What's the best way to empower your Manufacturing leaders with real-time order visibility?

Manufacturing can be a complicated process. Orders can come in quickly and unexpectedly, and it can be hard to keep track of what's going on. Order visibility is key to keeping Manufacturing Leaders organized and confident. A good solution will let them see all the orders that have been placed, as well as the estimated shipping times for each order. It helps them make informed decisions and adjust their production accordingly.

There are a number of solutions out there that claim to offer real-time order visibility. However, not all of them are reliable. It's important to find an option that works well for your team and fits your needs. Otherwise, you may be struggling to keep up with the ever-changing manufacturing landscape.

Let's take a look at the table of content below:

- What is Real-time Order Visibility?

- Why is real-time order visibility important for manufacturing leaders?

- Benefits of Real-Time Order Visibility

- Technologies or tools Implemented to Enable Real-time Order Visibility

- Types of Data Accessible through Real-Time Order Visibility

- Common Challenges in Implementing Real-Time Order Visibility

- Real-Time Order Visibility and Decision-Making

- Security and Privacy Considerations

- Implementing Real-Time Order Visibility: Best Practices

- Case Studies and Success Stories

- Frequently Asked Questions (FAQs) Associated with Real-Time Order Visibility

- Wrapping Up

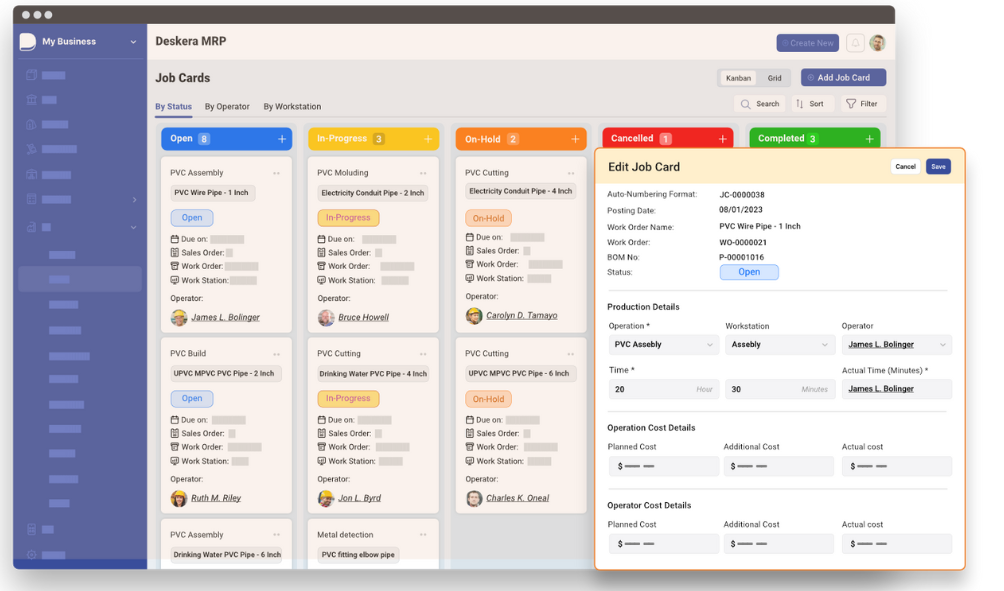

- How Deskera Can Assist You?

Let's get started!

What is Real-time Order Visibility?

Real-time order visibility refers to the ability to track and monitor the status, location, and progress of orders throughout the manufacturing process in real time.

Furthermore, it involves capturing and processing data related to orders, inventory, production, and logistics, and making that information readily available to manufacturing leaders and stakeholders.

Furthermore, real-time order visibility provides manufacturing leaders with up-to-the-minute insights into the various aspects of their orders. This includes information such as:

Order Status: Manufacturing leaders can track the progress of each order, from the moment it is received to its completion and delivery. They can identify bottlenecks, delays, or any issues that may arise during production.

Inventory Levels: Real-time order visibility enables leaders to monitor the availability of raw materials, components, and finished goods in their inventory. They can ensure that they have adequate stock to fulfill orders on time and make informed decisions regarding inventory management.

Production Schedules: Manufacturing leaders can view and adjust production schedules in real-time. They can track the allocation of resources, monitor machine utilization, and optimize production workflows to meet customer demands efficiently.

Supply Chain Insights: Real-time order visibility provides visibility into the entire supply chain. Leaders can monitor the movement of goods, track shipments, and identify potential disruptions. This helps in proactive problem-solving and ensures on-time delivery to customers.

Customer Demand: By having access to real-time data on orders, manufacturing leaders can gain insights into customer demand patterns. They can identify trends, forecast future demand, and align their production and inventory strategies accordingly.

Real-time order visibility is achieved through the integration of various technologies and systems. This includes the use of sensors, IoT devices, barcode scanners, and other data collection tools to capture real-time data. The data is then processed, analyzed, and presented through dedicated software platforms or manufacturing execution systems (MES). Cloud computing and advanced analytics play a crucial role in processing and delivering real-time insights to manufacturing leaders.

By having comprehensive and timely information about orders and production processes, manufacturing leaders can make data-driven decisions, proactively address issues, optimize resources, and ultimately enhance operational efficiency, customer satisfaction, and overall business performance.

Why is real-time order visibility important for manufacturing leaders?

Real-time order visibility is important for manufacturing leaders for several reasons:

Enhanced Decision-Making: Real-time order visibility provides manufacturing leaders with accurate and up-to-date information on order status, inventory levels, and production schedules.

This enables them to make informed decisions in real-time, such as prioritizing orders, allocating resources, and adjusting production schedules based on changing demands or unexpected events.

By having a holistic view of their operations, leaders can optimize processes, identify bottlenecks, and proactively address issues, leading to improved decision-making and operational efficiency.

Improved Customer Satisfaction: Real-time order visibility allows manufacturing leaders to track orders throughout the production and delivery process.

This enables them to provide accurate updates to customers regarding order status, estimated delivery times, and potential delays. By effectively managing customer expectations and providing timely information, leaders can enhance customer satisfaction, build trust, and strengthen relationships with clients.

Efficient Resource Management: Real-time order visibility helps manufacturing leaders optimize resource allocation. They can monitor machine utilization, identify idle or overburdened equipment, and make adjustments to maximize efficiency.

With better visibility into inventory levels, leaders can optimize stock levels, reduce waste, and ensure the timely availability of materials. This efficient resource management leads to cost savings, improved productivity, and reduced lead times.

Supply Chain Collaboration: Real-time order visibility facilitates collaboration and communication with suppliers, logistics providers, and other stakeholders in the supply chain.

By sharing real-time data on orders, inventory levels, and production schedules, manufacturers can improve coordination, streamline logistics, and address potential bottlenecks or disruptions. This collaborative approach enhances supply chain efficiency, reduces delays, and improves overall operational performance.

Agile Responsiveness: In today's dynamic business environment, manufacturing leaders need to be agile and responsive to market changes.

Real-time order visibility enables them to quickly adapt to fluctuations in customer demand, supply chain disruptions, or changing market conditions. By having real-time insights, leaders can adjust production planning, reassign resources, or make strategic decisions to stay competitive and meet customer expectations.

Overall, real-time order visibility empowers manufacturing leaders with actionable information, enabling them to optimize operations, improve customer satisfaction, manage resources efficiently, collaborate effectively, and respond swiftly to market dynamics. It plays a crucial role in driving operational excellence, profitability, and competitiveness in the manufacturing industry.

