Have you ever wondered why some businesses consistently receive materials on time while others face frequent delays? The answer often lies in one critical supply chain variable: supplier lead time. Whether you run a manufacturing unit or manage a retail operation, understanding how long it takes for your suppliers to deliver goods can make or break your operational rhythm. Supplier lead times influence everything from inventory levels to order fulfillment speed—and ultimately, customer satisfaction.

Supplier lead time refers to the total time between placing a purchase order and receiving the goods. While it may sound straightforward, even small fluctuations can disrupt production schedules, increase carrying costs, and strain cash flow. Companies that monitor this metric closely gain better control over demand planning, procurement, and stock availability. Those that ignore it often end up with excess inventory, stock-outs, or unplanned downtime.

In today’s fast-paced business environment, supplier lead times matter more than ever. With global supply chains becoming increasingly complex and unpredictable, businesses need accurate, real-time visibility into how long it takes for suppliers to fulfill orders. Proper lead time tracking helps teams anticipate risks, strengthen supplier relationships, and stay agile in the face of disruptions.

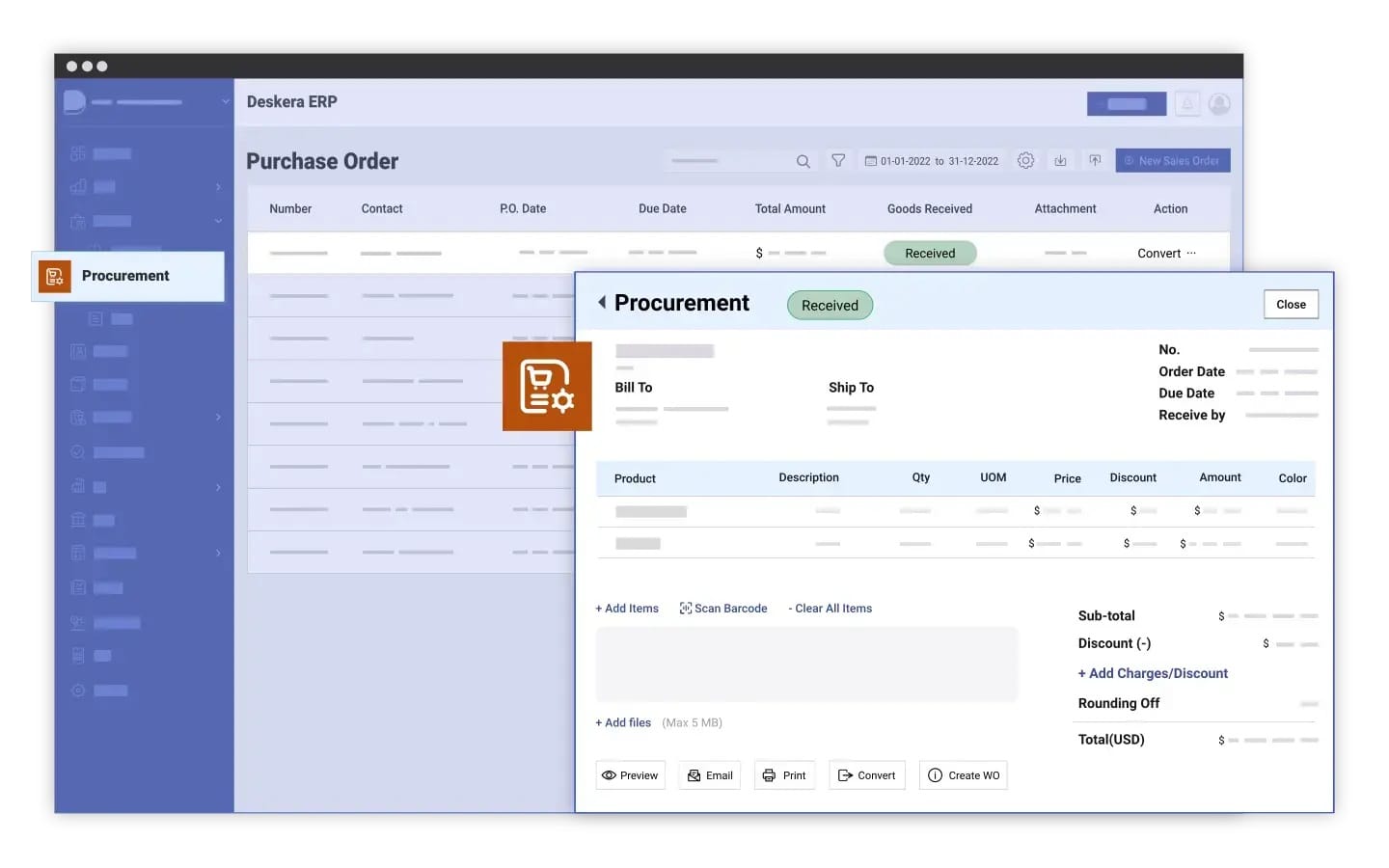

This is where modern tools like Deskera ERP play a crucial role. Deskera ERP offers real-time lead time tracking, automated purchase planning, and detailed supplier performance analytics—all within a single platform. By integrating procurement, inventory, and production data, it ensures businesses always have up-to-date information to make smarter decisions. With Deskera ERP, companies can reduce uncertainties, optimize inventory costs, and achieve higher supply chain responsiveness.

What Are Supplier Lead Times?

Supplier lead times refer to the total time between placing an order with a supplier and receiving the goods at your location. In other words, it is the elapsed time from order to receipt, as defined by the Association for Supply Chain Management (ASCM). This period includes several stages—order processing, production (if required), packaging, shipment, and final delivery. For custom-made or made-to-order items, lead time may also include the full manufacturing cycle, whereas for off-the-shelf products, it typically involves only order fulfillment and shipping.

Understanding supplier lead times is essential because it directly influences how effectively a business can plan inventory, schedule production, and meet customer demand. Even slight variations in lead times can disrupt operations, leading to stockouts, excess inventory, or production delays. Efficiently managing this metric helps businesses maintain the right stock levels, avoid bottlenecks, and ensure a smoother flow of materials across the supply chain.

