In today’s manufacturing landscape, the shop floor is the heartbeat of production. It’s where materials, machines, and manpower come together to deliver finished goods. However, managing shop floor operations efficiently remains a challenge for many businesses. A recent survey revealed that only 17.5% of companies have a fully digital shop floor management (dSFM) system, and the use of dSFM boards is strikingly low at just 7%. This highlights how traditional practices are still dominant, despite the growing need for digital transformation.

Another pressing issue is the burden of manual processes. Data collection and processing consumes nearly 57% of shop floor management time, while only 5% of machine data is automatically processed. This not only slows down production but also creates bottlenecks in decision-making and reduces overall agility. Manufacturers who rely heavily on manual reporting often find it difficult to keep pace with modern demands for speed, accuracy, and cost efficiency.

With these challenges in mind, effective shop floor management has become more critical than ever. It goes beyond scheduling and supervision—it’s about ensuring visibility, accountability, and continuous improvement across the production cycle. By integrating technology, standardizing workflows, and empowering teams, companies can turn their shop floors into hubs of efficiency and innovation. This guide will walk you through everything you need to know about shop floor management, from its core principles to the role of advanced digital solutions.

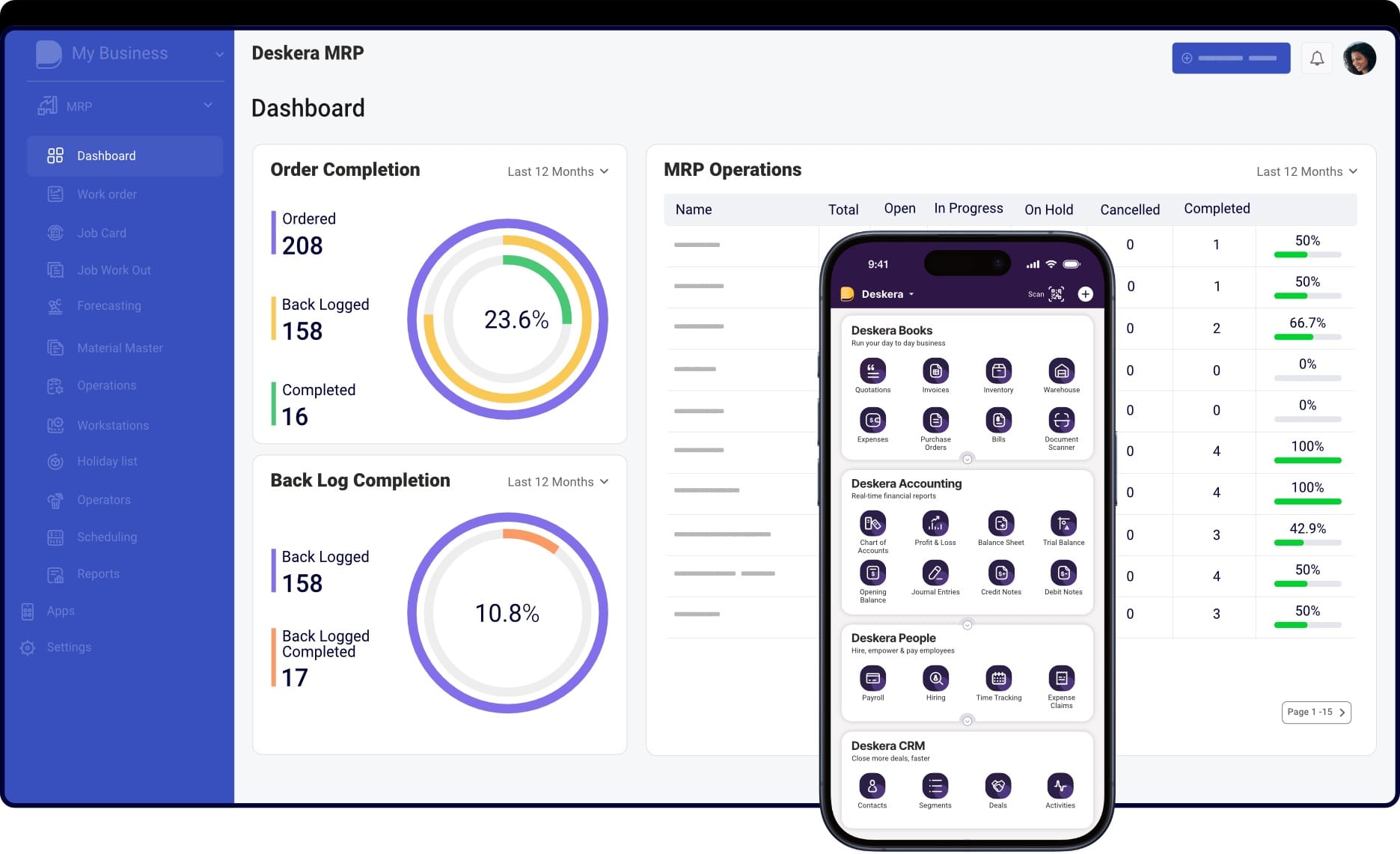

One such solution is Deskera MRP, a comprehensive platform designed to simplify and digitize shop floor operations. With features like automated production scheduling, real-time tracking, and AI-powered insights, Deskera helps manufacturers eliminate inefficiencies and gain better visibility into every aspect of production. Its mobile accessibility and scalability make it suitable for both small and large businesses, helping them move closer to a truly digital shop floor.

What is Shop Floor Management?

Shop Floor Management (SFM) is the structured approach to overseeing and optimizing all activities that take place on the production floor. It is more than supervision—it’s a system that brings together people, processes, and technology to ensure smooth and efficient operations. The shop floor is where value is created, and effective management ensures that materials, machines, and labor are coordinated seamlessly to meet production goals.

At its core, shop floor management focuses on standardization, waste reduction, safety, continuous improvement, and communication. It emphasizes creating visibility into daily operations, addressing problems directly at the source, and empowering teams to resolve issues quickly. By organizing workflows, scheduling tasks, and aligning resources, manufacturers can reduce downtime, eliminate bottlenecks, and enhance overall productivity without compromising on quality or safety.

SFM is also deeply rooted in Lean principles, often described through three pillars:

- Gemba – the shop floor itself, where value creation and waste identification happen.