Benefits of Real-Time Order Visibility

Real-time order visibility in manufacturing operations brings a range of benefits to the table. Here are some key advantages in detail:

Improved Operational Efficiency: Real-time order visibility allows manufacturing leaders to monitor and manage their operations more effectively. They can track the progress of orders, identify bottlenecks or delays, and take proactive measures to address issues. This leads to streamlined processes, reduced idle time, improved productivity, and optimized resource allocation. By eliminating manual tracking and reducing errors, real-time order visibility enhances overall operational efficiency.

Enhanced Customer Satisfaction: Real-time order visibility enables manufacturers to provide accurate and timely information to customers regarding order status, expected delivery dates, and any potential delays. Customers appreciate transparency and proactive communication. By keeping customers informed throughout the order lifecycle, manufacturing leaders can build trust, improve customer satisfaction, and foster long-term relationships. Satisfied customers are more likely to become repeat buyers and advocates for the brand.

Better Supply Chain Management: Real-time order visibility plays a crucial role in supply chain management. It enables manufacturers to track orders from suppliers, monitor inventory levels, and coordinate logistics operations. With real-time insights, leaders can identify potential supply chain disruptions, adjust production plans, and optimize inventory levels to meet customer demands efficiently. This leads to improved supply chain visibility, reduced lead times, and enhanced overall supply chain performance.

Data-Driven Decision Making: Real-time order visibility provides manufacturing leaders with accurate and up-to-date data on production, inventory, and customer demand. This data can be analyzed and utilized for data-driven decision making. Leaders can identify trends, make informed forecasts, and adjust production plans accordingly. Real-time insights enable them to respond quickly to market changes, optimize resource allocation, and make strategic decisions that drive business growth.

Efficient Problem Solving: Real-time order visibility empowers manufacturing leaders to identify and address production issues in a timely manner. By monitoring orders and processes in real-time, they can detect bottlenecks, quality issues, or production delays. This enables them to take immediate corrective actions, allocate additional resources, or implement process improvements to resolve problems promptly. Efficient problem-solving leads to reduced downtime, improved product quality, and increased customer satisfaction.

Continuous Process Improvement: Real-time order visibility provides a wealth of data that can be leveraged for continuous process improvement initiatives. Manufacturing leaders can analyze production metrics, identify areas for improvement, and implement changes to optimize efficiency. By closely monitoring order data, they can identify patterns, eliminate waste, and implement lean manufacturing practices. This promotes a culture of continuous improvement, ensuring that manufacturing processes evolve and adapt to changing business needs.

In summary, real-time order visibility brings numerous benefits, including improved operational efficiency, enhanced customer satisfaction, optimized supply chain management, data-driven decision making, efficient problem-solving, and continuous process improvement. By leveraging real-time insights, manufacturing leaders can drive competitiveness, operational excellence, and overall business success.

Technologies or tools Implemented to Enable Real-time Order Visibility

Several technologies and tools are used to enable real-time order visibility in manufacturing operations. Here are some key ones in detail:

Internet of Things (IoT) Devices: IoT devices play a vital role in capturing real-time data. These devices can be embedded in various components, equipment, and products throughout the manufacturing process. They collect and transmit data such as production status, machine performance, inventory levels, and location information. Examples of IoT devices include sensors, RFID tags, and barcode scanners.

Data Collection and Integration Systems: To gather data from different sources and devices, manufacturers employ data collection and integration systems. These systems collect data from IoT devices, as well as other sources such as enterprise resource planning (ERP) systems, manufacturing execution systems (MES), and supplier databases. They consolidate and integrate the data to provide a comprehensive view of orders and production processes.

Cloud Computing: Cloud computing is widely utilized to store and process large volumes of data generated by real-time order visibility systems. Cloud-based platforms offer scalable storage and computing power, allowing manufacturers to handle vast amounts of data in real-time. Cloud-based solutions also enable seamless access to order information from anywhere, facilitating remote monitoring and collaboration.

Analytics and Business Intelligence Tools: Analytics and business intelligence tools are employed to process and analyze the collected data. These tools help manufacturers derive meaningful insights and actionable information from the real-time order visibility data. Analytics techniques such as data mining, predictive analytics, and machine learning can be used to uncover patterns, trends, and anomalies in the data, enabling informed decision-making.

Visualization and Dashboarding Tools: Visualization tools and dashboards present real-time order visibility data in a user-friendly and easily understandable format. These tools provide intuitive visualizations, charts, graphs, and customizable dashboards that enable manufacturing leaders to monitor key metrics, track order status, and identify performance indicators at a glance. Visualization tools make it easier to communicate insights and trends, facilitating faster and more informed decision-making.

Mobile Applications: Mobile applications play a crucial role in providing real-time access to order visibility information. Manufacturing leaders and stakeholders can access real-time data on their smartphones or tablets, allowing them to monitor orders, track progress, and receive notifications even when they are on the go. Mobile applications provide convenience, accessibility, and agility in managing and overseeing manufacturing operations.

Integration with Enterprise Systems: Real-time order visibility systems need to integrate with other enterprise systems to ensure smooth data flow and information exchange. Integration with ERP systems, MES, customer relationship management (CRM) systems, and other relevant systems ensures that the real-time order visibility data is synchronized and consistent across different platforms. This integration enables seamless information sharing and collaboration across departments and stakeholders.

By leveraging these technologies and tools, manufacturers can capture, process, analyze, and present real-time order visibility data in a comprehensive and actionable manner. The combination of IoT devices, data collection systems, cloud computing, analytics tools, visualization, mobile applications, and system integration forms the foundation for enabling real-time order visibility in manufacturing operations.

Types of Data Accessible through Real-Time Order Visibility

Manufacturing leaders can access various types of data through real-time order visibility. Here are some examples:

Production Data: Real-time order visibility provides information about production processes, including machine performance, cycle times, production rates, and downtime. This data helps leaders monitor production efficiency, identify bottlenecks, and make informed decisions to optimize production workflows.

Inventory Data: Real-time order visibility allows leaders to track inventory levels, including raw materials, components, and finished goods. They can access real-time information on stock availability, reorder points, and inventory turnover. This data enables efficient inventory management, minimizes stockouts, and reduces carrying costs.

Order Status and Tracking: Real-time order visibility provides real-time updates on order status, including order processing, manufacturing progress, and shipment tracking. Manufacturing leaders can monitor the progress of individual orders, identify potential delays, and take proactive measures to ensure on-time delivery.

Quality Metrics: Real-time order visibility can provide data on quality metrics, such as defect rates, rework rates, and scrap levels. Leaders can monitor quality performance in real-time, identify areas for improvement, and implement corrective actions to enhance product quality.

Customer Demand and Insights: Real-time order visibility enables leaders to analyze customer demand patterns and preferences. By capturing data on order volumes, order frequencies, and customer feedback, leaders can gain insights into customer behavior, identify trends, and tailor their production and inventory strategies accordingly.

Key Metrics and Insights:

Production Schedule Adherence: Real-time order visibility allows leaders to measure the adherence to production schedules. They can track the progress of orders against planned timelines, identify any deviations, and take corrective actions to minimize delays and maintain production efficiency.

Inventory Turnover and Stockouts: Real-time order visibility provides metrics on inventory turnover, indicating how quickly inventory is moving. Leaders can monitor stock levels and identify situations where inventory is not meeting demand (stockouts) or when excess inventory is being carried. This helps optimize inventory levels and reduce costs.

