A multi-level Bill of Materials (BOM) holds the utmost significance in the realm of manufacturing and product development. Serving as a comprehensive hierarchical representation of the components and subassemblies required to construct a final product, it facilitates seamless coordination and efficiency throughout the production process.

By breaking down complex products into their constituent parts, a multi-level BOM ensures better visibility into the supply chain, enabling accurate inventory management, cost estimation, and demand forecasting.

Manufacturers can optimize their procurement strategies, identify potential bottlenecks, and streamline production schedules with enhanced clarity on dependencies between different levels of the BOM.

Moreover, this structured approach aids in troubleshooting and maintaining product quality, fostering innovation, and accelerating time-to-market. Embracing a multi-level BOM empowers businesses to enhance productivity, reduce errors, and ultimately deliver superior products to customers in a competitive and dynamic marketplace.

This article covers the following:

- Understanding the Foundation: The Role of Bill of Materials (BOM) in Manufacturing

- Navigating the Complexity: The Challenges of Modern Manufacturing

- Streamlining Production with Multi-level BOMs: A Comprehensive Overview

- Enhancing Collaboration and Communication: Cross-functional Benefits of Multi-level BOMs

- Mitigating Risks and Reducing Costs: Multi-level BOMs as Risk Management Tools

- Balancing Flexibility and Efficiency: Adapting to Change with Multi-level BOMs

- Leveraging Technology: Advanced Software Solutions for Managing Multi-level BOMs

- Case Studies: Real-world Success Stories of Multi-level BOM Implementation

- Best Practices for Implementing Multi-level BOMs in Your Manufacturing Process

- The Future of Manufacturing Complexity: Embracing Innovation with Multi-level BOMs

Understanding the Foundation: The Role of Bill of Materials (BOM) in Manufacturing

The Bill of Materials (BOM) is a crucial document in the manufacturing process that lists all the materials, components, and sub-assemblies required to build a product.

It serves as a comprehensive reference that helps manufacturers understand the structure and requirements of the product they are producing. The BOM acts as a central point of information and coordination between different departments, such as engineering, procurement, production, and inventory management.

Here's a breakdown of the key roles and importance of the Bill of Materials in manufacturing:

- Product Design and Development: During the product design phase, engineers and designers create a detailed list of all the materials and components needed to build the product. This BOM serves as a blueprint, ensuring that all necessary elements are accounted for and correctly incorporated into the product design.

- Cost Estimation: The BOM plays a significant role in cost estimation. By listing all the materials and their quantities, along with associated costs, manufacturers can accurately estimate the total cost of producing the product. This information is vital for determining the product's pricing, profitability, and feasibility.

- Procurement and Inventory Management: The BOM guides the procurement department on what materials and components to purchase. It includes information about suppliers, part numbers, and quantities required, streamlining the procurement process and minimizing the risk of errors in ordering. Moreover, the BOM helps maintain an efficient inventory system by keeping track of the required stock levels for each component.

- Manufacturing and Assembly: Once the product moves to the manufacturing stage, the BOM serves as a step-by-step instruction manual for the assembly process. It outlines the correct sequence in which components must be put together, ensuring that the final product meets the intended specifications and quality standards.

- Quality Control and Traceability: With a detailed BOM, manufacturers can establish effective quality control procedures. Each component can be traced back to its source, enabling manufacturers to identify any faulty or substandard materials and address potential issues in the production process.

- Product Variants and Configurations: For manufacturers producing multiple product variants or configurations, the BOM facilitates managing these different versions efficiently. By adjusting the BOM according to the specific requirements of each variant, manufacturers can easily switch between production runs.

- Lifecycle Management: Throughout the product's lifecycle, the BOM may undergo changes due to improvements, updates, or cost optimization. Proper version control and revision tracking of the BOM are essential to ensure that all stakeholders work with the latest and most accurate information.

- Collaboration and Communication: The BOM serves as a shared reference for various departments involved in the manufacturing process. It fosters effective communication among design, engineering, production, and procurement teams, reducing misunderstandings and enhancing overall collaboration.

Navigating the Complexity: The Challenges of Modern Manufacturing

Modern manufacturing indeed faces various challenges due to the complexity of today's global and technologically advanced landscape. Let's explore some of the key challenges:

- Advanced Technology Integration: While technological advancements have enabled increased efficiency and automation, the integration of these technologies into existing manufacturing processes can be complex and costly.

