How can businesses build supply chains that remain stable when markets shift, disruptions escalate, and customer expectations rise every year? The answer increasingly lies in real-time visibility—the ability to track goods, processes, and performance across the supply chain as they happen. In an environment where delays can ripple across global networks within hours, having accurate, up-to-the-minute insights has become essential for making faster, smarter decisions.

However, visibility remains one of the biggest gaps in modern supply chains. Recent supply chain visibility statistics reveal that 69% of companies still lack end-to-end visibility, while only 6% have full visibility across their operations. Another 62% report having only limited visibility, often relying on fragmented systems or manual reporting. These blind spots prevent businesses from anticipating disruptions, reducing risks, optimizing costs, and meeting customer expectations such as faster delivery times. Despite this, visibility continues to emerge as a top strategic priority globally—especially among larger enterprises that understand its direct connection to resilience and performance.

The shift toward real-time visibility is not just about technology; it is about equipping organizations with the ability to sense and respond. Businesses that invest in stronger visibility frameworks are better positioned to identify shortages early, track logistics delays, collaborate with suppliers, and adjust production before issues escalate. This proactive capability is what differentiates resilient supply chains from reactive ones that struggle to adapt.

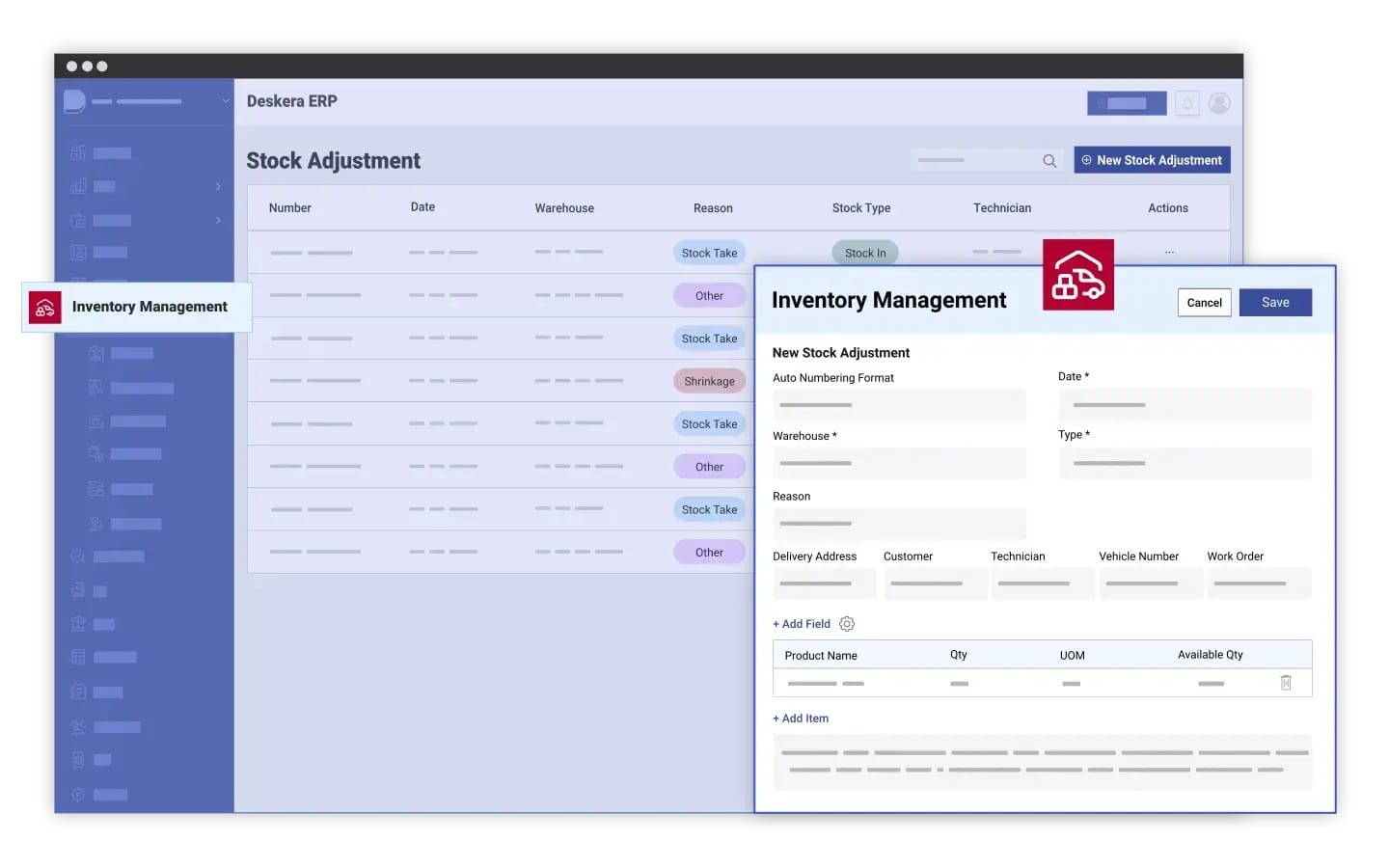

Modern cloud systems like Deskera ERP play a pivotal role in making real-time visibility accessible to businesses of all sizes. With features such as real-time inventory tracking, automated demand forecasting, integrated procurement, and mobile accessibility, Deskera ERP unifies supply chain data into a single, live platform. Its AI assistant, David, also provides predictive alerts and insights that help teams act faster and more confidently. By enabling end-to-end transparency, Deskera ERP supports companies in building supply chains that are agile, informed, and resilient.

What Is Real-Time Supply Chain Visibility?

Real-time supply chain visibility refers to an organization’s ability to monitor the movement of goods, inventory levels, supplier activities, production status, and logistics events as they happen—across every stage of the supply chain. Unlike traditional visibility, which relies on periodic updates or manual reports, real-time visibility provides continuous, live insights generated through integrated systems, IoT devices, cloud platforms, and advanced analytics.