Several factors influence supplier lead times, including the supplier’s capacity, product complexity, shipping method, and geographical distance between the buyer and the supplier. International orders may also face additional delays due to customs clearance, import procedures, and regulatory checks. Because of these variables, many businesses closely track or negotiate lead times with suppliers to improve efficiency, reduce costs, and minimize risks associated with supply chain disruptions.

A simple way to calculate supplier lead time is:

Supplier Lead Time = (Time of product receipt – Time of product order) / Total number of orders

When tracked consistently, this formula provides a reliable view of how long it typically takes for materials to arrive, helping businesses plan reorders more accurately and maintain operational stability.

Why Supplier Lead Times Matter

Supplier lead times play a crucial role in determining how smoothly a business can operate. When lead times are accurate and consistent, companies can plan inventory better, schedule production efficiently, and fulfill customer orders without delays. However, when lead times fluctuate, every part of the supply chain—from procurement to delivery—can feel the impact. Below are the key reasons why supplier lead times matter and how they influence overall business performance.

Impacts Inventory Levels

Accurate lead times help businesses maintain the right balance of stock. Longer lead times often force companies to carry more safety stock to avoid stockouts, increasing holding costs. Conversely, shorter and predictable lead times allow businesses to minimize inventory without risking shortages, resulting in lower storage and carrying expenses.

Improves Production Planning

When businesses know exactly how long it takes for materials to arrive, they can schedule production more effectively. Consistent lead times help prevent production stoppages, avoid last-minute rescheduling, and ensure that manufacturing processes run smoothly without material shortages.

Enhances Customer Satisfaction

Reliable lead times allow companies to meet delivery promises and respond quickly to demand changes. Faster replenishment means shorter order cycles and improved service levels. This consistency directly strengthens customer trust and customer loyalty, especially in industries where on-time delivery is critical.

Minimizes Supply Chain Risk

Monitoring lead time trends helps businesses identify potential issues early—such as supplier delays, capacity constraints, or transportation disruptions. By understanding these patterns, companies can take proactive steps like adjusting order quantities, exploring alternate suppliers, or modifying shipping methods to reduce supply chain uncertainty.