Implementing robotics, artificial intelligence, the Internet of Things (IoT), and other Industry 4.0 technologies requires skilled personnel and substantial investment.

- Supply Chain Disruptions: Globalization has made supply chains longer and more intricate. Disruptions, such as natural disasters, geopolitical issues, or pandemics (as evidenced by the COVID-19 pandemic), can have significant ripple effects on manufacturing processes, leading to delays, shortages, and increased costs.

- Data Management and Security: Modern manufacturing generates vast amounts of data from sensors, machines, and various systems. Effectively managing and analyzing this data is crucial for process optimization and decision-making. However, ensuring data security and protecting intellectual property from cyber threats are constant challenges.

- Skills Gap and Workforce Training: The adoption of advanced technologies demands a workforce with new skill sets. Unfortunately, there is often a gap between the skills required by modern manufacturing and the skills possessed by the existing workforce. Upskilling and reskilling employees are essential, but this can be challenging for both companies and employees.

- Sustainability and Environmental Concerns: With growing environmental awareness, manufacturers face pressure to reduce their environmental footprint.

Transitioning to sustainable practices and materials, as well as managing waste and energy consumption, presents a complex challenge that requires careful planning and investment.

- Regulatory Compliance: Manufacturers must adhere to a wide range of regulations and standards, both at the national and international levels. Compliance can be complex, time-consuming, and costly, especially for companies operating in multiple jurisdictions.

- Customization and Personalization: Modern consumers expect products tailored to their needs and preferences. Mass customization and personalized manufacturing require agile production processes that can quickly adapt to changing demands, which can be challenging for traditional manufacturing setups.

- Rapid Technological Obsolescence: Technology evolves at a rapid pace. Manufacturers must stay up-to-date with the latest advancements to remain competitive. However, this can lead to the risk of investing in technologies that may become obsolete sooner than expected.

- Global Competition: Manufacturing has become a global industry, and companies face competition from all around the world. To remain competitive, manufacturers must continuously innovate, optimize processes, and deliver high-quality products at competitive prices.

- Ethical and Social Concerns: Consumers are increasingly concerned about the ethical and social aspects of the products they purchase. Manufacturers must address issues related to labor practices, human rights, and supply chain transparency to build and maintain consumer trust.

Navigating these challenges requires a strategic approach, continuous learning, and a willingness to embrace change. Collaboration between industry, governments, and educational institutions can also play a crucial role in overcoming these complexities and fostering sustainable growth in modern manufacturing.

Streamlining Production with Multi-level BOMs: A Comprehensive Overview

Streamlining production with Multi-level Bills of Materials (BOMs) is a crucial aspect of efficient manufacturing processes. BOMs are hierarchical lists that outline all the components, sub-assemblies, and raw materials required to produce a final product.

In a multi-level BOM, these components can themselves be assemblies, creating a complex structure that reflects the entire production process. Here's a comprehensive overview of how multi-level BOMs can optimize production:

- Hierarchical Structure: Multi-level BOMs present a hierarchical structure, with the top level representing the final product and subsequent levels breaking down the components required for each assembly or sub-assembly. This clear organization aids in understanding the product's structure and facilitates easy navigation.

- Materials Planning and Procurement: By having a detailed list of all required components and raw materials, multi-level BOMs enable efficient materials planning and procurement. Manufacturers can accurately forecast material needs, avoid shortages, and optimize inventory levels, leading to cost savings and uninterrupted production.

- Production Scheduling and Resource Allocation: With multi-level BOMs, manufacturers can better schedule production tasks and allocate resources. By understanding the dependencies between different components, production managers can identify critical paths and potential bottlenecks, optimizing production timelines and resource utilization.

- Product Variants and Configurations: Multi-level BOMs accommodate product variants and configurations. Instead of creating a new BOM for each variant, manufacturers can define different options within the same BOM structure. This simplifies maintenance and reduces the chance of errors.

- Engineering Change Management: During the product lifecycle, design changes are inevitable. Multi-level BOMs ease the process of managing engineering changes by clearly identifying the impacted components. This helps in evaluating the cost and time implications of the modifications before implementation.

- Quality Control and Traceability: Multi-level BOMs aid in quality control by establishing clear relationships between components and the final product. In case of defects or issues, this traceability enables swift identification of the problematic components, making it easier to conduct recalls or implement corrective actions.