At its core, real-time visibility ensures that every stakeholder—from procurement and production teams to logistics partners and customers—has access to accurate, up-to-date information. This transparency enables businesses to identify potential issues early, forecast demand more precisely, and make informed decisions without delay. Whether it’s tracking a shipment in transit, monitoring inventory across multiple warehouses, or evaluating supplier performance, the flow of real-time data allows operations to run more smoothly and predictably.

Real-time visibility also eliminates the guesswork that often exists in complex supply chains. With multiple vendors, production sites, carriers, and distribution channels involved, even small disturbances can remain hidden until they evolve into costly problems. By creating a unified, live view of the entire network, businesses gain the ability to anticipate risks, correct course quickly, and maintain consistent service levels—even during disruptions.

In today’s fast-paced markets, real-time visibility is no longer a “nice to have.” It is a foundational capability that empowers companies to adapt swiftly, operate efficiently, and build supply chains that can withstand unforeseen challenges. As customer expectations, global uncertainties, and supply chain complexities continue to rise, organizations that invest in real-time visibility set themselves apart with agility, reliability, and smarter decision-making.

Why Real-Time Visibility Matters in Today’s Supply Chains

In an era defined by rapid market shifts, global disruptions, and rising customer expectations, real-time visibility has become a critical differentiator for supply chain success. Businesses can no longer rely on periodic updates or outdated reports—operations now demand continuous, accurate, and actionable insights. Real-time visibility empowers organizations to respond faster, operate more efficiently, and strengthen resilience across every link in the supply chain.

Below are the key reasons why real-time visibility is essential in today’s dynamic supply chain environment:

1. Rapidly Changing Customer Expectations

Customers now expect faster delivery, real-time updates, and seamless service across channels. Without real-time visibility, businesses struggle to offer transparency or meet promised timelines. Live tracking data helps organizations plan better, communicate accurately with customers, and deliver consistent service despite fluctuating demand.

2. Increasing Global Disruptions

Supply chains face continuous disruptions—from geopolitical tensions and port delays to climate-related events and raw material shortages. Real-time visibility allows companies to detect disruptions instantly and take proactive actions such as rerouting shipments, adjusting production schedules, or sourcing from backup suppliers. This minimizes downtime and reduces operational losses.