Order Cycle Time: Real-time order visibility enables leaders to measure the cycle time for order fulfillment, from order placement to delivery. By tracking this metric, leaders can identify areas for improvement, streamline processes, and reduce lead times, ultimately enhancing customer satisfaction.

Customer Satisfaction Metrics: Real-time order visibility allows leaders to monitor customer satisfaction metrics, such as on-time delivery performance, order accuracy, and customer feedback. By analyzing these metrics, leaders can identify areas where customer satisfaction can be improved and take actions to address customer concerns or preferences.

Overcoming Challenges in Implementing Real-Time Order Visibility:

Implementing real-time order visibility in manufacturing operations can come with certain challenges. Here are some strategies to overcome them:

Data Integration: Integrating data from various sources, such as IoT devices, legacy systems, and external databases, can be complex. Manufacturers should invest in robust data integration tools and technologies to ensure seamless data flow and synchronization across systems.

Scalability and Infrastructure: Real-time order visibility requires scalable infrastructure to handle large volumes of data and accommodate future growth. Cloud computing offers scalability, cost-efficiency, and flexibility, making it an ideal solution for managing real-time data.

Data Security: Real-time order visibility involves handling sensitive production and customer data. Manufacturers should prioritize data security measures, including encryption, access controls, and regular security audits, to protect data integrity and prevent unauthorized access.

Stakeholder Collaboration: Implementing real-time order visibility requires collaboration and buy-in from various stakeholders, including production teams, IT departments, and suppliers. Clear communication, training programs, and continuous engagement are essential to ensure successful adoption and utilization of real-time visibility systems.

Analytics and Insights: Real-time data is valuable only when converted into actionable insights. Manufacturers should invest in advanced analytics tools and resources to process and analyze the real-time data effectively. Hiring skilled data analysts or partnering with analytics service providers can help extract meaningful insights for decision-making.

By addressing these challenges proactively, manufacturers can successfully implement real-time order visibility, optimize operations, and gain a competitive edge in the market.

Common Challenges in Implementing Real-Time Order Visibility

Data Accuracy: Maintaining data accuracy is a challenge when implementing real-time order visibility. Inaccurate or inconsistent data can lead to incorrect insights and decisions. Challenges include data entry errors, data duplication, and data synchronization issues between different systems or data sources.

System Integration: Integrating various systems and data sources is a complex task. Manufacturers often have disparate systems, such as ERP (Enterprise Resource Planning), MES (Manufacturing Execution System), and SCM (Supply Chain Management) systems, which may not be designed to communicate with each other seamlessly. Integrating these systems and ensuring smooth data flow is crucial for real-time order visibility.

Change Management: Implementing real-time order visibility often requires organizational and cultural changes. Resistance to change from employees, lack of awareness about the benefits of real-time visibility, and inadequate training can hinder the successful adoption of new systems and processes.

Strategies and Best Practices for Overcoming Challenges

Data Accuracy:

a. Establish Data Governance: Implement data governance policies and procedures to ensure data accuracy, integrity, and consistency. Define data standards, data validation rules, and data quality metrics to maintain high-quality data.

b. Data Validation and Cleansing: Regularly validate and cleanse the data to identify and correct errors or inconsistencies. Implement data validation checks, automated data cleansing processes, and data verification protocols.

c. Master Data Management: Implement a master data management strategy to maintain a single source of truth for critical data elements across systems. This ensures consistent and accurate data across the organization.

System Integration:

a. Identify Integration Requirements: Conduct a thorough analysis of existing systems and data sources to identify integration requirements. Determine the data flow, data formats, and communication protocols needed for seamless integration.

b. Integration Platforms and APIs: Utilize integration platforms or APIs (Application Programming Interfaces) to facilitate data exchange between different systems. These tools provide pre-built connectors and workflows to simplify integration processes.

c. Data Mapping and Transformation: Develop data mapping and transformation guidelines to ensure data compatibility between systems. Convert and map data formats, units, and codes to ensure smooth integration and data synchronization.

Change Management:

a. Stakeholder Engagement: Involve key stakeholders from different departments early on in the process. Communicate the benefits and value of real-time order visibility, address concerns, and encourage active participation and feedback.

b. Training and Education: Provide comprehensive training programs to educate employees about the new systems, processes, and tools associated with real-time order visibility. Empower employees to use the systems effectively and understand their role in data accuracy and decision-making.

c. Change Champions: Identify change champions within the organization who can act as advocates for real-time order visibility. These individuals can help drive adoption, address concerns, and support their peers through the transition.

Real-Time Order Visibility and Decision-Making

Real-time order visibility provides manufacturers with timely and accurate information, empowering them to make data-driven decisions. Here's how real-time order visibility supports decision-making:

Improved Response Time: Real-time order visibility enables manufacturing leaders to quickly respond to changes in customer demand, production issues, or supply chain disruptions. With up-to-date information on order status, inventory levels, and production schedules, leaders can make prompt decisions to address bottlenecks, allocate resources efficiently, and meet customer expectations.

Enhanced Production Planning: Real-time order visibility allows for more accurate production planning. By analyzing real-time data on order volumes, customer demand, and production capacity, manufacturers can optimize production schedules, allocate resources effectively, and ensure on-time deliveries. This leads to increased operational efficiency and reduced costs.

Proactive Issue Resolution: Real-time order visibility helps identify issues or bottlenecks in the production process in real-time. With access to real-time data on machine performance, cycle times, and quality metrics, leaders can identify and address potential problems before they escalate, reducing downtime, rework, and customer dissatisfaction.

Demand Forecasting and Inventory Optimization: Real-time order visibility provides valuable insights into customer demand patterns and trends. By analyzing real-time data on order volumes, order frequencies, and customer feedback, manufacturers can accurately forecast demand, adjust inventory levels, and prevent stockouts or overstocking. This improves inventory management, reduces carrying costs, and enhances customer satisfaction.

Data-Driven Continuous Improvement: Real-time order visibility enables manufacturers to track key performance metrics, such as production cycle times, inventory turnover, and customer satisfaction. By analyzing these metrics in real-time, leaders can identify areas for improvement, implement process enhancements, and measure the impact of their decisions on operational performance.

By leveraging real-time order visibility, manufacturers can make informed decisions, respond swiftly to changing market dynamics, optimize operations, and ultimately achieve competitive advantages in today's fast-paced manufacturing landscape.

Real-time order visibility plays a significant role in enhancing decision-making for manufacturing leaders. Here's how it facilitates better decision-making in key areas:

Proactive Issue Resolution: Real-time order visibility empowers manufacturing leaders to proactively address production issues. By having real-time access to data on production processes, machine performance, and quality metrics, leaders can identify bottlenecks, anomalies, or potential issues as they arise. This allows them to take immediate action, allocate resources efficiently, and minimize disruptions. By addressing issues in real-time, leaders can prevent delays, reduce downtime, and maintain production efficiency.

Resource Optimization: Real-time order visibility enables leaders to optimize resources effectively. With real-time data on production schedules, inventory levels, and customer demand, leaders can make informed decisions about resource allocation. They can align production capacity with demand, optimize workforce utilization, and ensure that materials and equipment are available when needed. This helps reduce costs, improve operational efficiency, and maximize resource utilization.