- Cost Estimation and Analysis: Understanding the complete BOM structure allows for accurate cost estimation. Manufacturers can analyze the cost breakdown at each level, identifying cost drivers and opportunities for cost reduction without compromising on quality.

- Collaboration and Communication: Multi-level BOMs serve as a common language between different departments, such as engineering, production, procurement, and sales. Enhanced communication and collaboration streamline workflows and foster better decision-making throughout the organization.

- Integration with ERP Systems: Integrating multi-level BOMs with Enterprise Resource Planning (ERP) systems enables seamless data flow across the entire manufacturing process. This integration facilitates automated workflows, reduces manual data entry errors, and enhances overall operational efficiency.

- Continuous Improvement: By having a clear overview of the production process through multi-level BOMs, manufacturers can identify areas for continuous improvement, optimize efficiency, and enhance the overall production process.

In conclusion, multi-level BOMs are a valuable tool for streamlining production processes and optimizing resource utilization in manufacturing. They provide a comprehensive overview of the production process, support efficient materials planning and procurement, and facilitate better decision-making and collaboration across departments. By harnessing the benefits of multi-level BOMs, manufacturers can achieve increased productivity, reduced costs, and improved product quality.

Enhancing Collaboration and Communication: Cross-functional Benefits of Multi-level BOMs

In today's complex and fast-paced business environment, effective collaboration and seamless communication are crucial for the success of any organization. One area where these aspects are of utmost importance is in the management of Bill of Materials (BOMs). By adopting multi-level BOMs, companies can streamline their processes, promote cross-functional cooperation, and gain several benefits that contribute to overall operational efficiency and product excellence.

- What are Multi-level BOMs? A Bill of Materials (BOM) is a comprehensive list of all the components, sub-assemblies, and raw materials required to manufacture a product.

Multi-level BOMs take this concept a step further by breaking down each component into its constituent parts, creating a hierarchical structure that represents the entire product assembly process. This hierarchical representation provides a clear overview of the product's structure and enables cross-functional teams to collaborate more effectively.

- Facilitating Cross-functional Collaboration: Multi-level BOMs foster collaboration between different departments, such as design, engineering, manufacturing, procurement, and quality control.

Each team can access a shared and centralized BOM database, making it easier to understand how their work impacts other stages of the product's lifecycle. This shared visibility helps teams anticipate potential bottlenecks, resolve issues proactively, and work towards a common goal.

- Improved Communication and Information Sharing: A multi-level BOM acts as a single source of truth for all product-related information. This shared repository ensures that every team is working with up-to-date and accurate data.

With seamless information sharing, miscommunications and errors due to outdated information can be minimized, leading to a more efficient workflow and reduced rework.

- Enhanced Product Development and Design: For product development teams, multi-level BOMs offer an in-depth view of the product's architecture. This enables engineers and designers to understand how individual components interact with one another and how changes in one area might affect the overall product. As a result, product designs can be optimized for performance, cost, and manufacturability.

- Streamlined Manufacturing Processes: Manufacturing teams benefit greatly from multi-level BOMs as they can plan production more efficiently. Detailed information about sub-assemblies and raw materials allows for accurate procurement and production scheduling. This reduces lead times, minimizes material wastage, and improves overall production output.

- Supply Chain Optimization: With a multi-level BOM system in place, the procurement team gains valuable insights into the full spectrum of required components and materials. This enables them to negotiate better terms with suppliers, identify alternative sources when needed, and avoid supply chain disruptions.

- Real-time Updates and Collaboration: Modern multi-level BOM systems often come with real-time collaboration features. Team members can simultaneously work on the same BOM, view changes in real time, and discuss modifications, ensuring that all stakeholders are on the same page.

In conclusion, the adoption of multi-level BOMs brings numerous cross-functional benefits to organizations. By fostering collaboration, promoting effective communication, and providing a holistic view of the product's structure, companies can enhance their product development, manufacturing processes, and overall supply chain efficiency.

Embracing this technology is a strategic move that enables businesses to stay competitive, deliver high-quality products, and achieve operational excellence in an increasingly interconnected world.

Mitigating Risks and Reducing Costs: Multi-level BOMs as Risk Management Tools

Mitigating risks and reducing costs are essential objectives for any business. In the context of manufacturing and supply chain management, using multi-level BOMs (Bill of Materials) can be a valuable risk management tool.