3. The Complexity of Multi-Tier Supply Chains

Today’s supply chains span multiple suppliers, manufacturers, and logistics partners across regions. Limited visibility makes it challenging to identify bottlenecks or assess supplier performance. Real-time insights provide multi-tier transparency, enabling organizations to monitor supplier reliability, evaluate risks, and maintain stable operations even when working with diverse partners.

4. Need for Faster, Data-Driven Decisions

Decision-making in modern supply chains must be quick, accurate, and evidence-based. Real-time visibility provides the live data required to identify problems early, optimize workflows, improve inventory accuracy, and strengthen planning. With timely insights, businesses reduce uncertainty, enhance agility, and increase the overall speed and quality of operational decisions.

How Real-Time Visibility Enhances Supply Chain Resilience

Real-time visibility is the backbone of a resilient supply chain. In a world where disruptions—from supplier delays to transportation bottlenecks—can occur without warning, having immediate access to accurate information across the entire network is critical. It empowers companies to detect risks early, react faster to unexpected events, and ensure operational continuity even under severe pressure.

Instead of relying on reactive “firefighting,” real-time visibility enables organizations to work proactively, anticipate problems, and take corrective action before issues escalate. Below are the key ways real-time visibility directly strengthens supply chain resilience.

1. Improves Risk Identification and Early Warning

Real-time data allows companies to identify disruptions the moment they occur. Whether it’s a delayed shipment, a production bottleneck, a quality issue, or a sudden inventory shortage, early detection provides a valuable head start.

With real-time alerts, supply chain teams can:

- Reroute shipments before delays worsen

- Activate backup suppliers

- Adjust procurement or production

- Identify exceptions at the line-item level

Without visibility, these issues go unnoticed until downstream impacts—missed deadlines, revenue loss, or chargebacks—begin to surface. Many businesses describe this lack of transparency as the “black hole,” where orders disappear from view and no one can trace what went wrong.

2. Strengthens Demand and Inventory Planning

Real-time visibility offers accurate insight into stock levels, demand fluctuations, and replenishment needs—leading to smarter planning and smoother operations. It helps companies:

- Prevent stockouts by identifying shortages early

- Reduce excess inventory

- Eliminate the bullwhip effect

- Maintain steady production schedules

With real-time order and shipment visibility, businesses can also reconcile invoices, purchase orders, and receipts effortlessly through automated 3-way and 4-way matching. This reduces errors, improves inventory accuracy, and optimizes working capital.

3. Enhances Logistics and Shipment Tracking

Knowing exactly where goods are—and when they will arrive—is essential for resilience. Real-time shipment tracking provides continuous updates on shipment location, ETA, and potential delays. This enables better:

- Route optimization

- Carrier coordination

- Delivery commitment accuracy

- Exception handling

With 69% of consumers less likely to shop again if their order is delivered late, real-time visibility becomes essential for protecting customer satisfaction and brand reputation.

4. Boosts Supplier Performance Management

Multi-tier visibility helps companies monitor supplier performance at every level. Businesses can track:

- Lead times

- Delivery accuracy

- Quality metrics

- SLA compliance

Real-time insight helps identify weak suppliers early, prevent bottlenecks, and diversify the supplier base to reduce dependency risks. When businesses can clearly see supplier-related gaps, they are better positioned to negotiate, collaborate, and improve outcomes.

5. Supports Agile Decision-Making During Disruptions

During disruptions, agility is everything. Real-time visibility gives leaders the immediate data they need to make confident decisions such as:

- Switching to alternative suppliers

- Adjusting production schedules

- Prioritizing urgent orders

- Reallocating inventory across locations

- Expediting critical shipments

With proactive alerts and exception rules, businesses reduce chargebacks, avoid penalties, and maintain service levels. This agility becomes especially crucial considering that manufacturers and distributors lose nearly 8% of their revenue to chargebacks annually.