- Genchi Genbutsu – “go and see,” encouraging leaders to engage directly with workers and processes.

- Genjitsu – reliance on factual, precise data for accurate problem-solving and informed decision-making.

Ultimately, shop floor management is the foundation of operational excellence in manufacturing. It integrates tools like real-time monitoring dashboards, visual management boards, and performance metrics to ensure accountability and transparency.

When executed effectively, SFM enables companies to meet production targets, maintain consistent quality, and drive continuous improvement—making it a crucial factor in staying competitive in today’s fast-paced manufacturing landscape.

Objectives of Shop Floor Management

The primary goal of shop floor management is to ensure that manufacturing operations run smoothly, efficiently, and consistently. It focuses on balancing productivity, quality, and employee well-being while minimizing waste and downtime. The key objectives include:

- Enhancing Productivity: Streamlining processes, eliminating bottlenecks, and ensuring optimal use of machines, materials, and manpower to maximize output.

- Ensuring Quality: Maintaining high product standards by implementing standardized processes, conducting inspections, and adhering to strict quality controls.

- Reducing Waste: Applying Lean practices to minimize excess material usage, time wastage, and resource inefficiencies.

- Improving Communication: Facilitating seamless collaboration between shop floor employees, supervisors, and management to address issues quickly and maintain alignment.

- Boosting Employee Engagement: Empowering workers to identify problems, suggest improvements, and actively contribute to continuous improvement efforts.

- Ensuring Safety and Compliance: Establishing and enforcing safety protocols to protect employees, equipment, and the work environment while meeting regulatory requirements.

- Supporting Continuous Improvement: Encouraging a culture of Kaizen—small, incremental changes that drive long-term efficiency and innovation.

- Reducing Downtime: Implementing real-time monitoring and preventive measures to minimize machine breakdowns and production delays.

By meeting these objectives, shop floor management helps manufacturers deliver products on time, at the right quality, and at optimal costs—strengthening both operational performance and customer satisfaction.

Core Components of Shop Floor Management

Effective shop floor management is built on several core components that ensure efficiency, quality, and continuous improvement across operations. These components create a structured framework that aligns people, processes, and technology for optimal performance.

1. Lean Leadership Culture

A strong leadership culture is at the heart of shop floor management. Lean principles emphasize Genchi Genbutsu (go and see), encouraging leaders to actively engage with shop floor activities and understand issues firsthand. Coupled with Hoshin Kanri, which aligns organizational goals across all levels, this leadership style builds trust, accountability, and a culture of continuous improvement.