A BOM is a comprehensive list of components and materials required to produce a product. Multi-level BOMs go beyond a single-level list, showing the hierarchical relationship between the components, sub-assemblies, and the final product.

Here's how multi-level BOMs can help with risk management and cost reduction:

- Visibility and Transparency: Multi-level BOMs provide a clear and detailed view of the entire product structure. This visibility allows stakeholders to understand the dependencies between components and sub-assemblies. With better visibility, potential risks can be identified early in the production process, allowing for timely mitigation strategies.

- Risk Identification: By analyzing the multi-level BOM, it becomes easier to identify critical components or materials that may pose risks due to factors such as sole sourcing, long lead times, or single points of failure.

Identifying these high-risk elements enables proactive risk management actions, such as finding alternative suppliers or implementing safety stock measures.

- Supply Chain Resilience: In the face of disruptions like natural disasters, geopolitical events, or supplier bankruptcies, multi-level BOMs help to assess the impact of such incidents on the entire supply chain. This allows manufacturers to create contingency plans and diversify sourcing strategies to enhance supply chain resilience.

- Cost Optimization: Understanding the hierarchical relationship between components and sub-assemblies can aid in identifying cost-saving opportunities.

By optimizing the design and production processes, companies can reduce the overall cost of the final product. Additionally, multi-level BOMs can highlight expensive or redundant components that can be substituted with more cost-effective alternatives.

- Lead Time Management: Multi-level BOMs help manage lead times effectively. By knowing the lead times of each component and sub-assembly, manufacturers can avoid delays and ensure timely delivery of the final product to customers.

- Efficient Inventory Management: With a clear understanding of the BOM structure, companies can adopt a more efficient approach to inventory management. This means maintaining optimal stock levels for critical components while avoiding excess inventory that ties up capital and increases holding costs.

- Product Lifecycle Management: Multi-level BOMs facilitate better product lifecycle management. Companies can assess the impact of design changes or product updates on downstream components and sub-assemblies. This helps in making informed decisions that minimize costs and avoid costly rework.

- Continuous Improvement: Regularly reviewing and updating multi-level BOMs allows companies to engage in continuous improvement efforts. They can identify inefficiencies, bottlenecks, and risks that may have arisen after initial production, ensuring ongoing risk mitigation and cost reduction.

In conclusion, multi-level BOMs serve as valuable risk management tools that enhance visibility, improve supply chain resilience, and facilitate cost reduction initiatives. By having a comprehensive understanding of the product structure and its components, businesses can make informed decisions that optimize their processes and ensure a competitive edge in the market.

Balancing Flexibility and Efficiency: Adapting to Change with Multi-level BOMs

Balancing flexibility and efficiency is a critical aspect of supply chain management, especially when dealing with multi-level Bills of Materials (BOMs). A Bill of Materials is a hierarchical structure that lists all the components, materials, and subassemblies required to manufacture a final product. Multi-level BOMs refer to BOMs that contain subassemblies, which can themselves have their own BOMs.

Here are some strategies to adapt to change while managing multi-level BOMs:

- Agile and Responsive Manufacturing: Implement agile manufacturing practices that allow your production processes to quickly respond to changes in demand, design, or material availability. This includes having flexible production lines and versatile machinery that can adapt to different product configurations.

- Real-Time Communication and Collaboration: Facilitate seamless communication and collaboration between different departments involved in the supply chain, such as design, production, procurement, and inventory management. This ensures that everyone is on the same page and can respond promptly to any changes or challenges.

- Advanced Planning and Scheduling (APS) Systems: Utilize APS systems to optimize production schedules and capacity planning. These systems can account for changes in demand, lead times, and material availability, helping you adapt your production processes accordingly.

- Modular Design and Standardization: Encourage the use of modular design principles that enable easy swapping of components or subassemblies. Standardizing certain elements of the BOM can also improve efficiency by streamlining procurement and production processes.

- Buffer Stocks and Safety Margins: Maintain buffer stocks of critical components or materials to safeguard against supply chain disruptions. Safety margins in production schedules can also help accommodate unexpected changes without causing delays.

- Supplier Collaboration and Risk Management: Work closely with suppliers and establish strong relationships to have better visibility into their capabilities and potential risks. Diversify your supplier base to reduce dependency on a single source.