6. Enables Proactive Disruption and Risk Mitigation

According to the Business Continuity Institute, 72% of companies that faced supply chain disruptions lacked the real-time visibility needed to respond effectively. Real-time visibility helps businesses:

- Monitor developing risks

- Track trends and shifting priorities

- Manage disruptions before they turn costly

- Maintain continuity even during major breakdowns

When teams can see every order, shipment, document, and exception clearly, they gain the power to stay ahead of risk instead of reacting after damage occurs.

7. Improves Customer Satisfaction and Business Retention

A resilient supply chain is directly linked to customer experience. Real-time visibility helps businesses:

- Respond to customer inquiries accurately

- Resolve discrepancies quickly

- Provide reliable delivery estimates

- Improve fill rate and on-time performance

Organizations that invest in visibility often see strong improvements in performance. In fact, companies using robust visibility tools report:

- 65% improvement in customer satisfaction

- 50% reduction in avoidable fines and fees

- 55% less time spent searching for documents

- 30% reduction in revenue leakage

Real-time visibility enhances not just operational resilience, but also customer loyalty and long-term business growth.

Key Technologies Enabling Real-Time Visibility

Real-time supply chain visibility is possible only because of powerful, interconnected technologies that collect, transmit, and analyze data continuously. These tools help companies monitor each stage of their supply chain—from suppliers to warehouses to customers—without delays or blind spots. Together, they create a single source of truth that supports faster decision-making, agility, and operational control.

Below are the core technologies that make real-time visibility achievable in modern supply chains.

1. Internet of Things (IoT) Sensors

IoT devices such as GPS trackers, RFID tags, temperature sensors, and telematics units provide live updates on the location, condition, and movement of goods. They enable businesses to:

- Track shipments, vehicles, and containers in real time

- Monitor temperature, humidity, vibration, or spoilage risks

- Improve traceability from manufacturing to delivery

- Detect delays or anomalies instantly

IoT acts as the “eyes and ears” of the supply chain, offering accurate, continuous data from every touchpoint.

2. RFID and Barcode Scanning Systems

RFID tags and barcodes automate identification and verification of products, pallets, and shipments. They capture data instantly without manual entry, allowing organizations to:

- Track inventory movement across warehouses

- Improve picking, packing, and receiving accuracy

- Reduce errors caused by manual data entry

- Maintain real-time stock visibility

RFID’s ability to scan multiple items simultaneously makes it especially valuable for high-volume operations.

3. Cloud-Based Supply Chain Platforms

Cloud technology ensures all supply chain data is stored, synced, and accessible in real time across locations and devices. These platforms enable:

- Seamless collaboration between suppliers, warehouses, and logistics partners

- Centralized dashboards for end-to-end visibility

- Faster deployment compared to traditional on-premise systems

- Scalability as the business grows

Cloud infrastructure forms the backbone of modern visibility platforms, integrating all other technologies into one unified system.

4. AI and Predictive Analytics

Artificial intelligence transforms raw supply chain data into actionable insights. With machine learning and predictive models, companies can:

- Forecast demand more accurately

- Predict disruptions before they occur

- Optimize inventory levels

- Suggest ideal routes or reorder points

- Detect patterns in supplier or logistics performance

AI shifts companies from reactive management to proactive, insight-driven decision-making.

5. Real-Time Transportation Management Systems (TMS)

Modern TMS platforms monitor shipment movements across carriers, routes, and regions. They provide:

- GPS-enabled tracking

- Real-time ETA updates

- Route optimization

- Carrier performance reporting

- In-transit issue alerts

A TMS ensures continuous transparency across the logistics network, reducing delays, detention fees, and miscommunication.

6. Advanced Warehouse Management Systems (WMS)

A WMS provides real-time visibility into all warehouse activities, including:

- Stock levels across multiple locations

- Putaway, picking, and packing workflows

- Order status, fill rate, and lead times

- Worker productivity and equipment utilization

Integrated WMS solutions eliminate bottlenecks and ensure accurate inventory movement across the value chain.