2. Process Confirmation and Operational Control

This involves regular observation of the shop floor—often referred to as going to the Gemba—to verify critical processes, engage with workers, and ensure compliance with standards. By proactively supervising operations, managers can detect inefficiencies early, prevent problems from escalating, and maintain consistent operational control.

3. On-Site Communication and Meetings

Clear communication is vital for smooth shop floor management. Daily huddles, stand-up meetings, and structured SFM meetings bring managers and workers together to review progress, discuss issues, and agree on corrective actions. These practices foster transparency and empower employees by encouraging open dialogue and collaborative problem-solving.

4. Visual Management Tools (SFM Boards)

Shop floor operations rely heavily on visual tools such as SQCDP boards, Kanban systems, PDCA boards, and machine monitoring dashboards. These tools make performance data visible, simplify tracking, and align day-to-day activities with organizational goals. Visual management helps teams spot deviations quickly and take immediate corrective action.

5. Sustainable Problem-Solving

SFM encourages a problem-solving culture where employees at all levels are actively involved in identifying issues and developing solutions. The focus is not just on fixing problems temporarily but on preventing recurrence through root cause analysis and long-term countermeasures.

6. Performance Management

Monitoring and measuring performance is essential for operational excellence. Manufacturers track KPIs such as safety, quality, delivery, cost, and productivity to ensure goals are met consistently. Performance management in SFM emphasizes proactive improvement, helping organizations validate the effectiveness of their processes and strategies.

7. Continuous Improvement (Kaizen)

Kaizen, or continuous improvement, is a cornerstone of shop floor management. It empowers employees and managers to suggest and implement small, incremental changes that collectively lead to significant improvements over time. This fosters innovation, reduces waste, and ensures ongoing efficiency.

8. Real-Time Monitoring and Resource Management

Modern shop floor management also integrates real-time monitoring systems to track production, machine performance, and material flows. Coupled with efficient resource management—the optimal use of labor, machinery, and materials—this ensures bottlenecks are minimized, productivity is maximized, and downtime is reduced.

5 Pillars of Shop Floor Management

Effective shop floor management is built on five fundamental pillars. These pillars not only ensure smooth day-to-day operations but also drive continuous improvement, employee engagement, and long-term business growth.

1. Leadership on Site

The first and most critical pillar of shop floor management is active leadership presence on the production floor. Leaders who regularly visit the shop floor gain real-time insights into ongoing processes, challenges, and employee concerns. This presence fosters transparency, accountability, and quick decision-making.

- Regular Walks: Managers should spend at least 30–40% of their time directly in production to monitor operations.

- Direct Communication: Engaging with employees builds trust and encourages problem-sharing.

- Immediate Resolution: On-site presence helps leaders identify issues early and resolve them before they escalate.

- Coaching & Support: Leaders provide hands-on guidance, motivating teams and aligning them with organizational goals.

This pillar ensures that leadership is not distant but an integral part of everyday manufacturing operations.

2. Visual Management

Visual management transforms complex processes and data into clear, accessible, and transparent information that can be understood at a glance.

- Shop Floor Boards: Display real-time KPIs, current performance, and action items.

- Visualization Tools: Traffic-light coding, trend charts, and diagrams make deviations immediately recognizable.

- Fault Reporting: Systems like Andon boards enable quick problem escalation.

- Digital Dashboards: Modern shop floors benefit from dashboards that integrate machine data and ERP/MRP insights.

With strong visual management, performance gaps become visible immediately, helping teams react faster and continuously improve.

3. Standardized Communication

Consistent and structured communication ensures that information flows seamlessly across all levels of the organization.

- Daily Meetings: Short, 10–15 minute sessions at the start of shifts keep everyone aligned.

- Structured Agendas: Discussions focus on KPIs, bottlenecks, and immediate actions.

- Communication Cascade: Information flows through levels – team leader, department manager, and plant manager – ensuring clarity and accountability.

- Escalation Paths: Defined routes help in resolving critical issues quickly without confusion.

By standardizing communication, organizations reduce misunderstandings, align team goals, and keep operations running smoothly.

4. Continuous Improvement (CIP) & Problem Solving

Continuous improvement is the heartbeat of shop floor management. By embedding systematic problem-solving practices, companies can reduce errors, boost efficiency, and promote innovation.

- Problem-Solving Methods: Approaches like the 8D methodology, PDCA cycle, A3 reporting, and Root Cause Analysis ensure structured resolutions.