Adaptation to Changing Market Conditions: Real-time order visibility provides manufacturing leaders with the agility to adapt to changing market conditions. By closely monitoring real-time data on order volumes, customer demand, and market trends, leaders can quickly identify shifts in customer preferences, market demands, or supply chain disruptions. This information allows them to make data-driven decisions to adjust production priorities, allocate resources accordingly, and meet changing customer needs. Real-time order visibility enables manufacturers to be more responsive and adaptable, gaining a competitive edge in dynamic markets.

Security and Privacy Considerations

Real-time order visibility brings valuable insights and benefits, but it also introduces potential security concerns that manufacturers must address. Here are some key security considerations:

Data Protection: Protecting sensitive data is paramount when implementing real-time order visibility. Manufacturers should employ data encryption techniques to ensure data confidentiality during transmission and storage. Encryption safeguards data from unauthorized access, mitigates the impact of data breaches, and helps meet compliance requirements.

Secure Networks: Establishing secure networks is crucial to prevent unauthorized access to real-time order visibility systems. Manufacturers should implement robust firewalls, intrusion detection and prevention systems, and network segmentation to isolate sensitive data and control access. Regular security audits and vulnerability assessments help identify and address potential network vulnerabilities.

Access Controls: Implementing strong access controls is vital for protecting sensitive information. Manufacturers should enforce strict authentication mechanisms, such as multi-factor authentication, to verify user identities. Role-based access controls ensure that only authorized personnel have access to specific data and functionalities. Regular user access reviews and account management practices help maintain the integrity of access controls.

Data Privacy: Real-time order visibility involves processing and storing customer and production data. Manufacturers must comply with applicable data privacy regulations, such as GDPR, CCPA, or industry-specific regulations. They should obtain explicit consent for data collection and clearly communicate how the data will be used. Anonymizing or pseudonymizing personal data can further protect individual privacy.

Incident Response Plan: Manufacturers should develop a robust incident response plan to effectively address security incidents or data breaches. This plan should include predefined steps for detecting, containing, investigating, and mitigating security incidents. Regular testing and drills help ensure that the response plan is well-prepared and aligned with evolving security threats.

Implementing Real-Time Order Visibility: Best Practices

Implementing real-time order visibility in manufacturing operations requires careful planning and execution. Here is a step-by-step guide to help manufacturers successfully implement real-time order visibility:

Define Objectives and Scope: Clearly define the objectives of implementing real-time order visibility and identify the specific areas or processes where it will be implemented. This could include production scheduling, inventory management, order tracking, or quality control.

Assess Infrastructure Readiness: Evaluate your existing infrastructure to ensure it can support real-time data collection, processing, and analysis. Determine if any upgrades or enhancements are needed, such as network bandwidth, storage capacity, or computing resources. A robust infrastructure is crucial to handle the volume and velocity of real-time data.

Identify Data Sources: Identify the various data sources within your manufacturing operations, such as IoT devices, production systems, ERP (Enterprise Resource Planning) systems, or external databases. Determine the data points required for real-time order visibility, such as machine performance, inventory levels, or order status.

Data Integration: Establish a data integration strategy to collect and consolidate data from different sources into a central repository. This may involve integrating legacy systems, deploying IoT devices for data capture, or leveraging APIs for seamless data exchange. Choose appropriate integration tools and technologies to ensure data synchronization and accuracy.

Implement Real-Time Data Collection: Set up mechanisms to collect real-time data from the identified sources. This could involve deploying IoT sensors, implementing data capture mechanisms in production equipment, or leveraging automated data feeds from connected systems. Ensure that the data collection process is reliable, accurate, and scalable.

Data Processing and Analytics: Implement a data processing and analytics platform to transform raw data into actionable insights. Use technologies such as cloud computing, big data platforms, or data analytics tools to process and analyze real-time data. Apply relevant algorithms, machine learning models, or statistical techniques to derive meaningful insights.

Develop Dashboards and Visualization: Create intuitive dashboards and visualizations that present real-time data in a clear and actionable format. Dashboards should provide manufacturing leaders with a holistic view of production schedules, inventory levels, order status, and other key metrics. Customizable views and real-time alerts enable quick decision-making and proactive actions.

Stakeholder Collaboration: Engage stakeholders from various departments, including production, supply chain, IT, and management, in the implementation process. Collaborate closely to ensure their needs and requirements are considered. Provide training and support to enable stakeholders to effectively utilize real-time order visibility and make informed decisions based on the insights generated.

Continuous Improvement: Implementing real-time order visibility is an iterative process. Continuously monitor the performance and effectiveness of the system, gather feedback from stakeholders, and identify areas for improvement. Regularly review and refine data integration, analytics processes, and visualization to enhance the system's capabilities and address evolving needs.

Security and Privacy: Prioritize security and privacy considerations throughout the implementation process. Implement data encryption, access controls, and regular security audits to protect sensitive information. Comply with data privacy regulations and ensure data protection practices are in place.

By following these steps and considering the importance of infrastructure readiness, data integration, and stakeholder collaboration, manufacturers can successfully implement real-time order visibility. This will enable them to make data-driven decisions, optimize operations, and achieve competitive advantages in the manufacturing landscape.

Case Studies and Success Stories

Here are two real-world examples of manufacturing companies that have successfully implemented real-time order visibility and achieved significant improvements in operational efficiency and business outcomes:

Tesla:

Tesla, the renowned electric vehicle manufacturer, has implemented real-time order visibility across its manufacturing operations. By leveraging advanced technologies and data analytics, Tesla has achieved remarkable results:

Improved Production Planning: Real-time order visibility allows Tesla to monitor demand in real-time and adjust production schedules accordingly. This has helped them optimize production planning, reduce lead times, and minimize inventory carrying costs.

Efficient Inventory Management: Real-time order visibility enables Tesla to closely monitor inventory levels and track component availability. By having accurate visibility into their inventory, Tesla can optimize their supply chain, minimize stockouts, and reduce excess inventory.

Enhanced Customer Experience: With real-time order visibility, Tesla can provide accurate and up-to-date information to customers regarding order status and delivery timelines. This has resulted in improved customer satisfaction and loyalty.

Proactive Issue Resolution: Real-time order visibility empowers Tesla to proactively identify and address production issues. They can quickly identify bottlenecks or quality concerns, enabling them to take prompt action and maintain high production standards.

Tesla's implementation of real-time order visibility has significantly improved their operational efficiency, streamlined production processes, and enhanced their ability to meet customer demand.

Bosch:

Bosch, a global technology and engineering company, has successfully implemented real-time order visibility in their manufacturing operations. By leveraging IoT devices, data analytics, and cloud computing, Bosch has achieved notable benefits:

Supply Chain Optimization: Real-time order visibility allows Bosch to monitor the movement of materials and components throughout their supply chain. This helps them identify potential bottlenecks, optimize logistics, and ensure timely availability of inputs for production.

Predictive Maintenance: With real-time order visibility, Bosch can monitor the performance of machinery and equipment in real-time. By analyzing the data collected, they can proactively schedule maintenance activities, reducing downtime and improving overall equipment effectiveness.

Demand Forecasting: Real-time order visibility enables Bosch to capture and analyze customer demand patterns in real-time. By leveraging this data, they can generate accurate demand forecasts, optimize production capacity, and align their inventory levels to meet customer needs.

Continuous Improvement: Bosch utilizes real-time order visibility data to identify areas for improvement in their manufacturing processes. They can identify inefficiencies, implement process optimizations, and continuously enhance their operational performance.

Through the implementation of real-time order visibility, Bosch has achieved higher operational efficiency, improved supply chain management, and better responsiveness to customer demands.