- Continuous Improvement and Lean Manufacturing: Embrace lean manufacturing principles to eliminate waste and optimize production processes continually. Regularly review and update BOMs and production workflows to identify areas for improvement.

- Use of Technology and Analytics: Leverage technologies such as Internet of Things (IoT) sensors, RFID tracking, and data analytics to gain real-time insights into the supply chain. This data-driven approach can help you identify bottlenecks and areas where flexibility can be improved.

- Scenario Planning and Risk Assessment: Conduct scenario planning exercises to evaluate how changes in demand, regulations, or supply chain disruptions could impact your production processes. This proactive approach helps you prepare for various contingencies.

- Employee Training and Empowerment: Invest in training your workforce to be adaptable and cross-functional. Empower employees to make decisions within their areas of expertise, enabling quicker responses to changes.

By integrating these strategies into your supply chain management practices, you can strike a balance between flexibility and efficiency while handling multi-level BOMs and adapting to changes effectively. Remember that a well-managed supply chain is a key driver of success in today's dynamic business environment.

Leveraging Technology: Advanced Software Solutions for Managing Multi-level BOMs

Managing Multi-level Bills of Materials (BOMs) can be a complex task, especially in industries like manufacturing, aerospace, automotive, and electronics. Leveraging advanced software solutions can significantly improve efficiency, accuracy, and collaboration throughout the BOM management process. Here are some key features and benefits of using advanced software solutions for managing Multi-level BOMs:

- Centralized Database: Advanced BOM management software provides a centralized database to store all BOM-related information. This ensures that everyone involved in the product development process has access to the most up-to-date data, reducing the risk of errors and discrepancies.

- Version Control: Multi-level BOM management software typically includes version control functionality, enabling users to track changes made to BOMs over time. This allows for easy retrieval of previous versions and helps in maintaining an audit trail.

- Real-time Collaboration: With cloud-based BOM management solutions, multiple teams or stakeholders can collaborate in real time on BOMs, regardless of their location. This promotes efficient communication and reduces delays in decision-making.

- Automated BOM Generation: Advanced software can automatically generate BOMs based on product configurations, CAD models, or other data sources. This saves time and minimizes the risk of manual entry errors.

- Bill of Materials Visualization: Software with visualization capabilities allows users to view the BOM hierarchy in an easy-to-understand format, making it simpler to grasp the relationships between various components and subassemblies.

- Change Management and Notifications: The software can manage change requests, track revisions, and send notifications to relevant stakeholders whenever a change is implemented. This ensures that everyone is aware of updates and can adapt their processes accordingly.

- Integration with PLM and ERP Systems: Integration with Product Lifecycle Management (PLM) and Enterprise Resource Planning (ERP) systems ensures seamless data flow between different stages of product development and production. This reduces data duplication and improves overall process efficiency.

- Cost Estimation and Analysis: Advanced BOM management software often includes cost estimation tools that help in analyzing the cost impact of design changes and in identifying cost-saving opportunities.

- Compliance and Regulation Management: For industries with strict regulatory requirements, the software can assist in ensuring that products comply with relevant regulations and standards.

- Simulation and Visualization: Some solutions may offer simulation and 3D visualization features, allowing teams to evaluate the impact of design changes on product performance and visualize the final product.

- Supply Chain Collaboration: Software with supply chain collaboration capabilities enables manufacturers to communicate directly with suppliers and track the availability of components in real time.

- Analytics and Reporting: Advanced software can provide insights into BOM data through analytics and reporting features. This allows businesses to identify trends, inefficiencies, and opportunities for improvement.

In conclusion, leveraging advanced software solutions for managing Multi-level BOMs can enhance productivity, reduce errors, foster collaboration, and streamline the product development process. Businesses that adopt these technologies gain a competitive advantage by efficiently bringing high-quality products to market faster and at a lower cost.

Case Studies: Real-world Success Stories of Multi-level BOM Implementation

- Apple Inc.: Apple is renowned for its supply chain management and product development processes. Their multi-level BOM implementation has been critical to efficiently producing a wide range of products, including iPhones, iPads, and MacBooks.

The ability to manage complex BOM structures with numerous sub-assemblies and components has allowed them to streamline manufacturing and reduce lead times.

- Boeing: Aerospace companies like Boeing deal with intricate assemblies and thousands of parts for their aircraft. Implementing multi-level BOMs helps them manage the various components needed for each airplane model efficiently.