- Improvement Initiatives: Employee suggestions, Kaizen events, and quick-win actions encourage proactive participation.

- Long-Term Optimization: Projects focused on process automation, waste reduction, and better resource utilization lead to lasting benefits.

With CIP, organizations achieve measurable improvements such as 25–35% higher productivity and 40–50% shorter throughput times.

5. Employee Involvement

Employees are the backbone of manufacturing operations, and their active involvement is crucial for success.

- Empowerment: Workers should be given responsibility and authority for on-site decision-making.

- Skill Development: Ongoing training, coaching, and mentoring enhance employee capabilities.

- Recognition & Motivation: Acknowledging contributions boosts morale and engagement.

- Team Collaboration: Cross-functional collaboration ensures joint problem-solving and shared accountability.

Strong employee involvement not only reduces problem-solving times by 60–70% but also significantly increases motivation and retention.

Together, these five pillars create a robust shop floor management framework that enhances efficiency, strengthens teamwork, and drives sustainable growth in manufacturing.

Critical Elements of Shop Floor Management

Effective shop floor management rests on several critical pillars that ensure seamless operations, enhance productivity, and uphold product quality. Each element contributes to building a strong foundation for operational excellence and continuous improvement.

1. Workforce Management

Employees are the backbone of the shop floor. Effective workforce management involves assigning tasks, scheduling shifts, monitoring performance, and boosting morale. By ensuring the right people are in the right roles at the right time, manufacturers can minimize idle time and maximize efficiency.

- Shift scheduling to prevent workforce shortages

- Performance tracking to identify gaps

- Training programs to upskill employees

2. Production Planning and Scheduling

Planning and scheduling align daily operations with broader production goals. They help avoid bottlenecks, ensure timely completion of tasks, and balance workloads across workstations. A well-structured schedule keeps production on track and supports on-time delivery.

- Daily production plans and schedules

- Real-time adjustments for changing priorities

- Load balancing for consistent performance

3. Inventory and Material Management

Smooth production depends on the timely availability of raw materials and components. Effective inventory management prevents costly stockouts and overstocking while keeping production uninterrupted.

- Just-in-Time (JIT) material replenishment

- Automated inventory tracking systems

- Supplier coordination for timely deliveries

4. Machine and Equipment Management

Equipment health directly impacts shop floor productivity. Preventive and predictive maintenance ensures machines run smoothly and reduces unplanned downtime. Monitoring equipment performance also helps optimize efficiency.

- Preventive/predictive maintenance strategies

- IoT sensors for real-time machine health tracking

- Key metrics like Overall Equipment Effectiveness (OEE)

5. Quality Control and Assurance

Quality is a non-negotiable pillar of shop floor management. Integrating checks into the production process helps identify defects early, reduce waste, and maintain customer satisfaction.

- In-line inspections and real-time monitoring

- Standard Operating Procedures (SOPs) for consistency

- Root cause analysis to eliminate recurring defects

6. Real-Time Data Collection and Analytics

Data-driven decisions are central to modern shop floor efficiency. Real-time data collection enables managers to monitor KPIs, track progress, and respond to issues immediately.

- IoT-enabled devices for accurate tracking

- Analytics dashboards for performance monitoring

- Alerts and notifications for quick corrective action

7. Communication and Collaboration

Clear communication ensures alignment between operators, supervisors, and management. Daily huddles, reporting structures, and digital collaboration tools foster teamwork and quick issue resolution.

- Daily stand-up meetings for updates

- Collaboration tools for instant information sharing

- Visual boards like Kanban for task tracking

8. Compliance and Safety Management

Safety and compliance form the foundation of sustainable operations. Regular audits, adherence to safety guidelines, and compliance with standards like ISO or OSHA protect employees and ensure uninterrupted production.

- Workplace safety guidelines to prevent accidents

- Compliance with industry regulations

- Safety audits and training programs

Benefits of Shop Floor Management

An effective shop floor management system transforms the production environment into a highly coordinated, transparent, and efficient space. It not only improves day-to-day operations but also contributes to long-term growth and sustainability.

Below are the detailed benefits manufacturers can achieve:

1. Enhanced Productivity and Efficiency

Shop floor management ensures that every task, process, and resource is aligned to maximize output. Real-time monitoring systems help managers spot delays or inefficiencies, allowing for immediate corrective action. Standard operating procedures (SOPs) and continuous improvement practices further refine workflows.

Example: If a machine runs slower than expected, managers can quickly reallocate tasks to avoid production delays.