7. Blockchain Technology

Blockchain enhances visibility through secure, tamper-proof data sharing. It enables:

- Transparent, traceable records of every transaction

- Multi-party collaboration without data manipulation

- Faster dispute resolution

- Stronger compliance and auditability

This is especially useful for industries that demand high traceability, such as pharmaceuticals, food, and luxury goods.

8. API Integrations and EDI Systems

APIs and EDI allow systems across suppliers, carriers, and distributors to exchange data instantly. They support:

- Real-time updates between trading partners

- Automated document exchange (POs, ASNs, invoices)

- Faster order processing

- Reduced communication delays

APIs are ideal for real-time connectivity, while EDI remains essential for standardized B2B communication.

9. Digital Twin Technology

Digital twins create virtual replicas of supply chain assets, allowing businesses to simulate scenarios and identify risks. They help companies:

- Model demand changes or disruptions

- Optimize inventory and logistics strategies

- Predict system failures or bottlenecks

- Test improvements without operational risk

Digital twins turn real-time data into powerful visual simulations for smarter planning.

Benefits of Real-Time Visibility for Business Performance

Real-time visibility is no longer just an operational advantage—it is a strategic enabler of business performance and long-term growth. When companies gain continuous insight into their inventory, orders, production, and logistics, they unlock the ability to make faster decisions, reduce inefficiencies, and deliver superior customer experiences. This transparency not only improves day-to-day operations but strengthens financial performance, competitiveness, and resilience across the entire value chain.

Below are the key business benefits that real-time visibility delivers.

1. Improves Forecast Accuracy and Demand Planning

Real-time visibility ensures companies always have accurate, up-to-date data on stock levels, sales trends, and replenishment needs. This enables better forecasting and planning by:

- Reducing guesswork in demand predictions

- Preventing stockouts and overstocks

- Aligning production schedules with actual demand

- Avoiding the bullwhip effect across the supply chain

With more precise planning, businesses can optimize inventory investment and reduce carrying costs.

2. Enhances Operational Efficiency

When all stakeholders can view orders, shipments, inventory, and workflows in real time, operations become significantly more efficient. Visibility helps organizations:

- Identify bottlenecks quickly

- Reduce manual data entry and duplication

- Streamline procurement, warehousing, and fulfillment processes

- Improve order accuracy and processing times

The result is a leaner, faster supply chain that maximizes productivity and minimizes wasted effort.

3. Reduces Costs Across the Supply Chain

Real-time monitoring helps companies avoid disruptions and inefficiencies that often lead to unnecessary costs. It reduces:

- Emergency procurement and expedited shipping fees

- Chargebacks, fines, and penalties

- Revenue leakage caused by errors or delays

- Excess inventory and storage costs

By detecting problems early, businesses can correct issues before they become expensive setbacks.

4. Strengthens Supplier Collaboration and Accountability

Visibility into supplier performance—such as delivery timelines, fill rates, and quality metrics—creates a more transparent and accountable ecosystem. Companies benefit through:

- Better communication with suppliers and carriers

- Faster dispute resolution

- Improved trust and reliability

- Easier identification of high-risk or underperforming vendors

This level of oversight helps businesses build stronger, more stable supplier networks.

5. Enables Faster, Data-Driven Decision-Making

With real-time access to accurate data, decision-makers no longer rely on outdated reports or intuition. Visibility empowers leaders to:

- React to disruptions immediately

- Reallocate inventory intelligently

- Adjust production or procurement on the fly

- Prioritize high-impact issues

Fast, informed decisions help businesses maintain continuity, even when faced with sudden changes.

6. Enhances Customer Experience and Retention

Customers today expect full transparency and timely delivery. Real-time visibility enables businesses to meet these expectations by:

- Providing accurate delivery dates

- Minimizing delays and order errors

- Offering real-time tracking for orders

- Responding to customer inquiries instantly

Higher satisfaction leads to increased retention, stronger loyalty, and a competitive edge in the market.