These case studies highlight how manufacturing companies like Tesla and Bosch have leveraged real-time order visibility to drive significant improvements in their operational efficiency, supply chain management, and customer satisfaction. By adopting advanced technologies and data-driven decision-making, these companies have successfully optimized their manufacturing processes and gained a competitive edge in their respective industries.

General Electric (GE)

General Electric, a multinational conglomerate, implemented real-time order visibility across its manufacturing operations to enhance efficiency and customer satisfaction. By integrating IoT devices, cloud computing, and analytics, GE gained real-time insights into production processes, inventory levels, and order status. This enabled them to optimize production schedules, reduce lead times, and proactively address production issues. As a result, GE experienced improved on-time delivery, reduced inventory holding costs, and increased customer satisfaction.

Toyota Motor Corporation

Toyota, a leading automotive manufacturer, leveraged real-time order visibility to streamline its supply chain and enhance production efficiency. Through the integration of IoT devices and data analytics, Toyota gained real-time insights into production processes, inventory levels, and demand patterns. This allowed them to optimize production schedules, minimize inventory holding costs, and proactively respond to changing customer demands. As a result, Toyota achieved shorter lead times, reduced stockouts, and improved overall supply chain performance.

Procter & Gamble (P&G)

P&G, a global consumer goods company, implemented real-time order visibility to enhance their manufacturing operations and improve customer service. By integrating real-time data from their production lines, warehouses, and suppliers, P&G gained visibility into order status, inventory levels, and demand fluctuations. This enabled them to optimize production schedules, reduce stockouts, and ensure on-time delivery to customers. As a result, P&G experienced improved order fulfillment rates, reduced inventory holding costs, and increased customer satisfaction.

Schneider Electric

Schneider Electric, a leading energy management and automation solutions provider, implemented real-time order visibility to enhance their manufacturing processes and supply chain operations. By integrating IoT devices, cloud computing, and data analytics, Schneider Electric gained real-time visibility into their production lines, inventory levels, and order status. This enabled them to optimize production schedules, minimize stockouts, and improve order accuracy. As a result, Schneider Electric achieved improved production efficiency, reduced lead times, and enhanced customer satisfaction.

These real-world examples highlight how implementing real-time order visibility can drive significant improvements in operational efficiency, supply chain management, and customer satisfaction for manufacturing companies across different industries. By leveraging the power of real-time data and advanced technologies, these companies have gained a competitive edge and positioned themselves for success in today's dynamic business landscape.

Frequently Asked Questions (FAQs) Associated with Real-Time Order Visibility

Following, we’ve discussed some important frequently asked questions (FAQs) associated with real-time order visibility. Let’s learn:

Que 1: How does real-time order visibility improve supply chain management?

Real-time order visibility plays a crucial role in improving supply chain management by providing accurate and timely information about orders, inventory, and logistics. Here are several ways in which real-time order visibility enhances supply chain management:

Demand Planning and Forecasting: Real-time order visibility enables manufacturers to capture and analyze customer demand data in real-time. By tracking order volumes, patterns, and customer preferences, companies can generate more accurate demand forecasts. This helps in optimizing production capacity, managing inventory levels, and aligning the supply chain to meet customer needs effectively.

Inventory Management: Real-time order visibility provides real-time insights into inventory levels, stock movements, and reorder points. Manufacturers can track inventory in real-time and make informed decisions regarding replenishment, storage, and allocation. With accurate visibility into inventory, companies can reduce stockouts, prevent excess inventory, and optimize inventory holding costs.

Supply Chain Coordination: Real-time order visibility enables seamless coordination across the supply chain network. Manufacturers can share real-time information with suppliers, distributors, and logistics partners, ensuring everyone has visibility into order status, changes, and delivery schedules. This improves communication, reduces lead times, and enhances collaboration between all stakeholders involved in the supply chain.

Production Planning and Scheduling: Real-time order visibility allows manufacturers to monitor demand fluctuations and adjust production plans in real-time. By having visibility into order volumes, changes, and priorities, companies can optimize production schedules, allocate resources efficiently, and minimize production lead times. This helps in meeting customer demands promptly and reducing unnecessary costs associated with overproduction or underutilization of resources.

Proactive Issue Resolution: Real-time order visibility empowers manufacturers to identify and address potential supply chain disruptions or bottlenecks proactively. By monitoring order status, inventory levels, and production progress in real-time, companies can quickly detect issues and take corrective actions promptly. This helps in reducing delays, improving order fulfillment, and maintaining high levels of customer satisfaction.

Logistics Optimization: Real-time order visibility enables better management of transportation and logistics activities. By tracking order status, delivery schedules, and logistics performance, manufacturers can optimize route planning, improve load balancing, and reduce transportation costs. Real-time visibility into shipment tracking also enables proactive monitoring of delivery status, allowing companies to provide accurate delivery updates to customers.

Overall, real-time order visibility enhances supply chain management by providing accurate, up-to-date information, enabling proactive decision-making, and improving coordination across the supply chain network. By leveraging real-time data, manufacturers can optimize their inventory levels, production processes, and logistics operations, resulting in improved operational efficiency, reduced costs, and enhanced customer satisfaction.

Que 2: Can real-time order visibility help in reducing production lead times?

Yes, real-time order visibility can play a significant role in reducing production lead times. By providing timely and accurate information about orders, production processes, and potential bottlenecks, real-time order visibility enables manufacturers to take proactive measures to optimize production and streamline operations. Here's how real-time order visibility contributes to reducing production lead times:

Demand Visibility: Real-time order visibility allows manufacturers to have immediate access to customer orders and demand data. By monitoring order volumes, changes, and patterns in real-time, companies can accurately forecast demand and adjust production schedules accordingly. This ensures that production is aligned with actual customer demand, minimizing lead times associated with overproduction or delayed responses to demand fluctuations.

Production Planning and Scheduling: Real-time order visibility provides manufacturers with real-time insights into the status of production orders and capacity utilization. With this information, companies can optimize production planning and scheduling processes. They can identify available capacity, allocate resources efficiently, and adjust production priorities in real-time. By effectively managing production schedules, manufacturers can reduce idle time, eliminate bottlenecks, and shorten lead times.

Bottleneck Identification and Resolution: Real-time order visibility enables manufacturers to identify potential bottlenecks or issues in production processes as soon as they arise. By monitoring production progress, machine performance, and workflow efficiency in real-time, companies can quickly detect areas causing delays or inefficiencies. With this information, manufacturers can take immediate action to resolve bottlenecks, optimize workflows, and ensure smooth production operations, thereby reducing lead times.

Supply Chain Collaboration: Real-time order visibility facilitates collaboration and coordination with suppliers, enabling smoother supply chain operations. By sharing real-time information on order status, inventory levels, and delivery schedules, manufacturers can work closely with suppliers to ensure timely availability of materials and components. This minimizes supply chain disruptions and reduces lead times caused by delays in the availability of inputs.

Rapid Response to Changes: Real-time order visibility enables manufacturers to respond quickly to changes in customer orders or market demands. When changes occur, such as rush orders, order cancellations, or modifications, real-time visibility allows companies to promptly assess the impact on production schedules and adjust accordingly. This agility in responding to changes helps in minimizing lead times and meeting customer expectations.

Continuous Improvement: Real-time order visibility provides manufacturers with valuable data and insights to continuously improve production processes. By analyzing real-time data on production performance, efficiency, and cycle times, companies can identify areas for improvement and implement process optimizations. Continuous improvement initiatives reduce lead times by streamlining workflows, eliminating non-value-added activities, and enhancing overall production efficiency.