Outcome: Higher output with the same or fewer resources, shorter production cycles, and reduced operational friction.

2. Improved Product Quality

By embedding quality checks at each stage of production, shop floor management reduces the chances of defects going unnoticed. Techniques like root cause analysis, error-proofing (poka-yoke), and adherence to quality standards ensure products meet specifications consistently.

Example: Catching defective components during assembly rather than at the final inspection stage saves time and rework costs.

Outcome: Fewer recalls, reduced waste, and a strong reputation for reliable quality in the market.

3. Time and Cost Savings

Efficient scheduling and planning reduce idle time and ensure resources are allocated optimally. Non-value-added activities—such as waiting for materials, excessive transport, or rework—are systematically minimized.

Example: Using digital dashboards to track work-in-progress (WIP) can prevent overproduction and reduce storage costs.

Outcome: Significant reductions in production costs, faster turnaround times, and improved bottom-line results.

4. Waste Reduction

Shop floor management incorporates lean manufacturing principles that target and eliminate waste in all forms—overproduction, excess inventory, unnecessary motion, defective products, and underutilized talent.

Example: Implementing a “just-in-time” (JIT) system reduces excess inventory and ensures materials are available only when required.

Outcome: Lower material costs, reduced environmental impact, and a leaner, more sustainable operation.

5. Faster Information Flow

Transparency is at the heart of shop floor management. Through digital dashboards, visual management boards, and daily stand-up meetings, critical production data is shared openly. This ensures every team member—from machine operators to plant managers—has the same understanding of current performance.

Example: If a bottleneck is reported in real time, teams can immediately adjust schedules or resources to address it.

Outcome: Shorter decision-making cycles, fewer misunderstandings, and quicker responses to unexpected issues.

6. Stronger Communication and Collaboration

Shop floor management establishes clear communication channels between operators, supervisors, and management. This open communication reduces “operational blindness,” where teams are unaware of problems until it’s too late. Collaboration also ensures that problem-solving involves multiple perspectives.

Example: Cross-functional teams tackling a recurring machine breakdown may uncover both mechanical and procedural causes.

Outcome: Improved teamwork, a shared sense of accountability, and quicker resolution of challenges.

7. Reduced Downtime and Maintenance Costs

Unplanned equipment breakdowns can severely disrupt production. Shop floor management incorporates preventive and predictive maintenance practices, helping extend equipment life and minimize disruptions.

Example: IoT sensors tracking machine vibrations can alert teams to potential failures before they occur.

Outcome: Greater equipment reliability, fewer costly repairs, and a continuous production flow.

8. Better Resource Utilization

Optimizing the use of people, machines, and materials ensures that no resource is underused or overburdened. Managers can balance workloads, monitor workforce performance, and allocate resources based on real-time needs.

Example: A digital system can detect underutilized machinery during low demand and schedule it for maintenance, avoiding wasted energy.

Outcome: Balanced workloads, reduced overheads, and a smoother flow of operations.

9. Increased Employee Engagement

When employees are actively involved in decision-making and problem-solving, they feel more valued and accountable for their work. Shop floor management encourages continuous feedback and recognition of achievements.

Example: Workers contributing ideas in daily huddles feel ownership of improvements, leading to higher morale.

Outcome: A motivated workforce, reduced turnover, and a culture of continuous improvement.

10. Compliance and Safety

Strict safety standards and regulatory compliance are non-negotiable in manufacturing. Shop floor management integrates safety protocols, ensures employee training, and provides tools to monitor compliance effectively.

Example: Regular safety audits and digital logs help prevent accidents and ensure adherence to OSHA or ISO standards.

Outcome: Safer working conditions, reduced legal risks, and protection of both employees and company reputation.

Challenges of Shop Floor Management

While shop floor management offers immense benefits, it also comes with several challenges that manufacturing leaders must address. These challenges arise from the complexity of production environments, technological integration, workforce dynamics, and the need for continuous improvement. Recognizing and overcoming these barriers is critical to achieving efficiency, productivity, and sustainable growth.

1. Managing Multiple Workflows

Modern manufacturing often involves complex and overlapping workflows across different product lines. Coordinating these processes without a structured system can lead to confusion, bottlenecks, and missed deadlines.

Shop floor managers must ensure real-time visibility of operations, prioritize tasks effectively, and balance competing production schedules to avoid disruptions.