Direct Influence on Cash Flow

Lead times not only affect operational efficiency but also financial health. Longer lead times result in more capital tied up in inventory for extended periods. Shorter lead times improve working capital, allowing businesses to free up cash, reduce excess stock, and reinvest funds into other strategic areas of growth.

Key Factors That Affect Supplier Lead Times

Supplier lead times are influenced by a variety of operational, logistical, and external factors. Understanding these variables helps businesses anticipate delays, plan better, and set more accurate expectations with customers.

Below are the key factors that commonly affect how long it takes for suppliers to process, produce, and deliver an order.

Supplier Capacity and Workload

A supplier’s ability to handle orders efficiently depends heavily on their available production capacity. When suppliers face high demand, machine limitations, labor shortages, or peak-season pressure, lead times naturally increase. Efficient, well-staffed, and technologically equipped suppliers tend to process orders faster and more reliably.

Product Complexity

The nature of the product significantly impacts lead time. Standard, off-the-shelf items require little processing and can be shipped quickly. However, customized, made-to-order, or highly specialized products often require additional design, manufacturing, and quality checks—leading to longer and more variable lead times.

Quality of Supplier Communication

Clear and timely communication helps reduce misunderstandings, errors, and rework. If suppliers delay order confirmations, do not update status regularly, or lack a structured communication workflow, businesses may face unexpected delays. Strong communication bridges improve coordination, reduce discrepancies, and speed up fulfillment.

Shipping Method and Logistics Efficiency

The mode of transportation—air, sea, rail, or road—directly affects delivery speed. Air freight is faster but more expensive, whereas sea freight is cost-effective but slow. Logistics efficiency (such as route planning, carrier reliability, and warehouse handling time) also influences the overall lead time.

Geographical Distance Between Supplier and Buyer

The farther the supplier is from the buyer’s location, the longer the transit time. International shipments, remote manufacturing hubs, or cross-continent logistics often add several days or weeks. Local or regional suppliers typically offer shorter, more predictable lead times.

Customs, Regulations, and Compliance Requirements

For cross-border shipments, customs clearance, import/export documentation, inspection procedures, and government regulations can significantly extend lead times. Delays increase when paperwork is incomplete, tariffs change, or regulatory checks become more stringent.

Supplier Reliability and Process Efficiency

Suppliers with stable systems, streamlined workflows, and high on-time delivery performance can consistently meet committed lead times. Unorganized suppliers, outdated machinery, or inefficient workflows contribute to unpredictable and extended timelines.

External Disruptions and Market Conditions

Events such as natural disasters, port congestion, geopolitical tensions, strikes, fuel shortages, or economic instability can disrupt supply chains. These factors are often unpredictable and may cause sudden spikes in lead times, making contingency planning essential.

How to Reduce and Optimize Supplier Lead Times

Reducing and optimizing supplier lead times is essential for maintaining operational efficiency, improving inventory turnover, and staying competitive in today’s fast-paced market.

By adopting the right strategies and strengthening supplier relationships, businesses can shorten delivery cycles, create more predictable workflows, and reduce supply chain risk.

Below are effective ways to minimize lead times and achieve smoother, more reliable procurement operations.

Strengthen Supplier Relationships

Building strong, long-term partnerships encourages better collaboration and faster response times. When suppliers understand your business needs and trust your demand patterns, they often prioritize your orders, provide early updates, and work closely with you to resolve potential delays.

Use Reliable Local or Regional Suppliers

Shortening the physical distance between you and your suppliers can significantly reduce transit times. Local or regional suppliers often offer quicker shipping, fewer disruptions, and more predictable deliveries compared to international sources, especially for frequently used materials.

Automate Purchase Order Creation

Manual purchase orders slow down procurement. Automation through ERP systems helps generate POs instantly based on reorder points, demand forecasts, and stock levels. This reduces administrative delays and ensures timely order placement.

Share Demand Forecasts with Suppliers

Transparent communication about upcoming demand allows suppliers to plan production capacity, allocate resources, and prepare inventory in advance. Forecast sharing reduces unexpected bottlenecks and helps suppliers meet your lead time expectations more consistently.

Implement Vendor Managed Inventory (VMI)

VMI allows suppliers to monitor your inventory levels and replenish stock automatically when needed. This reduces delays in order approval cycles, eliminates stockouts, and ensures continuous material availability without lengthy back-and-forth communication.

