting quality data with machine performance records, Deskera helps identify defect sources early—strengthening TPM’s goal of zero defects and consistent, reliable output.

7. Enhanced Planning & Workload Optimization with MRP

Deskera MRP helps plan production schedules, allocate resources, and ensure machines are neither overloaded nor underutilized. This alignment between production planning and maintenance planning makes it easier to schedule maintenance during non-peak hours, reducing stoppages and increasing equipment availability.

8. Mobile-First Visibility & Collaboration

Deskera’s mobile-first experience allows operators, supervisors, and maintenance teams to stay connected at all times. They can track task status, approvals, inventory consumption, and upcoming maintenance schedules in real time—supporting TPM’s principle of shared responsibility and team involvement.

Key Takeaways

- TPM is a holistic maintenance philosophy that empowers operators, strengthens preventive practices, and targets perfect production—no breakdowns, no defects, no accidents—ultimately improving OEE and long-term equipment reliability.

- TPM integrates people, processes, and equipment into a unified system where every employee contributes to machine health, enabling higher uptime, safer operations, and sustained productivity improvements.

- The eight TPM pillars—built on a 5S foundation—provide a structured framework for proactive maintenance, continuous improvement, quality assurance, safety, and cross-functional teamwork that drives operational excellence.

- TPM reduces losses across six major areas—breakdowns, setup time, speed losses, stoppages, defects, and equipment investment—helping plants eliminate waste and maximize production capacity.

- Manufacturers adopting TPM experience higher OEE, lower costs, improved quality, safer workplaces, and stronger employee ownership, resulting in long-term reliability and sustainable performance gains.

- Successful TPM adoption requires cultural alignment, disciplined execution, consistent operator participation, and strong cross-departmental collaboration—barriers many plants must intentionally overcome.

- Digital systems and ERPs enhance TPM by enabling real-time visibility, accurate data capture, automated schedules, mobile collaboration, and faster root-cause analysis—making maintenance more predictable and efficient.

- Plants succeed with TPM when they build a strong 5S foundation, empower operators, maintain clear KPIs, encourage continuous improvement, and integrate maintenance seamlessly with production planning.

- Tracking KPIs like Availability, MTBF, MTTR, MTBPM, service level, and maintenance costs helps quantify TPM impact, identify improvement opportunities, and guide smarter decisions about equipment and resources.

- Deskera MRP strengthens TPM execution through centralized equipment data, automated maintenance schedules, real-time issue reporting, integrated inventory, root-cause traceability, and mobile-first collaboration across the plant.

Related Articles