2. Minimizing Downtime

Unexpected equipment failures or machine breakdowns can severely impact productivity and delivery timelines. Unplanned downtime not only causes production delays but also increases maintenance costs.

Implementing preventive maintenance strategies and predictive monitoring systems is essential, yet many organizations still struggle to integrate these practices seamlessly into their shop floor operations.

3. Dealing with Labor Shortages

With a growing shortage of skilled labor, manufacturers face challenges in maintaining efficiency and quality standards. Shop floor management must adapt by optimizing workforce allocation, implementing cross-training programs, and leveraging automation to fill skill gaps. However, balancing automation with human oversight remains a delicate challenge.

4. Handling Data Overload

IoT devices, sensors, and ERP systems generate vast amounts of real-time data from the shop floor. While this data holds valuable insights, many companies struggle to process, analyze, and apply it effectively.

Without the right tools for data visualization and integration, managers risk drowning in information without gaining actionable improvements.

5. Maintaining Consistent Quality Standards

As production scales up, maintaining uniform product quality becomes increasingly complex. Variability in raw materials, operator performance, or machine conditions can lead to defects and rework.

Shop floor management must enforce strict quality control measures, but doing so without slowing down production remains a significant challenge.

6. Balancing Cost Efficiency with Innovation

Manufacturers must continuously innovate to remain competitive, yet innovation often requires investment in new technologies and training.

Shop floor management faces the dual challenge of reducing costs while adopting new systems like digital dashboards, automated reporting, and advanced analytics, which can be resource-intensive initially.

7. Real-Time Communication Gaps

Effective shop floor management depends on seamless communication between operators, supervisors, and management. However, miscommunication or delays in relaying critical updates—such as deviations, breakdowns, or urgent orders—can create cascading inefficiencies. Standardized communication structures are crucial, but many organizations lack them.

8. Adapting to Demand Fluctuations

Customer demand is increasingly volatile in global markets. Shop floors must adapt quickly to sudden increases or decreases in demand without overburdening resources or creating excess inventory.

Striking this balance requires agile planning tools and flexible workforce strategies, which remain a challenge for many manufacturers.

Best Practices of Shop Floor Management

Effective shop floor management doesn’t just happen—it’s built on proven practices that combine structured systems, lean principles, digital tools, and a people-first mindset.

By following best practices, organizations can ensure smoother operations, higher efficiency, and stronger employee engagement while staying competitive in a rapidly evolving manufacturing landscape.

1. Implement a Daily Management System (DMS)

A Daily Management System is the backbone of shop floor management. It provides structure to everyday operations and ensures teams are aligned, accountable, and proactive.

- Benefits: Visibility into performance, faster issue escalation, and better coordination across shifts.

- How to apply:

- Set daily production goals and review them in short stand-up meetings.

- Track issues in real time and assign clear owners for resolution.

- Use digital DMS tools to ensure consistent communication across locations and shifts.

2. Use Visual Management for Real-Time Tracking

Making data visible helps everyone understand performance at a glance.

- Examples: Digital dashboards, performance boards, and add-on systems.

- Benefits:

- Boosts accountability and team ownership.

- Makes problems visible early, preventing escalation.

- Speeds up decision-making by reducing reliance on reports or middle layers of communication.

3. Conduct Regular Gemba Walks

Leaders should practice “going to the Gemba”—the place where value is created.

- Best practices:

- Spend time observing processes, not just reviewing reports.

- Ask open-ended questions and listen to frontline workers.

- Standardize checklists to ensure consistency across Gemba walks.

- Digitize observations to track follow-ups and ensure accountability.

4. Empower Teams to Own Problem-Solving

Frontline workers often see issues before managers do. Giving them the tools and authority to solve problems accelerates improvement.

- How to enable:

- Provide training in problem-solving techniques (5 Whys, Fishbone, PDCA, A3).

- Encourage fixing root causes rather than treating symptoms.

- Log and share learnings across shifts to avoid repetitive mistakes.

5. Apply the 5S Methodology

A clean, organized shop floor improves both efficiency and safety.

- Steps: Sort, Set in order, Shine, Standardize, Sustain.

- Benefits:

- Reduces time wasted searching for tools or materials.

- Improves safety by eliminating hazards.

- Makes abnormalities more visible, aiding in faster problem detection.

6. Invest in Real-Time Shop Floor Control Tools

Modern production demands real-time visibility and responsiveness.

- Tools: IoT-based monitoring, MES (Manufacturing Execution Systems), digital add-on boards.