Review Supplier Performance Regularly

Tracking metrics like on-time delivery rate, average lead time, and lead time variability helps identify which suppliers are consistently meeting expectations. Regular performance reviews enable businesses to address gaps, negotiate improvements, or switch to better-performing suppliers when necessary.

Allow Buffer Time for Critical Materials

For high-priority or frequently used items, adding a small buffer in procurement planning helps protect against unpredictable delays. While the goal is to reduce lead time, having a safety margin ensures smoother operations in case of supplier issues.

Use Digital Tools for Real-Time Visibility

Technologies like ERP systems, supplier portals, and shipment tracking tools offer real-time updates on order status. This transparency helps identify delays early, adjust production plans, and make quicker decisions to prevent disruptions.

Common Mistakes Businesses Make When Managing Supplier Lead Times

Managing supplier lead times may seem straightforward, but many businesses unintentionally make errors that lead to delays, increased costs, and operational inefficiencies. These mistakes often stem from assumptions, outdated processes, or inconsistent communication.

Understanding these pitfalls can help companies build stronger supplier relationships, streamline procurement, and maintain better control over their supply chain.

Relying Solely on Average Lead Times

Many businesses make the mistake of using only average lead times during planning. Averages don’t account for variability, seasonal fluctuations, or unexpected delays. This can result in inaccurate reorder points, leading to stockouts or excess inventory.

Not Accounting for Lead Time Variability

Lead times rarely remain constant. Production delays, transportation issues, or supplier capacity constraints can cause fluctuations. Failing to track variability prevents companies from building accurate safety stock levels or preparing for potential disruptions.

Poor Communication With Suppliers

A lack of timely communication—such as unclear specifications, delayed order confirmations, or no follow-up—often leads to misunderstandings and errors. Ineffective communication slows down the entire procurement cycle and increases the risk of late deliveries.

Using Outdated Lead Time Data

Many businesses calculate lead time once and never update it. However, supplier performance, logistics processes, and market conditions change over time. Using outdated lead time data results in inaccurate forecasting and poor decision-making.

Ignoring External Disruption Trends

Global events like port congestion, political instability, weather disruptions, or transportation strikes can significantly extend lead times. Companies that don’t monitor these trends are often caught off guard, affecting their ability to maintain continuity.

Not Diversifying Suppliers

Relying too heavily on a single supplier increases vulnerability. If that supplier faces delays, capacity issues, or quality problems, the entire supply chain suffers. Diversifying suppliers helps reduce risk and improve overall lead time reliability.

Lack of Supplier Performance Monitoring

Without regular evaluation, businesses miss signs of declining supplier reliability. Tracking metrics such as on-time delivery rates, quality issues, and lead time consistency is essential to maintaining strong supply chain performance.

Estimating Supplier Lead Times

Accurately estimating supplier lead times is essential for effective inventory planning, production scheduling, and maintaining consistent customer service levels.

While many businesses rely on the lead times quoted by suppliers, these estimates are not always dependable due to frequent fluctuations in production capacity, logistics, and external conditions. Instead, businesses can develop more accurate and reliable lead time estimates by analyzing their own purchasing and delivery data.

Below are the key methods companies can use to calculate realistic supplier lead times.

Analyze Historical Purchase Data

One of the most reliable ways to estimate supplier lead times is to examine past purchase order records. Buyers can review the time between placing an order and receiving the goods across multiple transactions for a specific supplier.

Key timestamps include the order placement date, supplier confirmation date, shipment dispatch date, and final delivery date.

Analyzing this data provides insights into average, minimum, and maximum lead times, helping businesses understand typical patterns and potential delays. This historical approach often proves more accurate than supplier-provided dates.

Evaluate Supplier Performance

Comparing actual delivery times with supplier-quoted lead times reveals how consistent a supplier truly is. Performance indicators—such as on-time delivery rates and frequency of missed deadlines—help buyers determine whether they can rely on the supplier’s commitments.

If discrepancies are common, businesses may need to build additional buffer time into their planning. Continuous performance tracking also highlights whether a supplier’s lead times are improving or declining over time.

Consider Variability Based on Order Type and Size

Lead times can vary significantly depending on the nature of the order. Customized, made-to-order products or large-volume purchases often take longer to produce and ship compared to standard, smaller orders.