7. Improves Compliance, Traceability, and Quality Control

Industries with strict regulatory requirements benefit significantly from end-to-end traceability. Real-time visibility supports:

- Detailed tracking of materials and product batches

- Immediate quality alerts

- Faster root-cause analysis

- Stronger audit readiness

Businesses can maintain compliance effortlessly while reducing risks related to recalls or regulatory penalties.

8. Boosts Overall Supply Chain Resilience

The most important benefit is resilience. Real-time visibility helps companies:

- Detect early signs of disruption

- Respond quickly and proactively

- Maintain production stability

- Reduce downtime and performance dips

A more resilient supply chain delivers stronger business continuity, even during economic, environmental, or geopolitical uncertainty.

Common Challenges Organizations Face When Implementing Visibility

While real-time visibility delivers significant value, many organizations struggle to implement it successfully. Legacy systems, fragmented data, and resistance to change often create barriers that slow down digital transformation efforts. Understanding these challenges is essential for designing a visibility strategy that is realistic, scalable, and aligned with long-term business goals.

Below are the most common obstacles companies face when implementing real-time supply chain visibility.

1. Fragmented and Siloed Data Across Systems

Many organizations use multiple disconnected systems—ERP, WMS, TMS, procurement tools, spreadsheets, and supplier portals. This creates data silos that make it difficult to establish a single source of truth.

Key issues include:

- Inconsistent data formats across departments

- Delayed or missing information

- Manual reconciliations leading to errors

- Limited visibility across multi-tier suppliers

Without integration, real-time visibility is impossible, as data cannot flow seamlessly across the supply chain.

2. Legacy Technology and Outdated Infrastructure

Older systems lack the flexibility and real-time capabilities required for visibility initiatives. They often:

- Cannot integrate with modern cloud platforms

- Limit automation and real-time data capture

- Require manual updates that slow decision-making

- Fail to scale with growing data volumes

These limitations force companies to either upgrade or replace legacy systems—an investment many hesitate to make.

3. Lack of Supplier and Partner Collaboration

Visibility requires participation from external partners, including suppliers, carriers, distributors, and 3PLs. However, many partners may:

- Operate on outdated systems

- Hesitate to share data due to privacy or competitive concerns

- Lack standardized processes

- Provide limited insight beyond first-tier operations

This lack of collaboration creates blind spots that undermine true end-to-end visibility.

4. Poor Data Quality and Inconsistent Reporting

Even with advanced tools, visibility initiatives fail if the underlying data is inaccurate or incomplete. Common problems include:

- Duplicate or missing data

- Incorrect inventory records

- Delays in updating order status

- Errors caused by manual entry

Bad data leads to bad decisions—especially in real-time scenarios where companies rely on data for rapid action.

5. High Implementation Costs and Complex ROI Justification

Implementing end-to-end visibility often requires investments in:

- IoT sensors

- Warehouse automation tools

- Cloud platforms

- Integration layers

- Advanced analytics

For some organizations, especially small and mid-sized ones, these costs may seem overwhelming. Additionally, visibility benefits are often indirect—reduced disruptions, improved accuracy, fewer fines—making ROI harder to quantify upfront.

6. Resistance to Change Among Internal Teams

Employees accustomed to traditional workflows may resist adopting new tools. Challenges include:

- Fear of automation replacing jobs

- Reluctance to learn new software

- Preference for manual or familiar processes

- Misalignment between IT and operations teams

Without proper training and communication, visibility solutions often face internal pushback.

7. Complex Integration with Existing Systems

Integration is one of the most difficult and time-consuming aspects of visibility implementation. Organizations must connect:

- ERP

- WMS

- TMS

- Supplier platforms

- Financial systems

- API and EDI networks

Lack of standardization or incompatible data structures makes integration challenging, leading to delays or incomplete deployment.

8. Security, Compliance, and Data Privacy Concerns

Sharing real-time data across partners and platforms raises security risks, including:

- Unauthorized access

- Data breaches

- Compliance violations (GDPR, industry-specific standards)

- Loss of sensitive supplier or pricing information

Organizations must invest in strong cybersecurity controls before enabling widespread data access.