- Benefits:

- Enables quick response to deviations.

- Provides accurate performance data for decision-making.

- Enhances collaboration with photos, notes, and live updates.

7. Align KPIs with Operational Excellence Goals

KPIs should reflect both team-level targets and broader business objectives.

- Key KPIs: Safety, Quality, Delivery, Cost, OEE (Overall Equipment Effectiveness).

- Best practice:

- Keep KPIs visible on the shop floor through boards or dashboards.

- Review them in daily meetings.

- Use KPIs to encourage action, not just reporting.

8. Standardize Workflows Across Teams

Consistency reduces variation and errors while making improvements measurable.

- Benefits:

- Easier onboarding and training for new employees.

- Identifies gaps and deviations quickly.

- Provides a foundation for continuous improvement initiatives.

- Digital tip: Use digital SOPs (Standard Operating Procedures) for easier updates and accessibility.

9. Ensure Seamless Communication Across Tiers

Communication is the glue that holds shop floor management together.

- Best practices:

- Establish tiered meetings (from operator to plant leadership).

- Use escalation paths to handle issues at the right level.

- Implement digital tiered meeting tools to track actions and resolutions.

10. Review and Iterate with a Lean Mindset

Shop floor management is never “done”—it evolves continuously.

- How to apply:

- Use the PDCA cycle (Plan-Do-Check-Act) for structured improvement.

- Run Kaizen events for small, quick wins.

- Reevaluate processes regularly and refine based on lessons learned.

- Celebrate and share success stories to build momentum.

11. Train and Develop the Workforce

Skilled employees are the foundation of effective shop floor management.

- Key aspects:

- Role-specific training for operational excellence.

- Regular safety training to prevent incidents.

- Cross-training for flexibility and adaptability.

- Structured onboarding for new hires.

- Ongoing coaching and recognition to maintain engagement.

12. Optimize Shop Floor Layout and Material Flow

Physical layout impacts efficiency as much as processes do.

- Best practices:

- Position machines and workstations to minimize unnecessary movement.

- Use lean techniques like line balancing or cellular layouts.

- Apply visual cues (color coding, floor markings, signage) to guide flow.

- Regularly review and adjust layouts to match demand changes.

13. Foster a Culture of Continuous Improvement

The most successful shop floors view improvement as everyone’s responsibility.

- How to encourage it:

- Build a Kaizen suggestion system.

- Set achievable improvement goals and measure results.

- Recognize contributions from employees at all levels.

- Promote transparency so everyone sees how their ideas drive change.

Role of Technology in Shop Floor Management

Technology plays a transformative role in modern shop floor management by enabling real-time visibility, improving efficiency, and empowering data-driven decisions. From connected devices to advanced analytics, digital tools ensure that manufacturing processes remain agile, productive, and competitive in today’s dynamic landscape. Below are some key technologies shaping shop floor operations:

1. Industrial Internet of Things (IIoT)

IIoT connects machines, sensors, and devices to collect real-time production data. It allows managers to track equipment health, material flow, and machine performance with greater accuracy. By predicting failures through anomaly detection, IIoT supports preventive maintenance, reducing unexpected downtime and enhancing resource utilization.

2. Enterprise Resource Planning (ERP) Systems

ERP systems integrate shop floor operations with core business functions such as inventory management, procurement, and finance. By creating synchronized workflows, ERP ensures seamless communication across departments, better production planning, and fewer material shortages, leading to improved overall efficiency.

3. Manufacturing Execution Systems (MES)

MES provides real-time visibility into production activities. It monitors machine utilization, operator tasks, and product quality, helping managers identify bottlenecks and inefficiencies quickly. MES supports compliance with quality standards while ensuring that production goals are consistently met.

4. Artificial Intelligence (AI) and Machine Learning (ML)

AI and ML technologies analyze vast datasets from shop floor activities to forecast demand, optimize production schedules, and predict equipment breakdowns. By automating decision-making and highlighting inefficiencies, they reduce downtime and improve productivity while increasing operational agility.

5. Robotic Process Automation (RPA) and Collaborative Robots (Cobots)

RPA automates repetitive administrative tasks, while cobots work alongside humans in manufacturing tasks like assembly, packaging, and inspection. Cobots reduce fatigue and error while enhancing precision and productivity, making the workforce more efficient and safer.

6. Augmented Reality (AR) and Virtual Reality (VR)

AR and VR technologies offer immersive experiences for training and remote troubleshooting. AR overlays digital instructions directly onto physical equipment, helping technicians perform tasks efficiently, while VR allows workers to practice procedures in a risk-free, simulated environment.