Buyers can review historical data segmented by order size, product category, and complexity to identify patterns. Understanding how different order types influence lead times enables more precise planning and realistic expectations.

Factor in Transit Times

Transit time constitutes a major portion of lead time, especially for international shipments. Buyers should estimate transit durations based on shipping methods—air, sea, road, or rail—and the distance between their facility and the supplier’s location.

Historical shipping data can highlight recurring issues such as customs delays, port congestion, or carrier inefficiencies. Incorporating these insights helps create a more accurate picture of total lead time.

Account for External Variables and Seasonality

Lead times can be affected by external factors such as holiday seasons, labor strikes, weather disruptions, or geopolitical events. Buyers should consider how seasonality or market conditions historically impacted deliveries. Factoring in these variables allows businesses to anticipate and prepare for predictable fluctuations.

Use Predictive Tools and ERP Analytics

Modern ERP systems and supply chain analytics tools can automatically calculate estimated lead times by combining historical data, supplier performance metrics, and live shipment tracking. These tools identify trends and anomalies, helping businesses forecast lead times more accurately and adjust planning parameters accordingly.

How Deskera ERP Helps Businesses Manage and Optimize Supplier Lead Times

Managing supplier lead times becomes significantly easier and more efficient when businesses have access to real-time data, automated workflows, and integrated supply chain insights. Deskera ERP provides all these capabilities within a unified platform, helping companies track, analyze, and improve lead times with far greater accuracy.

By streamlining procurement, inventory, and supplier management processes, Deskera ERP enables businesses to reduce uncertainties, enhance planning, and maintain consistent operational flow.

Below are the key ways Deskera ERP supports effective lead time optimization.

Real-Time Lead Time Tracking

Deskera ERP continuously captures data from every purchase order—right from order creation to final receipt. It automatically calculates actual lead times for each supplier, allowing businesses to compare real-world performance with promised timelines. This real-time visibility helps identify delays early and improves forecasting accuracy.

Automated Purchase Planning and PO Generation

The system uses intelligent automation to generate purchase orders based on reorder levels, demand forecasts, and historical lead time trends. By eliminating manual processes, Deskera reduces administrative delays and ensures that orders are placed at the right time, preventing stockouts and last-minute rush orders.

Supplier Performance Analytics

Deskera ERP includes detailed analytics dashboards that track supplier reliability, on-time delivery rates, average lead times, and lead time variability. These insights enable businesses to identify dependable suppliers, negotiate better timelines, and address performance issues proactively. Over time, it helps build a more resilient supplier network.

Integrated Inventory and Procurement Data

Because Deskera ERP integrates inventory, procurement, finance, and production modules, businesses gain complete visibility across their supply chain. This integration ensures that any delays in lead time immediately reflect in production schedules, stock levels, and purchase planning—making it easier to adjust operations without disruption.

Demand Forecasting and Inventory Optimization

Using advanced forecasting tools, Deskera ERP predicts future demand and aligns it with supplier lead time patterns. This helps businesses plan reorders more accurately, reduce excess inventory, and maintain optimal stock levels even during periods of fluctuating demand or extended lead times.

Key Takeaways

- Supplier lead times represent the total time from placing an order to receiving goods, making them a critical metric for planning inventory, production, and customer fulfillment.

- Accurate and consistent lead times help businesses optimize inventory levels, maintain smooth production schedules, enhance customer satisfaction, and protect cash flow.

- Supplier capacity, product complexity, logistics efficiency, geographical distance, regulations, and external disruptions all influence how long deliveries take.

- Businesses can shorten lead times by strengthening supplier relationships, automating procurement, improving forecasting, choosing reliable suppliers, and leveraging digital tools for real-time visibility.

- Relying on averages, ignoring lead time variability, using outdated data, poor communication, and failing to diversify suppliers often result in delays and operational inefficiencies.

- Using historical purchase data, performance metrics, transit analysis, and predictive tools helps businesses calculate more accurate lead time estimates and plan proactively.

- Deskera ERP enhances lead time management through real-time tracking, automated purchase planning, supplier analytics, demand forecasting, and integrated supply chain visibility.

Related Articles