By leveraging real-time order visibility, manufacturers can optimize production planning, identify and resolve bottlenecks promptly, collaborate effectively with suppliers, and respond rapidly to changes. These factors contribute to reducing production lead times, enabling companies to meet customer demands faster, improve customer satisfaction, and gain a competitive edge in the market.

Que 3: What data is typically available through real-time order visibility?

Real-time order visibility provides access to a wide range of data that is crucial for effective decision-making and operational management. Here are some key types of data typically available through real-time order visibility:

Order Information: Real-time order visibility provides detailed information about customer orders, including order numbers, product specifications, quantities, and delivery requirements. It allows manufacturers to track and monitor the status of each order in real-time, from the time it is received until it is fulfilled and shipped.

Production Data: Real-time order visibility captures data related to production processes and operations. This includes information on machine performance, cycle times, production rates, and downtime. By monitoring these metrics in real-time, manufacturers can gain insights into production efficiency, identify bottlenecks, and make data-driven decisions to optimize production workflows.

Inventory Data: Real-time order visibility enables visibility into inventory levels and stock movements. It provides information on raw materials, components, work-in-progress (WIP), and finished goods inventory. Manufacturers can track real-time inventory levels, identify shortages or excess stock, and make informed decisions on inventory replenishment and management.

Logistics and Shipment Data: Real-time order visibility includes data related to logistics and shipments. It provides information on shipment status, carrier details, tracking numbers, and estimated delivery dates. Manufacturers can track the movement of orders through the supply chain, monitor shipping performance, and proactively address any delays or issues to ensure on-time delivery.

Quality Metrics: Real-time order visibility captures data on quality metrics, such as defect rates, rework rates, and scrap levels. It allows manufacturers to monitor quality performance in real-time, identify potential quality issues or deviations, and take corrective actions promptly. This data helps improve product quality, reduce waste, and enhance customer satisfaction.

Customer Data and Feedback: Real-time order visibility may include customer-related data, such as customer names, contact information, and historical order data. It also captures customer feedback, reviews, and satisfaction ratings. This data provides valuable insights into customer preferences, trends, and demands, enabling manufacturers to better understand their customers and tailor their production and inventory strategies accordingly.

Financial Data: Real-time order visibility can integrate with financial systems to provide data related to order values, revenue, and profitability. By linking order data with financial information, manufacturers can analyze the financial performance of orders, track costs, and assess the profitability of different products or customer segments.

These are just some examples of the data typically available through real-time order visibility. The specific data elements may vary depending on the manufacturing processes, systems, and technology infrastructure in place. Real-time order visibility enables manufacturers to have a holistic view of their operations, helping them make informed decisions, improve efficiency, and enhance customer satisfaction.

Que 4: Is real-time order visibility compatible with different manufacturing processes or industries?

Yes, real-time order visibility can be compatible with different manufacturing processes and industries. The concept of real-time order visibility is applicable across various sectors and can be tailored to meet the specific needs and requirements of different industries. Here's why real-time order visibility is compatible with different manufacturing processes and industries:

Flexibility in Data Integration: Real-time order visibility can integrate with different systems and technologies, allowing it to capture and consolidate data from diverse sources. Whether it's a traditional manufacturing process or a highly automated one, real-time order visibility can adapt to the existing infrastructure and integrate with systems such as Enterprise Resource Planning (ERP) software, Manufacturing Execution Systems (MES), Internet of Things (IoT) devices, and other data collection tools.

Customizable Metrics and Insights: Real-time order visibility can provide industry-specific metrics and insights that align with the specific manufacturing processes and goals of different industries. For example, in the automotive industry, real-time order visibility may focus on metrics such as lead time, production cycle time, and quality defects. In the pharmaceutical industry, it may include metrics related to batch traceability, regulatory compliance, and shelf-life management. The metrics and insights can be customized to address the unique requirements and challenges of each industry.

Adaptability to Supply Chain Complexity: Real-time order visibility is well-suited to industries with complex supply chains involving multiple suppliers, distributors, and logistics partners. It provides transparency and coordination across the supply chain, enabling effective collaboration and real-time information sharing. Whether it's a make-to-order, make-to-stock, or engineer-to-order manufacturing process, real-time order visibility can support and optimize supply chain operations to meet industry-specific demands.

Compliance with Industry Standards: Real-time order visibility can be designed to comply with industry-specific regulations and standards. Industries such as healthcare, food and beverage, and aerospace have stringent requirements for traceability, product safety, and quality control. Real-time order visibility systems can be configured to capture and track the necessary data elements required for compliance, ensuring adherence to industry-specific regulations.

Scalability and Customization: Real-time order visibility solutions can scale and adapt to different manufacturing volumes and complexity levels. Whether it's a small-scale operation or a large-scale production facility, real-time order visibility can handle the volume of data generated and accommodate future growth. The system can be customized to fit the specific needs of the manufacturing process, including the type of products, order fulfillment models, and production workflows.

It's important to note that while the underlying principles and benefits of real-time order visibility are applicable across industries, the implementation may require industry-specific customization and configuration. Each industry has its own unique requirements, challenges, and operational nuances. Real-time order visibility solutions can be tailored to align with these specific needs, making it compatible with different manufacturing processes and industries.

Que 5: How does real-time order visibility enhance decision-making for manufacturing leaders?

Real-time order visibility plays a crucial role in enhancing decision-making for manufacturing leaders by providing timely and accurate information that enables data-driven and proactive decision-making. Here's how real-time order visibility enhances decision-making:

Improved Visibility and Insights: Real-time order visibility provides manufacturing leaders with up-to-date and comprehensive visibility into the entire order lifecycle, including customer orders, production processes, inventory levels, and order status. This real-time access to information enables leaders to gain valuable insights into their operations and make informed decisions based on the latest data.

Timely Identification of Issues: Real-time order visibility allows leaders to identify issues or bottlenecks in the production process as soon as they arise. They can monitor the progress of individual orders, track production metrics, and quickly detect any deviations or delays. This timely identification of issues enables leaders to take immediate action and implement corrective measures, minimizing the impact on production schedules and customer delivery.

Proactive Problem Solving: With real-time order visibility, manufacturing leaders can proactively address production issues and challenges. They can analyze the data and identify root causes of problems, enabling them to take proactive steps to resolve issues, optimize production workflows, and minimize disruptions. This proactive problem-solving approach helps in maintaining production efficiency and meeting customer expectations.

Optimal Resource Allocation: Real-time order visibility provides insights into production capacity, resource utilization, and demand fluctuations. Manufacturing leaders can analyze this data to make informed decisions regarding resource allocation, workforce planning, and equipment utilization. By optimizing resource allocation based on real-time information, leaders can maximize efficiency, minimize downtime, and reduce costs.

Agile Decision-Making: Real-time order visibility empowers manufacturing leaders to make agile decisions in response to changing market conditions or customer demands. They can quickly assess the impact of order changes, market trends, or supply chain disruptions, and adjust production plans accordingly. This agility in decision-making allows manufacturers to adapt and respond rapidly, ensuring customer satisfaction and competitive advantage.

Data-Driven Strategy: Real-time order visibility provides a wealth of data that can be analyzed to identify trends, patterns, and opportunities for improvement. Manufacturing leaders can leverage this data to make data-driven strategic decisions, such as product portfolio optimization, supply chain optimization, or process improvements. By basing decisions on data rather than assumptions, leaders can align their strategies with market demands and drive operational excellence.