7. Big Data Analytics

Big data tools capture and analyze large volumes of shop floor data, enabling managers to identify patterns and optimize processes. By leveraging real-time insights, manufacturers can address inefficiencies, streamline operations, and make smarter strategic decisions.

8. Cloud Computing

Cloud platforms provide remote access to dashboards and shop floor data. Managers can monitor operations, track performance, and make decisions from anywhere, ensuring better collaboration across teams and faster responses to production issues, especially in multi-plant environments.

9. Additive Manufacturing (3D Printing)

3D printing empowers manufacturers to prototype quickly and produce on-demand spare parts without maintaining large inventories. This reduces downtime, accelerates product development, and fosters innovation by allowing for rapid iterations and customization.

10. Maintenance Software (EAM or CMMS)

Enterprise Asset Management (EAM) and Computerized Maintenance Management Systems (CMMS) ensure machinery uptime by scheduling preventive maintenance, tracking repair histories, and managing spare parts inventory. This leads to extended equipment lifespan and reduced operational costs.

11. Collaborative Floor Workflow (CFW) Tools

CFW tools—like digital workboards and mobile apps—streamline communication on the shop floor. Workers and managers can share updates, track tasks in real time, and collaborate seamlessly, creating a more transparent and agile workflow.

How Can Deskera MRP Help You with Shop Floor Management?

Deskera MRP is designed to simplify and modernize shop floor management by integrating planning, execution, and monitoring into one intuitive platform. It addresses the common challenges manufacturers face and enables real-time visibility into operations, which is critical for maintaining efficiency and reducing production bottlenecks.

- Efficient Production Planning & Scheduling: Deskera MRP automates material requirements planning, helping businesses forecast demand accurately and schedule production without delays. This minimizes idle time and ensures smoother workflow coordination.

- Real-Time Data Tracking: With built-in automation and integration capabilities, Deskera MRP captures production data directly from the shop floor. This reduces manual data collection, speeds up decision-making, and provides accurate insights into machine utilization, work orders, and labor allocation.

- Inventory Optimization: Shop floor management often struggles with material shortages or excess stock. Deskera MRP balances raw material availability with production demand, reducing wastage while avoiding costly delays.

- Downtime Reduction: By integrating maintenance schedules and tracking machine performance, Deskera MRP helps identify potential issues early. This proactive approach minimizes unplanned downtime and keeps production lines running smoothly.

- Collaboration & Mobility: Deskera’s cloud-based system and mobile accessibility allow managers to oversee shop floor operations from anywhere. Teams across procurement, production, and sales can collaborate seamlessly, improving communication and workflow alignment.

In short, Deskera MRP empowers businesses with the right tools to improve productivity, minimize inefficiencies, and transform shop floor management into a strategic advantage.

Key Takeaways

- Shop floor management ensures smooth coordination of people, machines, and processes, forming the foundation of efficient manufacturing operations.

- Objectives of Shop Floor Management: The main objectives are to maximize productivity, reduce waste, streamline workflows, engage employees, and drive continuous improvement.

- Key Components of Shop Floor Management: Critical components include production scheduling, real-time monitoring, workforce management, inventory oversight, and performance tracking.

- Pillars of Shop Floor Management: Standardization, transparency, accountability, and continuous improvement are the core pillars that strengthen effective shop floor practices.

- Elements of Shop Floor Management: Essential elements like visual management, problem-solving routines, structured communication, and performance metrics ensure alignment across teams.

- Best Practices in Shop Floor Management: Applying lean principles, embracing digital tools, training employees, and conducting regular reviews are key practices for shop floor excellence.

- Benefits of Shop Floor Management: Strong shop floor management improves productivity, reduces costs, minimizes downtime, enhances product quality, and strengthens workforce efficiency.

- Challenges of Shop Floor Management: Businesses face hurdles such as managing multiple workflows, equipment downtime, labor shortages, and data overload, requiring systematic solutions.

- Role of ERP and MRP Systems in Shop Floor Management: ERP and MRP systems streamline processes, centralize data, improve planning accuracy, and enable real-time decision-making across the shop floor.

- How Deskera MRP Helps with Shop Floor Management: Deskera MRP supports manufacturers with automated planning, inventory optimization, downtime reduction, real-time visibility, and mobile accessibility for smarter decision-making.

Related Articles