This approach ensures smooth production and enables them to keep track of component revisions and substitutions, enhancing the overall quality of their aircraft.

- Toyota: Toyota, a leader in the automotive industry, has successfully implemented multi-level BOMs in its manufacturing process. Their BOM management has allowed them to optimize production and manage inventory efficiently, contributing to their reputation for reliability and quality.

- General Electric (GE): GE's diverse portfolio, spanning power generation, aviation, healthcare, and more, demands an effective BOM implementation to manage the complexity of its products. Multi-level BOMs have helped GE streamline their production processes and ensure the accuracy of product structures.

- Procter & Gamble (P&G): As a consumer goods company with a vast product range, P&G relies on multi-level BOMs to manage the various components and packaging materials for their products. The implementation of BOMs has improved their supply chain visibility, reducing costs and enhancing productivity.

Best Practices for Implementing Multi-level BOMs in Your Manufacturing Process

Implementing multi-level Bills of Materials (BOMs) in your manufacturing process can be a complex task, but it is crucial for efficient production and inventory management. Here are some best practices to consider when implementing multi-level BOMs:

- Accurate Data Management: Ensure that all BOM data is accurate, up-to-date, and easily accessible. Use a centralized database or an Enterprise Resource Planning (ERP) system to manage BOMs, and establish a clear version control process to track changes.

- Clear Hierarchical Structure: Organize BOMs in a clear hierarchical structure, with parent assemblies at the top level and sub-assemblies at lower levels. This hierarchy allows you to understand the relationships between components and assemblies, making it easier to manage the manufacturing process.

- Standardization of Part Numbers: Use standardized part numbers and naming conventions to avoid confusion and improve communication across different departments and suppliers.

- BOM Revision Control: Implement a revision control system to manage changes to BOMs. This ensures that everyone is working with the latest version and helps avoid costly production errors due to outdated information.

- Integration with Inventory Management: Integrate your BOMs with inventory management systems to maintain optimal stock levels of raw materials and components required for production. This integration will help prevent shortages and overstocking.

- Real-time Visibility: Implement a system that provides real-time visibility into the status of each level of the BOM. This helps you track production progress, identify bottlenecks, and respond quickly to any issues that may arise during the manufacturing process.

- Automated Material Requirements Planning (MRP): Utilize MRP software to automatically generate material requirements based on demand forecasts, sales orders, and lead times. This will help streamline the procurement process and optimize inventory levels.

- Supplier Collaboration: Foster good relationships with suppliers and involve them in the BOM management process. Regularly communicate with them about changes, lead times, and potential issues to ensure a smooth supply chain.

- Clear Documentation: Provide detailed documentation for each level of the BOM, including assembly instructions, part specifications, and any special handling requirements. This documentation is crucial for training new employees and ensuring consistent production quality.

- Regular Audits and Reviews: Conduct regular audits and reviews of your BOMs to identify any discrepancies, inaccuracies, or inefficiencies. Continuous improvement is key to optimizing your manufacturing process.

- Risk Assessment: Identify critical components and potential supply chain risks. Have contingency plans in place to mitigate disruptions, such as alternative suppliers or buffer stock.

- Training and Communication: Ensure that all relevant staff members, including production, purchasing, and engineering teams, are adequately trained in managing multi-level BOMs. Effective communication among these departments is essential for successful implementation.

By following these best practices, you can streamline your manufacturing process, improve efficiency, and minimize errors and delays caused by multi-level BOM complexities.

The Future of Manufacturing Complexity: Embracing Innovation with Multi-level BOMs

As of my last update in September 2021, I can provide insights into the potential future of manufacturing complexity and how Multi-level Bills of Materials (BOMs) could play a significant role in embracing innovation.

- Rise of Advanced Technologies: The future of manufacturing is likely to witness the integration of advanced technologies like Artificial Intelligence (AI), the Internet of Things (IoT), robotics, and additive manufacturing (3D printing). These technologies will enable greater automation, customization, and efficiency in the manufacturing process.

- Increased Product Customization: With the advent of technologies like 3D printing, manufacturers will be able to offer more personalized and customized products to consumers. This level of customization will require complex BOMs that can accommodate various product configurations and options.

- Demand for Smaller Batch Production: As consumer preferences shift towards more niche and unique products, there will be an increasing demand for smaller batch production runs. Multi-level BOMs will be essential in managing the intricacies of producing different product variations in smaller quantities.