Performance Monitoring and Continuous Improvement: Real-time order visibility enables leaders to monitor key performance indicators (KPIs) in real-time and measure their performance against set targets. They can track metrics such as on-time delivery, production cycle time, inventory turnover, and customer satisfaction. This continuous monitoring allows leaders to identify areas for improvement, set benchmarks, and implement continuous improvement initiatives to enhance operational performance.

In summary, real-time order visibility empowers manufacturing leaders with accurate and timely information, enabling them to make informed decisions, identify and address issues proactively, optimize resource allocation, and respond agilely to market dynamics. This results in improved operational efficiency, customer satisfaction, and overall business performance.

Que 6: Are there any security concerns associated with real-time order visibility?

Yes, there are security concerns associated with real-time order visibility, primarily due to the sensitive nature of the data involved. Here are some key security considerations:

Data Protection: Real-time order visibility involves the collection and transmission of sensitive data, such as customer information, production data, and inventory details. It is essential to implement strong data protection measures, including encryption, to safeguard the confidentiality and integrity of the data. Data should be encrypted both in transit and at rest to prevent unauthorized access or data breaches.

Secure Networks: The communication channels and networks used for real-time order visibility should be secure and protected against unauthorized access or interception. This requires implementing robust network security measures, such as firewalls, intrusion detection and prevention systems, and secure protocols (e.g., HTTPS) for data transmission. Regular monitoring and auditing of network traffic can help detect and mitigate potential security threats.

Access Controls: Controlling access to real-time order visibility systems is crucial to prevent unauthorized individuals from accessing sensitive information. Role-based access controls should be implemented, ensuring that only authorized personnel have access to specific data and functionalities. Strong authentication mechanisms, such as multi-factor authentication, should be employed to verify the identity of users accessing the system.

Data Governance and Compliance: Real-time order visibility systems should adhere to relevant data protection regulations and industry-specific compliance requirements. This includes compliance with data privacy laws, such as the General Data Protection Regulation (GDPR) or the California Consumer Privacy Act (CCPA). Implementing data governance practices, including data classification, data retention policies, and regular data backups, can help ensure compliance and minimize security risks.

Vendor and Third-Party Security: If real-time order visibility solutions involve the use of third-party vendors or cloud service providers, it is crucial to assess their security measures and ensure they meet industry standards. Contracts and service-level agreements should clearly define security responsibilities and requirements, including data protection, confidentiality, and breach notification protocols.

Regular Security Audits and Updates: Real-time order visibility systems should undergo regular security audits and vulnerability assessments to identify and address any potential security gaps or vulnerabilities. Patch management processes should be in place to ensure that software and systems are up to date with the latest security patches and updates.

Employee Awareness and Training: Human error and insider threats can pose security risks. It is important to educate employees about security best practices, such as strong password management, phishing awareness, and data handling procedures. Regular training sessions can help create a culture of security awareness within the organization.

By addressing these security concerns and implementing robust security measures, manufacturers can mitigate risks and protect sensitive data associated with real-time order visibility systems. It is important to prioritize security as an integral part of the implementation process to ensure the confidentiality, integrity, and availability of data.

Que 7: What challenges can arise when implementing real-time order visibility in manufacturing?

Implementing real-time order visibility in manufacturing operations can come with certain challenges. Here are some common challenges that organizations may face:

Data Integration: Real-time order visibility requires integrating data from various sources, including production systems, inventory management systems, customer databases, and external suppliers. Data integration can be complex, especially when dealing with disparate systems and data formats. Organizations need to invest in robust data integration tools and technologies to ensure seamless data flow and synchronization across systems.

System Compatibility: Manufacturing operations often rely on a mix of legacy systems, different software applications, and hardware devices. Ensuring compatibility and connectivity between these systems and real-time order visibility platforms can be a challenge. It may require implementing middleware or APIs (Application Programming Interfaces) to facilitate data exchange and communication between different systems.

Scalability and Infrastructure: Real-time order visibility involves processing and managing large volumes of data in real-time. Organizations need to ensure that their infrastructure can handle the increased data load and scale as the business grows. Cloud computing offers scalability, cost-efficiency, and flexibility, making it an ideal solution for managing real-time data and supporting the infrastructure requirements of real-time order visibility systems.

Data Accuracy and Quality: Real-time order visibility heavily relies on the accuracy and quality of data. Inaccurate or inconsistent data can lead to incorrect insights and decisions. Ensuring data accuracy and quality requires implementing data validation processes, data cleansing techniques, and data governance practices. Regular data audits and quality checks should be conducted to maintain data integrity.

Change Management: Implementing real-time order visibility often involves changes in existing processes, workflows, and roles within the organization. Resistance to change from employees or departments can pose challenges. It is crucial to have a change management plan in place, including communication, training, and engagement strategies, to ensure smooth adoption and acceptance of the new system.

Stakeholder Collaboration: Implementing real-time order visibility requires collaboration and buy-in from various stakeholders, including production teams, IT departments, suppliers, and potentially customers. Effective communication and collaboration among these stakeholders are essential to ensure successful implementation. Regular feedback loops and engagement with stakeholders throughout the process can help address concerns and ensure alignment.

Cost Considerations: Implementing real-time order visibility may involve upfront investments in technology infrastructure, software licenses, data integration tools, and employee training. Organizations need to carefully evaluate the costs and benefits associated with the implementation. Conducting a cost-benefit analysis and developing a realistic budget can help in managing costs effectively.

Data Security and Privacy: Real-time order visibility involves handling sensitive production and customer data. Organizations need to prioritize data security measures, including encryption, access controls, and regular security audits, to protect data integrity and prevent unauthorized access. Compliance with data protection regulations, such as GDPR or CCPA, is also critical.

By addressing these challenges proactively, organizations can successfully implement real-time order visibility, optimize their operations, and gain a competitive edge in the market. It is important to approach implementation with a well-defined plan, engage stakeholders, and leverage technology and best practices to overcome these challenges.

Que 8: How can manufacturers ensure data accuracy and reliability in real-time order visibility systems?

Ensuring data accuracy and reliability is crucial for the effectiveness of real-time order visibility systems in manufacturing. Here are some key strategies to achieve data accuracy and reliability:

Data Validation and Cleansing: Implement robust data validation and cleansing processes to ensure that the data entered into the system is accurate, consistent, and complete. This includes validating data formats, enforcing data integrity constraints, and performing data cleansing techniques to remove duplicates, inconsistencies, and errors.

Standardized Data Formats: Establish standardized data formats and definitions across different systems and data sources. This helps in maintaining consistency and compatibility when integrating data from various sources. Consistent data formats make it easier to analyze and compare data across different parts of the organization.

Real-Time Data Capture: Utilize real-time data capture mechanisms, such as IoT sensors, automated data collection devices, and machine-to-machine communication, to minimize manual data entry errors and ensure timely and accurate data capture. By capturing data directly from the source, manufacturers can reduce the risk of human error and delays in data availability.

Integration with Source Systems: Integrate real-time order visibility systems with the source systems that generate data, such as production machines, inventory management systems, and customer relationship management (CRM) platforms. This integration ensures that data is captured directly from the source systems, reducing the chances of data discrepancies or delays caused by manual data entry or data synchronization issues.

Data Governance and Documentation: Establish clear data governance practices, including data ownership, data validation rules, and data documentation. Define roles and responsibilities for data management and ensure that data quality standards and processes are documented and communicated throughout the organization. Regularly review and update data governance policies to adapt to changing business requirements.

Data Audits and Quality Checks: Conduct regular data audits and quality checks to identify and rectify any data accuracy issues. This involves validating data against predefined rules, performing data profiling to identify outliers or inconsistencies, and comparing data with independent sources to ensure accuracy. Implement automated data quality checks and alerts to proactively identify and address data discrepancies.

Employee Training and Awareness: Provide training and awareness programs to employees who handle and enter data into the system. Educate them about the importance of data accuracy, the impact of data errors on business decisions, and the correct procedures for data entry. Foster a culture of data integrity and accountability across the organization.

Continuous Improvement and Feedback Loops: Establish feedback loops with users and stakeholders to gather insights on data accuracy issues and areas for improvement. Encourage users to report any data discrepancies or concerns they encounter. Actively monitor data quality metrics and take proactive measures to address data accuracy issues as they arise.

By implementing these strategies, manufacturers can ensure that the data within their real-time order visibility systems is accurate, reliable, and trustworthy. This, in turn, enables better decision-making, process optimization, and improved overall operational efficiency.

Que 9: What are some best practices for implementing real-time order visibility in manufacturing operations?

Implementing real-time order visibility in manufacturing operations requires careful planning and execution. Here are some best practices to consider:

Define Clear Objectives: Clearly define the objectives and desired outcomes of implementing real-time order visibility. Identify the specific business challenges and opportunities that the system should address, such as improving production efficiency, reducing lead times, or enhancing customer satisfaction. This clarity will guide the implementation process and ensure alignment with organizational goals.

Assess Current Processes and Systems: Conduct a thorough assessment of existing processes, systems, and data sources. Identify bottlenecks, inefficiencies, and areas where real-time order visibility can bring significant improvements. Evaluate the compatibility of current systems with real-time visibility solutions and identify any gaps or integration requirements.

Build a Robust Infrastructure: Invest in a robust infrastructure that can handle the increased data load and support real-time data processing. This may include upgrading hardware, network capabilities, and server capacity. Consider cloud-based solutions that offer scalability, reliability, and cost-effectiveness. Work closely with IT teams to ensure infrastructure readiness.

Data Integration and Interoperability: Establish seamless data integration between different systems and sources of data. Implement data integration tools, APIs, or middleware to enable smooth data flow and synchronization. Ensure compatibility and interoperability between systems to avoid data silos and inconsistencies. Aim for a centralized and unified data repository.

Engage Stakeholders: Involve key stakeholders from different departments and levels of the organization in the implementation process. Collaborate with production teams, IT departments, logistics, and supply chain teams to ensure their requirements and perspectives are considered. Communicate the benefits of real-time order visibility to gain buy-in and address any concerns or resistance.

Employee Training and Change Management: Provide comprehensive training programs to employees who will be using the real-time order visibility system. Ensure they understand the system's capabilities, how to effectively use it, and the benefits it brings to their roles and responsibilities. Implement change management strategies to address any resistance to new processes or systems.

Start with a Pilot Project: Consider starting with a pilot project or phased implementation approach. Select a specific production line, product category, or a targeted area for initial implementation. This allows for testing, refinement, and validation of the real-time order visibility system before scaling it across the entire organization. Gather feedback and learn from the pilot to inform the broader rollout.

Monitor and Measure Performance: Establish key performance indicators (KPIs) and metrics to measure the effectiveness of the real-time order visibility system. Continuously monitor and analyze the system's performance against these metrics. Regularly review and refine the system based on insights gained from data analysis and user feedback. Seek opportunities for continuous improvement.

Data Security and Privacy: Prioritize data security and privacy considerations. Implement robust security measures, such as encryption, access controls, and regular security audits. Comply with relevant data protection regulations and ensure data integrity and confidentiality. Protect sensitive production and customer data from unauthorized access or breaches.

Continuous Optimization and Adaptation: Real-time order visibility is an ongoing process that requires continuous optimization and adaptation. Regularly review and refine the system to align with evolving business needs, technological advancements, and changing market conditions. Stay updated with industry trends and leverage new technologies or features that enhance the system's capabilities.

By following these best practices, manufacturers can successfully implement real-time order visibility and unlock its benefits, including improved operational efficiency, enhanced decision-making, and better customer satisfaction.

Que 10: Can real-time order visibility integrate with other enterprise systems or software?

Yes, real-time order visibility can integrate with other enterprise systems or software to enable seamless data flow and enhance overall operational efficiency. Here are some key integration possibilities:

Enterprise Resource Planning (ERP) Systems: Real-time order visibility can integrate with ERP systems to synchronize order data, inventory information, and production schedules. This integration enables real-time updates of orders, inventory levels, and production status, providing a comprehensive view of the manufacturing process within the ERP system.

Customer Relationship Management (CRM) Systems: Integration with CRM systems allows real-time order visibility to capture and update customer-related data, such as order history, preferences, and feedback. This integration helps in aligning production and supply chain activities with customer demands and enables personalized customer experiences.

Inventory Management Systems: Real-time order visibility can integrate with inventory management systems to provide accurate and up-to-date inventory information. This integration ensures that inventory levels are synchronized with order data, enabling efficient management of stock levels, minimizing stockouts, and optimizing inventory replenishment processes.

Manufacturing Execution Systems (MES): Integration with MES systems enables real-time order visibility to capture and monitor production data, including machine performance, production rates, and quality metrics. This integration provides manufacturing leaders with real-time insights into production processes, allowing them to proactively address issues, optimize production schedules, and improve overall efficiency.

Supply Chain Management (SCM) Systems: Integration with SCM systems facilitates the exchange of real-time order data, shipment tracking information, and supplier data. This integration enables end-to-end visibility across the supply chain, from order placement to delivery, helping in efficient supply chain planning, coordination, and optimization.

Business Intelligence (BI) and Analytics Platforms: Integration with BI and analytics platforms allows real-time order visibility to leverage advanced analytics capabilities. This integration enables the generation of real-time reports, dashboards, and data visualizations for decision-making, trend analysis, and performance monitoring. It empowers manufacturing leaders with actionable insights derived from real-time order data.

Internet of Things (IoT) Devices: Real-time order visibility can integrate with IoT devices to capture data directly from connected sensors, machines, or equipment on the shop floor. This integration enables real-time monitoring of machine performance, condition monitoring, and predictive maintenance. IoT integration enhances the accuracy and timeliness of data captured for real-time order visibility.

Mobile Applications: Real-time order visibility can be integrated with mobile applications to provide on-the-go access to order data, production updates, and key performance indicators. Mobile integration empowers manufacturing leaders and stakeholders with real-time insights and facilitates timely decision-making, even when they are away from their desks.

Integration with these enterprise systems and software ensures seamless data exchange, eliminates manual data entry, and enables a holistic view of the manufacturing operations. It streamlines processes, improves data accuracy, and enhances collaboration across different departments, leading to improved operational efficiency and better decision-making in the manufacturing organization.

Que 11: How does real-time order visibility contribute to customer satisfaction and improved service levels?

Real-time order visibility plays a crucial role in enhancing customer satisfaction and improving service levels in manufacturing. Here's how:

Accurate and Timely Information: Real-time order visibility provides customers with accurate and up-to-date information about their orders. They can track the progress of their orders, including production status, estimated delivery dates, and shipment tracking details. This transparency instills confidence in customers, reduces anxiety, and improves trust in the manufacturing company.