9. Difficulty Scaling Across Multiple Regions or Business Units

What works for one facility or region may not work for another. Challenges include:

- Varying regulatory requirements

- Different supplier capabilities

- Inconsistent digital maturity

- Multiple languages or currencies

Scaling visibility globally requires careful planning and a platform that supports diverse business needs.

10. Limited Skilled Resources and Technical Expertise

Real-time visibility projects demand specialized skills in data analytics, integration, automation, and cloud technologies. Many organizations struggle with:

- Shortage of skilled IT professionals

- Dependence on external consultants

- Slow internal adoption of digital tools

This knowledge gap often delays progress and reduces the overall effectiveness of visibility initiatives.

Best Practices to Improve Real-Time Visibility and Resilience

Building real-time visibility and a resilient supply chain requires more than adopting new tools—it demands a strategic, organization-wide approach. Companies must align technology, data, processes, and partners to create a transparent, agile, and predictive supply chain ecosystem. By following proven best practices, organizations can reduce risk, improve accuracy, and strengthen operational continuity even during disruption.

Below are the most effective best practices to enhance real-time visibility and long-term supply chain resilience.

1. Integrate All Systems Into a Unified Platform

One of the most critical steps is eliminating data silos. Businesses should integrate their ERP, WMS, TMS, procurement tools, and partner systems.

Benefits include:

- Seamless data flow across all functions

- A single source of truth for decision-making

- Reduced manual work and fewer discrepancies

- Faster access to real-time updates

Integration ensures end-to-end visibility from suppliers to customers.

2. Leverage IoT, RFID, and Sensor-Based Tracking

IoT sensors, RFID tags, GPS trackers, and telematics devices make it possible to monitor goods, equipment, and shipments continuously.

This helps organizations:

- Track exact shipment location and condition

- Prevent spoilage or damage

- Detect delays instantly

- Improve asset utilization

Sensor-enabled visibility strengthens accuracy and eliminates blind spots across the network.

3. Adopt Cloud-Based Supply Chain Management Tools

Cloud technology is essential for scalability, connectivity, and real-time collaboration.

Key advantages include:

- Centralized dashboards accessible from anywhere

- Faster deployment and lower IT maintenance

- Real-time updates across global operations

- Easy integration with partners and carriers

Cloud systems form the backbone of modern visibility-led supply chains.

4. Use Predictive Analytics for Anticipating Risks

AI and analytics help companies move from reactive to proactive supply chain management.

They enable businesses to:

- Forecast demand and supply fluctuations

- Predict equipment failures or bottlenecks

- Identify high-risk suppliers or routes

- Simulate “what-if” disruption scenarios

Predictive insights help organizations prepare for disruptions before they happen.

5. Strengthen Supplier and Partner Collaboration

Visibility must extend beyond your internal operations to multi-tier suppliers, logistics providers, and other partners.

Best practices include:

- Sharing real-time data and performance metrics

- Establishing communication protocols

- Setting clear expectations for updates and reporting

- Using standardized formats (EDI, APIs)

Collaboration reduces blind spots and creates a more stable and trustworthy supply chain ecosystem.

6. Standardize Data Collection and Reporting

Inconsistent data makes visibility unreliable. Set clear data standards for accuracy, timeliness, and formatting.

This helps:

- Improve reporting consistency

- Reduce errors caused by manual entry

- Ensure real-time dashboards reflect reality

- Enable better analysis across locations

Standardization ensures that visibility tools deliver accurate insights every time.

7. Implement Exception Management and Real-Time Alerts

Proactive exception handling prevents minor issues from turning into costly disruptions.

Companies should deploy alerts for:

- Delayed shipments

- Inventory shortages

- Quality deviations

- Failed or mismatched documents

- Supplier performance drop-offs

Instant notifications help teams respond in real time and stay ahead of operational risks.

8. Invest in Employee Training and Change Management

Technology alone cannot deliver visibility—people must know how to use it effectively.

Focus on:

- Building digital skills

- Training employees on dashboards and tracking tools

- Encouraging data-driven decision-making

- Overcoming resistance to new processes

A well-trained workforce ensures successful visibility implementation.

9. Establish KPIs and Continuously Monitor Performance

Visibility improves when companies measure what matters.

Key KPIs include:

- On-time delivery

- Order cycle time

- Inventory accuracy

- Lead time variability

- Supplier performance scores

Tracking KPIs helps identify gaps, optimize processes, and improve resilience over time.

10. Choose an ERP System That Supports Real-Time Monitoring

A modern, integrated ERP plays a central role in enabling visibility. It ensures unified data, automated workflows, and instant tracking across procurement, inventory, production, and logistics.

When selecting an ERP, look for:

- Real-time dashboards

- Multi-location inventory visibility

- Automated alerts and reporting

- Easy integration with WMS, TMS, and partner systems

- Mobile accessibility for field teams

An ERP built for visibility enables end-to-end control and strengthens operational resilience.

How Deskera ERP Helps Businesses Achieve Real-Time Visibility

Gaining end-to-end visibility across your supply chain requires more than isolated tools—it demands a unified system that connects data, processes, and people. Deskera ERP offers an integrated platform that helps businesses track inventory, orders, production, procurement, and financials in real time, ensuring complete operational clarity. Below are the key ways Deskera enables real-time visibility:

1. Unified, Cloud-Based Data for Always-On Monitoring

Deskera ERP centralizes all operational data—from procurement to delivery—into one cloud-based system. This eliminates data silos, ensuring every stakeholder works with accurate, real-time information at any moment.

2. Real-Time Inventory Tracking Across Locations

With multi-warehouse inventory visibility, stock levels, movements, and valuation updates happen instantly. Businesses can track incoming and outgoing inventory, batch details, expiry dates, and reorder alerts without delays.

3. Mobile Accessibility for On-the-Go Decision-Making

Deskera’s mobile app enables managers and teams to view dashboards, approve orders, track shipments, and monitor inventory from anywhere. This ensures faster response time, especially in fast-moving environments.

4. Integrated Procurement and Supplier Management

Deskera connects purchase orders, supplier lead times, vendor performance, and goods receipts in real time. This allows procurement teams to proactively adjust orders, avoid stockouts, and manage disruptions efficiently.

5. Automated Demand Forecasting and Production Planning

With built-in demand planning and MRP capabilities, Deskera forecasts material needs, identifies shortages, and recommends optimal production schedules. This enhances visibility into future requirements, not just current status.

6. Real-Time Alerts and Notifications

The system sends automated alerts for low stock, delayed shipments, pending approvals, and production bottlenecks. Businesses can act instantly instead of waiting for periodic reports.

7. Integrated Financial Visibility

Deskera links operational activities with financial modules, offering real-time insights into costs, cash flow, and profitability. This helps leaders evaluate the financial impact of supply chain decisions immediately.

8. Customizable Dashboards and Advanced Reporting

Deskera provides intuitive dashboards for monitoring supply chain KPIs, such as order fill rates, inventory turnover, lead times, and production efficiency. Users can generate custom reports and drill down into data for deeper visibility.

Key Takeaways

- Real-time supply chain visibility provides continuous, accurate, and end-to-end tracking of inventory, shipments, and operations, enabling companies to respond proactively rather than reactively.

- Modern supply chains demand speed and resilience, and real-time visibility ensures businesses can reduce disruptions, enhance agility, and meet rising customer expectations.

- IoT devices, RFID tags, cloud ERP systems, AI/ML analytics, and blockchain collectively deliver seamless data flow and accurate tracking across every stage of the supply chain.

- Enhanced visibility leads to fewer stockouts, improved forecasting, higher customer satisfaction, lower operational costs, and greater confidence in decision-making.

- Companies often struggle with data silos, legacy systems, integration complexity, poor data quality, and resistance to change, slowing down visibility initiatives.

- Successful visibility programs require cross-functional collaboration, process standardization, investment in scalable technology, and strong data governance.

- Deskera ERP unifies supply chain data across procurement, inventory, production, and finance, offering real-time tracking, automated alerts, and actionable insights to improve operational control.

Related Articles