- Supply Chain Integration: Manufacturing will become more interconnected with supply chains, allowing for real-time data sharing and collaboration between manufacturers and suppliers. Multi-level BOMs will play a crucial role in maintaining accurate inventory levels, managing lead times, and optimizing the supply chain.

- Complexity in Product Assembly: Innovative products might involve intricate assemblies with components coming from various sources. Multi-level BOMs will help manufacturers understand the dependencies and relationships between components, ensuring a streamlined assembly process.

- Risk Management and Compliance: With complex supply chains and intricate manufacturing processes, the risk of errors or non-compliance increases. Multi-level BOMs can aid in identifying potential risks and ensuring adherence to quality standards and regulations.

- Digital Twin Technology: The concept of the digital twin, a virtual representation of a physical product or process, will gain prominence in the manufacturing industry. Multi-level BOMs will be integral to creating and maintaining accurate digital twins, facilitating simulation, optimization, and predictive maintenance.

- Sustainability and Circular Economy: Manufacturing complexity will also be influenced by a growing emphasis on sustainability and the circular economy. Manufacturers will need to manage BOMs to account for recyclability, eco-friendly materials, and efficient resource usage.

- Collaborative Design and Engineering: Multi-level BOMs will encourage greater collaboration between design and engineering teams. As product development becomes more iterative and agile, BOMs will need to adapt quickly to accommodate design changes.

- Data-Driven Decision-Making: In the future, manufacturing processes will be increasingly data-driven. Multi-level BOMs, when combined with analytics and AI, will provide valuable insights that can improve decision-making, enhance efficiency, and reduce costs.

In summary, the future of manufacturing complexity will be marked by the adoption of advanced technologies, increased customization, and interconnected supply chains. Multi-level BOMs will serve as a crucial tool in managing this complexity, enabling manufacturers to embrace innovation, improve efficiency, and stay competitive in an evolving market.

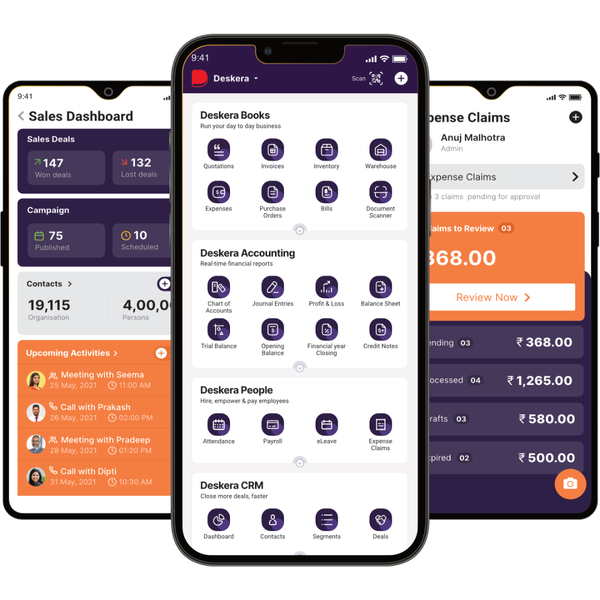

How Can Deskera Assist You?

Deskera ERP and MRP system can help you:

- Manage production plans

- Maintain Bill of Materials

- Generate detailed reports

- Create a custom dashboard

Deskera ERP is a comprehensive system that allows you to maintain inventory, manage suppliers, and track supply chain activity in real-time, as well as streamline a variety of other corporate operations.

Deskera MRP allows you to closely monitor the manufacturing process. From the bill of materials to the production planning features, the solution helps you stay on top of your game and keep your company's competitive edge.

Deskera Books enables you to manage your accounts and finances more effectively. Maintain sound accounting practices by automating accounting operations such as billing, invoicing, and payment processing.

Deskera CRM is a strong solution that manages your sales and assists you in closing agreements quickly. It not only allows you to do critical duties such as lead generation via email, but it also provides you with a comprehensive view of your sales funnel.

Deskera People is a simple tool for taking control of your human resource management functions. The technology not only speeds up payroll processing but also allows you to manage all other activities, such as overtime, benefits, bonuses, training programs, and much more. This is your chance to grow your business, increase earnings, and improve the efficiency of the entire production process.

Related Articles: